Porsche 928: Why is My Engine Bucking?

Without proper ignition and fuel, engine performance will suffer. While your car may idle and drive okay at slow speeds, the increased fuel and ignition demands at higher RPM may cause your engine to buck or surge because it is not receiving what it needs. Determine why your engine may be bucking here.

This article applies to the Porsche 928 (1979-1995).

Although the Porsche 928 may have sophisticated gadgets and electronics to optimize performance, some of the simpler, more traditional components may be the cause of an engine that bucks under certain driving conditions. Whether it be a fault in the ignition, intake, or fuel system, determining the problem can be a bit frustrating for expert and amateur mechanics alike. Take a look at some of the following components as these simple items can make for a world of difference in the driveability and performance of your 928.

Materials Needed

- Spark plug socket & ratchet

- Phillips screwdriver

- Digital multimeter

- Vacuum pump

- Penetrating oil

- Pressure gauge

Step 1 – Spark plug wires

A bucking or surging condition can often be the cause of worn or damaged spark plug wires. Many 928 owners have chased engine surging and bucking problems and thrown various new parts at the car only to have these same problems remain. The spark plug wires are often overlooked as they are strung across various components to make their way to each cylinder. The insulation on the plug wires can split and crack, which can allow the high voltage arc to jump from one lead to another. When the arc jumps, it can ignite the air/fuel mixture in a nearby cylinder at the wrong time in its stroke. This can lead to many poor running conditions including bucking and surging. While this may sound a bit far-fetched, many owners have been taken back by the dramatic improvement in engine performance and driveability that a newly installed set of spark plugs wires made.

Figure 1. Typical spark plug wire damage.

Figure 2. Example of spark plug wire arcing.

Pro Tip

An easy way to check for spark plug wire arcing is to open the hood, start the engine, and inspect the engine bay at night. In the dark, plug wire arcing will be easily spotted by its blue colored electrical spark. It is not uncommon for the engine bay to be lit up with multiple plug wires arcing.

Step 2 – Spark plugs

Some owners have experienced intermittent bucking and surging issues that seem to come and go for no apparent reason. If the spark plug wires check out okay, the problem could lie with the spark plugs. Owners have reported faulty spark plugs having extremely high resistance levels that would not allow the spark plug to fire and ignite the mixture in the cylinder. With nowhere for the voltage to go, it would skip to the next post in the distributor cap and prematurely fire the next cylinder in line. Some reported violent shaking and bucking around 3,500 RPM, while others reported a dead cylinder miss. Either way, it is a good idea to check the condition of your spark plugs. They are relatively cheap and easy to replace, and they may just cure that elusive bucking problem.

Step 3 – Coils

Ignition coils are a common source of engine bucking. The resistance of the coils can be checked with a digital multimeter; however, many owners have reported their coils have checked out to be okay, but still did not function correctly. By swapping to a new or known good coil, problems with engine bucking disappeared. Coils are fairly cheap to replace at around $50 a piece and are typically a wear item that periodically needs replacing.

Step 4 – Distributor cap/rotor

If other components of the ignition system check out okay, a faulty distributor cap or rotor may be the cause of a bucking engine condition. A distributor sends high-powered voltage from the ignition coil to each spark plug. This high voltage is transferred through the center of the distributor cap, into the rotor, and out again through the cap contact pins designated for each spark plug. With the cap and rotor being wear items, it is common to see poor contact between the rotor and cap pins as they age. Owners have even reported individual pins in the cap breaking off, therefore not supplying spark to several cylinders. With a dead miss in a cylinder or two, performance will greatly suffer. Inspecting the cap and rotor is free and can help uncover potential problems if the condition of either of these components are found to be suspect.

Step 5 – Fuel injectors

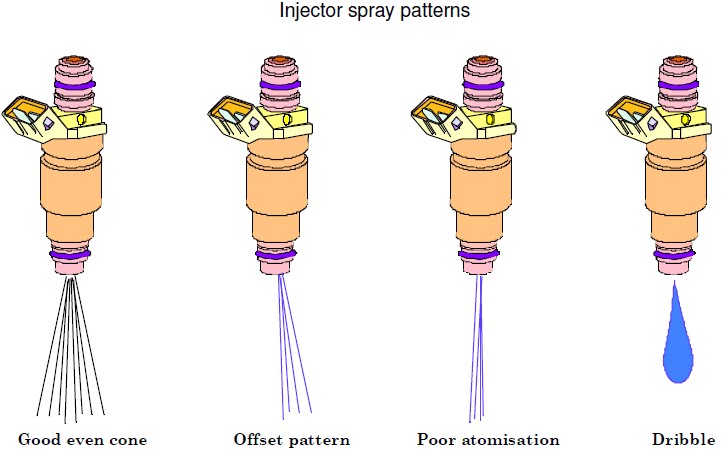

Partially clogged or dirty fuel injectors can cause poor running conditions. Fuel injectors have a precise spray pattern to atomize the fuel for the best possible combustion to take place. Over time, injectors can become clogged or dirty and this atomization process is disrupted. Surging and bucking under hard acceleration can be caused by dirty injectors because certain cylinders may not be receiving the proper amount of fuel that the ECU is requesting. This can cause misfires, detonation, and a general lack of performance. Fuel injector cleaners, such as Techron, can be run through the fuel system to clear up deposits in the injectors. If a fuel system cleaning is unsuccessful, injectors can be cleaned and rebuilt or replaced with new units entirely.

Step 6 – Fuel pressure

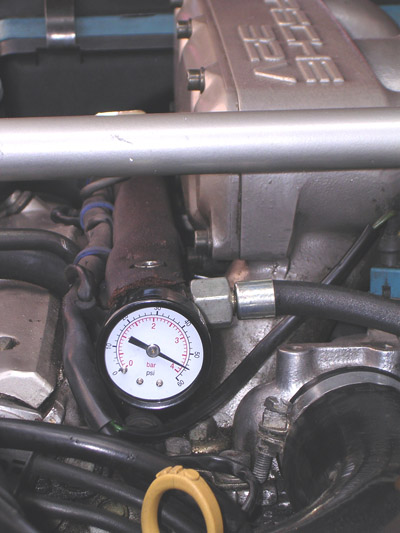

Proper fuel pressure needs to be at the fuel injectors for proper engine functioning. Unfortunately, if there is a blockage in any one a the fuel system components, an engine hesitation or bucking may occur at certain speeds. A fuel pressure test can be performed to ensure enough fuel is available to the injectors. While there are fittings to test for fuel pressure, they typically require a special connector. If the proper test gauge is not available, a homemade pressure tester can be teed into the fuel line between the rail and fuel pressure regulator on 32 valve cars. Fuel pressure should measure approximately 2.5 bar (37 psi). The pressure regulator return line can slowly be pinched closed while watching the gauge for pressure increase. If pressure does increase, the fuel pressure regulator is bad and should be replaced. If the pressure stays stable, a restriction is likely upstream in the fuel filter, fuel pump, fuel lines, or fuel ventilation.

Step 7 – Intake flap

The intake flap, commonly referred to as a "flappy valve" by 928 owners, is a butterfly valve located inside the intake manifold of 32 valve cars. This flap is controlled by engine vacuum and varies the geometry of the intake manifold for optimum performance at both low-end and top-end performance. Below 4,000 RPM, the flap closes off a portion of the intake manifold and improves low-end torque by allowing the engine to run as two 4-cylinder engines with tuned intake resonance. The flap opens above 4,000 RPM, allowing for improved flow through the intake and better top-end performance. Unfortunately, this flap is prone to sticking and can become non-functional. Owners have reported engine surging and bucking at 4,000 RPM if the flap has stuck in the open position. The operation of the flap can be checked by removing the rubber cap on the intake manifold and having a friend blip the throttle to 4,000 RPM. If operating correctly, the shaft should rotate 90 degrees back and forth. Also, check the vacuum fittings running to the flap controller to make sure vacuum is available to operate the flap. If the flap is frozen and does not operate, intake manifold removal is required to access the flap.

(Related Article: Porsche 928: How to Replace TPS - Rennlist.com)

Figure 8. Intake flap inside intake manifold.

Figure 9. Checking intake flap opertation.

Pro Tip

Owners have had success freeing a stuck flap by lubricating the shaft with a penetrating oil such as WD-40.

Related Discussions

- Trying to Solve Engine Bucking - Rennlist.com

- Bucking/Surging 84 Euro - Rennlist.com

- Hesitation 928 S2 - Rennlist.com