Cam timing specs.

#17

We must ensure the cam is rotated to the overlap position, but the crank turns twice for each rotation of the cams. If the crank indicates TDC, then the cam is either correct at overlap or not correct at firing. The cam position can only be determined by sight or by measuring whether there is compression (whistle). So rotate the crank into TDC position and if you heard a whistle on the that bank, then it's wrong it's on firing so rotate the crank another 360. With two whistles you can't go wrong because when it's correct the whistles will alternate when you spin the crank.

It's the same with all multi-cam, multibank engines, including aircooled BTW.

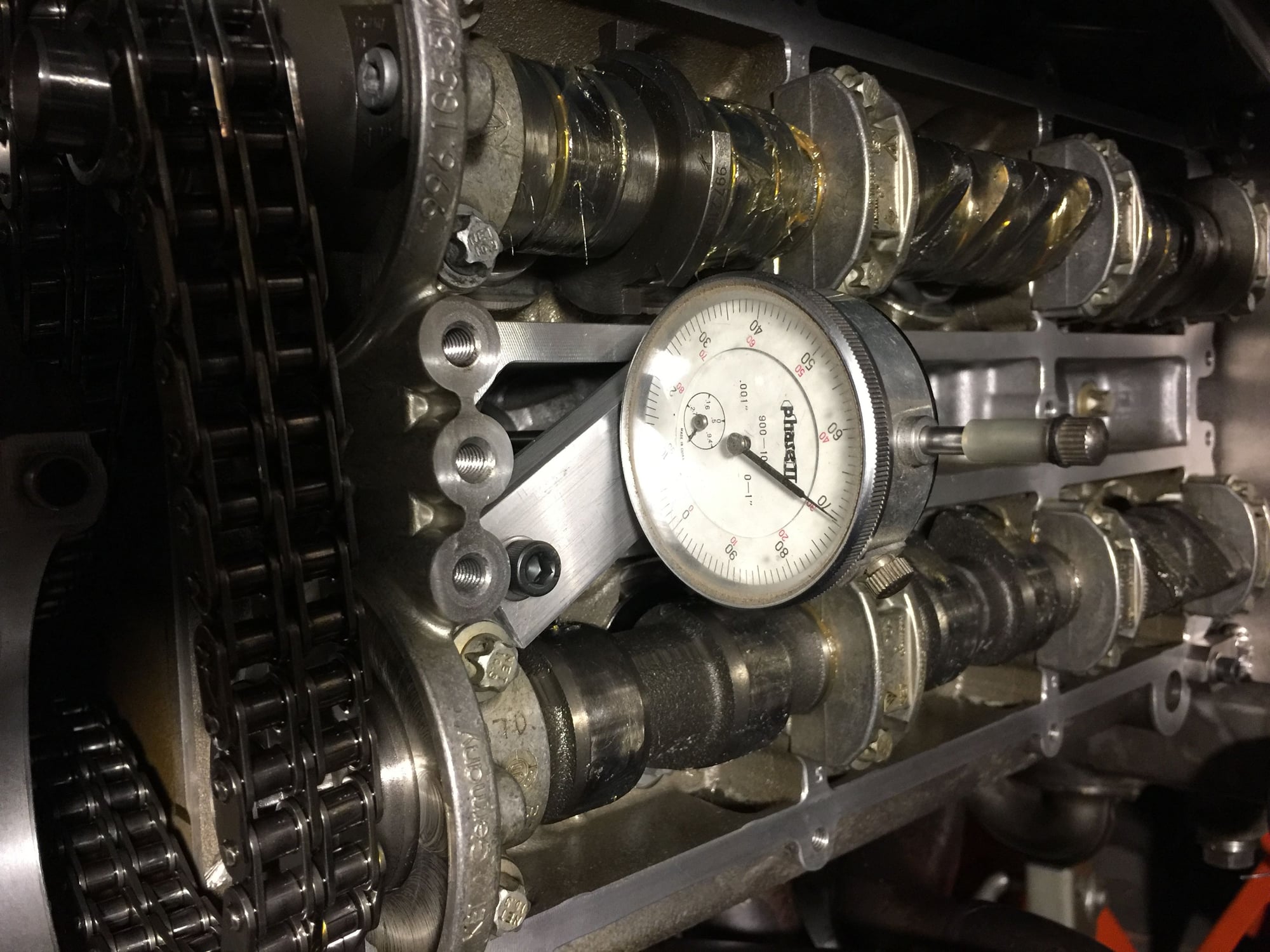

Glad you mentioned the dial gauge with the long probe. I made a holder for a dial gauge and purchased a long probe. Will look for a photo. Or you can buy an excellent rig from Stomski. The factory manual mentions that it is necessary to use a dial gauge.

One step better than the dial gauge is to use dial gauge plus degree wheel. The degree wheel is attached to the flywheel or crank pulley and measures the number of degrees of crank rotation where the piston stops briefly at TDC and crank is still rotating. When you know at which points on the wheel the piston was not moving, mark the center between those points and that is exactly TDC. But it's TDC either overlap or firing, 50/50 chance so you have to check the cam to determine which. This method is surely explained on the internet. One step better than the degree wheel is Stomski's digital degree wheel called DIGIDX. Same concept but more accurate. Worth watching the Stomski videos even if you don't buy. And I'll bet Steve Stomski would be very happy to help you on the phone.

This is fun typing all of this stuff. Thanks for the good conversation. Really hoping everything goes smoothly for you.

It's the same with all multi-cam, multibank engines, including aircooled BTW.

Glad you mentioned the dial gauge with the long probe. I made a holder for a dial gauge and purchased a long probe. Will look for a photo. Or you can buy an excellent rig from Stomski. The factory manual mentions that it is necessary to use a dial gauge.

One step better than the dial gauge is to use dial gauge plus degree wheel. The degree wheel is attached to the flywheel or crank pulley and measures the number of degrees of crank rotation where the piston stops briefly at TDC and crank is still rotating. When you know at which points on the wheel the piston was not moving, mark the center between those points and that is exactly TDC. But it's TDC either overlap or firing, 50/50 chance so you have to check the cam to determine which. This method is surely explained on the internet. One step better than the degree wheel is Stomski's digital degree wheel called DIGIDX. Same concept but more accurate. Worth watching the Stomski videos even if you don't buy. And I'll bet Steve Stomski would be very happy to help you on the phone.

This is fun typing all of this stuff. Thanks for the good conversation. Really hoping everything goes smoothly for you.

Alternatively, if my whistle (or balloon) blows on the opposite bank, then I know Im on the correct TDC overlap on bank one, and vice versa if I was doing bank 4-6.

I have watched Steves videos and had a very helpful email off him as I think I will buy the digidix and SR090 (I think thats the one) in the end. But for this task I dont think I need them quite yet, yet being the operative word!! I may well call him because I will need the tensioner tools as well, even if I ended up buying the cam setting plates.

I can imagine it being easier to maintain the correct timing with the locking plates and cam holding tools, than just the cam holding tools after using the stromski kit?

thanks again, will update you as soon as I am doing it which I think will be in a weeks time due to having to get the engine out first and other commitments

Last edited by theanalyst; 07-12-2019 at 04:10 PM.