UMW stage 2B dyno results.......

#61

Pro

wow... love hearing about your builds / progress!

Extremely impressive numbers and the linear power! You can tell from the dyno video that the power is super linear... I bet it's a joy to drive!

Extremely impressive numbers and the linear power! You can tell from the dyno video that the power is super linear... I bet it's a joy to drive!

#62

#64

Rennlist Member

With that crazy TQ powerband, have you experimented with short shifting at 6k to see what lap time difference you get?

My thought is more hours before rebuild and that rpm drop from shifting at 6k will still keep you at the beginning of max portion of torque.

I find myself shifting below redline often because the car still has plenty of TQ down low with Kevin's turbos. And, in the back of my mind, the idea of longevity plays an economic role. If such exists in a track ride

My thought is more hours before rebuild and that rpm drop from shifting at 6k will still keep you at the beginning of max portion of torque.

I find myself shifting below redline often because the car still has plenty of TQ down low with Kevin's turbos. And, in the back of my mind, the idea of longevity plays an economic role. If such exists in a track ride

#65

Rennlist Member

Thread Starter

With that crazy TQ powerband, have you experimented with short shifting at 6k to see what lap time difference you get?

My thought is more hours before rebuild and that rpm drop from shifting at 6k will still keep you at the beginning of max portion of torque.

I find myself shifting below redline often because the car still has plenty of TQ down low with Kevin's turbos. And, in the back of my mind, the idea of longevity plays an economic role. If such exists in a track ride

My thought is more hours before rebuild and that rpm drop from shifting at 6k will still keep you at the beginning of max portion of torque.

I find myself shifting below redline often because the car still has plenty of TQ down low with Kevin's turbos. And, in the back of my mind, the idea of longevity plays an economic role. If such exists in a track ride

1st......52mph

2nd.....87mph

3rd....117mph

4th....150mph

5th....178mph

6th....218mph

I normally will stay in 3rd down to about 50mph before dropping to 2nd gear. 3rd is the money gear as it's good for 50-117mph..

I'm not really sweating the longevity here as the oiling on this engine is substantially better than on a stock TT/GT2 motor. The RSR crank has twice the oiling channels as the stock TT/GT2 crank and its proven to work in a 9000rpm race application. Speaking of longevity, that is one of the reasons Chris wants to go with the bypass pipes as the elimination of the cat restriction will slow down the turbines a bit which will in turn lower EGTs and also and also provide benefits on the intake side. The larger freer flowing ICs will lower the intake restriction the compressors have to work against and also will lower downstream intake temps. All good stuff that will lower the stress on the engine.

Here is a little teaser....4" Aerospace ICs.. Same stuff used by Airbus, Boeing, and in F1. The cooling fin surface are is immense. Very lightweight at only 2.5lbs more each than 997.2s ICs! Efficient at flowing up to 1200hp for the pair. These are prototypes with cast end tanks. When time permits, the next set will have billet end tanks with possibly some more trick stuff thrown in.

[url=https://flic.kr/p/WJThp2]

[url=https://flic.kr/p/VAdYDU]

Last edited by powdrhound; 08-03-2017 at 06:47 PM.

#68

Rennlist Member

Thread Starter

#69

Rennlist Member

#70

Rennlist Member

#73

Pro

What's the idea for the flex joints? Is it due to the expansion and contraction from hot lapping to cool-down for you, or actual flex needed due to engine movement (less stress)?

#74

Rennlist Member

Thread Starter

The flex joints eliminate stress on the exhaust components from the expansion and contraction of metals when subjected to high heat cycling which will eventually result in cracking. There has to be "give" somewhere in the system. EVERY OEM exhaust employs flex joints for this reason.

#75

Rennlist Member

Thread Starter

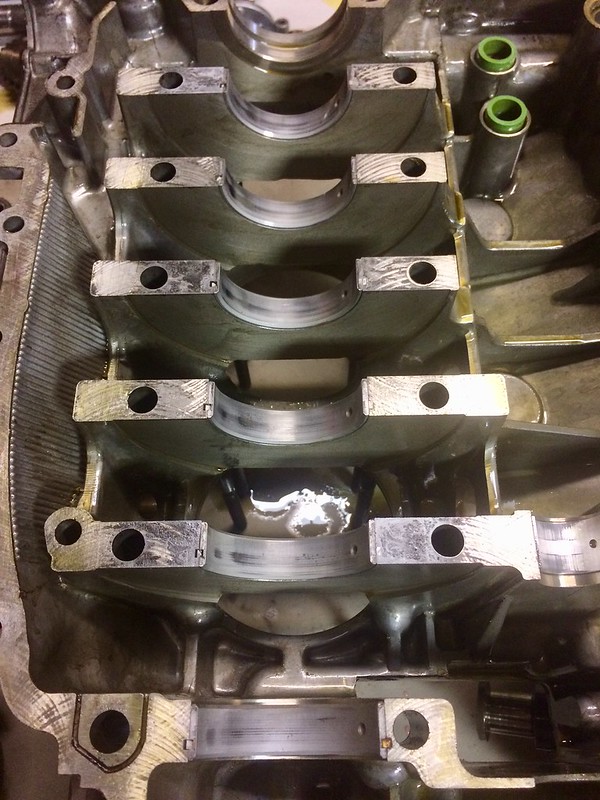

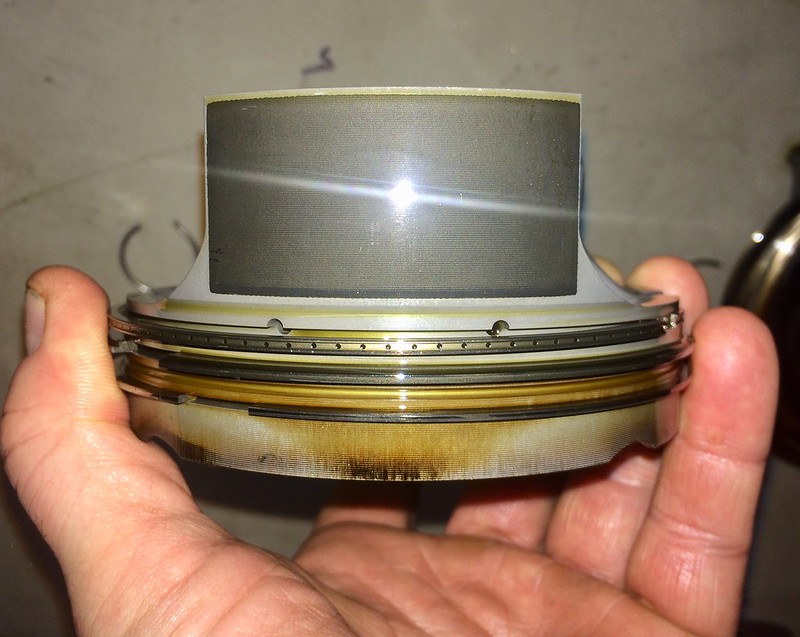

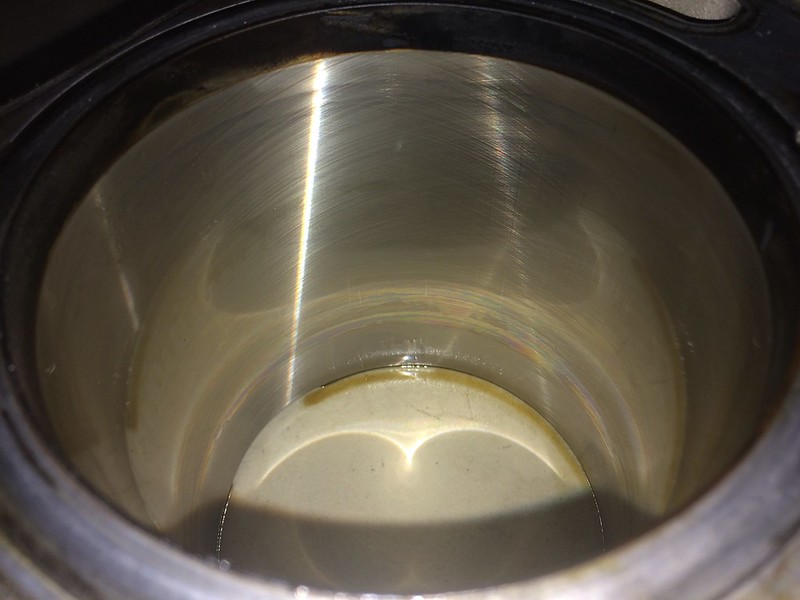

To follow up on this thread, I just had the engine removed from the car for a rebuild. Since the last 3.8 rebuild of the engine in early 2015, the engine has accumulated 278.3 ECU hours and a total of 8024 miles. Of this amount, 65hrs and 4024 miles were hard track use. The engine has performed flawlessly for the last 3 seasons with zero issues whatsoever. The last dyno at 52 track hrs spun the rollers at 620whp/720wtq on 91 octane at 1.25bar with a redline set at 7500. Originally were were planning to run it to 100hrs for the rebuild but I figured I'd rather take the conservative approach and pull the engine a year early to make sure all was in order. As it turns out, upon disassembly, there were indeed no issues and the engine could have easily been run to 100hrs, likely 120 or so. The engine burned about 0.3-0.5 quarts of oil per 1000 track miles. For those wondering, the break in procedure of the engine after it was last rebuilt was as typically performed by Porsche Motorsport, dynoed and then track driven at 100% right out of the gate.

Here are the observations after the teardown this week:

3.8 Mahle Motorsport pistons: Perfect condition, zero wear, machining striations intact on pistons

3.8 Mahle Motorsport 102mm liners: Perfect condition, zero wear, honing marks still visible on cylinder walls

Motorsport RSR cranshaft: Perfect condition

Crankshaft bearings: Light wear, nothing out of the ordinary

Thrust bearing: Normal to moderate wear

Pauter custom forged rods: Perfect condition

Rod bushing (small end): Perfect condition

Rod bearings: Normal wear, nothing out of the ordinary

Engine case: Normal fretting near the center, nothing out of the ordinary

McKenzie heads: No apparent issues noted but likely expect some valve guide wear (heads will be sent to Todd McKenzie for a refresh)

UMW K16/997GT2RS turbochargers: Perfect condition, zero axial and fore/aft play

One thing of note is that upon engine removal, it was evident that the driver's side OEM turbocharger support bracket was broken. This had put a load on the turbocharger and two of the turbocharger studs were clearly stressed and broke on removal. Not a huge issues as they can be drilled out with the turbos off the car. The only other small item was a broken worm clamp on one of the diverter valves. Even with a broken clamp there was no leak during a pressure test and as such the broken clamp had gone unnoticed. That's about it for any of the abnormals discovered during teardown.

The current crank, rods, and 3.8 pistons/liner will not be used in the rebuild. They will likely find a new home. The plan for the engine rebuild currently underway is the installation of the following new parts:

1. Porsche Motorsport Cup crankshaft (latest version)

2. Porsche Motorsport rod and crankshaft bearings

3. Porsche Motorsport 997RSR billet IMS

4. Mahle Motorport 4.0L (106mm) pistons and liners (case and water jackets will be machined)

5. Carillo custom billet rods

6. Bosch Motorsport adjustable FPR

7. Bosch Motorsport Fuel filter with integrated fuel pressure/temperature sensor

6. All Intake and exhaust lifters, Chains, all seals, hoses, etc.

The engine will initially be run with the existing UMW turbochargers and then I plan to swap over to Kevin's latest generation of his custom zero clearance K16s with his newest 997GT2RS billet compressor wheel (the existing turbos have the OEM cast 997GT2RS wheels). Kevin is in the process of building these for me right now. I will then send my current turbos to Kevin for a full refresh so that I have a brand new set of spares on hand.

While at it, I will also have my gearbox internals swapped into a new 996GT2 transmission case with the factory liquid to liquid cooler instead of the current air to liquid cooler I'm using. As with the last build, all work is being performed by Chris Cervelli at Cervelli Technical Service. A full Motorsport suspension upgrade is also planed with new subframes, uprights, new shocks, etc, etc. I'll do a separate write up on that later. Below are pics of the current engine breakdown. That's it for the update, cheers!

Here are the observations after the teardown this week:

3.8 Mahle Motorsport pistons: Perfect condition, zero wear, machining striations intact on pistons

3.8 Mahle Motorsport 102mm liners: Perfect condition, zero wear, honing marks still visible on cylinder walls

Motorsport RSR cranshaft: Perfect condition

Crankshaft bearings: Light wear, nothing out of the ordinary

Thrust bearing: Normal to moderate wear

Pauter custom forged rods: Perfect condition

Rod bushing (small end): Perfect condition

Rod bearings: Normal wear, nothing out of the ordinary

Engine case: Normal fretting near the center, nothing out of the ordinary

McKenzie heads: No apparent issues noted but likely expect some valve guide wear (heads will be sent to Todd McKenzie for a refresh)

UMW K16/997GT2RS turbochargers: Perfect condition, zero axial and fore/aft play

One thing of note is that upon engine removal, it was evident that the driver's side OEM turbocharger support bracket was broken. This had put a load on the turbocharger and two of the turbocharger studs were clearly stressed and broke on removal. Not a huge issues as they can be drilled out with the turbos off the car. The only other small item was a broken worm clamp on one of the diverter valves. Even with a broken clamp there was no leak during a pressure test and as such the broken clamp had gone unnoticed. That's about it for any of the abnormals discovered during teardown.

The current crank, rods, and 3.8 pistons/liner will not be used in the rebuild. They will likely find a new home. The plan for the engine rebuild currently underway is the installation of the following new parts:

1. Porsche Motorsport Cup crankshaft (latest version)

2. Porsche Motorsport rod and crankshaft bearings

3. Porsche Motorsport 997RSR billet IMS

4. Mahle Motorport 4.0L (106mm) pistons and liners (case and water jackets will be machined)

5. Carillo custom billet rods

6. Bosch Motorsport adjustable FPR

7. Bosch Motorsport Fuel filter with integrated fuel pressure/temperature sensor

6. All Intake and exhaust lifters, Chains, all seals, hoses, etc.

The engine will initially be run with the existing UMW turbochargers and then I plan to swap over to Kevin's latest generation of his custom zero clearance K16s with his newest 997GT2RS billet compressor wheel (the existing turbos have the OEM cast 997GT2RS wheels). Kevin is in the process of building these for me right now. I will then send my current turbos to Kevin for a full refresh so that I have a brand new set of spares on hand.

While at it, I will also have my gearbox internals swapped into a new 996GT2 transmission case with the factory liquid to liquid cooler instead of the current air to liquid cooler I'm using. As with the last build, all work is being performed by Chris Cervelli at Cervelli Technical Service. A full Motorsport suspension upgrade is also planed with new subframes, uprights, new shocks, etc, etc. I'll do a separate write up on that later. Below are pics of the current engine breakdown. That's it for the update, cheers!

Last edited by powdrhound; 12-31-2017 at 11:30 AM.