Oil (quantity) gauge 100% failure

#18

Rennlist Member

Thread Starter

Added 1.25 quarts and now show at warmed idle:

quantity gauge needle @ 330 o'clock (it lives!)

temp gauge needle @ 730 o'clock

pressure gauge needle @ 230 o'clock

dipstick reading @ near top

In short, I was short (oil) and had/have no sensor problem.

I now know the correaltion between them all.

quantity gauge needle @ 330 o'clock (it lives!)

temp gauge needle @ 730 o'clock

pressure gauge needle @ 230 o'clock

dipstick reading @ near top

In short, I was short (oil) and had/have no sensor problem.

I now know the correaltion between them all.

#19

Weathergirl

Rennlist Member

Rennlist Member

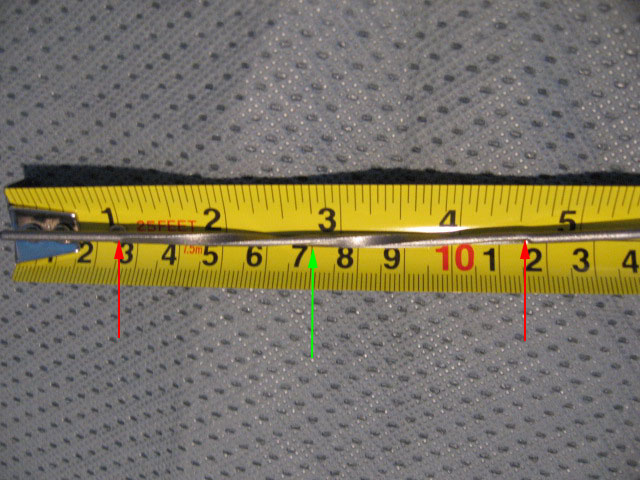

One question about the dipstick: Mine doesn't look like the photo--it has about 3" of twist through the entire oil level range, rather than the dimple and small twist at each end of the range. Was the design changed at some point?

#20

Rennlist Member

JA -

Excellent thoughts . One question:

. One question:

"To check the sensor you need to attach a multimeter to the opposite side of the same connector and move the operating float on the sensor in the tank."

I have not yet looked at the tank/sensor configuration, so how would I move the float while it's still in the tank?

Thanks,

MP

Excellent thoughts

. One question:

. One question:"To check the sensor you need to attach a multimeter to the opposite side of the same connector and move the operating float on the sensor in the tank."

I have not yet looked at the tank/sensor configuration, so how would I move the float while it's still in the tank?

Thanks,

MP

#21

Technical Guru

Rennlist Member

Rennlist Member

Originally Posted by RallyJon

One question about the dipstick: Mine doesn't look like the photo--it has about 3" of twist through the entire oil level range, rather than the dimple and small twist at each end of the range. Was the design changed at some point?

original unmarked photo courtesy of Dudley

Originally Posted by martyp

I have not yet looked at the tank/sensor configuration, so how would I move the float while it's still in the tank?