Center Lock Wheel Tool Suggestions Please

#16

Addict

Rennlist

Lifetime Member

Rennlist

Lifetime Member

If the question is "what should I bring to help the shop" I would just throw in a 1/2 to 3/4 socket adapter and this:

https://www.toolsource.com/split-bea...6.html?tsqtid=

https://www.toolsource.com/split-bea...6.html?tsqtid=

And don't forget the grease, although you can just spread the leftover from the last application before re-setting the centerlock in a pinch: https://www.suncoastparts.com/product/04302000.html

If you're on the road and need to plug a tire, it's a lot easier to find the leak and plug it if you can jack the car up and spin it rather than driving forward and back a bit at a time. I carry an old 928 jack kit for that. You can find them on Ebay and/or a dismantler for < $100. Google Porsche 928 jack

You could definitely use one of SmokingGTS alignment tools to save your calipers and rotors from dings when putting the wheels on and off.

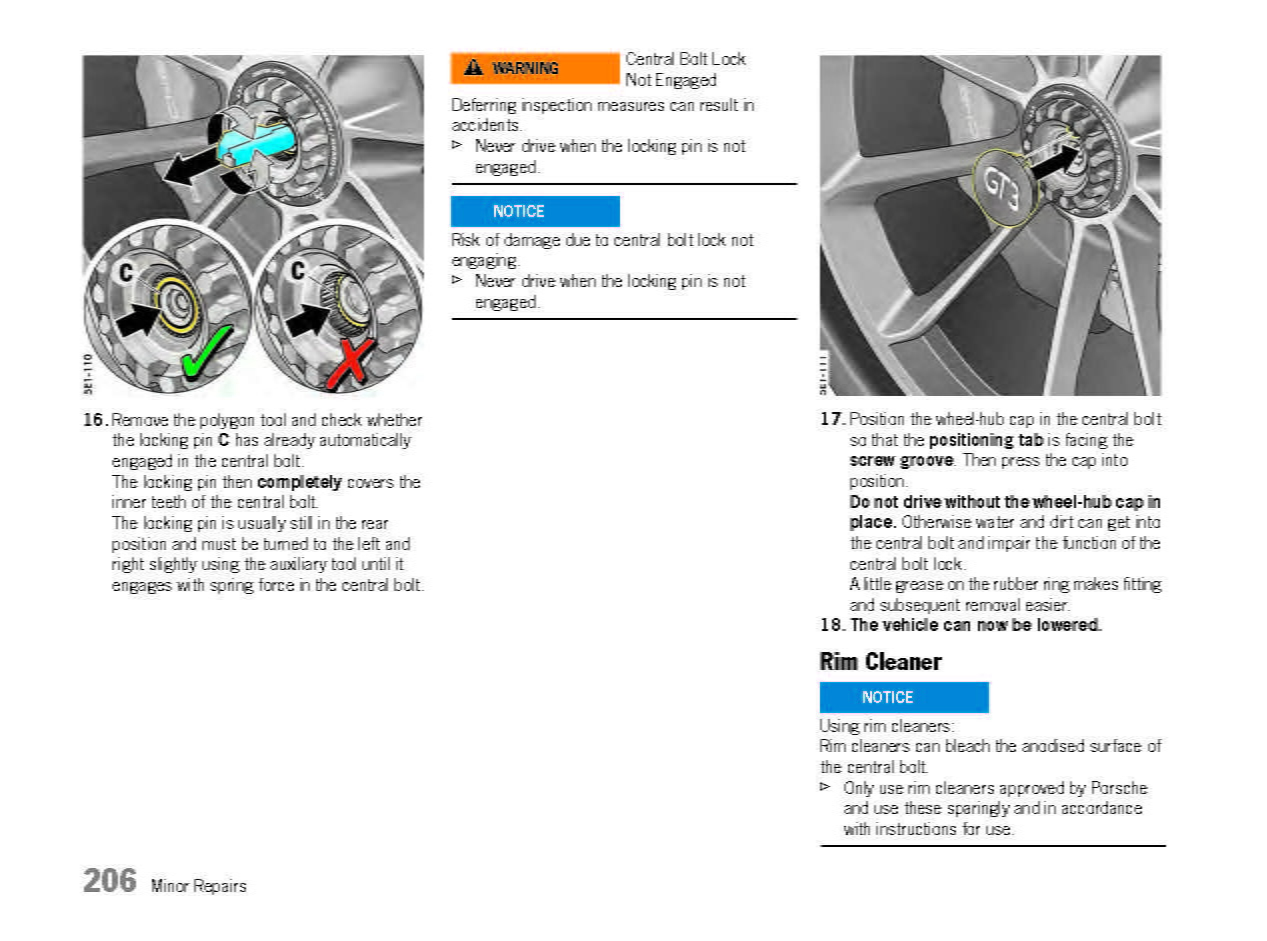

As far as the procedure, you can watch YouTube videos, but you need to read the manual starting on p. 203 if you're going to mess with mounting wheels yourself.

HTH,

TT

Last edited by Tom Tweed; 08-25-2017 at 09:30 PM. Reason: add images of manual

The following 2 users liked this post by Tom Tweed:

BigHeadDennis (06-25-2021),

ER911S (04-19-2021)

#17

Addict

Rennlist

Lifetime Member

Rennlist

Lifetime Member

since we have so many experts here, I have a question as well.

Now that I am taking my RS to the track more frequently, how are you guys checking to ensure the wheels are tightened appropriately? Obviously with the lugs its easy, but these CLs are a pain. What is recommended? Hate to lose a wheel if it can be avoided. Thanks in advance, as the DEs pile up!

Now that I am taking my RS to the track more frequently, how are you guys checking to ensure the wheels are tightened appropriately? Obviously with the lugs its easy, but these CLs are a pain. What is recommended? Hate to lose a wheel if it can be avoided. Thanks in advance, as the DEs pile up!

TT

#18

Instructor

since we have so many experts here, I have a question as well.

Now that I am taking my RS to the track more frequently, how are you guys checking to ensure the wheels are tightened appropriately? Obviously with the lugs its easy, but these CLs are a pain. What is recommended? Hate to lose a wheel if it can be avoided. Thanks in advance, as the DEs pile up!

Now that I am taking my RS to the track more frequently, how are you guys checking to ensure the wheels are tightened appropriately? Obviously with the lugs its easy, but these CLs are a pain. What is recommended? Hate to lose a wheel if it can be avoided. Thanks in advance, as the DEs pile up!

Bottom line...don't worry, Be happy and race "the wheels off"

#19

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

A list I put together for my RS ...

Tools:

(1) Porsche collapsible breaker bar - 997.361.161.00

(2) Torque wrench - Precision Instruments C4D600F - tooltopia

http://www.tooltopia.com/precision-i...s-c4d600f.aspx

(3) Discussion ==> https://rennlist.com/forums/997-gt2-...ue-wrench.html

(4) brake pedal holder - http://www.tooldiscounter.com/ItemDi...ookup=LIS21520

(5) Grease - https://www.suncoastparts.com/product/04302000.html

(6) Ed's (SmokinGTS) Delrin centering tool

Tools:

(1) Porsche collapsible breaker bar - 997.361.161.00

(2) Torque wrench - Precision Instruments C4D600F - tooltopia

http://www.tooltopia.com/precision-i...s-c4d600f.aspx

(3) Discussion ==> https://rennlist.com/forums/997-gt2-...ue-wrench.html

(4) brake pedal holder - http://www.tooldiscounter.com/ItemDi...ookup=LIS21520

(5) Grease - https://www.suncoastparts.com/product/04302000.html

(6) Ed's (SmokinGTS) Delrin centering tool

#20

Drifting

I would not worry about losing a wheel. At approximately 500 ftlbs and the safety lock hub I can't see how you would lose a wheel. The only way would be to snap off the hub entirely. Race cars only tighten to about 300fp with an air gun impact wrench. Don't get hung up with all of the directions written by german lawyers "the car must be elevated, you must back off the nut approximately 20 degrees and re-tighten...." blah blah. If you really look at the physics involved with center locks, they are very safe. That's why all race cars (except nascar and other domestic series) use center locks. Where is the greatest force as a wheel rotates...you guessed it...as you move away from the center. The least centrifugal force force is in the center of the wheel. BUT what you trade off is lateral and torsion strength of the hub itself.

Bottom line...don't worry, Be happy and race "the wheels off"

Bottom line...don't worry, Be happy and race "the wheels off"

#21

I did mine for the first time on Monday night, swapping my wheels from left to right to prepare for my next track weekend.

I'd read at least once or twice the opinions about pulling up on the breaker bar or torque wrench rather than pushing down to avoid stress on the suspension.

I did that for the front wheels. After doing that, it became pretty obvious that if I stuck to that procedure I wouldn't be able to get out of bed the next day and if I made it a regular habit then I'd be on the path to permanent back injury.

I did the back ones by pushing down on the bars.

Firstly, it's worth mentioning that the manual says absolutely nothing about this and the pictures show the bar near vertical with the "push" going either forward or back depending on loosening or tightening. I might try that next time but I have a feeling there won't be enough friction between my shoes and the ground to make that work.

Thinking further about the forces involved (and maybe a little to justify my decision regarding self-preservation) I've decided that it doesn't really make much difference no matter how you slice it. You're not pulling down the suspension when you push down on the bar. You're applying torque to the center no matter which way you do it. It's a turning force, not a straight force in any direction. When pulling up or pushing down I didn't get the impression I was putting much stress on the suspension one way or the other.

If someone has some good reason to have a strong opinion on this, I'd love to hear it. In the meantime, I'm satisfied that I am comfortable enough with this procedure to do it again and again going forward.

And I still think the whole bloody system is idiotic for a track car.

I was ridiculously cautious with the pieces to ensure they didn't get any dirt on them as getting grit into the paste and then grinding it into the system seems like a terrible idea. Just one more thing you don't need to worry about with normal reliable lug nuts or bolts.

I'd read at least once or twice the opinions about pulling up on the breaker bar or torque wrench rather than pushing down to avoid stress on the suspension.

I did that for the front wheels. After doing that, it became pretty obvious that if I stuck to that procedure I wouldn't be able to get out of bed the next day and if I made it a regular habit then I'd be on the path to permanent back injury.

I did the back ones by pushing down on the bars.

Firstly, it's worth mentioning that the manual says absolutely nothing about this and the pictures show the bar near vertical with the "push" going either forward or back depending on loosening or tightening. I might try that next time but I have a feeling there won't be enough friction between my shoes and the ground to make that work.

Thinking further about the forces involved (and maybe a little to justify my decision regarding self-preservation) I've decided that it doesn't really make much difference no matter how you slice it. You're not pulling down the suspension when you push down on the bar. You're applying torque to the center no matter which way you do it. It's a turning force, not a straight force in any direction. When pulling up or pushing down I didn't get the impression I was putting much stress on the suspension one way or the other.

If someone has some good reason to have a strong opinion on this, I'd love to hear it. In the meantime, I'm satisfied that I am comfortable enough with this procedure to do it again and again going forward.

And I still think the whole bloody system is idiotic for a track car.

I was ridiculously cautious with the pieces to ensure they didn't get any dirt on them as getting grit into the paste and then grinding it into the system seems like a terrible idea. Just one more thing you don't need to worry about with normal reliable lug nuts or bolts.

Last edited by Wild Weasel; 05-16-2018 at 03:49 PM.

#22

Instructor

Hahah! Boy the lawyers have you guys by the *****!! I have been going to the track on center locks for three years and with zero issues. I torque to 450ftlbs. I re-grease about every four or five changes. Donít stress about the ďprocedureĒ. Itís physics. Just think about it. Relax. Your wheels wonít fall off hahah!

#23

Instructor

Once you use one you will never use a huge leverage bar again. Here's what I have:

https://store.snapon.com/Geared-Head...t-P634899.aspx

https://store.snapon.com/Geared-Head...t-P634899.aspx

https://store.snapon.com/Geared-Head...--P634900.aspx

your link is not working for me.

TIA

#24

Is this what you are talking about?

https://store.snapon.com/Geared-Head...--P634900.aspx

your link is not working for me.

TIA

https://store.snapon.com/Geared-Head...--P634900.aspx

your link is not working for me.

TIA

#25

I did mine for the first time on Monday night, swapping my wheels from left to right to prepare for my next track weekend.

I'd read at least once or twice the opinions about pulling up on the breaker bar or torque wrench rather than pushing down to avoid stress on the suspension.

I did that for the front wheels. After doing that, it became pretty obvious that if I stuck to that procedure I wouldn't be able to get out of bed the next day and if I made it a regular habit then I'd be on the path to permanent back injury.

I did the back ones by pushing down on the bars.

Firstly, it's worth mentioning that the manual says absolutely nothing about this and the pictures show the bar near vertical with the "push" going either forward or back depending on loosening or tightening. I might try that next time but I have a feeling there won't be enough friction between my shoes and the ground to make that work.

Thinking further about the forces involved (and maybe a little to justify my decision regarding self-preservation) I've decided that it doesn't really make much difference no matter how you slice it. You're not pulling down the suspension when you push down on the bar. You're applying torque to the center no matter which way you do it. It's a turning force, not a straight force in any direction. When pulling up or pushing down I didn't get the impression I was putting much stress on the suspension one way or the other.

If someone has some good reason to have a strong opinion on this, I'd love to hear it. In the meantime, I'm satisfied that I am comfortable enough with this procedure to do it again and again going forward.

And I still think the whole bloody system is idiotic for a track car.

I was ridiculously cautious with the pieces to ensure they didn't get any dirt on them as getting grit into the paste and then grinding it into the system seems like a terrible idea. Just one more thing you don't need to worry about with normal reliable lug nuts or bolts.

I'd read at least once or twice the opinions about pulling up on the breaker bar or torque wrench rather than pushing down to avoid stress on the suspension.

I did that for the front wheels. After doing that, it became pretty obvious that if I stuck to that procedure I wouldn't be able to get out of bed the next day and if I made it a regular habit then I'd be on the path to permanent back injury.

I did the back ones by pushing down on the bars.

Firstly, it's worth mentioning that the manual says absolutely nothing about this and the pictures show the bar near vertical with the "push" going either forward or back depending on loosening or tightening. I might try that next time but I have a feeling there won't be enough friction between my shoes and the ground to make that work.

Thinking further about the forces involved (and maybe a little to justify my decision regarding self-preservation) I've decided that it doesn't really make much difference no matter how you slice it. You're not pulling down the suspension when you push down on the bar. You're applying torque to the center no matter which way you do it. It's a turning force, not a straight force in any direction. When pulling up or pushing down I didn't get the impression I was putting much stress on the suspension one way or the other.

If someone has some good reason to have a strong opinion on this, I'd love to hear it. In the meantime, I'm satisfied that I am comfortable enough with this procedure to do it again and again going forward.

And I still think the whole bloody system is idiotic for a track car.

I was ridiculously cautious with the pieces to ensure they didn't get any dirt on them as getting grit into the paste and then grinding it into the system seems like a terrible idea. Just one more thing you don't need to worry about with normal reliable lug nuts or bolts.

I donít think the forced in question here matter much. The loads on the road / track are massive in comparison.

#26

i think itís because the suspension is designed to take the load going up towards the body and not down and away from it.

#27

Rennlist Member

Is this what you are talking about?

https://store.snapon.com/Geared-Head...--P634900.aspx

your link is not working for me.

TIA

https://store.snapon.com/Geared-Head...--P634900.aspx

your link is not working for me.

TIA

Looks the same, but what do I know?

The snap on is a 4X multiplier, I think you can get 5X with Armstrong. Just remember to divide the torque values by 4 or whatever multiplier you get.

There is a loss of precision through the gearing in the multiplier, like 5 or 10%, so I overtorque slightly to compensate- but I donít think itís necessary.

Also FYI use a wood block for the reaction bar to avoid leaving divots in your garage floor or in the track asphalt.

#28

Rest easy, ITS not the center lock torqueing that's going to kill you, ITS the wheel HUB failure. My friends 991 at Mid Ohio this weekend CRACKED all the spokes but one on his center locks. Evidently the Porsche wheels are only good for street use if you VALUE your life.

#29

Three Wheelin'

Ryan

#30

Addict

Rennlist Member

Rennlist Member

Which model 991 and which wheels? Would be interested if GT3 forged wheels (occasionally bent, but haven't seen a catastrophic failure posted).