The quest to resolve a pesky flat spot, with help from Steve Wong

#1

Pro

Thread Starter

I have owned my 964 since December 2008, originally purchased as a daily driver, but now reserved for fun at the weekends. Over the last year I have noticed a flat spot below 4,500 revs. There seemed to be a noticeable hesitation when accelerating which was bugging me. I mentioned this to Paul Stevens at Purely 9 whilst in for a regular service but he didn't spot anything obvious and didn't really notice the flat spot during a test drive. I started to wonder whether I was imagining things, but was fairly sure after nearly 5 years of ownership something wasn't quite with the old girl.

So, when StanUK951 suggested a Rennlister group run over to Surrey Rolling Roads, I figured it was a great opportunity to see just how well she is actually running. As reported in the Rolling Road thread ( https://rennlist.com/forums/964-foru...r-uk-964s.html ) it achieved a healthy 252 BHP, which we all agreed was quite impressive bearing in mind the car has 87k miles on an un-rebuilt engine. The only mods being a K&N panel filter in a drilled airbox, a cat by-pass and a G Pipe. However, the dyno graphs did show a flat spot which given my previous suspicions did make sense.

My fello Rennlisters on the day suggested that may I should get in touch with Steve Wong, so I did just that. Well what a thoroughly helpful and knowledgeable chap Steve is. Steve took a look at the RR data for me and suggested that the air/fuel data was not clean and had him suspecting that the full throttle microswitch may not be activating, or perhaps throttle was not fully opening when the accelerator pedal was fully depressed. He suggested that I should check them and when all is working properly, his standard chip set up for the premuffler / bypass configuration would be well set up for an ideal max power air fuel ratio at full throttle and it will certainly fix the current lean condition the car had below 4500 rpm with the stock chip. So a Steve Wong chip was ordered and once delivered, I booked the car back in with Paul Stevens to check those items and the chip replacement. I know the chip replacements are an easy DIY job, but these things have a habit of being more complicated as soon as I get involved and I don't have a great deal of patience when things go wrong

After a couple of hours with the car, Paul reported back that the throttle microswitch was in fact broken and the throttle was not opening fully, as Steve Wong suspected... result! So later that day off I went to pick up the car from Purely9, anxious to see if the flat spot had been rectified along with any noticeable performance improvements from the new chip. Well, I most certainly wasn't disappointed. The results were probably a mixture of Paul's throttle function fixes and the new chip, but there was certainly a difference in the way the car drove and I am well chuffed. The throttle response is much more instant and the power delivery is a lot smoother through the rev range.

So now the plan is to get the Porka back down to Surrey Rolling Road to see if the dyno now tells a different story to last time. I will post my findings as soon as I have...

So, when StanUK951 suggested a Rennlister group run over to Surrey Rolling Roads, I figured it was a great opportunity to see just how well she is actually running. As reported in the Rolling Road thread ( https://rennlist.com/forums/964-foru...r-uk-964s.html ) it achieved a healthy 252 BHP, which we all agreed was quite impressive bearing in mind the car has 87k miles on an un-rebuilt engine. The only mods being a K&N panel filter in a drilled airbox, a cat by-pass and a G Pipe. However, the dyno graphs did show a flat spot which given my previous suspicions did make sense.

My fello Rennlisters on the day suggested that may I should get in touch with Steve Wong, so I did just that. Well what a thoroughly helpful and knowledgeable chap Steve is. Steve took a look at the RR data for me and suggested that the air/fuel data was not clean and had him suspecting that the full throttle microswitch may not be activating, or perhaps throttle was not fully opening when the accelerator pedal was fully depressed. He suggested that I should check them and when all is working properly, his standard chip set up for the premuffler / bypass configuration would be well set up for an ideal max power air fuel ratio at full throttle and it will certainly fix the current lean condition the car had below 4500 rpm with the stock chip. So a Steve Wong chip was ordered and once delivered, I booked the car back in with Paul Stevens to check those items and the chip replacement. I know the chip replacements are an easy DIY job, but these things have a habit of being more complicated as soon as I get involved and I don't have a great deal of patience when things go wrong

After a couple of hours with the car, Paul reported back that the throttle microswitch was in fact broken and the throttle was not opening fully, as Steve Wong suspected... result! So later that day off I went to pick up the car from Purely9, anxious to see if the flat spot had been rectified along with any noticeable performance improvements from the new chip. Well, I most certainly wasn't disappointed. The results were probably a mixture of Paul's throttle function fixes and the new chip, but there was certainly a difference in the way the car drove and I am well chuffed. The throttle response is much more instant and the power delivery is a lot smoother through the rev range.

So now the plan is to get the Porka back down to Surrey Rolling Road to see if the dyno now tells a different story to last time. I will post my findings as soon as I have...

#3

Nordschleife Master

That's awesome!

What was done to correct the WOT switch? Was it a matter of adjusting the switch position to engage properly at WOT or was the actual switch faulty?

What was done to correct the WOT switch? Was it a matter of adjusting the switch position to engage properly at WOT or was the actual switch faulty?

#4

Rennlist Member

I would bet the throttle microswitch actuating cam broke...if you do a search you'll find out that you can't just order a new cam. You either have to MacGuyver the existing cam or check out the fellow rennlister that manufactured some new ones. A search will further elucidate!

#6

Burning Brakes

Amazing how many 964's are running around with the throttle not operating the WOT switch. Without this the ECU will not switch to its full power map so you should see a nice bhp jump next time you get on a dyno.

Trending Topics

#9

Pro

Thread Starter

I would bet the throttle microswitch actuating cam broke...if you do a search you'll find out that you can't just order a new cam. You either have to MacGuyver the existing cam or check out the fellow rennlister that manufactured some new ones. A search will further elucidate!

#10

Racer

Thanks for the write up Paul.

Mine has a flat spot on take off, I believe it has been chipped and has cat bypass. Needs an investigation...

Rolling road looks to be the place to start.

Mine has a flat spot on take off, I believe it has been chipped and has cat bypass. Needs an investigation...

Rolling road looks to be the place to start.

#11

Nordschleife Master

If it's an actual mechanical fault, not an electric/failed switch, then it should be easy to test.

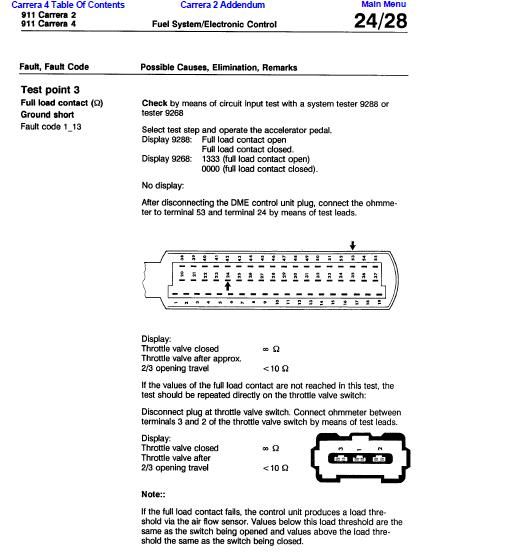

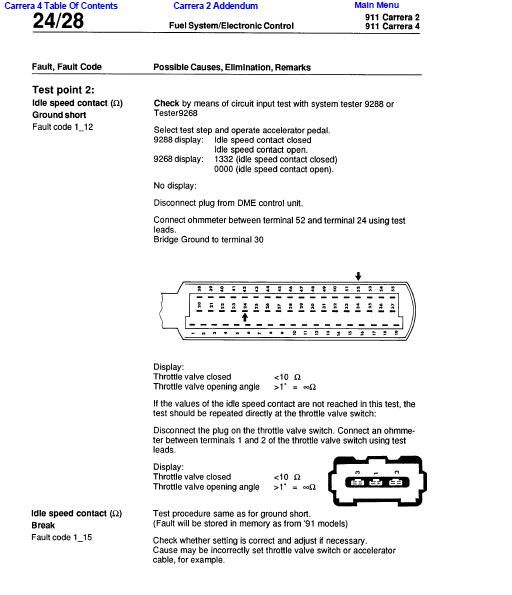

With the engine off, have someone sit in the car and press the gas pedal to WOT while you put your head near the middle of the intake plenum. You'll first hear the idle switch click when the throttle body opens then you should hear the WOT switch click as the opposite end of the throttle movement and opposite side of the throttle body.

There has to be a way to test the functionality of these switches using a diagnostic tool. Anyone?

With the engine off, have someone sit in the car and press the gas pedal to WOT while you put your head near the middle of the intake plenum. You'll first hear the idle switch click when the throttle body opens then you should hear the WOT switch click as the opposite end of the throttle movement and opposite side of the throttle body.

There has to be a way to test the functionality of these switches using a diagnostic tool. Anyone?

#12

Rennlist Member

If it's an actual mechanical fault, not an electric/failed switch, then it should be easy to test.

With the engine off, have someone sit in the car and press the gas pedal to WOT while you put your head near the middle of the intake plenum. You'll first hear the idle switch click when the throttle body opens then you should hear the WOT switch click as the opposite end of the throttle movement and opposite side of the throttle body.

There has to be a way to test the functionality of these switches using a diagnostic tool. Anyone?

With the engine off, have someone sit in the car and press the gas pedal to WOT while you put your head near the middle of the intake plenum. You'll first hear the idle switch click when the throttle body opens then you should hear the WOT switch click as the opposite end of the throttle movement and opposite side of the throttle body.

There has to be a way to test the functionality of these switches using a diagnostic tool. Anyone?

That's how I found my WOT cam was split. My scantool showed my WOT microswitch was intermittently being actuated, then subsequently getting less actuated until I'd have to mash the pedal all the way to the floor. Then it just wasn't working at all. I found that the cam looked like it was still on it's axle (for lack of a better word) but had cracked and was spinning freely about the axle. When I went to touch it, it fell apart into two pieces. I ended up doing the drill holes, thin wire, and JB Weld the two pieces back together, snapped it back onto the axle (it looks to be a press-fit type of assembly although it looks like a circlip or something similar could be installed as the axle has a groove in it on the outboard side of the cam once it's installed...this will make sense once you look at the whole assembly). Now my WOT microswitch is actuated everytime and my scantool confirms this!

#13

Nordschleife Master

I have all these components off the car at the moment and I had removed and reinstalled the idle and WOT switch from the throttle body, and in doing so, I adjusted the placement of the switches to be right on the verge at the end of travel. Perhaps I should re-adjust them prior to reassembly to move the engagement point further away from the end of travel.

Any input on the positioning for the idle switch? Should I set that one up so that it is still engaged w/ very slight throttle?

Any input on the positioning for the idle switch? Should I set that one up so that it is still engaged w/ very slight throttle?

#15

Instructor