VW/Audi 07K (2.5L 20V I5) Swap Thread

#646

Rennlist Member

I think cold rolled steel plate should be better than cast aluminum (stock 944 BH) for absorbing a clutch... or flywheel...

#647

Rennlist Member

My concern wasn't about the mount bracket itself but rather the engine block, though maybe silly to question the stiffness of a monolithic chunk of cast steel...

With the torque tube and "rear mounts" the engine is cantilevered out in space, where originally there was a giant front (transverse) mount carrying the front of the weight.

With the torque tube and "rear mounts" the engine is cantilevered out in space, where originally there was a giant front (transverse) mount carrying the front of the weight.

#648

Racer

My concern wasn't about the mount bracket itself but rather the engine block, though maybe silly to question the stiffness of a monolithic chunk of cast steel...

With the torque tube and "rear mounts" the engine is cantilevered out in space, where originally there was a giant front (transverse) mount carrying the front of the weight.

With the torque tube and "rear mounts" the engine is cantilevered out in space, where originally there was a giant front (transverse) mount carrying the front of the weight.

#649

Racer

While Iím waiting for bits and pieces for engine swaps , I will be working on the stopping portion of the 944 build . My Cayenne calipers came in yesterday . Next is a set of late suspension to rebuild and then work out making the adapters to put it all together .

#650

Rennlist Member

#651

Not Alan but I'll chime in here

Time, patience, and lots of grinding wheels!

Jk but looks like most of it can be cut out on a plasma table, except for the back part, which would be easier to make on a CNC machine (or lathe, if you're that ambitious), purely for accuracy needs. Then tack weld it all together. Check fitment. More welding. Deffinitely could be done at home, but as good as I am at arts & crafts, this is something I'd rather leave to some professionals.

Time, patience, and lots of grinding wheels!

Jk but looks like most of it can be cut out on a plasma table, except for the back part, which would be easier to make on a CNC machine (or lathe, if you're that ambitious), purely for accuracy needs. Then tack weld it all together. Check fitment. More welding. Deffinitely could be done at home, but as good as I am at arts & crafts, this is something I'd rather leave to some professionals.

#652

Rennlist Member

Patrick,

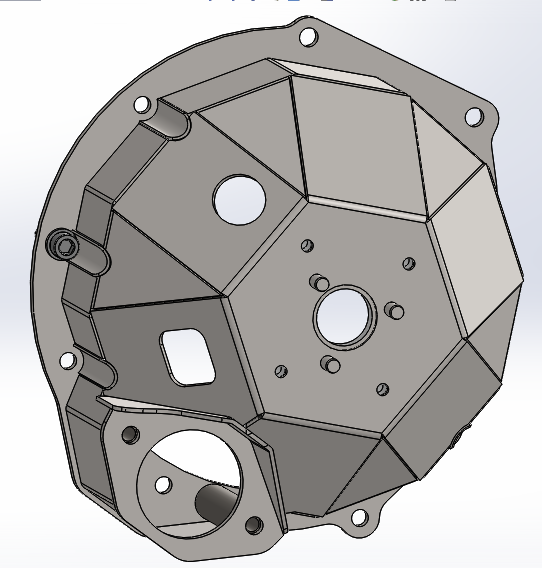

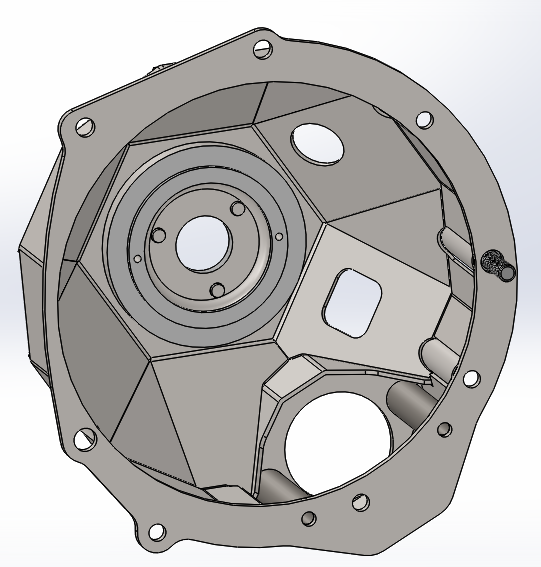

Here's our current plan... The faceted bell shape will be made from 4 pieces of 1/8" cold rolled steel, laser cut into flat patterns, and then press broken into shape by a sheet metal fabrication company that I have been using for 10 years. The ring that bolts to the engine and the starter mounting plate will be 1/4" cold rolled steel, also laser cut. The pieces will be assembled on a jig that holds the engine plate precisely aligned to the output flange (which bolts to the front of the torque tube). The round part inside the bell will be cnc machined, and will have mounting holes for the torque tube bolts, alignment pins, and the clutch slave. That part will be aligned to the output flange on the jig using dowel pins. The entire assembly will be tacked together on the jig before removal. Then, it will be fully welded at all seams (mostly MIG) in a criss-cross pattern to minimize warpage. After it is fully welded and cooled down, the alignment will be checked on the fixture. Then the whole assembly will be powder coated.

We are planning to start by making one (mine) to test this process. If we find that the welding process causes too much misalignment, then we will have a post-machining process to true everything up before powder coating.

The fabrication and welding will be done by my brother in law, who is a master fabricator and has been a motorsports fabrication instructor at a technical college for over 20 years. I have the utmost confidence in the quality of his work. (He will also be doing the welding on my other parts, such as the engine mounts and oil pan).

Here's our current plan... The faceted bell shape will be made from 4 pieces of 1/8" cold rolled steel, laser cut into flat patterns, and then press broken into shape by a sheet metal fabrication company that I have been using for 10 years. The ring that bolts to the engine and the starter mounting plate will be 1/4" cold rolled steel, also laser cut. The pieces will be assembled on a jig that holds the engine plate precisely aligned to the output flange (which bolts to the front of the torque tube). The round part inside the bell will be cnc machined, and will have mounting holes for the torque tube bolts, alignment pins, and the clutch slave. That part will be aligned to the output flange on the jig using dowel pins. The entire assembly will be tacked together on the jig before removal. Then, it will be fully welded at all seams (mostly MIG) in a criss-cross pattern to minimize warpage. After it is fully welded and cooled down, the alignment will be checked on the fixture. Then the whole assembly will be powder coated.

We are planning to start by making one (mine) to test this process. If we find that the welding process causes too much misalignment, then we will have a post-machining process to true everything up before powder coating.

The fabrication and welding will be done by my brother in law, who is a master fabricator and has been a motorsports fabrication instructor at a technical college for over 20 years. I have the utmost confidence in the quality of his work. (He will also be doing the welding on my other parts, such as the engine mounts and oil pan).

#653

If the fabricated bellhousing goes ahead, might there be an option to have the exterior welds ground smooth before powder coating (for an upcharge to cover labor).

Also, would the three torque tube alignment pins be replaceable like they are on the original Porsche piece?

thanks! Great work as always.

Also, would the three torque tube alignment pins be replaceable like they are on the original Porsche piece?

thanks! Great work as always.

#654

Rennlist Member

If the fabricated bellhousing goes ahead, might there be an option to have the exterior welds ground smooth before powder coating (for an upcharge to cover labor).

Also, would the three torque tube alignment pins be replaceable like they are on the original Porsche piece?

thanks! Great work as always.

Also, would the three torque tube alignment pins be replaceable like they are on the original Porsche piece?

thanks! Great work as always.

Yes, the alignment pins will be removable using a simple hydraulic press. The holes for the pins will be through holes, so you can push them out from the inside.

#655

No we will not be grinding the welds smooth. That weakens the joints, so not a good idea for a structural part such as this. Don't worry, the welds will look very good without grinding.

Yes, the alignment pins will be removable using a simple hydraulic press. The holes for the pins will be through holes, so you can push them out from the inside.

Yes, the alignment pins will be removable using a simple hydraulic press. The holes for the pins will be through holes, so you can push them out from the inside.

#657

#658

#659

Racer

I have no personal experience with that , but all my friends have kids and my brother . I am the blacksheep , LOL .I`ll be 46 end of next month .

#660