Refresh951's Hybrid Ultra Stroker Build

#91

Rennlist Member

Thread Starter

So I spent much of the Christmas break researching turbos for my build. I have learned a great deal but I am still far from getting my mind around all the variables. One thing I know for sure is that the proper turbo selection is critical to achieving my goals. With my 2.5L I spent a great deal of time researching bolt on options and it proved to be very beneficial.

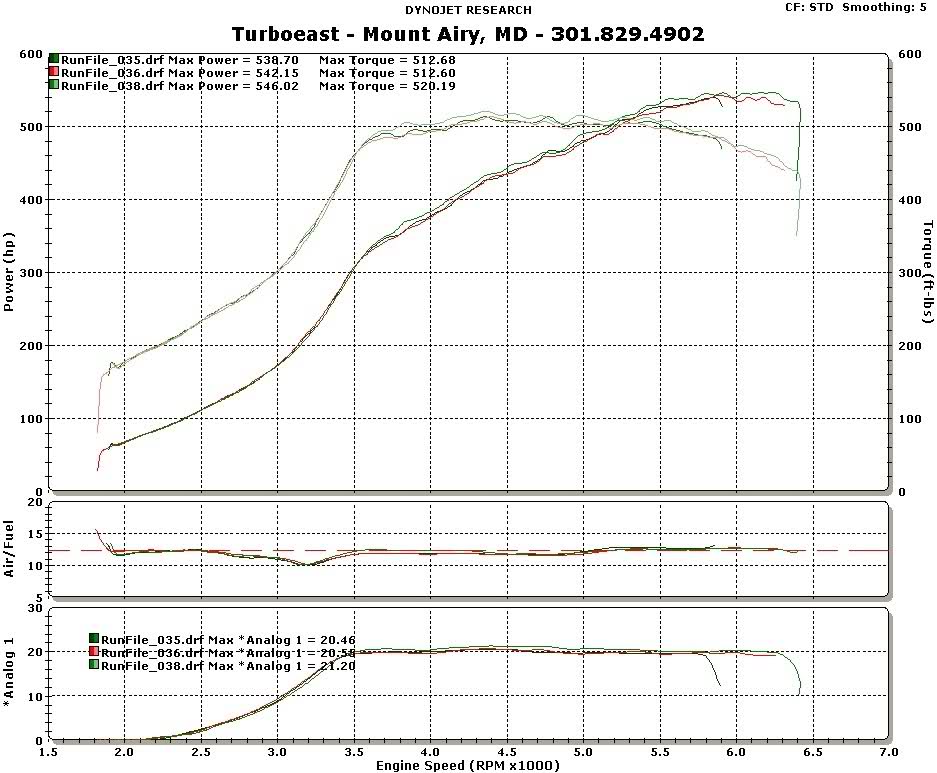

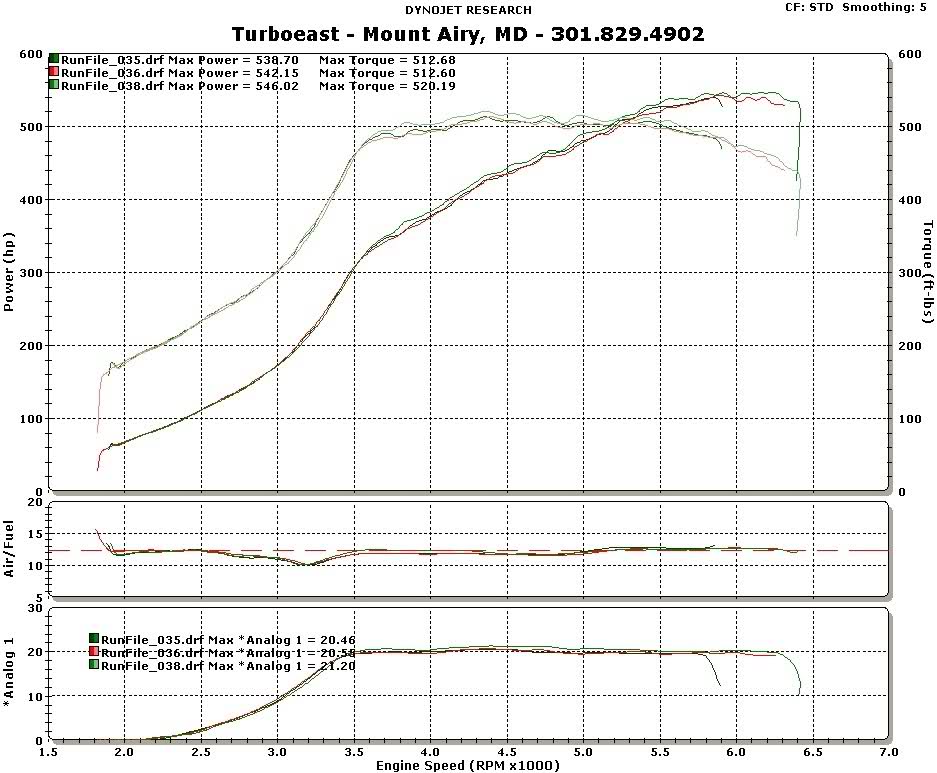

I have been looking primarily at Garrett GT and Holset HX Turbos. I keep coming back to the GT3582R with a Tial SS turbine housing. If I go GT3582R the critical choice will be .82 ar or 1.06 ar. Right now I am leaning towards the .82 ar because of the quicker spool. Duke's Green Hunter dyno is very impressive with impressive spool (16V). Duke was running the GT3582R .82 ar:

Duke never ran higher than 17 psi nor did he run E85. My question was can the GT3582R .82 ar deliver 550 rwhp with my setup? I am thinking it will take around 22-23 psi to meet my goals (possibly a bit more). I have looked at a lot of dyno sheets on other forums. Here is a Supra dyno running an IS300 3L with a single scroll GT3582R .82 ar. Pretty impressive if real and not that different than Duke's dyno but obviously higher boost. Looks like the .82 ar could deliver at least 21 psi to redline. This dyno is pretty much my goal although with I want slightly better afr's.

Any thoughts?

I have been looking primarily at Garrett GT and Holset HX Turbos. I keep coming back to the GT3582R with a Tial SS turbine housing. If I go GT3582R the critical choice will be .82 ar or 1.06 ar. Right now I am leaning towards the .82 ar because of the quicker spool. Duke's Green Hunter dyno is very impressive with impressive spool (16V). Duke was running the GT3582R .82 ar:

Duke never ran higher than 17 psi nor did he run E85. My question was can the GT3582R .82 ar deliver 550 rwhp with my setup? I am thinking it will take around 22-23 psi to meet my goals (possibly a bit more). I have looked at a lot of dyno sheets on other forums. Here is a Supra dyno running an IS300 3L with a single scroll GT3582R .82 ar. Pretty impressive if real and not that different than Duke's dyno but obviously higher boost. Looks like the .82 ar could deliver at least 21 psi to redline. This dyno is pretty much my goal although with I want slightly better afr's.

Any thoughts?

#92

Firstly, Duke has a CR of 9.5 while you are planning on 8.3, plus he may be able to run a far more aggressive ignition profil than you (and me!) thanks to his 16V head. To me this means he is getting a spool with his GT3582R than may not be reached with an 8V head.

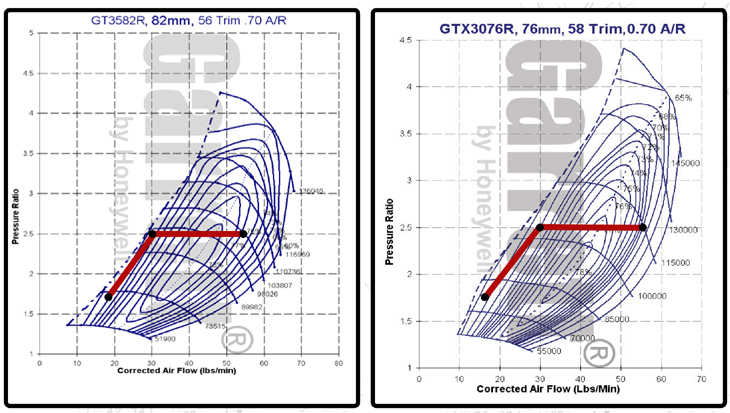

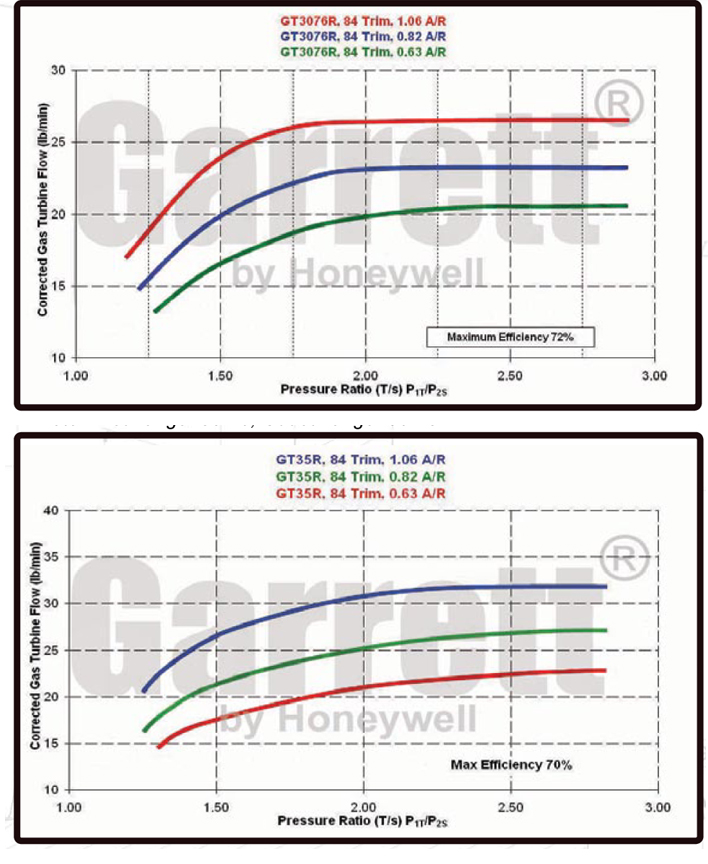

Secondly, the GT3582R has become osbolete since the GTX3076R came out. The latter will flow the same and spool better thanks to its lighter wheels. In fact it flows so much that Garrett launched the GTX3576R so that this 76mm "X" comp wheel could flow as much as it could. It also means that by the time you need a GTX3576R you will necessarily choose the large 1.06 turbine housing, because the GT30's 0.82 and 1.06 housing flow respectively the same as the GT35's 0.63 and 0.82. The GT30 turbine is also more efficient than the larger GT35 turbine. At least that is what the turbine charts from Garrett say.

On paper, a GTX3076R with a 1.06 turbine housing should therefore have the same peak flow as a GT3582R with a 0.82 turbine housing. The GTX3076R will however necessarily spool better because both its wheels are smaller/lighter than the GT3582R's.

Thirdly, when checking out for the GTX3076R compressor map, make sure you check out the GTX3576R's compressor map instead. Though both turbos use the same compressor, Garrett has strangely published a comp map for the GTX3076R that was apparently established with a 0.70 A/R compressor cover, while the GTX3076R is actually sold as standard with a 0.60 A/R compressor cover, as is the GTX3576R.

Secondly, the GT3582R has become osbolete since the GTX3076R came out. The latter will flow the same and spool better thanks to its lighter wheels. In fact it flows so much that Garrett launched the GTX3576R so that this 76mm "X" comp wheel could flow as much as it could. It also means that by the time you need a GTX3576R you will necessarily choose the large 1.06 turbine housing, because the GT30's 0.82 and 1.06 housing flow respectively the same as the GT35's 0.63 and 0.82. The GT30 turbine is also more efficient than the larger GT35 turbine. At least that is what the turbine charts from Garrett say.

On paper, a GTX3076R with a 1.06 turbine housing should therefore have the same peak flow as a GT3582R with a 0.82 turbine housing. The GTX3076R will however necessarily spool better because both its wheels are smaller/lighter than the GT3582R's.

Thirdly, when checking out for the GTX3076R compressor map, make sure you check out the GTX3576R's compressor map instead. Though both turbos use the same compressor, Garrett has strangely published a comp map for the GTX3076R that was apparently established with a 0.70 A/R compressor cover, while the GTX3076R is actually sold as standard with a 0.60 A/R compressor cover, as is the GTX3576R.

Last edited by Thom; 01-05-2013 at 03:32 PM.

#93

Addict

Rennlist Member

Rennlist

Small Business Partner

Rennlist Member

Rennlist

Small Business Partner

Duke's higher CR also means less ignition advance compared to a 8.3 engine. Further, the 16v head will want less ignition advance than an 8v head due to the centered spark-plug and better combustion chamber.

#94

I experimented with less ignition timing during the spool up phase as I expected that higher EGTs would improve the spool but it actually made it worse. I did not even notice a difference in EGT during spool up, but a difference would eventually show up only when the turbo is already spooled to peak boost and the engine has reached its upper rpm range under WOT.

For the same CR, the 16V will knock with a more aggressive ignition profile than the 8V head, so maybe Duke's ignition profile would work on a 8V head engine with a CR of 8.3 but the resulting dynamic compression ratio should be lower on the 8V, whence a slower spooling turbo.

For the same CR, the 16V will knock with a more aggressive ignition profile than the 8V head, so maybe Duke's ignition profile would work on a 8V head engine with a CR of 8.3 but the resulting dynamic compression ratio should be lower on the 8V, whence a slower spooling turbo.

#95

Drive-by provocation guy

Rennlist Member

Rennlist Member

Join Date: Apr 2002

Location: NAS PAX River, by way of Orlando

Posts: 10,439

Likes: 0

Received 0 Likes

on

0 Posts

I experimented with less ignition timing during the spool up phase as I expected that higher EGTs would improve the spool but it actually made it worse. I did not even notice a difference in EGT during spool up, but a difference would eventually show up only when the turbo is already spooled to peak boost and the engine has reached its upper rpm range under WOT.

For the same CR, the 16V will knock with a more aggressive ignition profile than the 8V head, so maybe Duke's ignition profile would work on a 8V head engine with a CR of 8.3 but the resulting dynamic compression ratio should be lower on the 8V, whence a slower spooling turbo.

For the same CR, the 16V will knock with a more aggressive ignition profile than the 8V head, so maybe Duke's ignition profile would work on a 8V head engine with a CR of 8.3 but the resulting dynamic compression ratio should be lower on the 8V, whence a slower spooling turbo.

#96

Rennlist Member

Thread Starter

Firstly, Duke has a CR of 9.5 while you are planning on 8.3, plus he may be able to run a far more aggressive ignition profil than you (and me!) thanks to his 16V head. To me this means he is getting a spool with his GT3582R than may not be reached with an 8V head.

Secondly, the GT3582R has become osbolete since the GTX3076R came out. The latter will flow the same and spool better thanks to its lighter compressor wheel. In fact it flows so much that Garrett launched the GTX3576R so that this 76mm "X" comp wheel could flow as much as it could. It also means that by the time you need a GTX3576R you will necessarily choose the large 1.06 turbine housing, because the GT30's 0.82 and 1.06 housing flow respectively the same as the GT35's 0.63 and 0.82. The GT30 turbine is also more efficient than the larger GT35 turbine. At least that is what the turbine charts from Garrett say.

On paper, a GTX3076R with a 1.06 turbine housing should therefore have the same peak flow as a GT3582R with a 0.82 turbine housing. The GTX3076R will however necessarily spool better because the compressor wheel is lighter than the GT3582R's.

Thirdly, when checking out for the GTX3076R compressor map, make sure you check out the GTX3576R's compressor map instead. Though both turbos use the same compressor, Garrett has strangely published a comp map for the GTX3076R that was apparently established with a 0.70 A/R compressor cover, while the GTX3076R is actually sold as standard with a 0.60 A/R compressor cover, as is the GTX3576R.

Secondly, the GT3582R has become osbolete since the GTX3076R came out. The latter will flow the same and spool better thanks to its lighter compressor wheel. In fact it flows so much that Garrett launched the GTX3576R so that this 76mm "X" comp wheel could flow as much as it could. It also means that by the time you need a GTX3576R you will necessarily choose the large 1.06 turbine housing, because the GT30's 0.82 and 1.06 housing flow respectively the same as the GT35's 0.63 and 0.82. The GT30 turbine is also more efficient than the larger GT35 turbine. At least that is what the turbine charts from Garrett say.

On paper, a GTX3076R with a 1.06 turbine housing should therefore have the same peak flow as a GT3582R with a 0.82 turbine housing. The GTX3076R will however necessarily spool better because the compressor wheel is lighter than the GT3582R's.

Thirdly, when checking out for the GTX3076R compressor map, make sure you check out the GTX3576R's compressor map instead. Though both turbos use the same compressor, Garrett has strangely published a comp map for the GTX3076R that was apparently established with a 0.70 A/R compressor cover, while the GTX3076R is actually sold as standard with a 0.60 A/R compressor cover, as is the GTX3576R.

http://blog.perrinperformance.com/ga...omparo-part-2/

Cost is also a consideration.

#97

Drive-by provocation guy

Rennlist Member

Rennlist Member

Join Date: Apr 2002

Location: NAS PAX River, by way of Orlando

Posts: 10,439

Likes: 0

Received 0 Likes

on

0 Posts

Refresh have you considered doing these same motors as a crate motor for sales? I would think this set up would easily sell for $7-8K retail leaving you a nice profit for your time and other 944/951/924/968 owners with a turn key drop in crate motor with crazy reliable power.

#98

Addict

Rennlist Member

Rennlist

Small Business Partner

Rennlist Member

Rennlist

Small Business Partner

I experimented with less ignition timing during the spool up phase as I expected that higher EGTs would improve the spool but it actually made it worse. I did not even notice a difference in EGT during spool up, but a difference would eventually show up only when the turbo is already spooled to peak boost and the engine has reached its upper rpm range under WOT.

The end-result was that the overall acceleration was not really improved. Even though there was more boost earlier, the reduced timing made less power. Essentially cancelling out any real benefit.

#99

Rennlist Member

Thread Starter

Refresh have you considered doing these same motors as a crate motor for sales? I would think this set up would easily sell for $7-8K retail leaving you a nice profit for your time and other 944/951/924/968 owners with a turn key drop in crate motor with crazy reliable power.

#100

I came to the same conclusion probably before reaching the required bottom ignition profile... No point making the car slower and the engine much less responsive just to get better spool IMO.

#101

Our engines produce so much heat that extracting this heat out of the engine bay is IMO preferable to the hardly noticeable difference in spool that wrapping the relevant part of the exhaust may make.

#103

Burning Brakes

I experimented with less ignition timing during the spool up phase as I expected that higher EGTs would improve the spool but it actually made it worse. I did not even notice a difference in EGT during spool up, but a difference would eventually show up only when the turbo is already spooled to peak boost and the engine has reached its upper rpm range under WOT.

For the same CR, the 16V will knock with a more aggressive ignition profile than the 8V head, so maybe Duke's ignition profile would work on a 8V head engine with a CR of 8.3 but the resulting dynamic compression ratio should be lower on the 8V, whence a slower spooling turbo.

For the same CR, the 16V will knock with a more aggressive ignition profile than the 8V head, so maybe Duke's ignition profile would work on a 8V head engine with a CR of 8.3 but the resulting dynamic compression ratio should be lower on the 8V, whence a slower spooling turbo.

But on the low vs high compression I dont think the compression ratio plays a big part in spool, certainly not the big difference you see here. Higher CR engines dont take in more air they just use that air more efficiently. Increasing the CR does not increase the exhaust pulse strength therefore it does not spool the turbo faster. If you had 2 8v engines one at 8:1 and one at 10:1 there should not be much in it.

Once you throw in the 16v head its a different ball game and the fact that it allows more timing advance is probably much more of a factor, along with the ability to flow more air, get more fuel in and hence more power at lower rpm = better spool. In a nutshell the 16v engine is a better/ more efficient pump so it makes sense that it spools better, this also may be further helped by the variocam. All in all comparing the boost response of a given turbo to an 8v is not really going to give any meaningful results when the engines are so different at the top end.

#104

Rennlist Member

Thread Starter

Secondly, the GT3582R has become osbolete since the GTX3076R came out. The latter will flow the same and spool better thanks to its lighter wheels. In fact it flows so much that Garrett launched the GTX3576R so that this 76mm "X" comp wheel could flow as much as it could. It also means that by the time you need a GTX3576R you will necessarily choose the large 1.06 turbine housing, because the GT30's 0.82 and 1.06 housing flow respectively the same as the GT35's 0.63 and 0.82. The GT30 turbine is also more efficient than the larger GT35 turbine. At least that is what the turbine charts from Garrett say.

On paper, a GTX3076R with a 1.06 turbine housing should therefore have the same peak flow as a GT3582R with a 0.82 turbine housing. The GTX3076R will however necessarily spool better because both its wheels are smaller/lighter than the GT3582R's.

On paper, a GTX3076R with a 1.06 turbine housing should therefore have the same peak flow as a GT3582R with a 0.82 turbine housing. The GTX3076R will however necessarily spool better because both its wheels are smaller/lighter than the GT3582R's.

#105

Rennlist Member

Thread Starter

With the GT3582R I could go with .84 a/r and could later change the hotside to a 1.06 a/r. With the GTX3076R I will get what I get and that will be that. Is the GT3076R's efficiency worth this limitation and extra cost? If it will deliver between 525 and 550 rwhp it just might be an awesome choice.