Banjo bolt instead of coolant bleed screw?

#1

Rainman

Rennlist Member

Rennlist Member

Thread Starter

Anybody tried this? Thoughts?

Would be like putting a "steam vent" kit at the front of the head for continuous steam/air purge and minor coolant circulation.

Could tee into the hose from rad tank -> expansion tank.

Would be like putting a "steam vent" kit at the front of the head for continuous steam/air purge and minor coolant circulation.

Could tee into the hose from rad tank -> expansion tank.

#7

Post a picture of your setup and how you tied it back in if you could. I've been thinking about doing something like this myself for awhile, an auto bleeder. My only concern was though that if the water neck constantly pushes coolant out it might lose some pressure for it's intended path? I also considered installed a valve so I could vent when I needed to without a mess but then close it when I'm done.

Trending Topics

#8

Nordschleife Master

Could someone please explain why you would need to constantly bleed a sealed system. Seems to me that itís just adding complexity and components that are just a further source of failure to cure a problem that doesnít exist.

#9

Rainman

Rennlist Member

Rennlist Member

Thread Starter

more shiny parts

even i've been wondering what purpose it would serve after being bled initially. but people sure like that steam vent kit..

pure speculation here, but say you've got a HG that is starting to fail that you don't know about)...perhaps giving the exhaust gas and steam etc somewhere to vent might get you home?

even i've been wondering what purpose it would serve after being bled initially. but people sure like that steam vent kit..

pure speculation here, but say you've got a HG that is starting to fail that you don't know about)...perhaps giving the exhaust gas and steam etc somewhere to vent might get you home?

#10

I'm more interested in venting the coolant without getting it all over the motor. Installing a valve in the water neck would allow you to attach a hose and run it to the overflow tank. This would be an auto bleeder system for first start ups. Once it vents everything you just shut the valve and remove the hose. No extra parts really.

#11

Interesting idea. I like it in regard to the control it offers during the fill and vent process. I'm not convinced there would be benefit beyond that.

It's easy to imagine small amounts of air developing inside a normal cooling system from local boiling around combustion surfaces or even from low pressure boiling (cavitation) around the water pump impeller.

If that air finds the front gooseneck, I expect there would be sufficient flow to eventually carry it back to the expansion reservoir. This is where it is different from the popular steam vent which, if I understand the design, allows system air to escape from a local high trap, in the back of the cylinder head, that normal circulation does not readily purge. Also worth study is that a continuous vent from the gooseneck, depending on where in the system it terminates (above or below liquid level) would, in a static condition (engine off), likely introduce system air into the gooseneck. Given that the gooseneck is the highest point of the cooling system and water will seek level. Right? I'm picturing that auto feed dog / cat water bowl device��

It's easy to imagine small amounts of air developing inside a normal cooling system from local boiling around combustion surfaces or even from low pressure boiling (cavitation) around the water pump impeller.

If that air finds the front gooseneck, I expect there would be sufficient flow to eventually carry it back to the expansion reservoir. This is where it is different from the popular steam vent which, if I understand the design, allows system air to escape from a local high trap, in the back of the cylinder head, that normal circulation does not readily purge. Also worth study is that a continuous vent from the gooseneck, depending on where in the system it terminates (above or below liquid level) would, in a static condition (engine off), likely introduce system air into the gooseneck. Given that the gooseneck is the highest point of the cooling system and water will seek level. Right? I'm picturing that auto feed dog / cat water bowl device��

#12

Drifting

I'm more interested in venting the coolant without getting it all over the motor. Installing a valve in the water neck would allow you to attach a hose and run it to the overflow tank. This would be an auto bleeder system for first start ups. Once it vents everything you just shut the valve and remove the hose. No extra parts really.

I guess all that's needed is a fitting with shutoff that screws into the coolant neck, replacing the bleed screw? That's a pretty small thread though

#14

Yes, the tank is higher than the gooseneck but I believe the prescribed liquid level in the tank is lower than the vent outlet in the gooseneck.

#15

Drifting

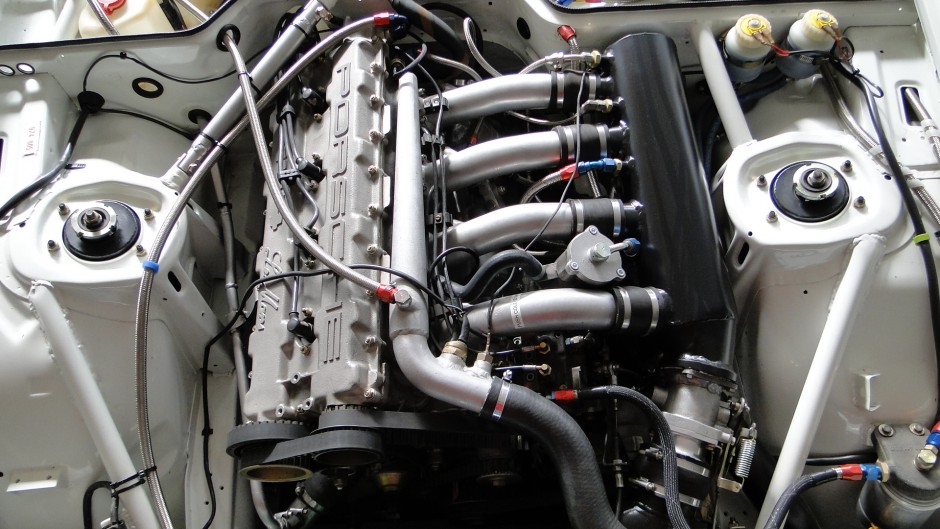

The LR stem vent kit is for the 8v head to ensure air doesn’t get trapped at the rear of the cylinder head. LR has that info on there website describing why. That LaMans head is a 16v which may not have that same issue. It may be worth having it at the goose neck for the 16v head thou.