Question - LCA lubrication

#1

Racer

Thread Starter

I'm finishing up a motor mmount oil pan gasket project and am about to reinstall the lower control arms. should I lubricate the bushing on the back of the lower control arm before installing the bracket?

thanks all!

thanks all!

#2

Rennlist Member

What does the WSM say?

If for some reason you don't have a set, or the pocket change cost CD with it, no.

The proper anti-seize on the bolts, which are different front to rear on the LCA, is important at this step too.

Roger sells the CD if you dont wanna buy the full hard copy set.

If for some reason you don't have a set, or the pocket change cost CD with it, no.

The proper anti-seize on the bolts, which are different front to rear on the LCA, is important at this step too.

Roger sells the CD if you dont wanna buy the full hard copy set.

#3

Archive Gatekeeper

Rennlist Member

Rennlist Member

No.

#6

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Yup - if possible bounce the nose to "settle" the front end so you are torquing those bolts at rest ride height. Otherwise those bushings will be in a constant bind.

#7

Rennlist Member

I generally tighten the bolts with the suspension loaded but obviously it is not fully settled. I then drive the car, undo the bolts a turn with the suspension [hopefully] fully settled and re-torque them.

The manual talks about leaving the bolts a couple of threads slack or something to that effect that I did not really understand [German English?] suggesting that it was OK to drive around with somewhat "loose bolts" until the thing. I was not at all happy with this so do it the way I do. Can anyone explain more meaningfully what the factory intended in this regard?

Rgds

Fred

The manual talks about leaving the bolts a couple of threads slack or something to that effect that I did not really understand [German English?] suggesting that it was OK to drive around with somewhat "loose bolts" until the thing. I was not at all happy with this so do it the way I do. Can anyone explain more meaningfully what the factory intended in this regard?

Rgds

Fred

Trending Topics

#8

Rennlist Member

Join Date: Feb 2011

Location: Mostly in my workshop located in Sweden.

Posts: 2,226

Received 442 Likes

on

244 Posts

I generally tighten the bolts with the suspension loaded but obviously it is not fully settled. I then drive the car, undo the bolts a turn with the suspension [hopefully] fully settled and re-torque them.

The manual talks about leaving the bolts a couple of threads slack or something to that effect that I did not really understand [German English?] suggesting that it was OK to drive around with somewhat "loose bolts" until the thing. I was not at all happy with this so do it the way I do. Can anyone explain more meaningfully what the factory intended in this regard?

Rgds

Fred

The manual talks about leaving the bolts a couple of threads slack or something to that effect that I did not really understand [German English?] suggesting that it was OK to drive around with somewhat "loose bolts" until the thing. I was not at all happy with this so do it the way I do. Can anyone explain more meaningfully what the factory intended in this regard?

Rgds

Fred

┼ke

#9

Drifting

No lube on bushing.

For the bolts. I left them loose as per WSM and did couple of test drives to settle front before torquing. They are tricky to access, so for each side I would pull up onto kerb with wheel turned to create room underneath, and have bolt heads in good position for torque wrench. Anti-seize on bolts of course - whatever the WSM recommended (think it was TA).

For the bolts. I left them loose as per WSM and did couple of test drives to settle front before torquing. They are tricky to access, so for each side I would pull up onto kerb with wheel turned to create room underneath, and have bolt heads in good position for torque wrench. Anti-seize on bolts of course - whatever the WSM recommended (think it was TA).

#10

Rennlist Member

I have the red cover USA version of the manuals. On page 40-5 for Hex bolt item 19, and on page 40-11 for item 23 [later models] it says quote:

"Coat threads with Optimoly [do not coat the shank], Screw in until only two threads are visible. Do not tighten until assembly is completed and s[prings have settled"

Unquote

What visible threads are they talking about as non are visible- that or I cannot see straight!

My assumption is that they mean the bolt should be such that it is backed off by two turns from the torqued position as though that is enough to hold things in place but this seems strange to me. Leave the bolts two turns slack and I might expect the bolts will drop out from vibrations by the time the suspension has fully settled.

Rgds

Fred

#11

Rennlist Member

Rennlist Site Sponsor

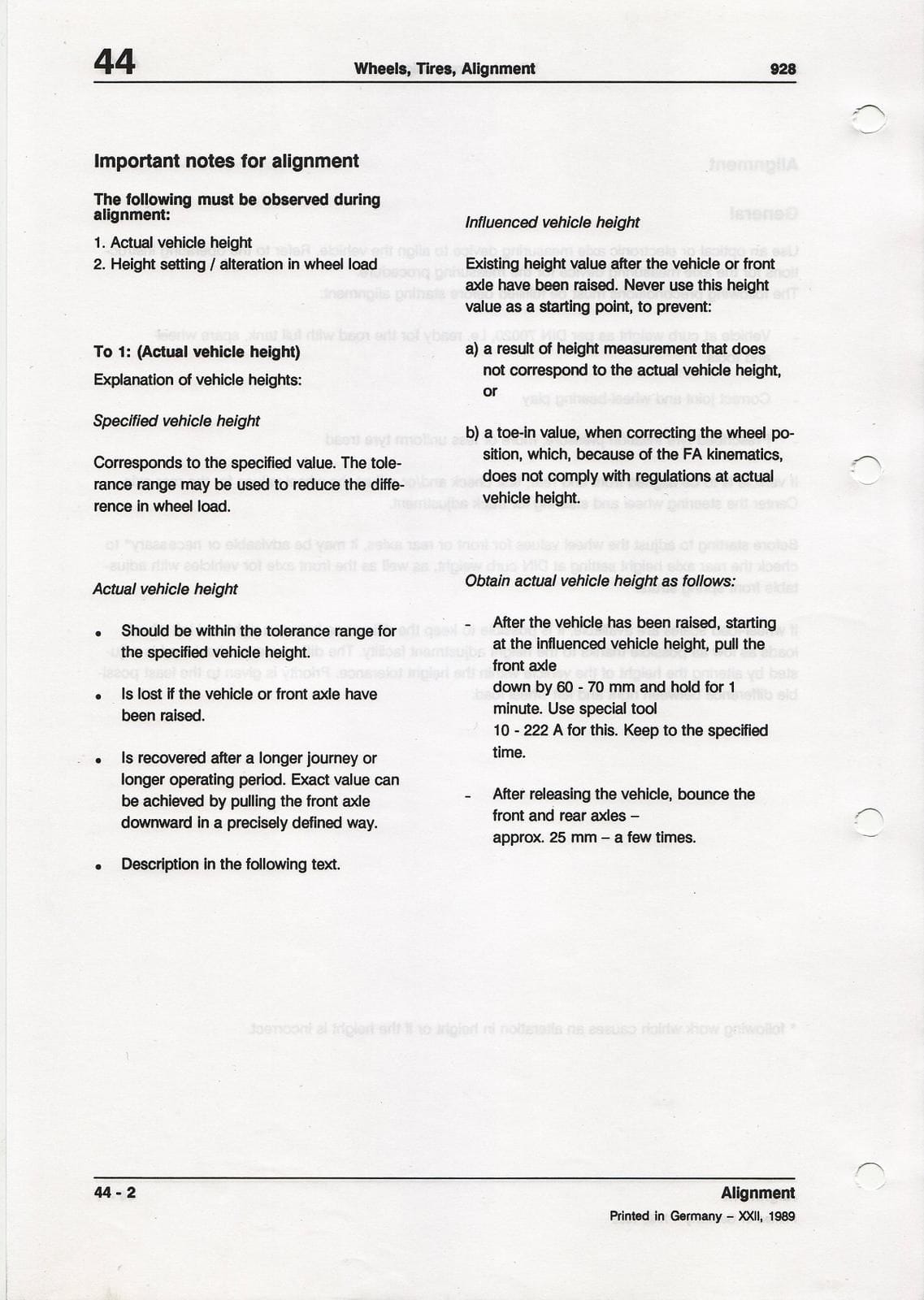

Remember that the dealers didn't drive the car to settle the suspension - they used the pull-down tool specified in the workshop manual...

#12

Rennlist Member

Join Date: Feb 2011

Location: Mostly in my workshop located in Sweden.

Posts: 2,226

Received 442 Likes

on

244 Posts

┼ke,

I have the red cover USA version of the manuals. On page 40-5 for Hex bolt item 19, and on page 40-11 for item 23 [later models] it says quote:

"Coat threads with Optimoly [do not coat the shank], Screw in until only two threads are visible. Do not tighten until assembly is completed and s[prings have settled"

Unquote

What visible threads are they talking about as non are visible- that or I cannot see straight!

My assumption is that they mean the bolt should be such that it is backed off by two turns from the torqued position as though that is enough to hold things in place but this seems strange to me. Leave the bolts two turns slack and I might expect the bolts will drop out from vibrations by the time the suspension has fully settled.

Rgds

Fred

I have the red cover USA version of the manuals. On page 40-5 for Hex bolt item 19, and on page 40-11 for item 23 [later models] it says quote:

"Coat threads with Optimoly [do not coat the shank], Screw in until only two threads are visible. Do not tighten until assembly is completed and s[prings have settled"

Unquote

What visible threads are they talking about as non are visible- that or I cannot see straight!

My assumption is that they mean the bolt should be such that it is backed off by two turns from the torqued position as though that is enough to hold things in place but this seems strange to me. Leave the bolts two turns slack and I might expect the bolts will drop out from vibrations by the time the suspension has fully settled.

Rgds

Fred

I have found the text and I am putting it down in German for anyone else speaking German to read. German is my third language after Swedish and English.

Quote: Gewinde mit Optimoly HT fetten (Optimoly HT am Schraubenschaft nicht zulńssig). Bis auf 2 Gńnge einschrauben. EndgŘltiges Festziehen mit 120Nm erst am Ende des Montagevorgangs nach mehrmaligem Einfedern des Fahrzeuges.

My interpretation of the German text is as follows:

"Quote: Grease the threads with Optimoly HT (no grease allowed on the bolt shank - the part of the bolt having no threads). Do not tighten the bolt fully, leave up to 2 threads of slack (assume they mean two turns on the bolt)

Final tightening with 120 Nm (88.5 ft lb) at the end of the assembly process after the suspension has been pushed down (compressed) several times."

Hope this has been to your help.

┼ke

PS I do not know how Porsche do it when pushing down the suspension several times in order to get the suspension settled. We all know the car need to be driven for an extended number of miles until the suspension has settled fully.

#14

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

I suspect everything in the WSM is written to a shop, no DIY'ers at home. Since an alignment is required after installing or re-installing suspension arms, that procedure follows which pulls the car down to proper ride height before tightening the bolts.

┼ke, here is the only image I'm ware of in the WSM:

#15

Rennlist Member

I suppose we could always ask an elephant to sit on top of the engine whilst torquing the bolts- probably equivalent to pulling it down.

Rgds

Fred