Custom Lifetime 928 Motor Mounts by Hans

#46

Burning Brakes

Not to rain on anyone's parade, but a certain amount of thought and intelligence is required whenever anything is substituted for a product that was engineered around a specific application.

The hydraulic motor mounts that Porsche supplied were not just random chunks of rubber designed to hold up the engine, but were designed to "absorb" the harmonics and frequencies that the 928 engine generates.

Very specific harmonics and frequencies, unique to the 928 engine!

The hydraulic motor mounts that Porsche supplied were not just random chunks of rubber designed to hold up the engine, but were designed to "absorb" the harmonics and frequencies that the 928 engine generates.

Very specific harmonics and frequencies, unique to the 928 engine!

For me NVH is very important but compared to modern cars the 928 has lots of rough edges and I suspect they would be there still when using parts designed by Porsche. For motor mounts on my 1986... I used real Corteco MT2698H with good results. The quality of these mount varies greatly depending on the source. I clearly got some good ones which were in a labeled Corteco multi color box with "hydraulic" stickers. They were slightly more expensive than commonly described here and on the general inter-webs. After installed, the engine was far smoother. I've observed no unusual 2nd order harmonics and I remember how bad they were on my 1979. I'm autisticly sensitive to NVH but have learned to deal. Compared to an Audi S8 (v8) and BMW 750il (V12) the 928 engine is gruff at any RPM.

#47

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Solid Rubber Ford Mount

Volvo Hydraulic Mount

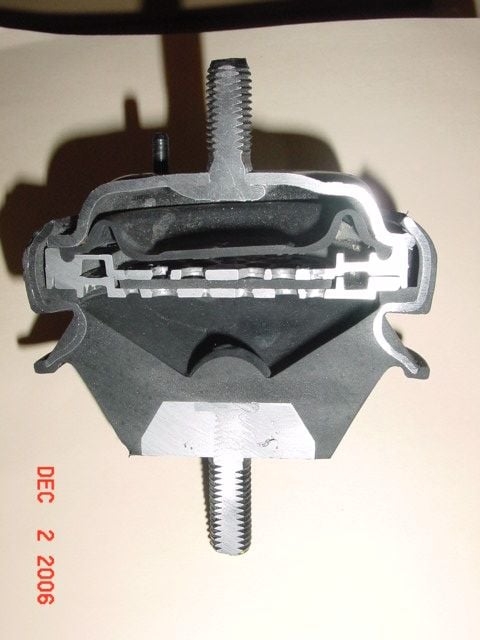

Porsche Factory Mount - Collapsed

What is really great is that we have choices. If we were all stuck with the Porsche mounts at $650 a pair it would be different.

I sell the Volvo mounts and have sold thousands with zero issues. In my 15 years of selling 928 parts I have sold less than 10 sets of original Porsche mounts.

This is one of my pet subjects and I have researched it in detail for over 10 years. When I bought my first 928 - 1993 GTS - back in the early 2000's with 60k miles I was dissatisfied with the engine vibration felt in the seat of my pants. I followed the guides on the email based Rennlist and found the mounts had collapsed. I had them replaced with factory Porsche mounts and was very happy with the result until they failed after about 2 years and less than 15k miles later. At that time I was a much more savvy 928 owner and personally swapped them for the Ford solid rubber mounts. 2019 and 170k miles they are still good today. Engine is as smooth as it gets in 928 land.

When there were manufacturing issues with the Ford mounts I changed supply to the Volvo mounts after they had been used successfully in the UK for over 6 years on a number of 928's.

Volvo mounts are certainly NOT 18mm different in height to the original mounts - 7mm is the difference in free height - once installed with the engine weight it is more like 4mm. Volvo mounts are hydraulic and better at attenuating vibration than solid mounts. They, like the Porsche mounts, are filled with water and a little antifreeze. I dissected a number of mounts and found little difference in the design when comparing Porsche to Volvo.

Both Rein Automotive and Corteco list the Volvo mount under the Porsche number - 928 375 039 00. Same engine mount as used by Volvo.

Attached are pictures of the Ford, Volvo and Porsche mounts and you can draw your own conclusions. I have also talked to a number of manufactures, like Corteco, and they confirm that there really is nothing "special" or "magical" about motor mount design. There words not mine.

Pay your money takes your choice.

Pictures above.

__________________

Does it have the "Do It Yourself" manual transmission, or the superior "Fully Equipped by Porsche" Automatic Transmission? George Layton March 2014

George Layton March 2014

928 Owners are ".....a secret sect of quietly assured Porsche pragmatists who in near anonymity appreciate the prodigious, easy going prowess of the 928."

Does it have the "Do It Yourself" manual transmission, or the superior "Fully Equipped by Porsche" Automatic Transmission?

George Layton March 2014

George Layton March 2014928 Owners are ".....a secret sect of quietly assured Porsche pragmatists who in near anonymity appreciate the prodigious, easy going prowess of the 928."

The following users liked this post:

Greg Nichols (06-11-2023)

#49

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

yet ....????

928 engines have an inherent vibration/frequency right about 1200rpms and then again in the 2200-2500rpm range. First harmonic, second harmonic stuff. No amount of balancing of the engine components will take this away....it can be felt in every car.

Ironic that they also were perhaps looking for the cheap fix??

I would bet top dollar that the OEM mounts were not tested in any sort of vibration /acoustic rig and subsequently tuned to the specifics of the 928 engine harmonics in the early 70 and 80s. They were designed to be robust and to fit , no more.

The following users liked this post:

Bigfoot928 (02-11-2024)

#50

Let's keep in mind that this was the 70's and 80's and look at the general tech available at the time.

Also if we go with the scientific harmonics discussion, doesn't stroking an engine throw the factory engine mounts out the window due to different harmonics? We need to looking forward tech wise not in the rear view with today's what if's.

#51

Burning Brakes

I found some evidence these type of mount were engineered and tested harmonically in Germany in the link below. The 3rd cited author was apparently an Mercedes Benz employee. There are quite a few MB and MB related parts on the 928.

https://www.researchgate.net/publica...hen_Netzwerken

Just a theory... I would suspect in the mid 80's Mercedes Benz may have feeling NVH pressure from Jaguar's V12 and BMW's planned V12 so they developed this type of mount for NVH issues for their V8. Porsche probable got it early in its development cycle. MB may have not used them as this early design was too fragile.

All Crossplane V8's have the same problem... somewhere in the firing order to 2 adjacent cylinder have to fire back to back for the MB it's 1 and 2. For the Porsche it's 6 and 5.

https://www.researchgate.net/publica...hen_Netzwerken

Just a theory... I would suspect in the mid 80's Mercedes Benz may have feeling NVH pressure from Jaguar's V12 and BMW's planned V12 so they developed this type of mount for NVH issues for their V8. Porsche probable got it early in its development cycle. MB may have not used them as this early design was too fragile.

All Crossplane V8's have the same problem... somewhere in the firing order to 2 adjacent cylinder have to fire back to back for the MB it's 1 and 2. For the Porsche it's 6 and 5.

#52

Rennlist

Basic Site Sponsor

Basic Site Sponsor

yet ....????

that just tells me Porsche also went the cheap route and in the end said....."hey, lets just throw this type of engine mount on and see what it does.? ".....

Ironic that they also were perhaps looking for the cheap fix??

I would bet top dollar that the OEM mounts were not tested in any sort of vibration /acoustic rig and subsequently tuned to the specifics of the 928 engine harmonics in the early 70 and 80s. They were designed to be robust and to fit , no more.

that just tells me Porsche also went the cheap route and in the end said....."hey, lets just throw this type of engine mount on and see what it does.? ".....

Ironic that they also were perhaps looking for the cheap fix??

I would bet top dollar that the OEM mounts were not tested in any sort of vibration /acoustic rig and subsequently tuned to the specifics of the 928 engine harmonics in the early 70 and 80s. They were designed to be robust and to fit , no more.

If you people understood the lengths Porsche went to to make these cars smooth....you'd not make statements like this.

Just like randomly throwing the frequency absorber out of the torque tube (when rebuilding) is one of the dumbest things that anyone has ever suggested (each and every torque tube was individually spun, under load, and the frequency recorded. Then, each torque tube was individually "tuned", with a specific absorber, to tune out that specific frequency), or leaving the lower pulley off of the timing belt (someone else's really, really dumb idea), the mounts were specifically tuned, for this car and this engine.

If you guys want Volvo priced parts....buy a Volvo.

__________________

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

#53

You'd loose your top dollar.....and the bottom one, too.

If you people understood the lengths Porsche went to to make these cars smooth....you'd not make statements like this.

Just like randomly throwing the frequency absorber out of the torque tube (when rebuilding) is one of the dumbest things that anyone has ever suggested (each and every torque tube was individually spun, under load, and the frequency recorded. Then, each torque tube was individually "tuned", with a specific absorber, to tune out that specific frequency), or leaving the lower pulley off of the timing belt (someone else's really, really dumb idea), the mounts were specifically tuned, for this car and this engine.

If you guys want Volvo priced parts....buy a Volvo.

If you people understood the lengths Porsche went to to make these cars smooth....you'd not make statements like this.

Just like randomly throwing the frequency absorber out of the torque tube (when rebuilding) is one of the dumbest things that anyone has ever suggested (each and every torque tube was individually spun, under load, and the frequency recorded. Then, each torque tube was individually "tuned", with a specific absorber, to tune out that specific frequency), or leaving the lower pulley off of the timing belt (someone else's really, really dumb idea), the mounts were specifically tuned, for this car and this engine.

If you guys want Volvo priced parts....buy a Volvo.

I can't believe it's "one of the dumbest," are you sure?

Does this mean all your workarounds and new parts you have developed from all the years you have been working on 928s should be trashed too because they are not from Porsche?

Cheers my friend.

#54

Rennlist

Basic Site Sponsor

Basic Site Sponsor

Far cry from a good idea.

#55

Burning Brakes

I think we need a litte nuance here in the discussion. The general technology available back when the 928 was designed did not allow for a vibration analysis of the engine via analytical means based on a complete 3D model, etc. However, by testing, I think it would have been easy even back then to identify the proper frequencies of the engine and to design a mount that would damp approximately those frequencies.

Now, I have doubts about the accuracy of the damping given the design of the motor mounts. It could very well be that these types of mounts (dampers) target a range of frequencies and are designed in parallel for specific load cases. It would be interesting for somebody form the motor mount design field to chime in on this. I would have guessed the 928 engine to heavier than a Volvo engine. That being said my PO installed Ford mounts years ago and they still seem ok.

Now, I have doubts about the accuracy of the damping given the design of the motor mounts. It could very well be that these types of mounts (dampers) target a range of frequencies and are designed in parallel for specific load cases. It would be interesting for somebody form the motor mount design field to chime in on this. I would have guessed the 928 engine to heavier than a Volvo engine. That being said my PO installed Ford mounts years ago and they still seem ok.

#57

Nordschleife Master

First off, I really question the idea that the engineers went that far with the car. Spinning each TT to make sure it was properly damped? They couldn't even sort out the flex plate migration issue. Tuning the MMs to the specific harmonics of the engine? They couldn't even get the oil breathing issues sorted out on the 32v motors. They couldn't even put a hydraulic TB tensioner on the 928, when every other motor of the time (including the 968) had one.

There's also the very simple fact that the front engined water-coolers have become the 'poor man's Porsche. 924 and descendants, 928, Cayenne and even the Panamara have all depreciated enough that 'ordinary working folks' can afford them.

The difference between Volvo MMs & Genuine Porsche isn't enough for me to be able to justify the cost. The factory ones may be better. But not 6 times better.

Similarly, I did the MMs in my 944 last winter. Porsche factory were $200 each. Knock off UROs were $30. The reviews on the URO are not the best. They likely won't last as long. But I do my own work, so I'm not out the cost of labor if I need to replace them twice (or even three or four times) as often.

I'd love a Precision/Greg Brown stroker motor. Those are amazing pieces of engineering and technology. But I have not spent the cost ofone of those on my Cayenne, 928 & 944. Combined. Total. Purchase, parts, the labor I didn't do myself. Probably even gas & insurance.

If I had to buy all Porsche parts, and pay dealer labor cost, there's no way I could own one of these, let alone 3.

The fact that we have a very dedicated community, including folks like Ken, Constantine, Carl, Roger and even Greg; who go 'all in' to find parts and develop fixes for the stuff the engineers got wrong is awesome.

It allows a lot of folks to own and drive these cars. Many cars that would have been scrapped (or would have self destructed) are out on the road. Cars that would have developed Thrust Bearing failure, cars that would have ingested enough oil to ruin the motor, cars that would have just been left to rot because the parts were too costly.

Folks who wouldn't be able to own & drive & maintain an 'exotic super car' without the community here.

Maybe my car isn't quite as smooth as it could be with the Volvo MMs. I don't know. I DO know that it's a whole lot better than it was with the original squashed ones.

There's also the very simple fact that the front engined water-coolers have become the 'poor man's Porsche. 924 and descendants, 928, Cayenne and even the Panamara have all depreciated enough that 'ordinary working folks' can afford them.

The difference between Volvo MMs & Genuine Porsche isn't enough for me to be able to justify the cost. The factory ones may be better. But not 6 times better.

Similarly, I did the MMs in my 944 last winter. Porsche factory were $200 each. Knock off UROs were $30. The reviews on the URO are not the best. They likely won't last as long. But I do my own work, so I'm not out the cost of labor if I need to replace them twice (or even three or four times) as often.

I'd love a Precision/Greg Brown stroker motor. Those are amazing pieces of engineering and technology. But I have not spent the cost ofone of those on my Cayenne, 928 & 944. Combined. Total. Purchase, parts, the labor I didn't do myself. Probably even gas & insurance.

If I had to buy all Porsche parts, and pay dealer labor cost, there's no way I could own one of these, let alone 3.

The fact that we have a very dedicated community, including folks like Ken, Constantine, Carl, Roger and even Greg; who go 'all in' to find parts and develop fixes for the stuff the engineers got wrong is awesome.

It allows a lot of folks to own and drive these cars. Many cars that would have been scrapped (or would have self destructed) are out on the road. Cars that would have developed Thrust Bearing failure, cars that would have ingested enough oil to ruin the motor, cars that would have just been left to rot because the parts were too costly.

Folks who wouldn't be able to own & drive & maintain an 'exotic super car' without the community here.

Maybe my car isn't quite as smooth as it could be with the Volvo MMs. I don't know. I DO know that it's a whole lot better than it was with the original squashed ones.

The following 2 users liked this post by Wisconsin Joe:

Bigfoot928 (02-11-2024),

MAX928 (05-07-2020)

#60

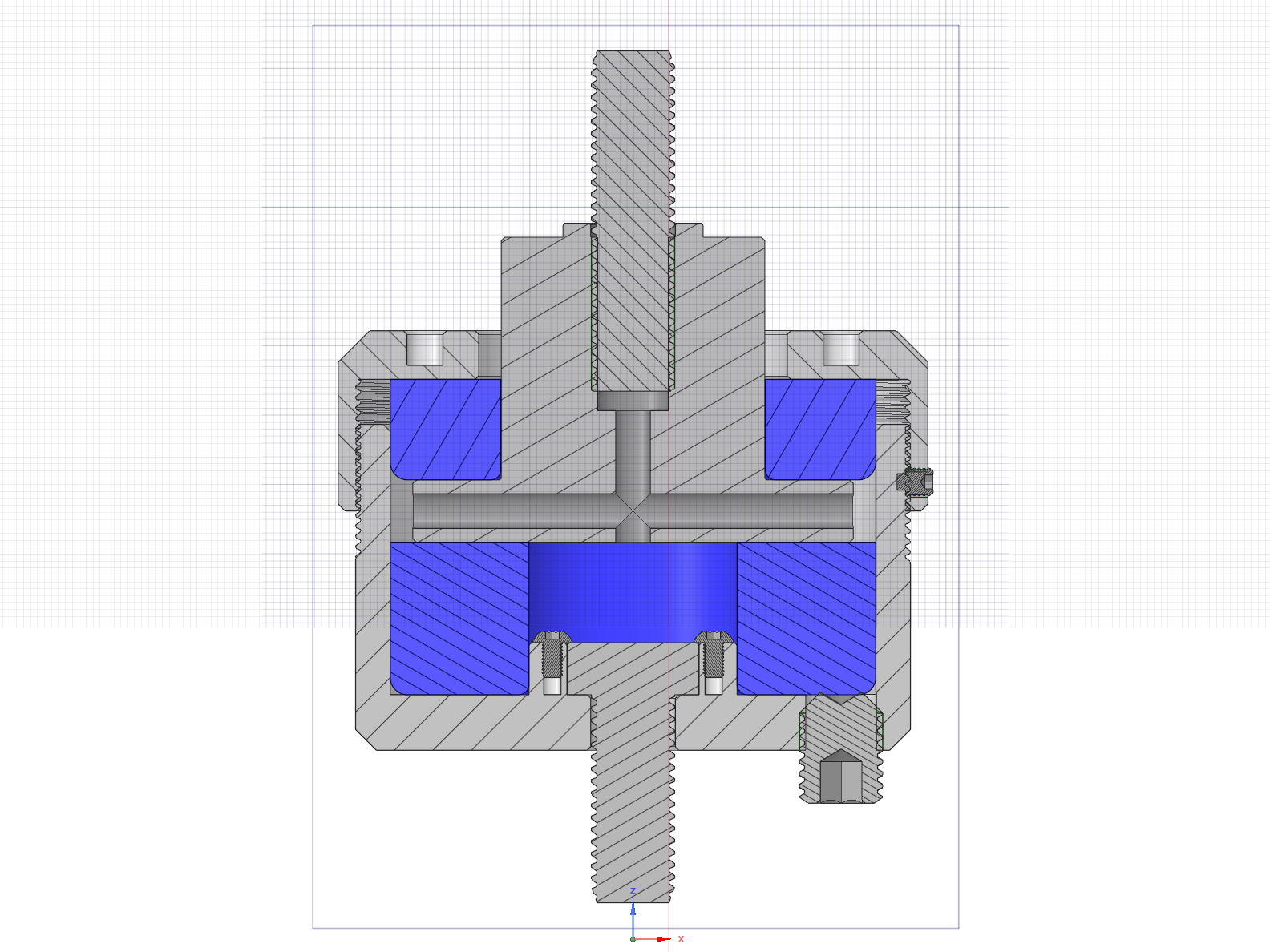

The rubber discs, as designed, do not appear to have a lot of compliance built into them, which makes them stiffer than they should be, increasing the resonant frequency of the isolator system. This has the effect of shifting the vibration transmissibility curve to the right to the point where lower frequency resonances in the drive train are not going to be attenuated as much as they should be. As the design sits, there is no place for the rubber to displace to. Perhaps revise the rubber disc design such as is shown below. This design allows for the rubber to displace and fill in the voids both radially and axially.

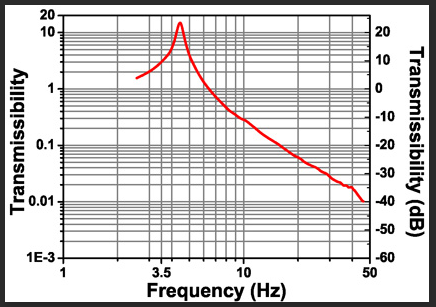

In case one in wondering what I mean by transmissibility curve, below is a typical curve of a vibration isolator. Perhaps I should write a whitepaper for the community describing in more detail.