1990 928 S4 radiator fan problems

#1

Intermediate

Thread Starter

Join Date: Jun 2014

Location: Reedsburg Wi

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

FIXED! I have looked and troubleshot most of the system. the problem is I want to get my AC converted to R134. the mechanic told me my radiator fans are not working when the AC high side makes pressure. the fans do work when i have driven it hard. both come on when temp is up to operating temperature. I tried the key on, fan switch to #2 and ac switch on. the fans do not run at all.

I have pulled and checked fuse 29 and 30 reinstalled and both sides for 12 volts.

replaced the relay IV.

jumper-ed pins on the final stage amp for each fan and they work fine. I think it was pins 1-5 and 4-8.

I was thinking of going to a new modern dual fan controller but cannot find one that takes multiple inputs like the original controller.

I have pulled and checked fuse 29 and 30 reinstalled and both sides for 12 volts.

replaced the relay IV.

jumper-ed pins on the final stage amp for each fan and they work fine. I think it was pins 1-5 and 4-8.

I was thinking of going to a new modern dual fan controller but cannot find one that takes multiple inputs like the original controller.

Last edited by alcetus; 06-23-2016 at 12:07 PM.

#2

Rennlist Member

My 1990 GT was converted. No problems with using the original fans. As a note: Even when the system was without any pressure, the fans would come on when the AC button was pushed. I imagine that the radiator fans would still come on with AC pressure on the high side as I doubt there is any measurement of AC pressure that would switch on/off the radiator fans (but of course, I am not a pro, so could be wrong). Could it be your switch?

Also, now that I think of it; my 1990 S4 was converted and it also had the original fans.

Also, now that I think of it; my 1990 S4 was converted and it also had the original fans.

#3

Rennlist Member

If the fans are working OK when there is a demand from the cooling system but not when the a/c is working to me this suggests a problem with the a/c control unit on the central panel.

Hopefully someone will corroborate this- I suspect it is another case of relay failure.

Hopefully someone will corroborate this- I suspect it is another case of relay failure.

#4

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

IIRC, the signal for the fans to come on with AC is part of the compressor clutch relay function. If you've replaced the relay with an external one as many have done, you may have missed this important function.

Within the control head, there's a diode in the circuit for the fan controller that, if it fails, will affect fan function. Greg Brown is the guru of these control head unit rebuilds. Contact him or one of our vendors to consider options if you aren't comfortable with board-level component diagnosis and replacement in the control head.

The AC-on signal from that relay is sent to the fan controller unit that sits next to the passenger's seat under the carpet cover. There are two connectors there that may benefit from being carefully removed and reseated. A little spray DeOxit contact cleaner may help, although the contacts are "self-wiping" and generally just need to be removed and replaced a couple times.

Fan speeds with the AC on are determined by a pressure transducer that is connected to the top of the high-pressure manifold at the receiver-drier. This is front side of the radiator and condenser, on the right (passenger side on US cars). Look for a small sensor that has two thumbscrews and wires attached, sometimes with rubber boots over the connections.

Besides the electrical connections that can be cleaned, the sensor mounts onto what looks like a standard charge port on that manifold. Underneath the sensor is a Schraeder valve, like a tire valve but it has different rubber seals in it. The originally-fitted valves have rubber seals that are not compatible with the refrigerant oil used with R-134a. A complete conversion includes replacing all the o-rings and hoses in the system, also six Schraeder valves, with new pieces suitable for the new refrigerant oil. O-rings in the sensor base and the pressure safety switch deserve replacement too, all with updated materials. If the old o-ring seals and Schraeder valves are left in, there's a chance that some of the rotted original seals have plugged the pressure sensor.

----

The workshop manuals have a pretty extensive troubleshooting section for the fans and controllers. It's essential that you have fans running with the AC going, especially when you have done a R-134a conversion. R-134a offers a slightly higher pressure vs temperature profile when compared with the original R12. No worries when the fans are working correctly. With marginal airflow over the condenser though, you risk some seriously high condenser pressures, sometimes enough to cause other problems. The pressure safety switch will stop the compressor when hi-side pressure exceeds about 400 PSI, but it cycles the compressor back on after a few seconds as pressure falls. The next safety function is a blow-out plug on the receiver drier, assuming something else in the 25 year old system hasn't failed first.

Within the control head, there's a diode in the circuit for the fan controller that, if it fails, will affect fan function. Greg Brown is the guru of these control head unit rebuilds. Contact him or one of our vendors to consider options if you aren't comfortable with board-level component diagnosis and replacement in the control head.

The AC-on signal from that relay is sent to the fan controller unit that sits next to the passenger's seat under the carpet cover. There are two connectors there that may benefit from being carefully removed and reseated. A little spray DeOxit contact cleaner may help, although the contacts are "self-wiping" and generally just need to be removed and replaced a couple times.

Fan speeds with the AC on are determined by a pressure transducer that is connected to the top of the high-pressure manifold at the receiver-drier. This is front side of the radiator and condenser, on the right (passenger side on US cars). Look for a small sensor that has two thumbscrews and wires attached, sometimes with rubber boots over the connections.

Besides the electrical connections that can be cleaned, the sensor mounts onto what looks like a standard charge port on that manifold. Underneath the sensor is a Schraeder valve, like a tire valve but it has different rubber seals in it. The originally-fitted valves have rubber seals that are not compatible with the refrigerant oil used with R-134a. A complete conversion includes replacing all the o-rings and hoses in the system, also six Schraeder valves, with new pieces suitable for the new refrigerant oil. O-rings in the sensor base and the pressure safety switch deserve replacement too, all with updated materials. If the old o-ring seals and Schraeder valves are left in, there's a chance that some of the rotted original seals have plugged the pressure sensor.

----

The workshop manuals have a pretty extensive troubleshooting section for the fans and controllers. It's essential that you have fans running with the AC going, especially when you have done a R-134a conversion. R-134a offers a slightly higher pressure vs temperature profile when compared with the original R12. No worries when the fans are working correctly. With marginal airflow over the condenser though, you risk some seriously high condenser pressures, sometimes enough to cause other problems. The pressure safety switch will stop the compressor when hi-side pressure exceeds about 400 PSI, but it cycles the compressor back on after a few seconds as pressure falls. The next safety function is a blow-out plug on the receiver drier, assuming something else in the 25 year old system hasn't failed first.

#5

Intermediate

Thread Starter

Join Date: Jun 2014

Location: Reedsburg Wi

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

Thank you for the quick replies. I will look at the schematics and re-seat the controller connections. I have not replaced the clutch relay, just the one associated with the fan and fog lights. I am component repair capable, I was an Air Force avionics tech for 10 years.

When you say control head, is that the fan flapper control in the passenger foot well?

All o-rings were replaced with new compatible to R-134.

I will look at the shop manuals too.

When you say control head, is that the fan flapper control in the passenger foot well?

All o-rings were replaced with new compatible to R-134.

I will look at the shop manuals too.

#7

Drifting

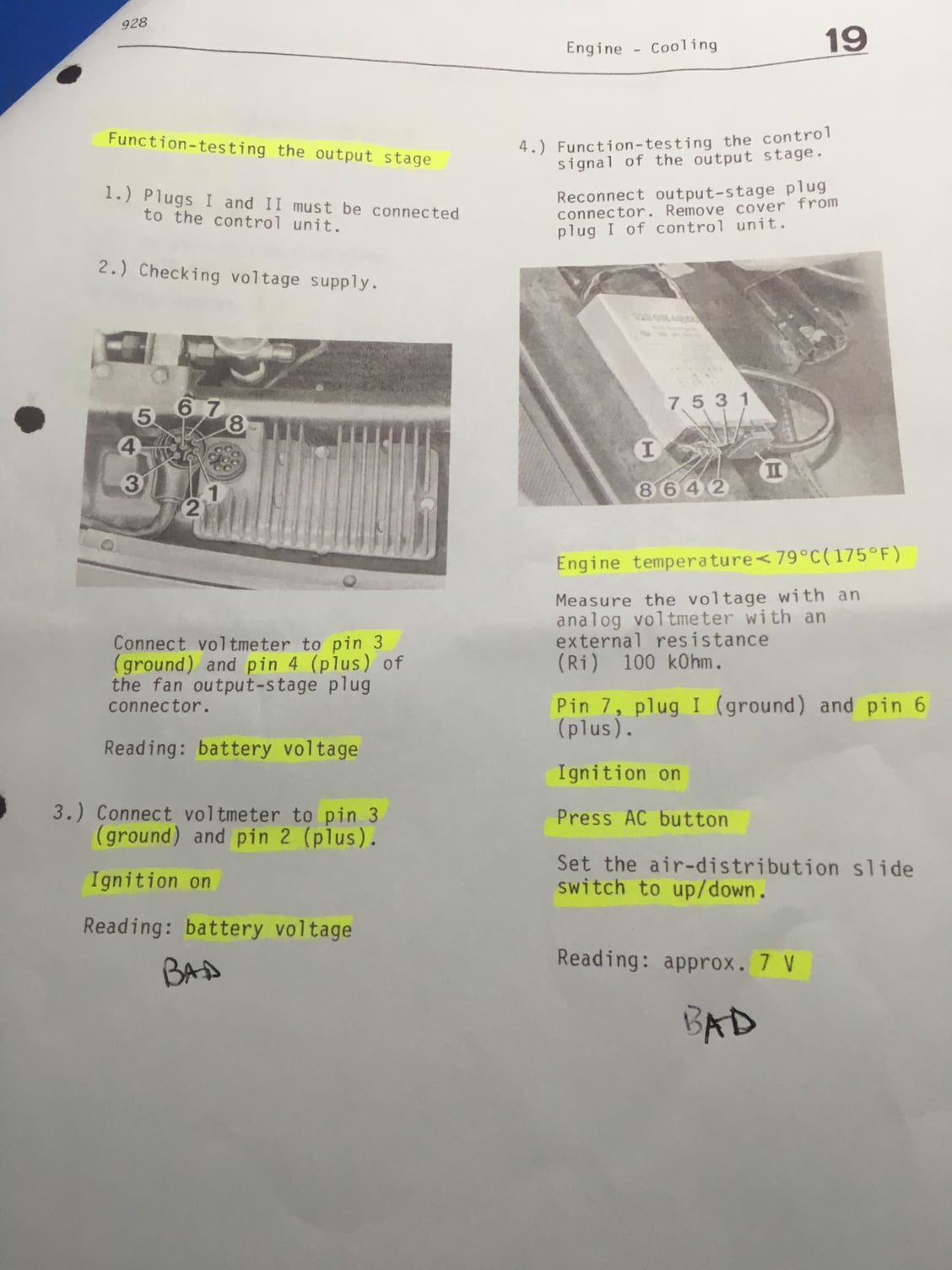

Don't your tests indicate problem with fan controller, not the output stage? The test in section 3 checks power supply to output stage, and section 4 test is on controller itself.

Trending Topics

#10

Intermediate

Thread Starter

Join Date: Jun 2014

Location: Reedsburg Wi

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

I put a used controller in and same problem. no love in finding a final stage amp. I think mine is fine though. I rebuilt it last year and did continuity checks on everything and all looks good, plus fans work all other time unless I try with AC switch on and interior fan at #2. Time to dig in....

#11

Hi, I recently had issues with my fans as well and it turned out to be a contact problem at the output stage. I ran all the test and concluded that I had a bad output stage module. In a last attempt, I cleaned out the output stage pins, and its working perfectly now. I might just be your problem as well.

#12

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Read through this thread: https://rennlist.com/forums/928-foru...ans-toast.html

It includes some power-flow diagnostics that will help you along. In all but a very few (two...) cases that I've had hands on, the root cause has been poor connections at the battery and/or melted/damaged fuse holder(s) for the fans. In the attached thread, the OP was able to read battery voltage at the final-stages connection with the connector lifted, as there was still a weak connection at the battery. Since you are experiencing a primary power flow problem (based on your initial results), it makes sense to start at the battery connections with some cleaning and tightening, then work forward to the fuse panel and fuses, and finally to the final stages module. Testing at the final stages connector with the connector unplugged can give you a false-positive, witness the attached case. Be Sure to clean and secure the ground connections for the fans on the front apron. Good Idea to do ALL of the grounds as part of annual PM.

It includes some power-flow diagnostics that will help you along. In all but a very few (two...) cases that I've had hands on, the root cause has been poor connections at the battery and/or melted/damaged fuse holder(s) for the fans. In the attached thread, the OP was able to read battery voltage at the final-stages connection with the connector lifted, as there was still a weak connection at the battery. Since you are experiencing a primary power flow problem (based on your initial results), it makes sense to start at the battery connections with some cleaning and tightening, then work forward to the fuse panel and fuses, and finally to the final stages module. Testing at the final stages connector with the connector unplugged can give you a false-positive, witness the attached case. Be Sure to clean and secure the ground connections for the fans on the front apron. Good Idea to do ALL of the grounds as part of annual PM.

#13

Intermediate

Thread Starter

Join Date: Jun 2014

Location: Reedsburg Wi

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

I will check out my power distribution this weekend. My fans do come on when engine is up to operating temp, just not when AC is on. I am getting it charged up today. just in case it is something to do with no coolant in ac system. I was converting it to R134 when I found the problem.

#14

Rennlist

Basic Site Sponsor

Basic Site Sponsor

I have looked and troubleshot most of the system. the problem is I want to get my AC converted to R134. the mechanic told me my radiator fans are not working when the AC high side makes pressure. the fans do work when i have driven it hard. both come on when temp is up to operating temperature. I tried the key on, fan switch to #2 and ac switch on. the fans do not run at all.

I have pulled and checked fuse 29 and 30 reinstalled and both sides for 12 volts.

replaced the relay IV.

jumper-ed pins on the final stage amp for each fan and they work fine. I think it was pins 1-5 and 4-8.

I was thinking of going to a new modern dual fan controller but cannot find one that takes multiple inputs like the original controller.

I have pulled and checked fuse 29 and 30 reinstalled and both sides for 12 volts.

replaced the relay IV.

jumper-ed pins on the final stage amp for each fan and they work fine. I think it was pins 1-5 and 4-8.

I was thinking of going to a new modern dual fan controller but cannot find one that takes multiple inputs like the original controller.

BTW....That switch will not be optimum for R134a and the high side pressure will be higher than ideal because of this.

#15

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

I will check out my power distribution this weekend. My fans do come on when engine is up to operating temp, just not when AC is on. I am getting it charged up today. just in case it is something to do with no coolant in ac system. I was converting it to R134 when I found the problem.

The sensor is the upper of the two elements mounted on the metal manifold for the drier. It's a small brass-colored cylinder, with individual wires connected to posts with either nuts or thumb-nuts. It should have rubber angle boots over those connections.

As far as Greg's note about having the wrong temp-vs-pressure profile for R-134a, he's right of course. At higher temperature loading, the R-134a pressure is higher for the same temperature, which will cause the fans to ramp up speed earlier than it would with the original R12. This is not a bad thing if you are in a warmer climate, where earlier condenser fan operation might actually improve the AC performance, albeit at the expense of fan life.