'87 S4 Timing Death

#31

#32

Rennlist Member

There's also been a couple of observations of the belt being loose with a PKT, after the engine cooled. The spring in the NTN/Audi tensioner is not strong enough to pull the slack around to the tensioner, as a hot engine cools. Depending on which way the 5/8 cam was pushing on the belt when the engine stopped, this could have pushed the slack towards the crank-- maybe causing it to ride up on the crank gear.

Links:

Third paragraph here: https://rennlist.com/forums/928-foru...l#post11285442

"With just my fingertips" here: https://rennlist.com/forums/928-foru...l#post12804751

More here: https://rennlist.com/forums/928-foru...l#post12804932

My conclusion at that time was that it was unnerving to see a slack belt, but I didn't think it hurt anything-- as soon as the engine cranks all of the slack is pulled around to the tensioner side and taken up. But what if it initially slipped and then rode up on the crank gear instead? Riding on the teeth means a larger diameter which means the belt goes faster which advances the cams. Just a theory, but it is hard to imagine how else the cams got ahead of the crank.

Links:

Third paragraph here: https://rennlist.com/forums/928-foru...l#post11285442

"With just my fingertips" here: https://rennlist.com/forums/928-foru...l#post12804751

More here: https://rennlist.com/forums/928-foru...l#post12804932

My conclusion at that time was that it was unnerving to see a slack belt, but I didn't think it hurt anything-- as soon as the engine cranks all of the slack is pulled around to the tensioner side and taken up. But what if it initially slipped and then rode up on the crank gear instead? Riding on the teeth means a larger diameter which means the belt goes faster which advances the cams. Just a theory, but it is hard to imagine how else the cams got ahead of the crank.

#33

Pro

Thread Starter

Now everyone can see my frustration. Although this was my first 928 timing belt/water pump job, I am very comfortable with timing belt replacements having done hundreds on Saab 4-cam V6s and other cars. I was very careful and meticulous, using the best parts and upgrades available (water pump, racing belt, Porkensioner, sprockets, etc) and thought I was doing everything I could to not have to go back into this area of the car for a long time. Even with my labor cost being my time, I spent a considerable amount of money to get the car running and driving, with the intent being to have a car that would start and drive reliably whenever I randomly wanted it to. And that is exactly what it did...until last March.

The scenarios people have thrown out there make sense to me, and I truly appreciate your feedback and considered opinions. It has been a long time now, and I am over my disgust and just want to move on and get it running again.

So...what would you do/check next? We all know there are bent valves, but what should I do next to determine the cause of failure? What would you guys like to see? I know there may be no answer...I may have to put heads on it and put it all back together and pray this doesn't happen again...or sell it and stick to Saab turbos and Pontiacs that don't do **** like this...I took a gamble and put a parts car back on the road, but as we say around my shop..."sometimes cars are just begging for death."

The scenarios people have thrown out there make sense to me, and I truly appreciate your feedback and considered opinions. It has been a long time now, and I am over my disgust and just want to move on and get it running again.

So...what would you do/check next? We all know there are bent valves, but what should I do next to determine the cause of failure? What would you guys like to see? I know there may be no answer...I may have to put heads on it and put it all back together and pray this doesn't happen again...or sell it and stick to Saab turbos and Pontiacs that don't do **** like this...I took a gamble and put a parts car back on the road, but as we say around my shop..."sometimes cars are just begging for death."

#34

Pro

Thread Starter

I can post as many detailed pictures as you guys want...just tell me what you want to see.

Can someone please confirm that the distributor rotor can only bolt on the cam "Y" one way?

Can someone please confirm that the distributor rotor can only bolt on the cam "Y" one way?

#36

Nordschleife Master

Do I understand it correctly that the belt appears longer now than it should be? Out of curiosity, were the block or the heads resurfaced? The reason for me to ask this is to understand whether the belt was always loose or whether the event caused the belt to stretch.

I am operating under the assumption that the engine was rotating forward when the belt jumped. As a first rule of thumb, I would say that if the cam(s) became retarded, then the belt jumped when the crankshaft was trying to accelerate the camshafts. If the cams became advanced, then the belt jumped when the crankshaft was trying to decelerate the camshafts, like maybe revving it up and shutting down the throttle.

If the crank gear jumped, you'd expect both cams to have advanced/retarded the same amount, at least until other subsequent damage takes place. If only one camshaft gear jumped, then you'd expect to observe different cam timing per bank.

The most plausible way for the crank gear to jump is that some foreign objects make it on to the tension side of the belt and the engine rotating forward pulls those foreign objects between the belt and the crank gear. Think animals making nests on the belt or kids dropping rocks down the timing belt cover breather holes, just to create a mental image.

It is plausible to me that foreign objects between the crank gear and the belt would cause the belt to stretch, too. Small rocks on the gear tooth aren't going to fully yield, nor probably the steel gear, so it seems to be it's the belt that needs to be stretch.

In general, I am of the school that when a toothed belt is sufficiently wrapped around matching gears and rotating in the correct direction, it's hard for the belt to jump. In my thinking, the slack side tensioner is there just to keep the belt sufficiently wrapped around the gears. Foreign objects on the belt prevent the belt from wrapping around the gears.

I am operating under the assumption that the engine was rotating forward when the belt jumped. As a first rule of thumb, I would say that if the cam(s) became retarded, then the belt jumped when the crankshaft was trying to accelerate the camshafts. If the cams became advanced, then the belt jumped when the crankshaft was trying to decelerate the camshafts, like maybe revving it up and shutting down the throttle.

If the crank gear jumped, you'd expect both cams to have advanced/retarded the same amount, at least until other subsequent damage takes place. If only one camshaft gear jumped, then you'd expect to observe different cam timing per bank.

The most plausible way for the crank gear to jump is that some foreign objects make it on to the tension side of the belt and the engine rotating forward pulls those foreign objects between the belt and the crank gear. Think animals making nests on the belt or kids dropping rocks down the timing belt cover breather holes, just to create a mental image.

It is plausible to me that foreign objects between the crank gear and the belt would cause the belt to stretch, too. Small rocks on the gear tooth aren't going to fully yield, nor probably the steel gear, so it seems to be it's the belt that needs to be stretch.

In general, I am of the school that when a toothed belt is sufficiently wrapped around matching gears and rotating in the correct direction, it's hard for the belt to jump. In my thinking, the slack side tensioner is there just to keep the belt sufficiently wrapped around the gears. Foreign objects on the belt prevent the belt from wrapping around the gears.

Last edited by ptuomov; 05-20-2016 at 08:10 AM.

#37

Pro

Thread Starter

Good question.

I have a receipt from a PO (this car has had many) showing the heads were replaced, I believe with heads from an '88. I assume there was a timing belt failure but I don't think it says (I will check when I get to work this morning).

If I recall correctly, the Porkensioner was extended about 8mm upon initial installation. I may have posted about it at the time, or I may have messaged Ken privately, can't remember.

I have a receipt from a PO (this car has had many) showing the heads were replaced, I believe with heads from an '88. I assume there was a timing belt failure but I don't think it says (I will check when I get to work this morning).

If I recall correctly, the Porkensioner was extended about 8mm upon initial installation. I may have posted about it at the time, or I may have messaged Ken privately, can't remember.

#38

Pro

Thread Starter

I found my post back in 2013. It was extended 9mm at the time. Given the heads were replaced, it is possible if not likely that they were machined. Perhaps the stock tensioner can be used in this scenario, but a Porkensioner should not be?

#39

Pro

Thread Starter

Maybe the "perfect storm" is machined heads, Porkensioner, and racing belt together. Anybody else have that combination? Of course I am assuming the heads were cut...I don't know for sure.

#41

Rennlist Member

Join Date: Aug 2014

Location: Adirondack Mountains, New York

Posts: 2,420

Received 318 Likes

on

166 Posts

Remarks from an unqualified observer:

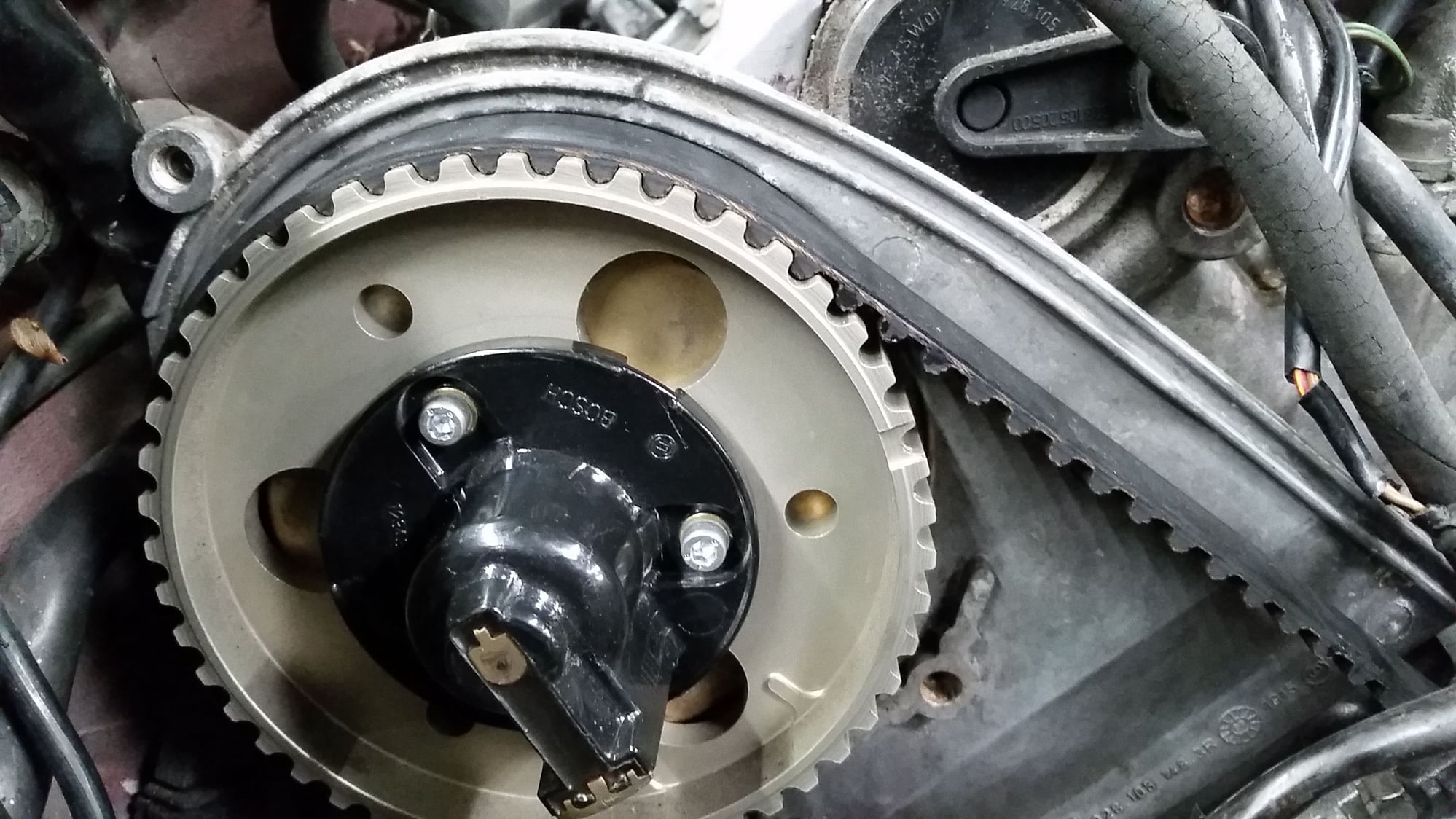

1. In the photo shown earlier, reproduced in post #31 above, the apparent width of the belt on the right of the photo (that is, if you put a ruler on the photo), is narrower than when it meets the gear. (The perspective changes as it rounds the gear, but I'm talking about the initial point of contact, the tangent, before it has turned - or so it seems to me.) It also looks like it has ridden up and/or has eaten into the plate behind the gear. And, as Sean points out, it is running further aft on the gear than it should. Another element of the Perfect Storm? What happens when the belt runs way aft? Can it ride up on the sloped washer thing behind the crank gear, when untimely coupled with a bit of slack and the need to run backwards?

2. When you get the belt out, see if you can determine its length relative to a new one (or better, with several, including serviceable used belts).

3. Examine the wear marks on the piston of the PKT, relative to its present resting position, and relative to its position when the slack in the belt is moved to its normal position (at the PKT roller).

4. Compare the backside of the belt to other used belts and, of course, whether the water pump shows signs of seizure. Also examine the aft edge of the belt in light of Point 1. (Why would you have an old belt lying around? Only if you are a pack rat, like me.)

5. Think of all the times you've been lucky with old cars. Despite how we feel about them, they are inanimate objects; you're not being punished.

6. Can you fix the !#&#!!$ convertible top of my '95 Saab?

1. In the photo shown earlier, reproduced in post #31 above, the apparent width of the belt on the right of the photo (that is, if you put a ruler on the photo), is narrower than when it meets the gear. (The perspective changes as it rounds the gear, but I'm talking about the initial point of contact, the tangent, before it has turned - or so it seems to me.) It also looks like it has ridden up and/or has eaten into the plate behind the gear. And, as Sean points out, it is running further aft on the gear than it should. Another element of the Perfect Storm? What happens when the belt runs way aft? Can it ride up on the sloped washer thing behind the crank gear, when untimely coupled with a bit of slack and the need to run backwards?

2. When you get the belt out, see if you can determine its length relative to a new one (or better, with several, including serviceable used belts).

3. Examine the wear marks on the piston of the PKT, relative to its present resting position, and relative to its position when the slack in the belt is moved to its normal position (at the PKT roller).

4. Compare the backside of the belt to other used belts and, of course, whether the water pump shows signs of seizure. Also examine the aft edge of the belt in light of Point 1. (Why would you have an old belt lying around? Only if you are a pack rat, like me.)

5. Think of all the times you've been lucky with old cars. Despite how we feel about them, they are inanimate objects; you're not being punished.

6. Can you fix the !#&#!!$ convertible top of my '95 Saab?

#42

Pro

Thread Starter

I appreciate your thoughts.

I do not have any other 928 timing belts around, new or used. I might have saved the belt I took off the car, but I doubt it, as it was rusty (yes, I am saying a belt was rusty...remember, no hood on car when I got it, stored outside with a cover pooling water over the hoodless engine).

I will check what you are saying today if possible...shop is very busy these days (which is a good thing).

I can fix your '95 900 top. I am probably one of the most experienced people in the country with the '95-'98 900 convertible top. I started at a Saab dealer in 1995, when your car was brand new. No offense, but that is one of the worst Saabs ever made. Please tell me it is a turbo automatic and not a V6 5-speed (auto is better). They made about 25,000 '95 convertibles, and they were released a year late as the new 900 was introduced for MY94 in the hardtop edition but the vert wasn't ready. It still wasn't ready. I had to do amazing amounts of updates, almost daily, and it was worse the lower the VIN. I worked on car number 100...should have been recalled and crushed. It really wasn't a very good design...ASC did it for Saab (like Mercedes). Anyway, let me guess...your tonneau motor goes RACKRACKRACKRACK when it tries to flip the tonneau open.

I do not have any other 928 timing belts around, new or used. I might have saved the belt I took off the car, but I doubt it, as it was rusty (yes, I am saying a belt was rusty...remember, no hood on car when I got it, stored outside with a cover pooling water over the hoodless engine).

I will check what you are saying today if possible...shop is very busy these days (which is a good thing).

I can fix your '95 900 top. I am probably one of the most experienced people in the country with the '95-'98 900 convertible top. I started at a Saab dealer in 1995, when your car was brand new. No offense, but that is one of the worst Saabs ever made. Please tell me it is a turbo automatic and not a V6 5-speed (auto is better). They made about 25,000 '95 convertibles, and they were released a year late as the new 900 was introduced for MY94 in the hardtop edition but the vert wasn't ready. It still wasn't ready. I had to do amazing amounts of updates, almost daily, and it was worse the lower the VIN. I worked on car number 100...should have been recalled and crushed. It really wasn't a very good design...ASC did it for Saab (like Mercedes). Anyway, let me guess...your tonneau motor goes RACKRACKRACKRACK when it tries to flip the tonneau open.

#43

Rennlist Member

First of all my sincere commiserations to Hai.

Having read through the various thoughts expressed to date one thing struck me and that is that rational thinking suggests the belt slipped over the crank sprocket in such a way that the cams are now 8 teeth advanced but lateral thinking might perceive that they are 40 teeth retarded - remember that is less than two crank revs during a start process that usually takes 3 cranks to fire and in this instance there was no [reported] firing so what exactly happened?

There was no overrun scenario so that can be rule out. Could a backfire occur without Hai sensing it? in my experience there is no mistaking a backfire when it happens and Hai sounds as though he is a well experienced practitioner.

When the photos were taken is it known for sure that the crank was at TDC or is that assumed based on the position of the damper?

In any kind if failure analysis one needs to be sure about what is a given and what is presumed/assumed in order to make sense of the failure. At the moment it looks a pretty safe bet that valves will have bent sad to say.

Given the racing belt does not stretch as much as the stock belt is that a potential adder to the problem?

Greg states that he has experience of a backfire causing a belt to jump so presumably he knew for sure it backfired and that with a stock tensioner.

Now we raise the possibility of machined heads -if so by how much and did that take the PKT out of its working range? Ken says the extension should be 5mm but do we see numbers like 8mm mentioned? If these numbers were measured were they adequately analysed?

Was it an unusually cold day with the car left outside?

At lower temperatures the belt presumably becomes ever more stiffer could this have any impact?

At lower temperatures can the PKT respond quick enough?

Could the stiffer belt have contributed to the failure mode whatever it was?

Has the belt length changed due to over stressing of some kind?

As with most failures once the facts emerge pictures start to form and a chain of events becomes apparent if the problem is to converge.

At the moment I have no idea what actually caused the problem. I do like Greg's Perfect Storm analogy-when major failures occur it is usually the combination of several unlikely events occurring simultaneously.

Rgds

Fred

Having read through the various thoughts expressed to date one thing struck me and that is that rational thinking suggests the belt slipped over the crank sprocket in such a way that the cams are now 8 teeth advanced but lateral thinking might perceive that they are 40 teeth retarded - remember that is less than two crank revs during a start process that usually takes 3 cranks to fire and in this instance there was no [reported] firing so what exactly happened?

There was no overrun scenario so that can be rule out. Could a backfire occur without Hai sensing it? in my experience there is no mistaking a backfire when it happens and Hai sounds as though he is a well experienced practitioner.

When the photos were taken is it known for sure that the crank was at TDC or is that assumed based on the position of the damper?

In any kind if failure analysis one needs to be sure about what is a given and what is presumed/assumed in order to make sense of the failure. At the moment it looks a pretty safe bet that valves will have bent sad to say.

Given the racing belt does not stretch as much as the stock belt is that a potential adder to the problem?

Greg states that he has experience of a backfire causing a belt to jump so presumably he knew for sure it backfired and that with a stock tensioner.

Now we raise the possibility of machined heads -if so by how much and did that take the PKT out of its working range? Ken says the extension should be 5mm but do we see numbers like 8mm mentioned? If these numbers were measured were they adequately analysed?

Was it an unusually cold day with the car left outside?

At lower temperatures the belt presumably becomes ever more stiffer could this have any impact?

At lower temperatures can the PKT respond quick enough?

Could the stiffer belt have contributed to the failure mode whatever it was?

Has the belt length changed due to over stressing of some kind?

As with most failures once the facts emerge pictures start to form and a chain of events becomes apparent if the problem is to converge.

At the moment I have no idea what actually caused the problem. I do like Greg's Perfect Storm analogy-when major failures occur it is usually the combination of several unlikely events occurring simultaneously.

Rgds

Fred

#44

Addict

Rennlist Member

Rennlist Member

My best guess: The lack of the guide roller allowed the belt to jump time at the crank pulley. Can you put the cams into a position where they pull the belt tight against the tensioner and put slack into the non-tensioned side? Over time can this compress the PKT? I guess I could find out since I have an S4 with the covers off handy. I have seen a lot of timing belt rollers that appear to be there to address some slack whip not seen in normal operation and have never been inclined to remove one (why?!?).

Second best: There is a section of belt with missing teeth we have not seen. The crank index walks a tooth or two every time it comes around. The cams stay in phase due to extra teeths but cam timing relative to the crank progresses or regresses.

If the belt were stretched the tensioner would have to be maxed out and one cam would be more out of phase than the other, if the stretch were consistent along the length of the belt.

-Joel.

Second best: There is a section of belt with missing teeth we have not seen. The crank index walks a tooth or two every time it comes around. The cams stay in phase due to extra teeths but cam timing relative to the crank progresses or regresses.

If the belt were stretched the tensioner would have to be maxed out and one cam would be more out of phase than the other, if the stretch were consistent along the length of the belt.

-Joel.

#45

Considering that the PK Tensioner was at 9mm extension and now at 10mm is the smoking gun imo. I have installed a new Gates regular belt with a PK Tensioner and with it pinned it was all I could do just to string it and get it on the gears, it was tight.

I would measure the belt circumference and compare it to the spec, maybe defective and it's too long.

I would measure the belt circumference and compare it to the spec, maybe defective and it's too long.