Continuation of the fuel rail thread

#46

Rennlist

Basic Site Sponsor

Basic Site Sponsor

If it is possible, it would be really a great data point, if you could get down and touch the various parts of your fuel system.

Trust me, if there are harmonics, you will know....and if they are anything like the ones on my system.....you will instantly know that something either needs to be done or everything is fine.

__________________

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

#47

Developer

LS1 is a funny example, because by my understanding the factory stock fuel rails still had a fuel damper built in.

I like your comment about the sequential injection being less effected by pressure waves than bank fire - good point.

#48

I had an advantage....my return lines were right on top and really simple to put your hands on....so this was virtually a no-brainer test.

If it is possible, it would be really a great data point, if you could get down and touch the various parts of your fuel system.

Trust me, if there are harmonics, you will know....and if they are anything like the ones on my system.....you will instantly know that something either needs to be done or everything is fine.

If it is possible, it would be really a great data point, if you could get down and touch the various parts of your fuel system.

Trust me, if there are harmonics, you will know....and if they are anything like the ones on my system.....you will instantly know that something either needs to be done or everything is fine.

If you have ideas feel free to toss them out.

#49

Race Car

You're right, my bad. I should have used a better example. The point is was trying to make was to look at all the aftermarket fuel rail setups and see they have removed their dampeners too.

I like your comment about the sequential injection being less effected by pressure waves than bank fire - good point.

I like your comment about the sequential injection being less effected by pressure waves than bank fire - good point.

Dan

'91 928GT S/C

475hp/460lb.ft

475hp/460lb.ft

#50

Rennlist Member

There are harmonics and it's very noticeable on the Sharktuner. Smoothing them out by adding more fuel along those cells has worked to a point. I'm looking at a couple different solutions and if I end up doing something that works well I'll be letting everyone know. Flow is not a problem at this point, maxing out the MAF is.

If you have ideas feel free to toss them out.

If you have ideas feel free to toss them out.

IF...if you had 20rpm resolution around it, in all 5 places you hit it..you might be able to do something.

But at that point, you simply cant add enough fuel to rid it..and then not have a SUPER fat remaining problem around it within the same cell, bleeding into the next.

Batch fire without dampers is a disaster.

#51

Rennlist

Basic Site Sponsor

Basic Site Sponsor

I thought that maybe the front damper would be enough and perhaps the rear damper was just overkill.

The other thought I had was that possibly the rear damper was used because Porsche originally plumbed the rear with two regulators, but decided they only needed one and putting in an additional damper was easier than retooling all the fuel rails and the lines.

Not hardly the case. These Porsche people usually do something for a reason.....and you had better have your thinking cap on (if you have one) before you start "playing" engineer.

The pulsing in that one line was severe enough that I was concerned that the line might "blow" off the fittings......and again, I use "uber" line with crimped on true "high volume" -6 fittings (.278" ID in a swept tube 90 degree hose end versus .227" ID.....as pictured in the thread about "high volume" billet fuel rails.)

I have to get these fittings directly from Germany....everything made in the US seems to be small.

That .060" change in OD is huge, since volume goes up as the square of the cross-sectional area!

The other thought I had was that possibly the rear damper was used because Porsche originally plumbed the rear with two regulators, but decided they only needed one and putting in an additional damper was easier than retooling all the fuel rails and the lines.

Not hardly the case. These Porsche people usually do something for a reason.....and you had better have your thinking cap on (if you have one) before you start "playing" engineer.

The pulsing in that one line was severe enough that I was concerned that the line might "blow" off the fittings......and again, I use "uber" line with crimped on true "high volume" -6 fittings (.278" ID in a swept tube 90 degree hose end versus .227" ID.....as pictured in the thread about "high volume" billet fuel rails.)

I have to get these fittings directly from Germany....everything made in the US seems to be small.

That .060" change in OD is huge, since volume goes up as the square of the cross-sectional area!

#52

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

I'm amused by the term "fluid dampened" on a "larger system". It's hydraulic. Larger moving mass means larger pulse energy as injectors open and close. The only 'fluid dampener' available in that system would be a restriction downstream, playing on the DP across the restriction to smooth the pressure spikes. I'm guessing that the backpressure-type FPR is pretty busy, confused by the non-linear upstream flow demands. Even the spring-type dampener with diaphragm will have a point where there is some resonance back through the system.

I love this stuff...

I love this stuff...

#53

Rennlist Member

I'm amused by the term "fluid dampened" on a "larger system". It's hydraulic. Larger moving mass means larger pulse energy as injectors open and close. The only 'fluid dampener' available in that system would be a restriction downstream, playing on the DP across the restriction to smooth the pressure spikes. I'm guessing that the backpressure-type FPR is pretty busy, confused by the non-linear upstream flow demands. Even the spring-type dampener with diaphragm will have a point where there is some resonance back through the system.

I love this stuff...

I love this stuff...

#54

Rennlist

Basic Site Sponsor

Basic Site Sponsor

I'm amused by the term "fluid dampened" on a "larger system". It's hydraulic. Larger moving mass means larger pulse energy as injectors open and close. The only 'fluid dampener' available in that system would be a restriction downstream, playing on the DP across the restriction to smooth the pressure spikes. I'm guessing that the backpressure-type FPR is pretty busy, confused by the non-linear upstream flow demands. Even the spring-type dampener with diaphragm will have a point where there is some resonance back through the system.

I love this stuff...

I love this stuff...

We don't need dampers? Porsche was stupid?

We do need dampers?

Because if you don't think it is necessary.....I'd invite you down to put your hand on the return line that normally gets the damper and tell me everything is fine. (I have duplicate plumbing that allows me to install or remove the damper in literally minutes.)

One interesting data point....for me.

One rail on Rob's car (prior to installing the second damper) was hooked up to the fuel pressure regulator with a short hose. The other rail was hooked up to the same regulator, with a much longer hose. The short hose had minimal pulsing. The longer hose had severe pulsing.

Once I installed the second damper, the pulsing on the long hose was virtually gone. The pulsing on the short hose was still the same.

I'd submit that the regulator is a "restricted orifice" and reduces the pulsing. I'd think that the damper might just be a diaphragm with a spring that "absorbs" the pulsing.....much like a fuel accumulator does.

For our next "tuning" session, I'm going to put a third damper between the rail that goes directly to the regulator and said regulator.

I'm not convinced that the dips and highs in the dyno results are air flow related or fuel related....but I intend to find out.....as I always do.

Test and retest. Correct as required.

#55

Archive Gatekeeper

Rennlist Member

Rennlist Member

I should have held a GoPro against that undamped rear fuel crossover hose while the car was running. That would have been an interesting, blurry, video.

Anyone ever put some sort of 'wideband' pressure transducer on the ball end of the right front fuel rail and generated a graph of the fuel pressure over fractions of a second? It would be interesting to watch what happens to fuel pressures as the cars with alterations in the numbers and location of dampers as they pass through the rpm ranges that are associated with AFR 'resonances' on datalogs.

Anyone ever put some sort of 'wideband' pressure transducer on the ball end of the right front fuel rail and generated a graph of the fuel pressure over fractions of a second? It would be interesting to watch what happens to fuel pressures as the cars with alterations in the numbers and location of dampers as they pass through the rpm ranges that are associated with AFR 'resonances' on datalogs.

#56

Addict

Rennlist Member

Rennlist Member

Greg,

I'm not running any fuel dampers on my car. I haven't tried the "hands on" test, but will try it once I get the cam situation taken care of. Be interesting to see if it's a function of fuel volume, pressure, fuel line length, or some other variable.

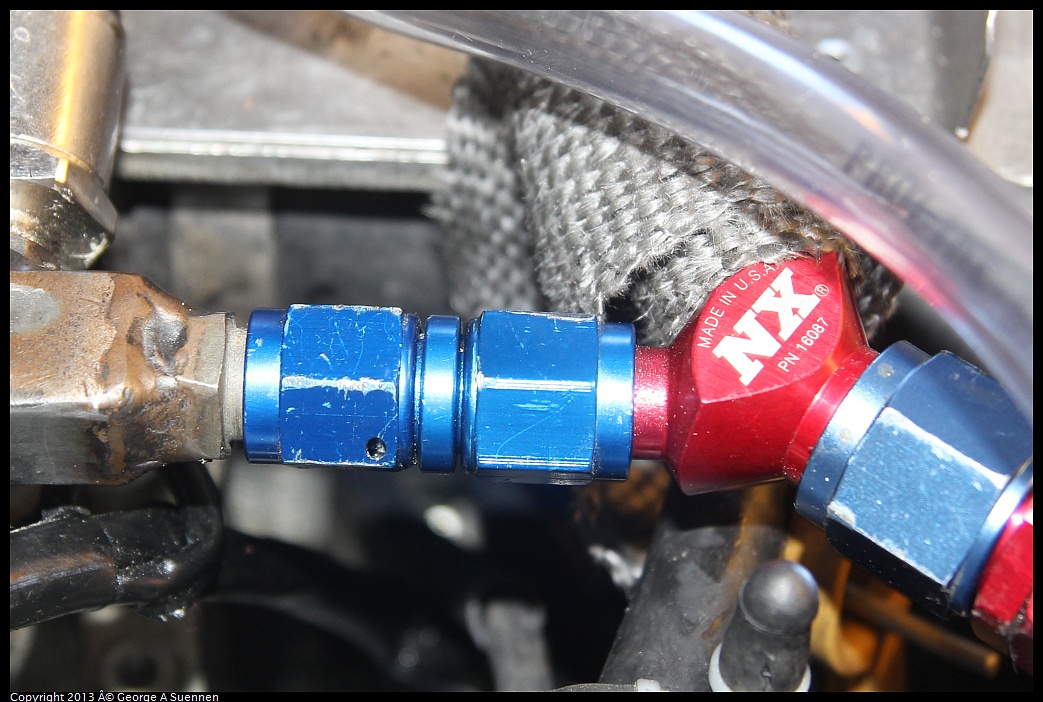

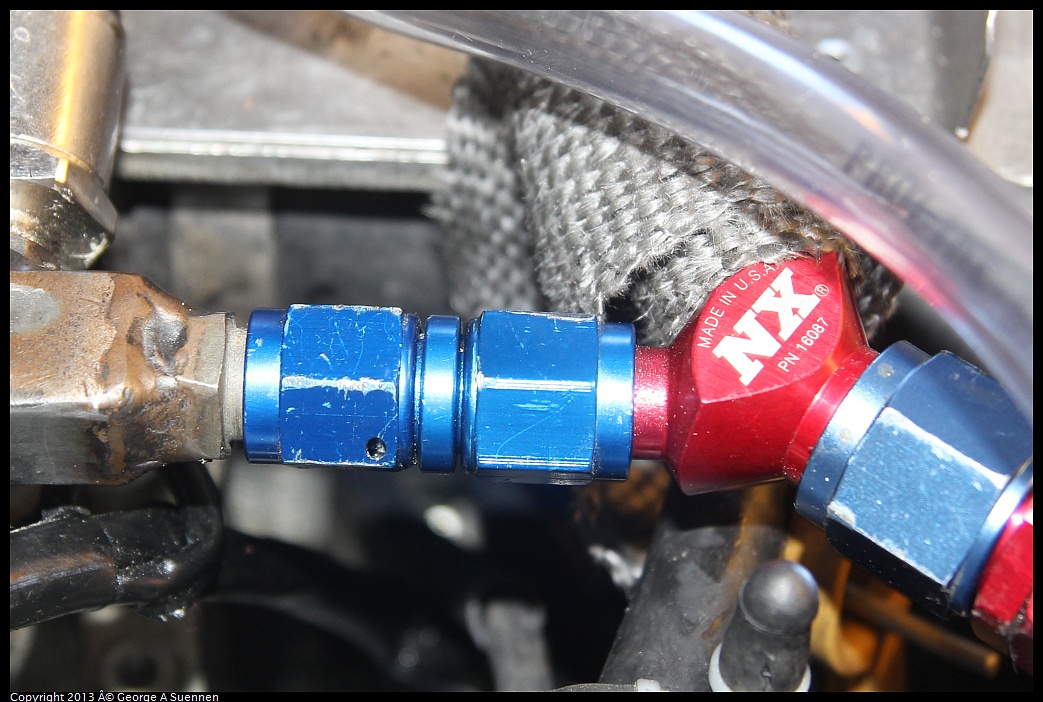

I'm running -8AN fuel line from the back to the engine bay, then splitting it to -6 AN at the front of the fuel rail:

Then -6AN to the fuel regulator, then split the returning fuel between the two 10mm stock fuel lines (old feed and old return lines). They rejoin at a -10 AN Tee, before going back to the fuel cell.

The 044 fuel pump has separate -8 AN check valve before it joins the -8 AN line from the 040 fuel pump, which had a Jay Racing check valve attached.

Don't have much info about the check valve, but here's a link:

http://www.jayracing.com/fuel-fittin...let-p-227.html

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

06 Cayenne S Havanna/Sand Beige (PASM)

http://928.jorj7.com

I'm not running any fuel dampers on my car. I haven't tried the "hands on" test, but will try it once I get the cam situation taken care of. Be interesting to see if it's a function of fuel volume, pressure, fuel line length, or some other variable.

I'm running -8AN fuel line from the back to the engine bay, then splitting it to -6 AN at the front of the fuel rail:

Then -6AN to the fuel regulator, then split the returning fuel between the two 10mm stock fuel lines (old feed and old return lines). They rejoin at a -10 AN Tee, before going back to the fuel cell.

The 044 fuel pump has separate -8 AN check valve before it joins the -8 AN line from the 040 fuel pump, which had a Jay Racing check valve attached.

Don't have much info about the check valve, but here's a link:

http://www.jayracing.com/fuel-fittin...let-p-227.html

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

06 Cayenne S Havanna/Sand Beige (PASM)

http://928.jorj7.com

#57

Addict

Rennlist Member

Rennlist Member

I should have held a GoPro against that undamped rear fuel crossover hose while the car was running. That would have been an interesting, blurry, video.

Anyone ever put some sort of 'wideband' pressure transducer on the ball end of the right front fuel rail and generated a graph of the fuel pressure over fractions of a second? It would be interesting to watch what happens to fuel pressures as the cars with alterations in the numbers and location of dampers as they pass through the rpm ranges that are associated with AFR 'resonances' on datalogs.

Anyone ever put some sort of 'wideband' pressure transducer on the ball end of the right front fuel rail and generated a graph of the fuel pressure over fractions of a second? It would be interesting to watch what happens to fuel pressures as the cars with alterations in the numbers and location of dampers as they pass through the rpm ranges that are associated with AFR 'resonances' on datalogs.

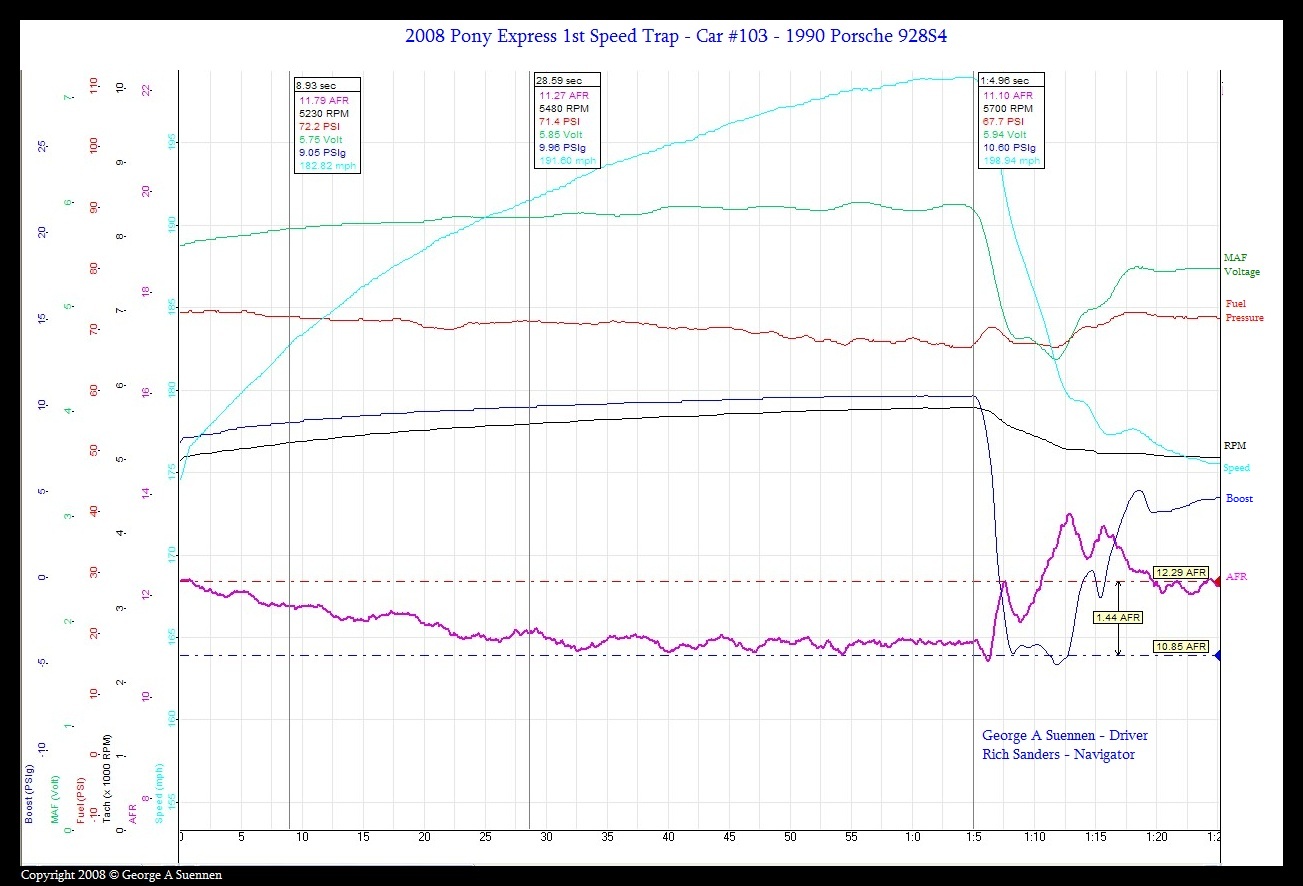

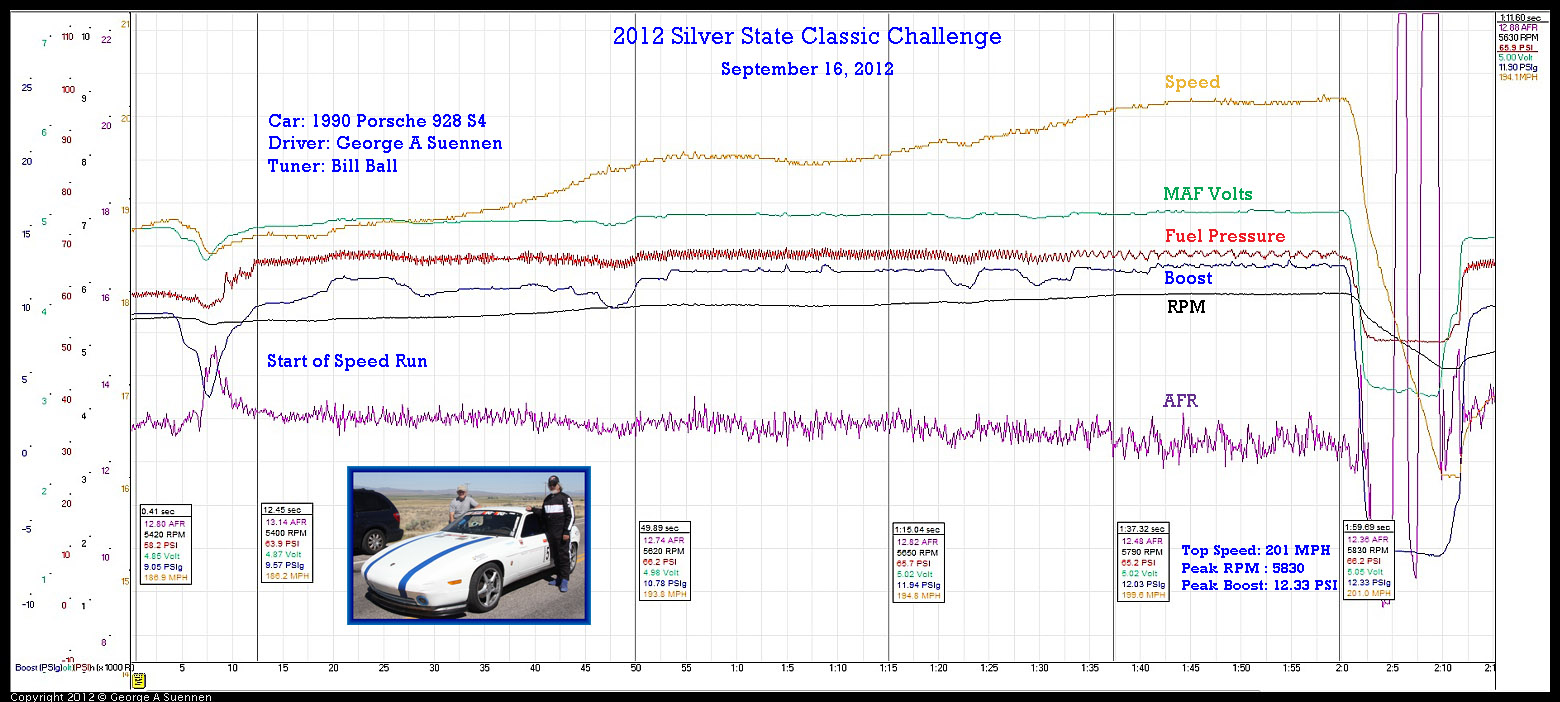

Here's a couple I've posted before from 2008 and 2012 ORR events.

With:

Without:

Of course there were numerous other changes to the fuel system (and other parts of the car) between these two runs.

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

06 Cayenne S Havanna/Sand Beige (PASM)

http://928.jorj7.com

#58

Rennlist Member

Join Date: Oct 2009

Location: Michigan... Grand Rapids

Posts: 758

Likes: 0

Received 2 Likes

on

1 Post

Just saw this thread and thought I would chime in

I have tried a few different methods of fueling in my kits. Simply put, most of the systems on current autos do not have dampers... Why, because they use sequential injection. Which of course gets rid of the big single pulse harmonic. Initially I used fuel rails just like Carls, but I was getting a nasty thunking noise in the car. You could hear it go right up the fuel line all the way to the tank. When idling, it sounded like I had a bad rod bearing. I attempted to add dampers to the rails, but it was just too much of a pain in the ***. Plus I... I wanted to keep the install as simple as possible. Plus II.. having no retaining clips on the injectors to the rails does no leave one with a warm fuzzy fealing. Pluss III... there was no gain in fuel flow. So I went back to the stock rails and modified them

As to the fuel harmonics... Yes they are there. I did not initially notice them, but when Jeff M put 60lb injectors into his car he had issues. So I bought and tested some 60's. Initially I didn't notice anything, but after driving the car for a while with the 60's, one harmonics in particular showed up. At 2700rpm, and about 1/3 throttle I was feeling a little hesitation. At 1/4 throttle nothing, at 3/4 and up nothing, but I knew something wasn't right, and nothing much showed up on the WB. So I hooked up an AF meter, and it would go crazy right there. I recorded a little video to show Jim C, so I will post it if I can find it. When I went back to 36lb injectors it changed & lessened, but it is still slightly there.

BATCH INJECTION IS NOT OUR FRIEND!!!

I have tried a few different methods of fueling in my kits. Simply put, most of the systems on current autos do not have dampers... Why, because they use sequential injection. Which of course gets rid of the big single pulse harmonic. Initially I used fuel rails just like Carls, but I was getting a nasty thunking noise in the car. You could hear it go right up the fuel line all the way to the tank. When idling, it sounded like I had a bad rod bearing. I attempted to add dampers to the rails, but it was just too much of a pain in the ***. Plus I... I wanted to keep the install as simple as possible. Plus II.. having no retaining clips on the injectors to the rails does no leave one with a warm fuzzy fealing. Pluss III... there was no gain in fuel flow. So I went back to the stock rails and modified them

As to the fuel harmonics... Yes they are there. I did not initially notice them, but when Jeff M put 60lb injectors into his car he had issues. So I bought and tested some 60's. Initially I didn't notice anything, but after driving the car for a while with the 60's, one harmonics in particular showed up. At 2700rpm, and about 1/3 throttle I was feeling a little hesitation. At 1/4 throttle nothing, at 3/4 and up nothing, but I knew something wasn't right, and nothing much showed up on the WB. So I hooked up an AF meter, and it would go crazy right there. I recorded a little video to show Jim C, so I will post it if I can find it. When I went back to 36lb injectors it changed & lessened, but it is still slightly there.

BATCH INJECTION IS NOT OUR FRIEND!!!

#60

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Sorry for lack of thread clarity. It was a critical commentary to post 41 in this thread.

I don't camp-out on these discussions, so I get more of a 'digest mode' look at them. So my replies are somewhat disconnected I guess.

Sorry!

I don't camp-out on these discussions, so I get more of a 'digest mode' look at them. So my replies are somewhat disconnected I guess.

Sorry!