PKT warning light?

#1

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Possible solution?

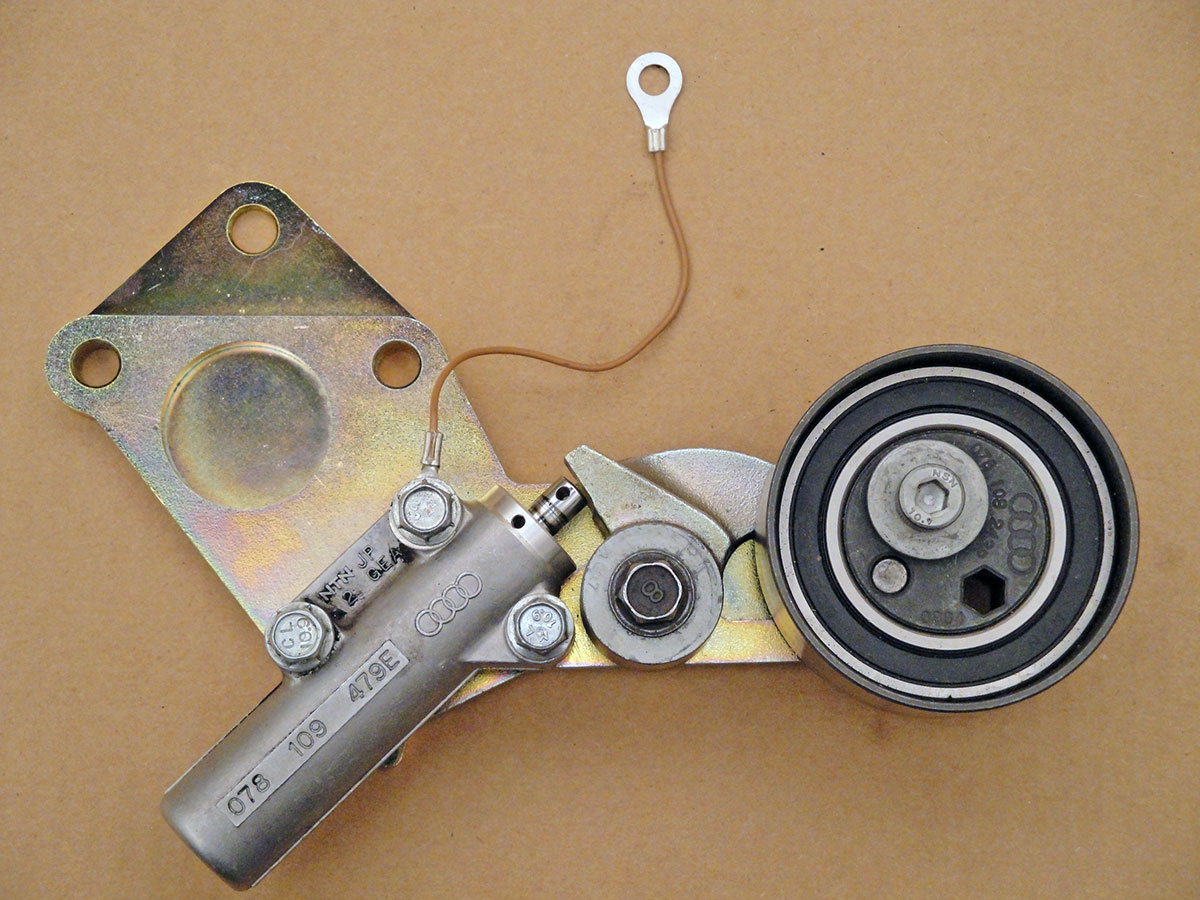

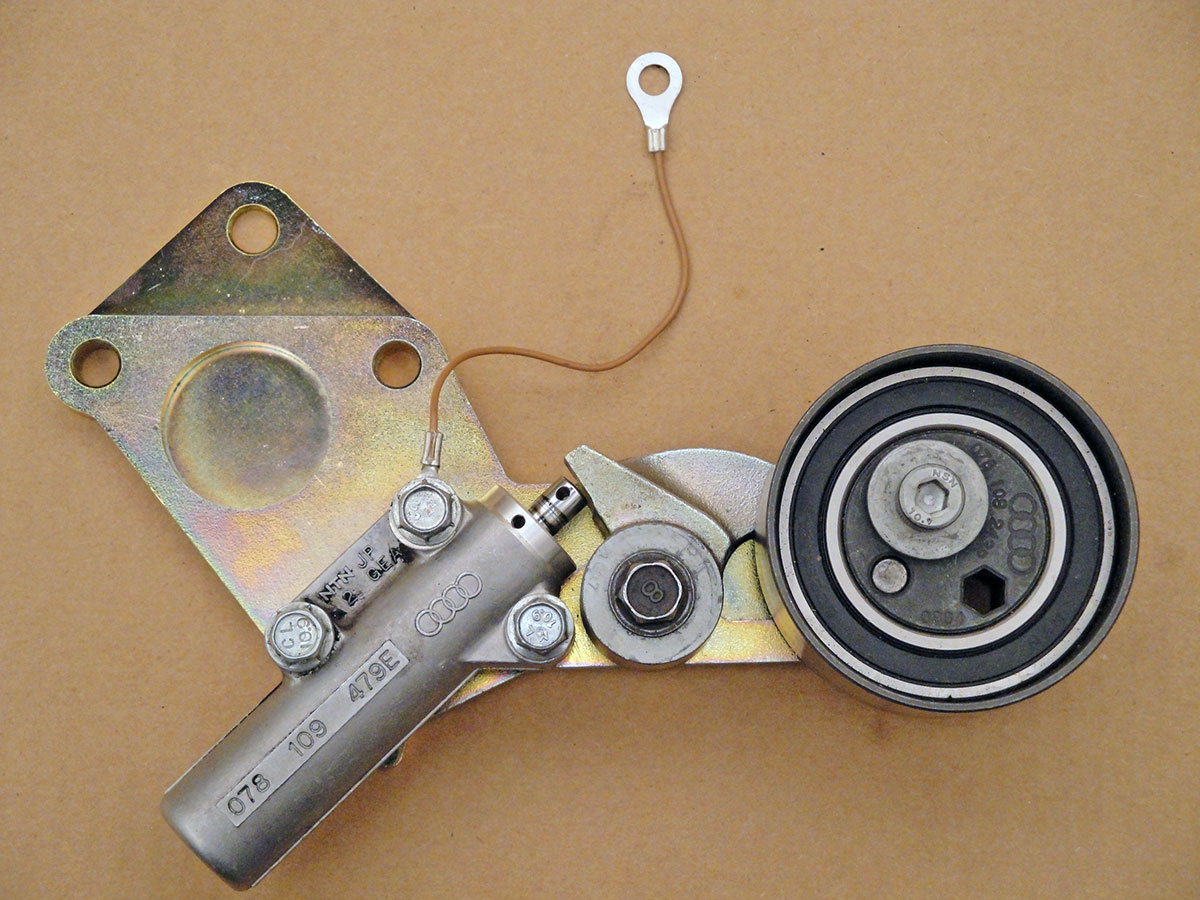

Isolate the Tensioner/Damper and attach the warning light wire to it.

This would break ground with both over and under extension.

I reckon it could be about as reliable as the factory 'sensor'.

The arm conducts to the bracket and the pulley.

The piston conducts to the T/D housing at all extensions.

There is a small amount of travel past max extension (pic below).

The warning light will trigger with an intermittent break, IE. it will stay on even if ground is restored.

Should make a small L-bracket to hold the fancy cover connector outside of the cover and plug the cover.

What's required

Heat shrink tubing on the T/D bolts.

Thin Mylar washers on both sides of the T/D bolt holes.

Wire to the factory connector with 5/16" (8mm) terminal at T/D.

Requires drilling T/D holes slightly larger, ~7mm (current holes are a cone shape, 8->6mm).

Isolate the Tensioner/Damper and attach the warning light wire to it.

This would break ground with both over and under extension.

I reckon it could be about as reliable as the factory 'sensor'.

The arm conducts to the bracket and the pulley.

The piston conducts to the T/D housing at all extensions.

There is a small amount of travel past max extension (pic below).

The warning light will trigger with an intermittent break, IE. it will stay on even if ground is restored.

Should make a small L-bracket to hold the fancy cover connector outside of the cover and plug the cover.

What's required

Heat shrink tubing on the T/D bolts.

Thin Mylar washers on both sides of the T/D bolt holes.

Wire to the factory connector with 5/16" (8mm) terminal at T/D.

Requires drilling T/D holes slightly larger, ~7mm (current holes are a cone shape, 8->6mm).

#4

Official Bay Area Patriot

Fuse 24 Assassin

Rennlist Member

Fuse 24 Assassin

Rennlist Member

I believe over extension can be detected with the use of a small dowel in the hole where the pin is located. If a small pin can be fabbed up, then inserted into the hole once the pin is pulled, all that would be needed is a metal stop of some sorts to trigger the ground and light.

#5

Rennlist Member

Trying to mimic the OEM system might be folly. Couldn't we measure the distance between the two holes in real-time as an indication of belt stretch?

#7

Vegas, Baby!

Rennlist Member

Rennlist Member

I've been running Gates HTD belts on my Harley's for over 40 years. Other than the width, or the length, the belts are exactly the same. They don't stretch! Detergent oil will cause the fibers to break down, and shred the teeth. Plus there's a lot more torque on a primary, or final drive belt on a Harley, and we don't use tensioners. The primary drive belt has an idler pulley, but it's only snugged up to the belt. Final drives belts must be able to swing up, and down as the swing arm moves with the suspension, but the belt geometry remains the same, as does the tension. The belts and pulleys last the life of the power train.

Ken's tensioner works! We no longer need the warning light.

I'm running one of Ed's Guardian water pumps, in the Vegas heat, and zero problems.

Ken's tensioner works! We no longer need the warning light.

I'm running one of Ed's Guardian water pumps, in the Vegas heat, and zero problems.

Trending Topics

#8

Inventor

Rennlist Member

Rennlist Member

Thread Starter

If the T/D is not damping or the piston is not extending then the the belt will flutter/flap (like the stock system).

Movement of the belt will be telegraphed through the pulley and lever.

The piston spring is quite strong. Normally, the piston is firmly held against the lever.

It would take just one break of the piston to lever contact to trigger a warning.

As shown in the pic above, the lever and pulley have a small amount of travel (<1 mm from the piston tip) before the pulley pin hits the stop built into the bracket.

At full extension, the belt will be undamped, so the lever should occasionally lift off of the piston.

It's not a great way of checking for overextension, but this is a much more rare event.

Movement of the belt will be telegraphed through the pulley and lever.

The piston spring is quite strong. Normally, the piston is firmly held against the lever.

It would take just one break of the piston to lever contact to trigger a warning.

As shown in the pic above, the lever and pulley have a small amount of travel (<1 mm from the piston tip) before the pulley pin hits the stop built into the bracket.

At full extension, the belt will be undamped, so the lever should occasionally lift off of the piston.

It's not a great way of checking for overextension, but this is a much more rare event.

#10

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

#11

Rennlist Member

Wasn't that a feature in the early 928's O2 sensor? Of course you could right down the mileage when you installed it. :-)

#12

#13

Captain Obvious

Super User

Super User

If the T/D is not damping or the piston is not extending then the the belt will flutter/flap (like the stock system).

Movement of the belt will be telegraphed through the pulley and lever.

The piston spring is quite strong. Normally, the piston is firmly held against the lever.

It would take just one break of the piston to lever contact to trigger a warning.

As shown in the pic above, the lever and pulley have a small amount of travel (<1 mm from the piston tip) before the pulley pin hits the stop built into the bracket.

At full extension, the belt will be undamped, so the lever should occasionally lift off of the piston.

It's not a great way of checking for overextension, but this is a much more rare event.

Movement of the belt will be telegraphed through the pulley and lever.

The piston spring is quite strong. Normally, the piston is firmly held against the lever.

It would take just one break of the piston to lever contact to trigger a warning.

As shown in the pic above, the lever and pulley have a small amount of travel (<1 mm from the piston tip) before the pulley pin hits the stop built into the bracket.

At full extension, the belt will be undamped, so the lever should occasionally lift off of the piston.

It's not a great way of checking for overextension, but this is a much more rare event.

#14

Rennlist Member

Hi Ken I think your mod is a viable solution and should give us "PKTensioners" some indication if the dynamic Audi tensioner is not holding constant pressure.

With that being said I do believe that with any critical system as our T Belts, a routine maintenance inspection is unavoidable. With or w/out an idiot light

Ken do you think that the Mylar washers may cause the T/D bolts not to hold torque?

Keep up the good work !

Thanks,

Dave K

With that being said I do believe that with any critical system as our T Belts, a routine maintenance inspection is unavoidable. With or w/out an idiot light

Ken do you think that the Mylar washers may cause the T/D bolts not to hold torque?

Keep up the good work !

Thanks,

Dave K

#15

Inventor

Rennlist Member

Rennlist Member

Thread Starter

I haven't looked yet at how to connect the wire. I'd like to avoid going under the TB cover so there's no chance of it getting under the belt, somehow.