Newest Project - Lower Intake Manifold for Fabricated S4 Intakes

#31

Rennlist

Basic Site Sponsor

Basic Site Sponsor

Greg,

That price was for 3D printing the test part, but honestly the cast part shouldn't be too far off that either. Sent out the file for review with two foundries I have decent relationships with, and should have an idea if there are any manufacturability issues, pattern and estimated production costs.

My goal is to keep them under $500/set. I will apply to be a Ross Machine Racing distributor closer to, and should be able to supply all the bits to make some interesting intakes. I think that it should be possibly to have sheetmetal intakes under the $1k mark, but don't hold me to it yet.

Thanks

Hans

That price was for 3D printing the test part, but honestly the cast part shouldn't be too far off that either. Sent out the file for review with two foundries I have decent relationships with, and should have an idea if there are any manufacturability issues, pattern and estimated production costs.

My goal is to keep them under $500/set. I will apply to be a Ross Machine Racing distributor closer to, and should be able to supply all the bits to make some interesting intakes. I think that it should be possibly to have sheetmetal intakes under the $1k mark, but don't hold me to it yet.

Thanks

Hans

I took my intake manifold "off the shelf" about two weeks ago and we've been "finishing' it up, for those two weeks. Now into our third week....and I had 4 weeks into it, when I put it "on the shelf". Sure, there were a couple of weeks of designs that got "tossed" for various reasons....but that had to be done, anyway....and everyone is going to "go though" that same learning curve.

It's not a simple thing. Porsche did an amazing job of "packaging" what they needed to do, in a tiny space. Yes, not equal length. Yes, crazy turns. Yes, crappy flow for make huge power....but still had plenty of flow to make the power they wanted to make.

Improving on that design isn't all that easy. Which is why, even though everyone thinks the intake manifold is the problem to making "big" horsepower, there are so few "aftermarket" intake manifolds that are actually done and tested.

__________________

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

The following users liked this post:

GUMBALL (10-29-2023)

#32

Rennlist Member

Thread Starter

Dr. Bob,

I would reccomend welding the elbows, as shown in my renderings, and then a flat flange for use with Extrudabody or similar 45mm ITBs. They are already setup with the bushing, linkage.... etc.

I dont have enough experience with ITB's to even consider designing them. Mike Simard is the guy you want to talk to if you want a ready-made ITB solution for the 928.

I am trying to make a non-specific 928 "intake lego" for use with just about any configuration. This design is the most recent in versions going back to last May. It is the most versatile, so dont plan any major revisions unless I get some feedback from the foundry in regards to adding/removing material for a better quality casting.

Thanks for the suggestion though,

Hans

I would reccomend welding the elbows, as shown in my renderings, and then a flat flange for use with Extrudabody or similar 45mm ITBs. They are already setup with the bushing, linkage.... etc.

I dont have enough experience with ITB's to even consider designing them. Mike Simard is the guy you want to talk to if you want a ready-made ITB solution for the 928.

I am trying to make a non-specific 928 "intake lego" for use with just about any configuration. This design is the most recent in versions going back to last May. It is the most versatile, so dont plan any major revisions unless I get some feedback from the foundry in regards to adding/removing material for a better quality casting.

Thanks for the suggestion though,

Hans

#33

Nordschleife Master

If you can get the flanges and rails priced at $500 or under, you'll sell a lot.

If you can get somewhat configurable runners and trumpets included for another $400, you'll sell many of those as well.

Those are cheap enough that people might buy them just to play with them and it would not be a great tragedy if the intake project sits on the shelf for some time.

You may want to leave the plenum components for people to work on by themselves, as everyone seems to have an opinion, a****ole, and a plenum idea.

Are you planning to use the S4/GT/GTS throttle body? Or is the plan to use an aftermarket throttle body? If the S4 throttle body element is not a binding restriction, the ability to use that would lower the total cost greatly. Does anyone know whether the whole cast throttle body element is a restriction or not?

If you can get somewhat configurable runners and trumpets included for another $400, you'll sell many of those as well.

Those are cheap enough that people might buy them just to play with them and it would not be a great tragedy if the intake project sits on the shelf for some time.

You may want to leave the plenum components for people to work on by themselves, as everyone seems to have an opinion, a****ole, and a plenum idea.

Are you planning to use the S4/GT/GTS throttle body? Or is the plan to use an aftermarket throttle body? If the S4 throttle body element is not a binding restriction, the ability to use that would lower the total cost greatly. Does anyone know whether the whole cast throttle body element is a restriction or not?

#34

Rennlist Member

Thread Starter

There is no reason why you couldnt retain the stock throttle, but I see the largest advantage as being able to relocate the throttle to the front of the manifold, and do something similar to what the LS series engines have with a filter in front of the radiator.

I do plan on offering a new throttle quadrant bracket, I need to work that out later the week and see if I need to include bosses on the flange or use points on the valve cover mounting.

Thanks

Hans

I do plan on offering a new throttle quadrant bracket, I need to work that out later the week and see if I need to include bosses on the flange or use points on the valve cover mounting.

Thanks

Hans

#35

As you suggest, just focus on this one design and bring down the production costs, and it will go great from there.

#36

Rennlist Member

Thread Starter

Well double disappointment on the intake project. I sent the drawing out to several foundries for bid in 356-T6, and they are coming back higher than I would like, even from people I have worked with in the past. If anyone has a reccomended source, I wold love to take a look. Patterns are running between $4700 and $7500 so far (still waiting on a few).

It was brought to my attention that there are several thin-spots from the way I made the tube/casting interface, so I will take a look at changing that a bit to thicken that area up a bit.

It is pretty clear at this point, that there is limited hope for a my original hopeful $500/set of cast flanges... my cost is above that with every manufacturing technique I can think of. I should have done this a couple years ago when things were cheaper.

I still plan on getting these made, but thinking they will be in the $750-$950/pair price range.

Anyone interested in a set at a price around that area? Will help me figure out what kind of tooling I should be using.

Thanks

Hans

It was brought to my attention that there are several thin-spots from the way I made the tube/casting interface, so I will take a look at changing that a bit to thicken that area up a bit.

It is pretty clear at this point, that there is limited hope for a my original hopeful $500/set of cast flanges... my cost is above that with every manufacturing technique I can think of. I should have done this a couple years ago when things were cheaper.

I still plan on getting these made, but thinking they will be in the $750-$950/pair price range.

Anyone interested in a set at a price around that area? Will help me figure out what kind of tooling I should be using.

Thanks

Hans

Last edited by hans14914; 04-23-2013 at 05:57 PM.

#37

Rennlist Member

Is there a chance it could be done with modern plastics , arent the chevy manifolds plastic ?

I know the holden ones here in Oz are , and they seem to last a long time.

I know the holden ones here in Oz are , and they seem to last a long time.

#39

Does the complexity of the manifold matter when you are casting? If you were to make it more, say, wedge shaped, like the one I sent you - would that make any difference?

#40

Addict

Rennlist Member

Rennlist Member

Join Date: Feb 2004

Location: Monterey Peninsula, CA

Posts: 2,374

Likes: 0

Received 16 Likes

on

12 Posts

Well double disappointment on the intake project. I sent the drawing out to several foundries for bid in 356-T6, and they are coming back higher than I would like, even from people I have worked with in the past. If anyone has a reccomended source, I wold love to take a look. Patterns are running between $4700 and $7500 so far (still waiting on a few).

It was brought to my attention that there are several thin-spots from the way I made the tube/casting interface, so I will take a look at changing that a bit to thicken that area up a bit.

It is pretty clear at this point, that there is limited hope for a my original hopeful $500/set of cast flanges... my cost is above that with every manufacturing technique I can think of. I should have done this a couple years ago when things were cheaper.

I still plan on getting these made, but thinking they will be in the $750-$950/pair price range.

Anyone interested in a set at a price around that area? Will help me figure out what kind of tooling I should be using.

Thanks

Hans

It was brought to my attention that there are several thin-spots from the way I made the tube/casting interface, so I will take a look at changing that a bit to thicken that area up a bit.

It is pretty clear at this point, that there is limited hope for a my original hopeful $500/set of cast flanges... my cost is above that with every manufacturing technique I can think of. I should have done this a couple years ago when things were cheaper.

I still plan on getting these made, but thinking they will be in the $750-$950/pair price range.

Anyone interested in a set at a price around that area? Will help me figure out what kind of tooling I should be using.

Thanks

Hans

I share your pain.. The prices are now insane to build stuff properly....

I wish I had this done years ago.. It would be so much cheaper.... Also why I don't think that the 928 bits I am making are suitable for a business.. Although, as promised, I will make a setup for anyone who wants, and is able to pay for it... (After I test it of course..)

I wish I had this done years ago.. It would be so much cheaper.... Also why I don't think that the 928 bits I am making are suitable for a business.. Although, as promised, I will make a setup for anyone who wants, and is able to pay for it... (After I test it of course..)Anyway, Good luck with your setup.. I have a west coast foundry referred to me by a relative who used to be with Paxton and is now in aerospace. I'll be happy to refer the place to you after I get back to the USA and discuss my hill of beans with them if you still need it.

Best,

#42

Rennlist Member

Thread Starter

Plastic would be an option if I wanted a more complete manifold, but there is already a part like this offered by 928MS. The part I propose is different, as it is the absolute minimalistic part I could design, allowing for any number of upper assemblies. Being cast in 356-T6 allows it to be welded to off-the-shelf tubes and bends.

I received a more feasible bid today, but still holding out for something better.

I received a more feasible bid today, but still holding out for something better.

#43

Plastic would be an option if I wanted a more complete manifold, but there is already a part like this offered by 928MS. The part I propose is different, as it is the absolute minimalistic part I could design, allowing for any number of upper assemblies. Being cast in 356-T6 allows it to be welded to off-the-shelf tubes and bends.

I received a more feasible bid today, but still holding out for something better.

I received a more feasible bid today, but still holding out for something better.

The intake flanges for the two valve engines were slightly better than that, I used one set successfully, I did eventually sell one set for around $250 and I still have another set unsold. Now these fit perfectly and allow the owner/fabricator to create their own design and factory fuel rails can bolt up with minimal modification. So their value is around $250. How do you think you are going to go at close to a grand? Also the market now knows that GBs manifold is about and it is difficult to produce.

Personally the only spot in the market I see is for a flange plate adaptor to a throttle body setup. Maybe Mike would be interested in working with you on that, although it would compromise his existing setup by being a competitor but there is always price as a separator of products.

These throttles I have in mind are the most advanced on the market. A 45 mm throttle will be all that is needed for standard sized 928 engines. The also make oval sized equivalent throttles that would be a good fit for the 928. That will take the engine well over 600 HP.To back that up a 2.5 litre Honda with 45 mm throttles did 313 axle HP at 8,000 rpm on a dynopack dyno.

Here's an article by Renault F1, the reason it is relevant is that, it is the same style throttle just made for the street. The blade is alloy and is 2 mm thick but tapered. They have been experimenting with thinner carbon composite blade but there isn't a lot of low hanging fruit as they already achieve 99.5% efficiency versus losses in normal throttles of between 7 to 10%. The company making these throttles was started by ex F1 engineers.

http://www.f1technical.net/features/...f5055981723661

I also know they put a set of their throttles on the new BMW M3. 4.0 litre, with the engine remapped it did 490 rwhp. No other changes were made.

The range of cars these throttles have been offered for is getting quite big, a lambo v12 recently did 800 HP, a GT3 engine did 513 HP, a racing Honda 2.7 litre engine did 383 rwhp on a dynopack dyno (11,200 rpm) unfortunately no 928 package is offered, so a flange plate is needed to do that. Also I know they only recommend a full length runner, so any design needs to crossover the bank and be around 13 to 15" in length depending on the intended rpm range.

#44

Official Bay Area Patriot

Fuse 24 Assassin

Rennlist Member

Fuse 24 Assassin

Rennlist Member

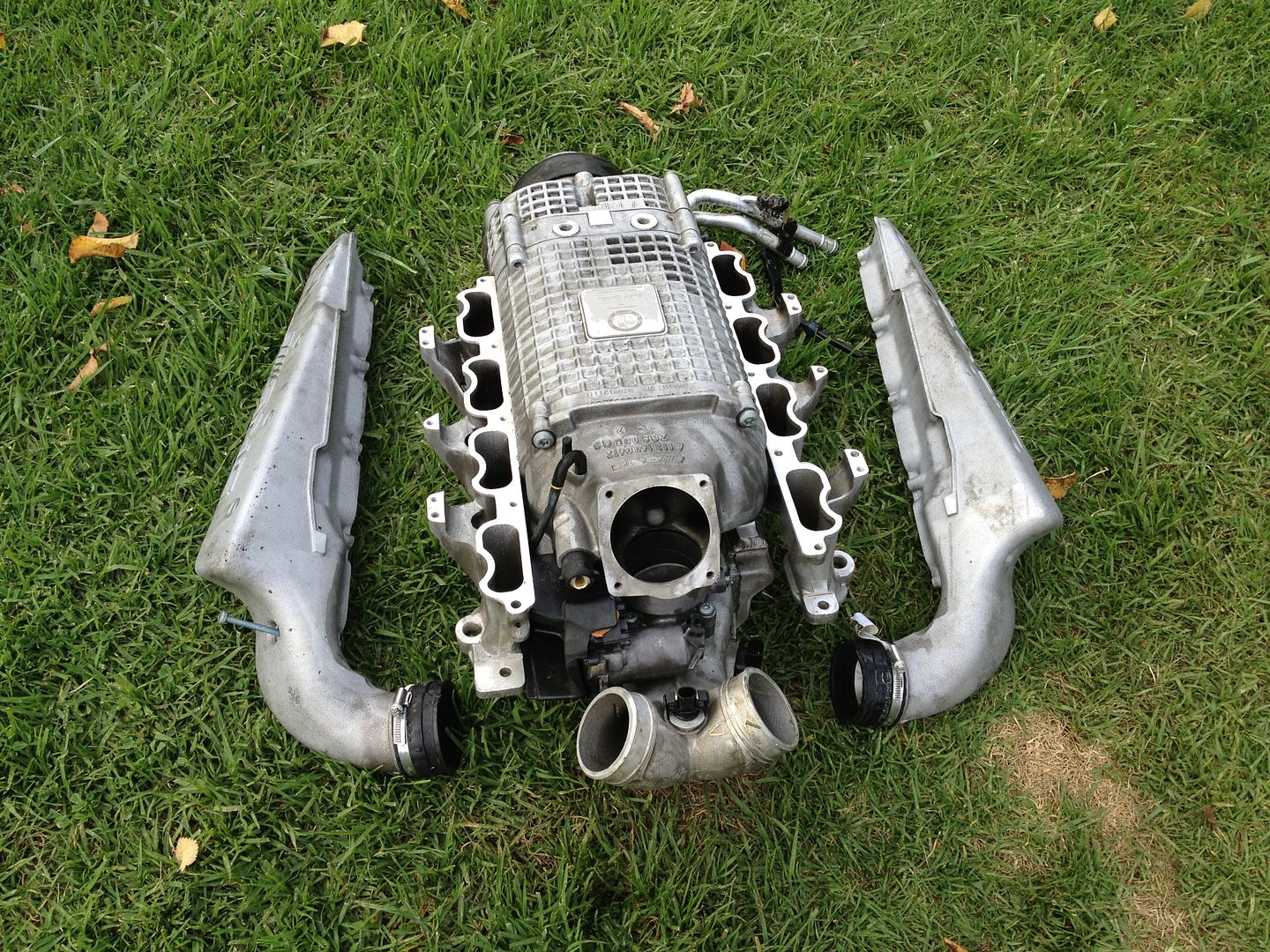

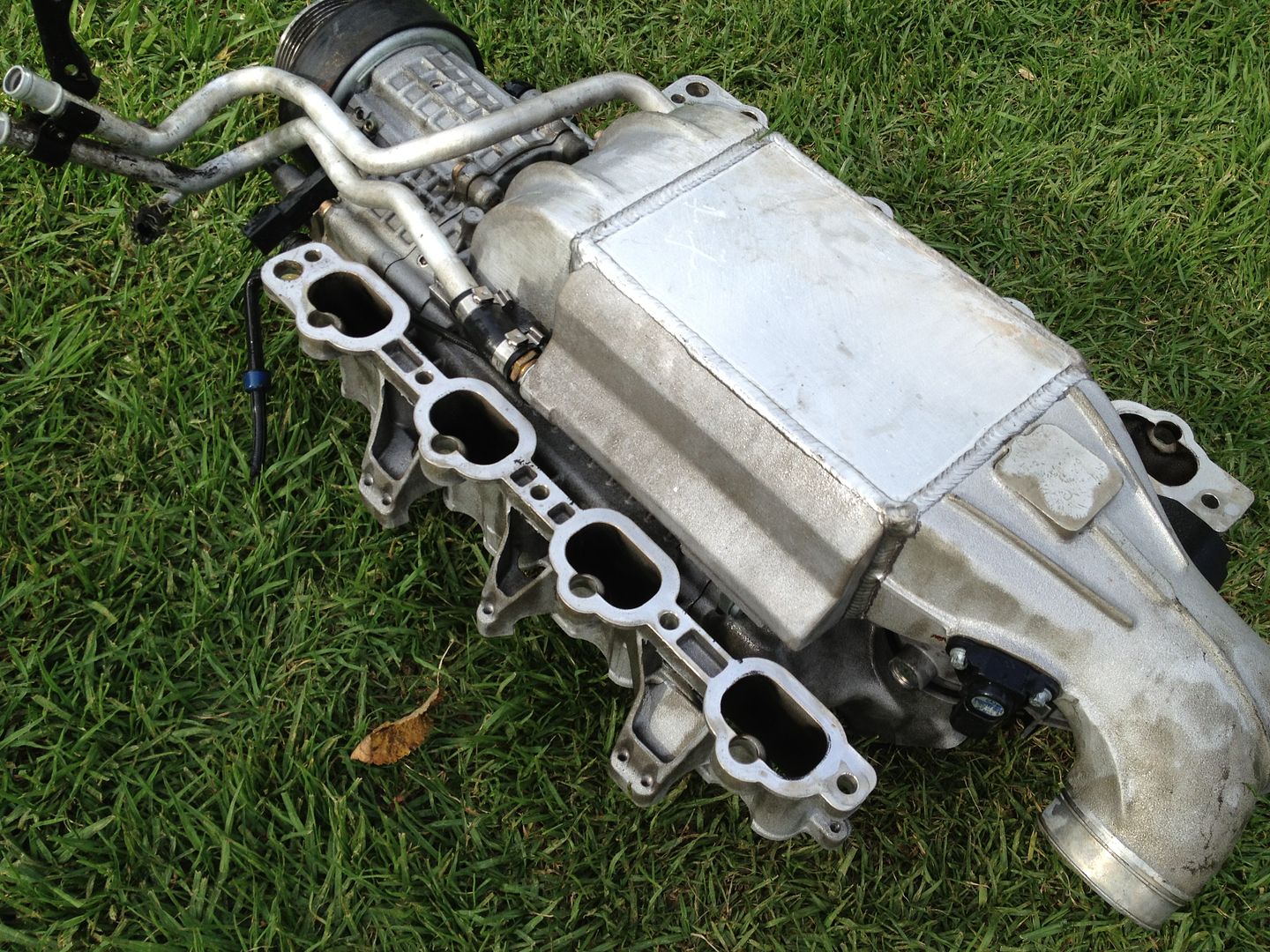

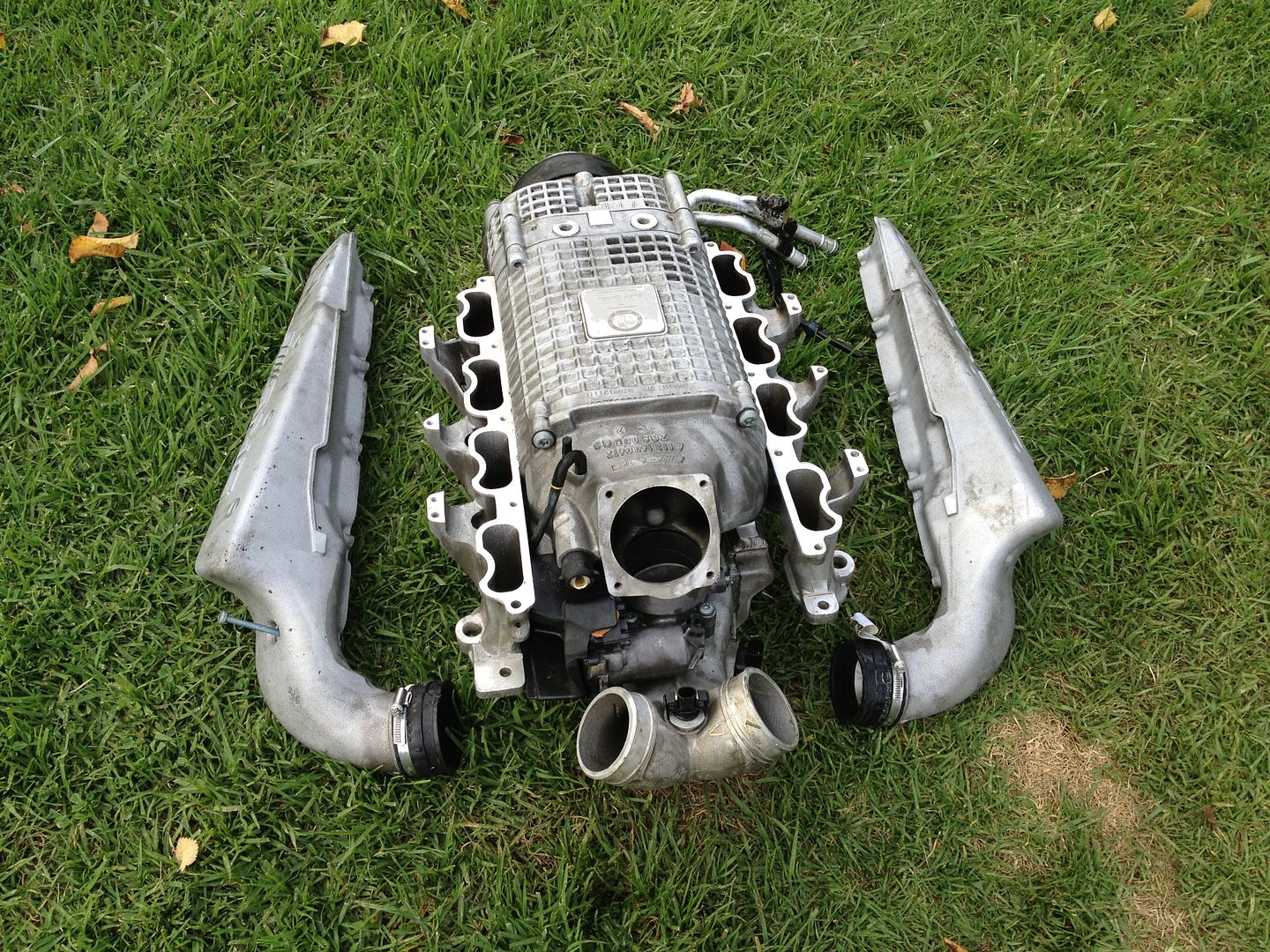

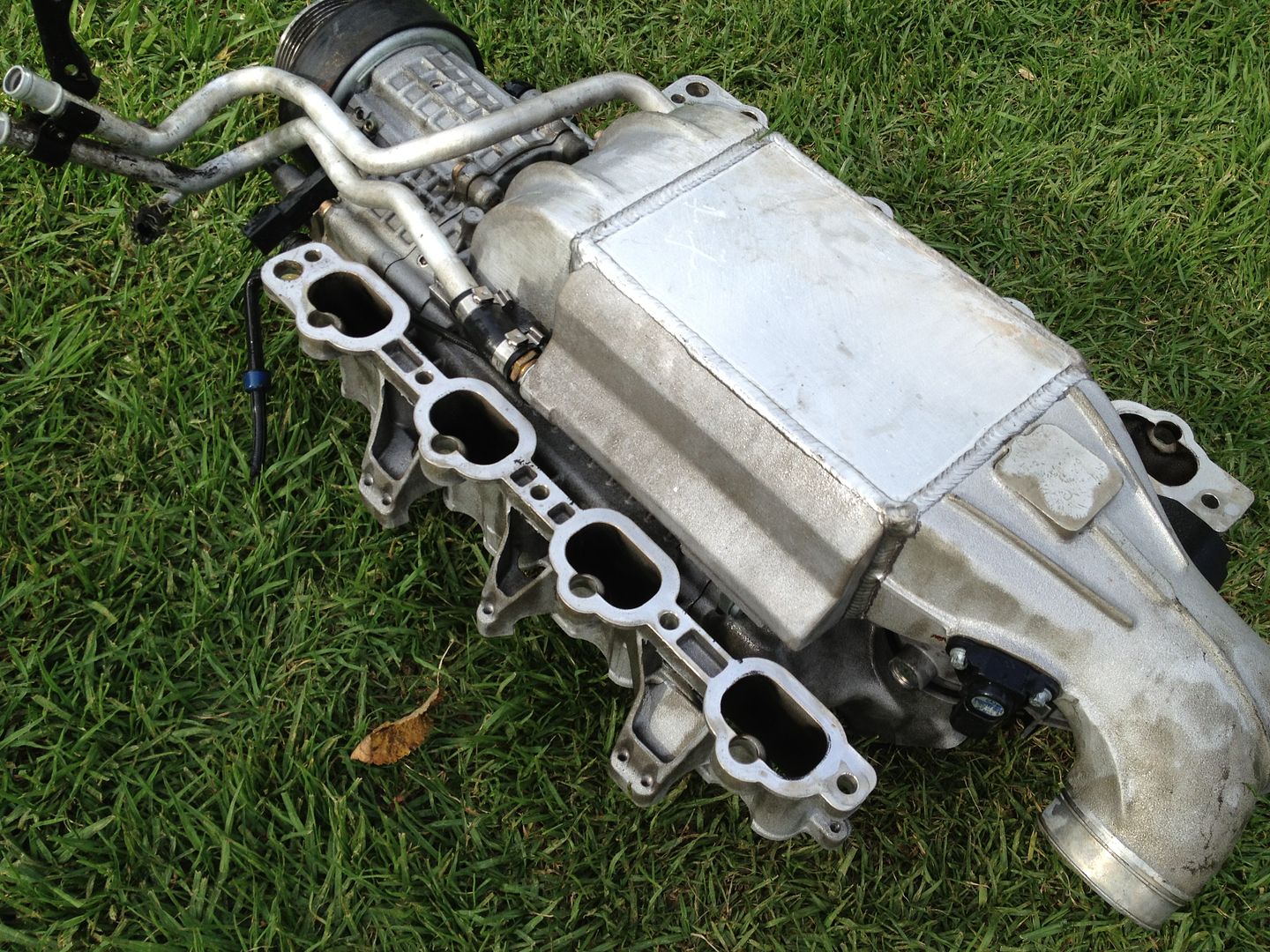

As I think about it, these fabbed parts would come in handy for building a manifold for another Eaton type setup similar to Keel's Supermodel and 928 Spec's one.

#45

Race Car

Now you're talking. And if you could fabricate some rectangular boxes which connect to a Y-pipe in the rear that connect to an intercooler in the engine-V which then connects upwards into a twin-screw supercharger, you will have almost perfectly replicated an AMG setup. I wonder if an E55 intercooler would fit in the V of the 928 engine; I'm pretty sure it would...

Dan

'91 928GT S/C 475hp/460lb.ft

475hp/460lb.ft

Dan

'91 928GT S/C

475hp/460lb.ft

475hp/460lb.ft

Last edited by dprantl; 04-24-2013 at 09:30 PM.