Newest Project - Lower Intake Manifold for Fabricated S4 Intakes

#91

Rennlist

Basic Site Sponsor

Basic Site Sponsor

Greg, you are probably right, I am jut surprised that the port matching is so extremely poor. There are likely lots of other issue which have a larger effect, but its just startling to me when compared to the quality of materials and tolerances elsewhere in the engine. I have heard that there was closer attention to port matching on the GT and CS engines.... have you seen anything to support that? Just curious.

I've been waiting to see what Porken finds out....he's a man on a mission!

__________________

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

#92

Inventor

Rennlist Member

Rennlist Member

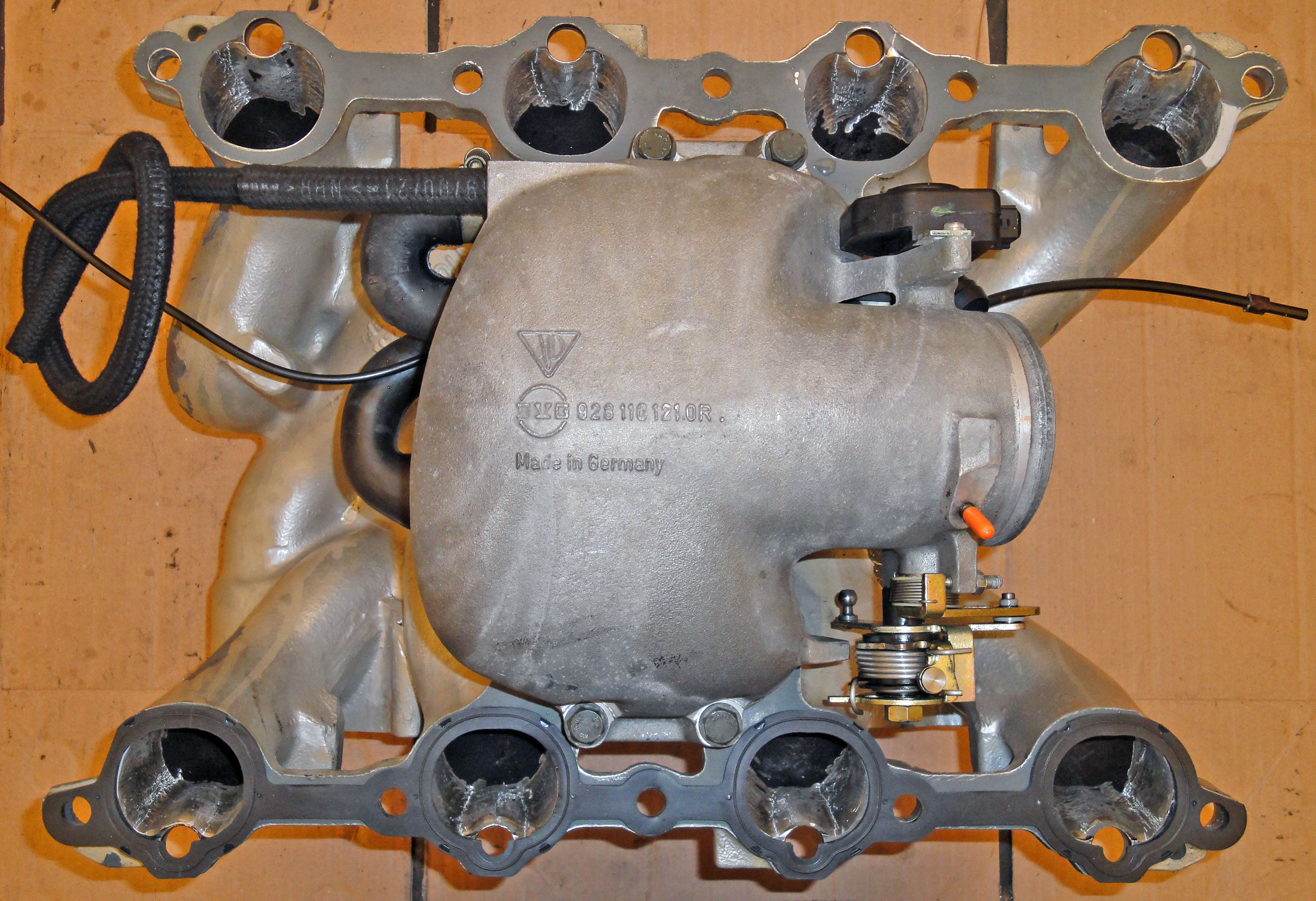

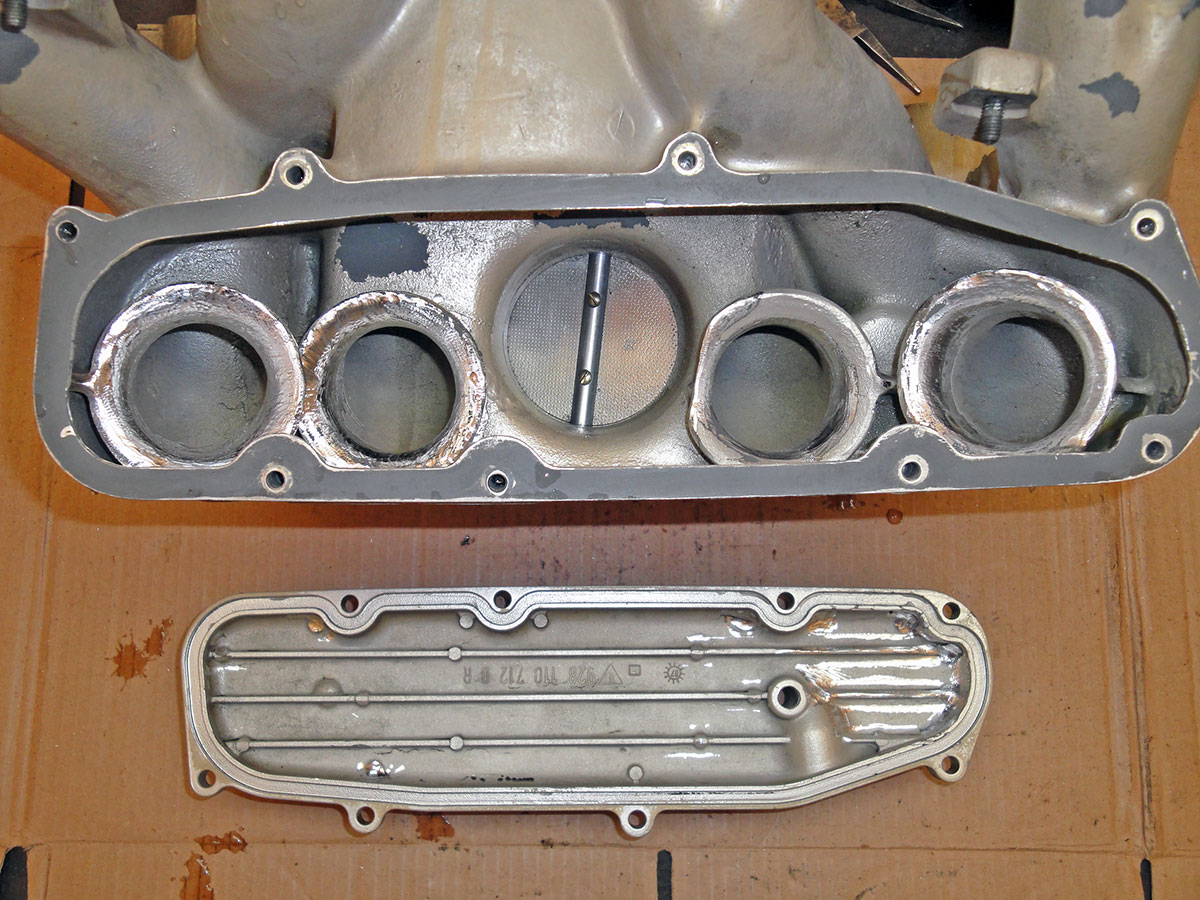

The last four pictures are the same acrylic flange laid over a factory intake manifold, centered on the bolt holes. You can see how well the factory located the injectors, but how the intake manifold port itself is offset inwards. There is a huge ledge there that the air would hit.

I would be interested to see the effect of simply port matching an S4 engine.

I would be interested to see the effect of simply port matching an S4 engine.

(This is why there is a TOP to the gasket.)

On my early '88, I found the head ports to all be very close to the lower gasket opening.

Some ports on the manifold had areas that needed to be matched to the upper opening, but it wasn't nearly as bad as all of the S3 manifolds I worked on.

Gasket matching and cleaning up the trumpets did not make a significant difference in RW HP or TQ on my '88.

I felt part throttle response was improved, though. It may make a difference with larger cams and/or more cubes...

Yamabond on the (factory made) skinny sections (#1, #8).

Outside horns nearest cover made 'tulip' shaped towards inside.

Casting sprues and reinforcement ribs near closest horn (#5) reduced.

Ribs strengthen covers for best sound/harmonic reflection (flappy effect).

Last edited by PorKen; 10-28-2013 at 06:03 PM. Reason: pics

#94

In Soviet Russia, intake ports you!

#95

Rennlist Member

Thread Starter

So, I didnt have a chance to take pictures, but the fit is better than I could have ever imagined. The 3D print passed the fingernail drag test with flying colors. I still need to check the clearance to the waterbridge, which I will do tonight. Pictures will be up tonight, and I will take the part to Third Coast for inspection. Lets get this made, need a couple more hands, and then will collect deposits and get the tooling ordered.

Thanks

Hans

Thanks

Hans

#96

Awesome.

Have you spoken to Greg in depth to make sure there is nothing you are doing that can work with his needs?

Have you spoken to Greg in depth to make sure there is nothing you are doing that can work with his needs?

#97

Rennlist Member

Thread Starter

Here are some quick pictures I took in the parking lot. Not sure I will have time to post good ones later tonight. I have a lot to do before heading out for Third Coast.

Hope you enjoy them.

Hans

Hope you enjoy them.

Hans

#98

Rennlist Member

Thread Starter

Injector bung

Note that there is a shoulder so the injector can not drop into the port. Also the pintle is shrouded in the casting, but the meat could easily be machined away if you wanted it to be exposed to the flow. These are also designed with the smaller bore for use with the original o-rings, not the large "S4" o-rings.

Note that there is a shoulder so the injector can not drop into the port. Also the pintle is shrouded in the casting, but the meat could easily be machined away if you wanted it to be exposed to the flow. These are also designed with the smaller bore for use with the original o-rings, not the large "S4" o-rings.

#100

Wow. Really clear imaging and a way to wrap our brains around what the interaction is like.

Great stuff.

The other thread has some info about port volume. Has anyone read anything technical about injector placement? It starts to matter at higher rpms - but maybe too high to worry about here.

I am not suggesting moving yours.

Great stuff.

The other thread has some info about port volume. Has anyone read anything technical about injector placement? It starts to matter at higher rpms - but maybe too high to worry about here.

I am not suggesting moving yours.

#101

Rennlist Member

Thread Starter

Dan,

You can create functional parts from an SLS printer. The output of the printer I have access to is very durable, but not sure I would use it for this application. I may take a look at making a flanged version and outsource the printing to an SLS house I use. I do think that the cast aluminum version is the most practical application though, as welding is required either way.

Brendan - it would be possible to move the injector higher, but there is a notch in the head that you would have go include. I do have a model that accommodates this feature, but think the factory location is fine, especially with the correct injector.

You can create functional parts from an SLS printer. The output of the printer I have access to is very durable, but not sure I would use it for this application. I may take a look at making a flanged version and outsource the printing to an SLS house I use. I do think that the cast aluminum version is the most practical application though, as welding is required either way.

Brendan - it would be possible to move the injector higher, but there is a notch in the head that you would have go include. I do have a model that accommodates this feature, but think the factory location is fine, especially with the correct injector.

#102

Yes, I think we would see little benefit until after 7k rpm. And then you have packaging issues. Did you look at the injector dynamics units?

#103

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Amazing technology Hans, really is. Its great that you get to work with it. This process is going to revolutionize manufacturing as it trickles down in price and availablity. The time in which you can go from design to prototype has been cut literally to minutes.

Looks awesome!

Looks awesome!

#104

Supercharged

Rennlist Member

Rennlist Member

Join Date: May 2002

Location: Back in Michigan - Full time!

Posts: 18,925

Likes: 0

Received 59 Likes

on

33 Posts

This sure beats the days when they would carve this stuff out of a large chunk of butter and put in on display at the state fair.

Great work Hans. I'd be very interested in the next stage as it relates to a new/better twin-screw design with a much better intercooler. Keep me in the loop.

Great work Hans. I'd be very interested in the next stage as it relates to a new/better twin-screw design with a much better intercooler. Keep me in the loop.

#105

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

This sure beats the days when they would carve this stuff out of a large chunk of butter and put in on display at the state fair.

Great work Hans. I'd be very interested in the next stage as it relates to a new/better twin-screw design with a much better intercooler. Keep me in the loop.

Great work Hans. I'd be very interested in the next stage as it relates to a new/better twin-screw design with a much better intercooler. Keep me in the loop.

475hp/460lb.ft

475hp/460lb.ft