Cam timing effects, 32V

#1

Inventor

Rennlist Member

Rennlist Member

Thread Starter

(...and octane, too! Starting pg 11.)

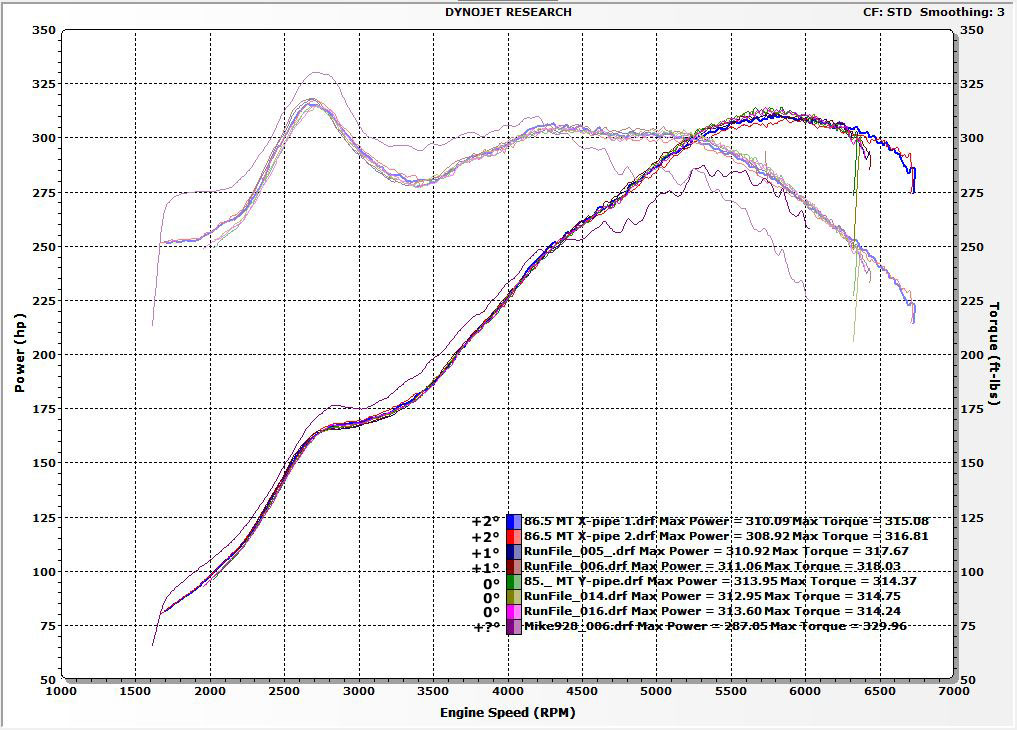

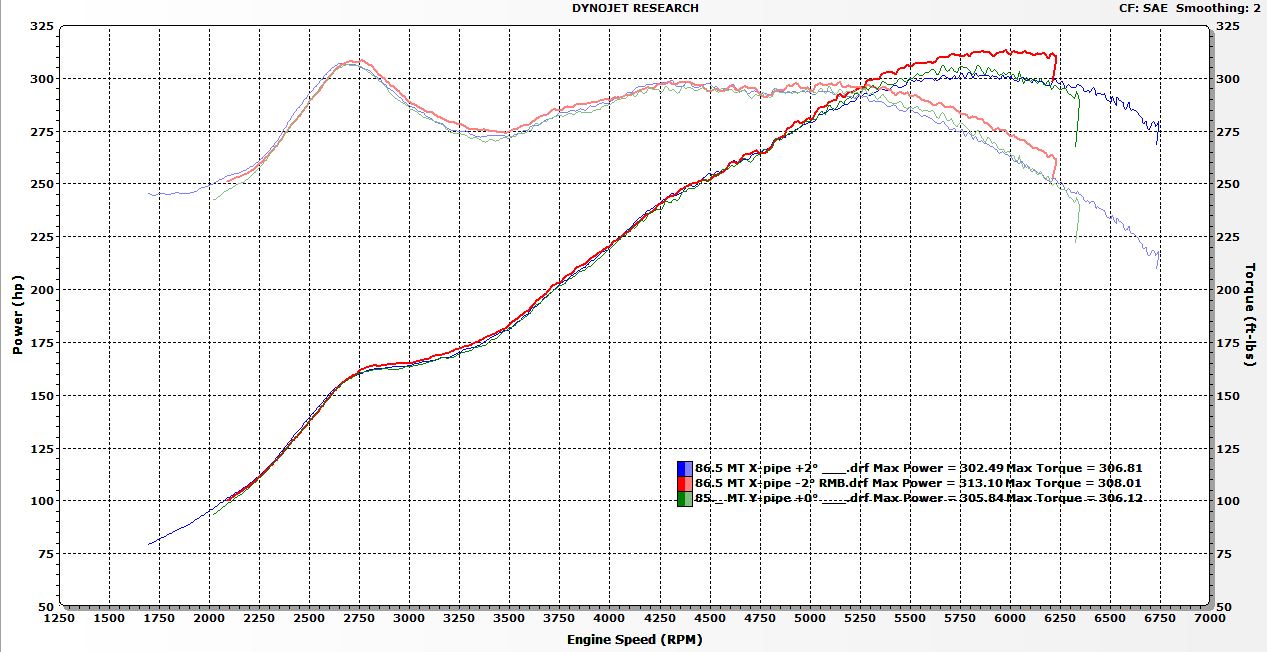

S3, as measured by the PK32V'r.

Narrow usuable range of ▒2░, but a trade of ▒8 HP for TQ (or more) appears possible at the 300 RW TQ/HP level.

More TQ is possible with more advance, at the expense of significant HP loss. Retarding more than ~2░ reduces HP and TQ everywhere.

I would recommend +1 or +2░ for autos, and -1 or -2░ for manuals, based on these findings.

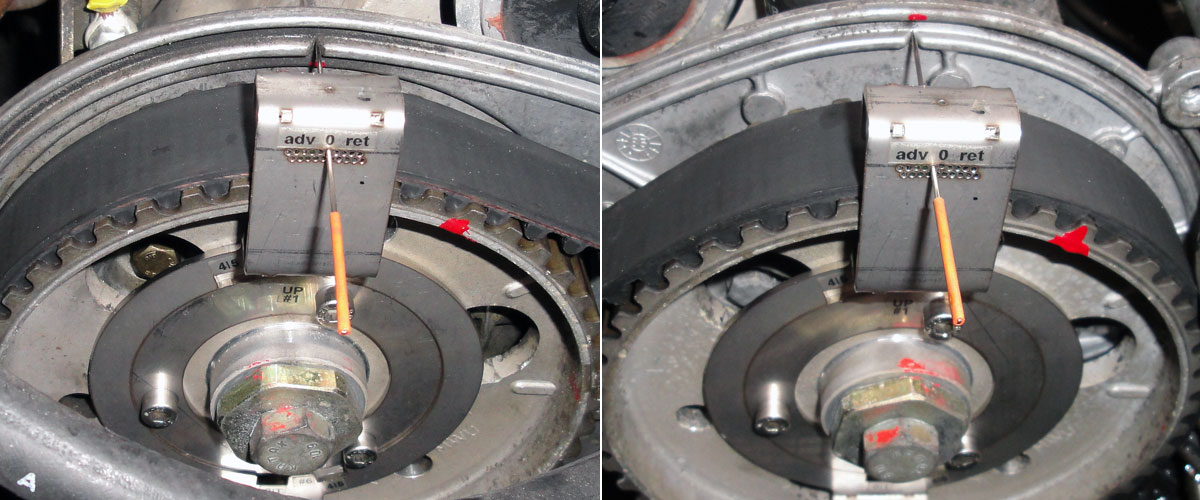

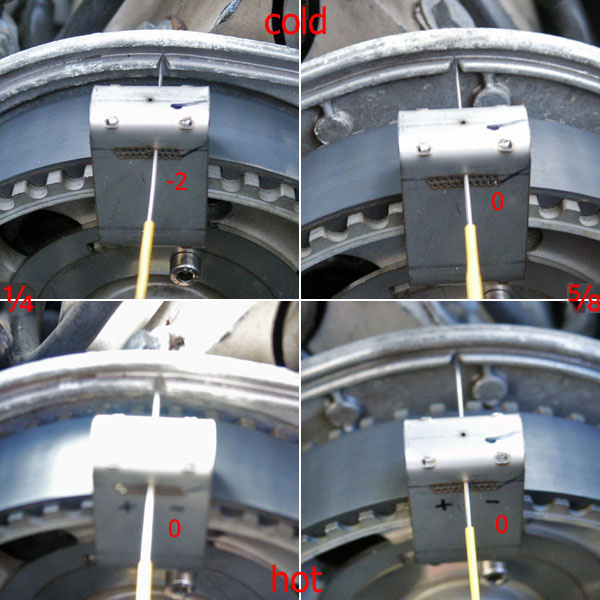

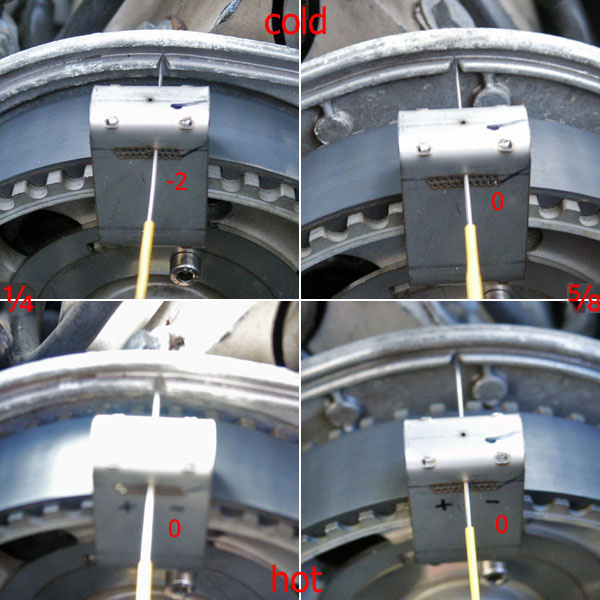

Note: set cold, the 1-4 reading should be -2░ over the 5-8 to compensate for engine expansion when hot. Measured/set hot, both sides equal.

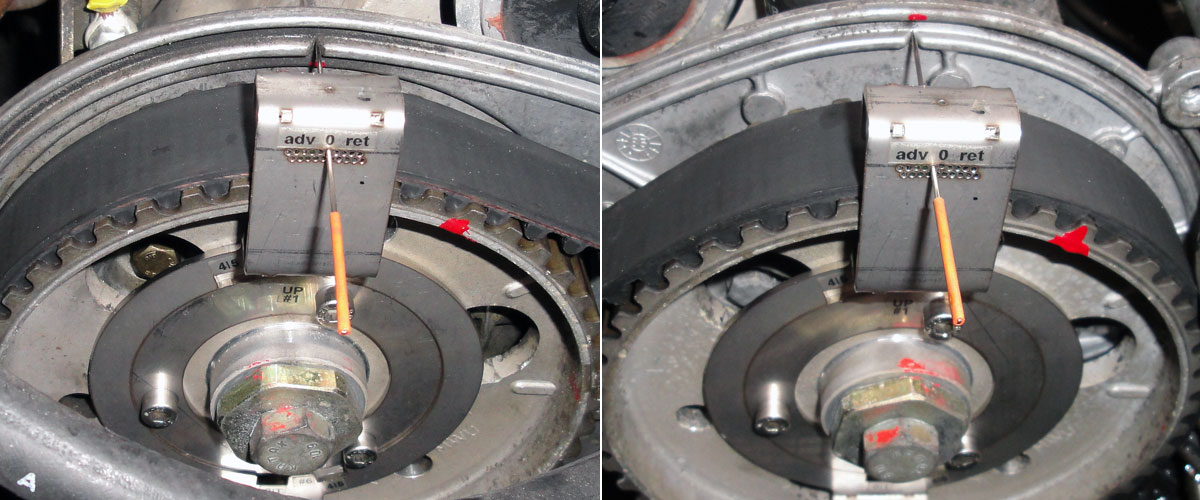

'86.5, +2░ target. (0░, +2░ cold)

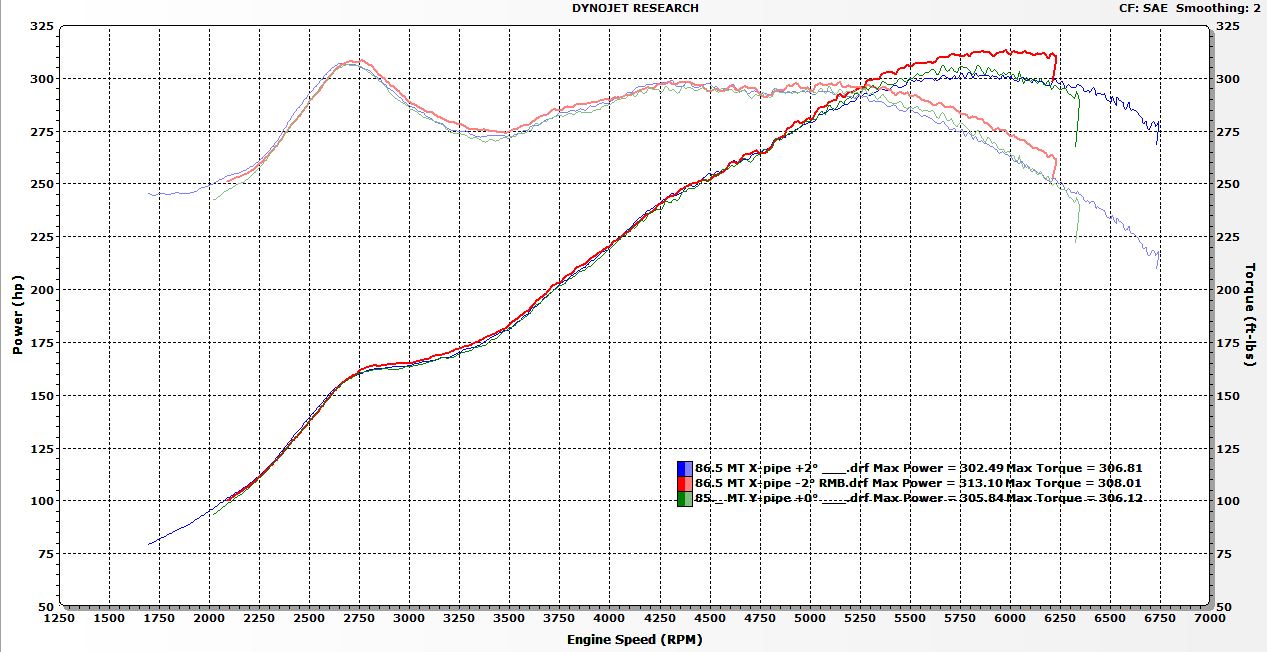

Update. Retarded cam timing, along with intake gasket matching. Change in TQ peak rpm is easy to see from +2 to -2.

Update. Measurement change from cold to hot.

S3, as measured by the PK32V'r.

Narrow usuable range of ▒2░, but a trade of ▒8 HP for TQ (or more) appears possible at the 300 RW TQ/HP level.

More TQ is possible with more advance, at the expense of significant HP loss. Retarding more than ~2░ reduces HP and TQ everywhere.

I would recommend +1 or +2░ for autos, and -1 or -2░ for manuals, based on these findings.

Note: set cold, the 1-4 reading should be -2░ over the 5-8 to compensate for engine expansion when hot. Measured/set hot, both sides equal.

'86.5, +2░ target. (0░, +2░ cold)

Update. Retarded cam timing, along with intake gasket matching. Change in TQ peak rpm is easy to see from +2 to -2.

Update. Measurement change from cold to hot.

Last edited by PorKen; 04-28-2012 at 05:51 PM.

#3

Inventor

Rennlist Member

Rennlist Member

Thread Starter

All those colors are different years and different dyno sessions...showing the hand crafted, low tolerance (GT like) build quality of '85-'86.5 32v engines.

I haven't dynoed S4 engines, but I would say the same effect would apply as S4s have equal HP/TQ ratings. S3s have lower factory HP than TQ ratings, but with proper ignition advance, they have equal HP/TQ when the cams are set to zero.

I haven't dynoed S4 engines, but I would say the same effect would apply as S4s have equal HP/TQ ratings. S3s have lower factory HP than TQ ratings, but with proper ignition advance, they have equal HP/TQ when the cams are set to zero.

#4

Rennlist Member

It is drawing a long bow comparing different sessions , different days , was it the same dyno ? what was the temperature ? barometric pressure , tire temp , gearbox temp , were they the even the same tires?

As an operator you would expect to see anolomies from different sessions , see the scriggly lines , that is obviously traction loss .

AS i have one of Porken tools , when the next engine is built , I will be providing this displayed as the tool allows the timing to be changed accurately and simply I hope .

A question on past experience , (my tool is still in its box unused as yet ) when I have set the cams to spec , ie with a dial gauge on the lifters to set a zero , I have found that the marks never line up . How does the tool compensate for this 0 position ?

Does it have a zero position as default , so you can add or subtract ?

As an operator you would expect to see anolomies from different sessions , see the scriggly lines , that is obviously traction loss .

AS i have one of Porken tools , when the next engine is built , I will be providing this displayed as the tool allows the timing to be changed accurately and simply I hope .

A question on past experience , (my tool is still in its box unused as yet ) when I have set the cams to spec , ie with a dial gauge on the lifters to set a zero , I have found that the marks never line up . How does the tool compensate for this 0 position ?

Does it have a zero position as default , so you can add or subtract ?

#6

Rennlist Member

Ken,

Excellent post- very informative. Supports findings on Louie's website and interesting to see your suggested workable limits. I have driven an S4 auto with the cams retarded to give more power and did not like it at all and thus your recommendation for the S4 makes sense.

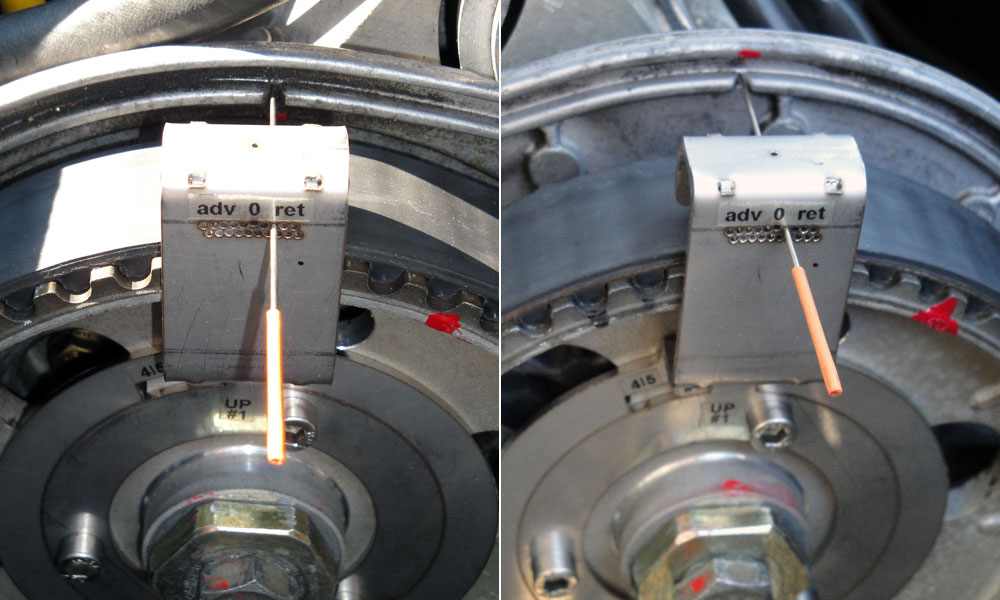

My GTS chassis is powered by the motor from my [late] 90 S4. It is fitted with the GTS inlet cam and the S4 exhaust. When timing the cam in the main dealers workshop we used the timing settings for the GTS cam. With a lot of guidance from Louie, John [Speake] and Jim C I shark tuned the car with a bit of advance over stock at top end and evenb more mid range until the onset of knocks. I also targetted AFR at 13.5 for top end and about 13 mid range. With a Louie X pipe, big central muffler and a RMB at the rear the end result was very acceptable. I later fitted plenum spacers [no tuning] to gain a little top end and later on I purchased one of your timing gauge kits and checked the timing. There was a 2 degree difference [cold] between the two banks as per your photo's and I seem to remember the timing needles sat just like your photo shows but I will check that again when the weather cools down a bit in a few more weeks time.

The PK32VR is a great tool and I would recommend it to anyone on the list who is vaguely DIY capable. I also support your recommendation to advance the cam for torque on the S4. I may well try that in due course.

Regards and best wishes

Excellent post- very informative. Supports findings on Louie's website and interesting to see your suggested workable limits. I have driven an S4 auto with the cams retarded to give more power and did not like it at all and thus your recommendation for the S4 makes sense.

My GTS chassis is powered by the motor from my [late] 90 S4. It is fitted with the GTS inlet cam and the S4 exhaust. When timing the cam in the main dealers workshop we used the timing settings for the GTS cam. With a lot of guidance from Louie, John [Speake] and Jim C I shark tuned the car with a bit of advance over stock at top end and evenb more mid range until the onset of knocks. I also targetted AFR at 13.5 for top end and about 13 mid range. With a Louie X pipe, big central muffler and a RMB at the rear the end result was very acceptable. I later fitted plenum spacers [no tuning] to gain a little top end and later on I purchased one of your timing gauge kits and checked the timing. There was a 2 degree difference [cold] between the two banks as per your photo's and I seem to remember the timing needles sat just like your photo shows but I will check that again when the weather cools down a bit in a few more weeks time.

The PK32VR is a great tool and I would recommend it to anyone on the list who is vaguely DIY capable. I also support your recommendation to advance the cam for torque on the S4. I may well try that in due course.

Regards and best wishes

Trending Topics

#8

Inventor

Rennlist Member

Rennlist Member

Thread Starter

It is drawing a long bow comparing different sessions , different days , was it the same dyno ? what was the temperature ? barometric pressure , tire temp , gearbox temp , were they the even the same tires?

As an operator you would expect to see anolomies from different sessions , see the scriggly lines , that is obviously traction loss .

Does it have a zero position as default , so you can add or subtract ?

As an operator you would expect to see anolomies from different sessions , see the scriggly lines , that is obviously traction loss .

Does it have a zero position as default , so you can add or subtract ?

The +1░ and 0░ runs were from the same '85 5-speed on different days. (The +?░ run is included to show the effect of too much advance on another '85 5-speed, different dyno, temps, etc.)

Hadn't thought about traction loss for the squiggles. Interesting.

The PK32V'r mounts in place of the distributor rotor to the cam gear hub which is centered on the cam key. (Note that on a non-adjustable 16V cam gear, the small notch at the rear of the gear is also centered on the cam key.) Using the WSM dial indicator method, both banks are advanced ~2░ so the PK32V'r 'zero' is advanced this amount. (The 2░ advance may have been put in to compensate for belt stretch retard at high rpms.)

#9

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Oops.

I rechecked the run dates, and the +1 and zeros may be reversed as to when I reset the timing. (Those could just be from different EZF chips.) I got all excited looking at the numbers, but forgot the run counts were reset by my dyno guy.

I know from previous dyno sessions that advancing will raise the TQ peak at the expense of HP, but now I can't say for certain that retarding slightly will reverse the TQ/HP peaks, or just make it lose power. (5░ retard did make it lose bigtime.) I'll try and hit the dyno next week, (uh-gain) and see...

I rechecked the run dates, and the +1 and zeros may be reversed as to when I reset the timing. (Those could just be from different EZF chips.) I got all excited looking at the numbers, but forgot the run counts were reset by my dyno guy.

I know from previous dyno sessions that advancing will raise the TQ peak at the expense of HP, but now I can't say for certain that retarding slightly will reverse the TQ/HP peaks, or just make it lose power. (5░ retard did make it lose bigtime.) I'll try and hit the dyno next week, (uh-gain) and see...

#11

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Terry - I can't afford the exchange rate!

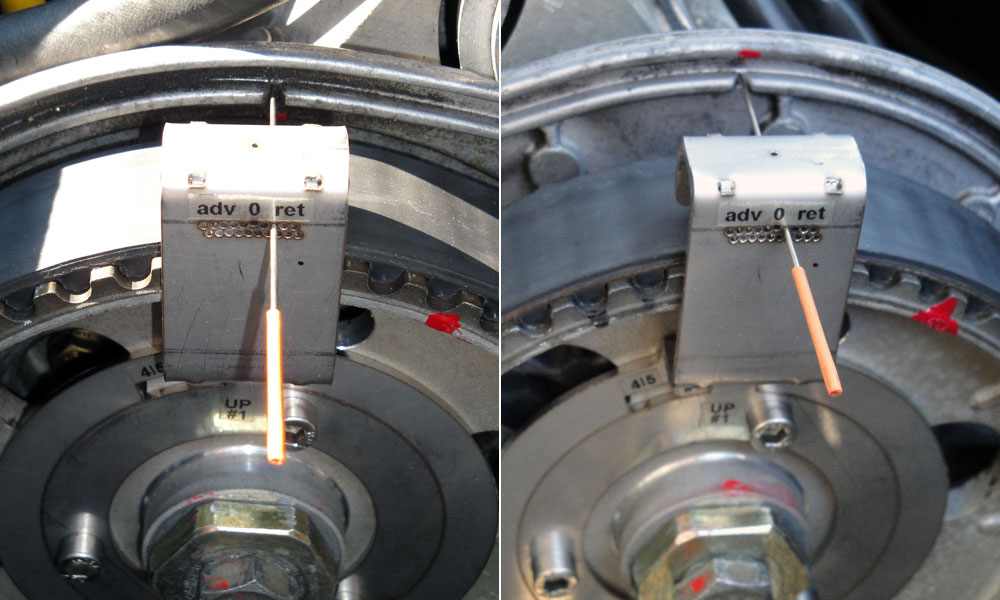

It only took ~4 hours (oh, my back!), but I adjusted my '86.5 5-speed to -2░ (-4░/-2░ cold).

It is difficult to retard the 5-8 side accurately because spring pressure tries to advance it to the end of the slot. Trying to retard just loosens the bolt. I finally was able to do it by retarding the timing approx. 4░, then advancing accurately to -2░. To retard, I loosened the cam bolt and clamp ring bolts, then turned the crank CW until the gear turned, but the cam was kept stationary by spring pressure. (I then torqued the cam bolt to 47ftlb, tightened the clamp ring bolts, cranked the engine by hand around to #1 0|T again, and installed the adjustment spacer.) To advance, I held with a 30mm wrench while applying slight pressure with a 17 - I left a small amount of tension on one of the clamp ring bolts to slow the movement down (this was the key in the end).

In this case, the procedure was complicated by the cams being set to +2░ because a mechanic in the past strung the belt one tooth off, and 'fixed' it by adjusting to the max in the slot. In order to restring the belt over the cam gears w/o removing the center cover...I removed the tensioner/damper, slid the belt off the 1-4 gear, back on the correct tooth (mark the belt and tooth to move to), did the same for the 5-8, (slowly) reset the T/D in a vice, reinstalled it... (JEDI MASTER ON CONTROLLED COURSE. DO NOT ATTEMPT THIS AT HOME!)

(JEDI MASTER ON CONTROLLED COURSE. DO NOT ATTEMPT THIS AT HOME!)

It only took ~4 hours (oh, my back!), but I adjusted my '86.5 5-speed to -2░ (-4░/-2░ cold).

It is difficult to retard the 5-8 side accurately because spring pressure tries to advance it to the end of the slot. Trying to retard just loosens the bolt. I finally was able to do it by retarding the timing approx. 4░, then advancing accurately to -2░. To retard, I loosened the cam bolt and clamp ring bolts, then turned the crank CW until the gear turned, but the cam was kept stationary by spring pressure. (I then torqued the cam bolt to 47ftlb, tightened the clamp ring bolts, cranked the engine by hand around to #1 0|T again, and installed the adjustment spacer.) To advance, I held with a 30mm wrench while applying slight pressure with a 17 - I left a small amount of tension on one of the clamp ring bolts to slow the movement down (this was the key in the end).

In this case, the procedure was complicated by the cams being set to +2░ because a mechanic in the past strung the belt one tooth off, and 'fixed' it by adjusting to the max in the slot. In order to restring the belt over the cam gears w/o removing the center cover...I removed the tensioner/damper, slid the belt off the 1-4 gear, back on the correct tooth (mark the belt and tooth to move to), did the same for the 5-8, (slowly) reset the T/D in a vice, reinstalled it...

(JEDI MASTER ON CONTROLLED COURSE. DO NOT ATTEMPT THIS AT HOME!)

(JEDI MASTER ON CONTROLLED COURSE. DO NOT ATTEMPT THIS AT HOME!)

Last edited by PorKen; 09-06-2011 at 02:37 AM.

#12

Rennlist Member

How would you get the belt one tooth off? I mean, put it on, keeping it tight from gear to gear to gear. It seems you would really have to try to do this.

#13

Inventor

Rennlist Member

Rennlist Member

Thread Starter

I've done it quite a few times (in the hundreds of times I've R&R'ed the belt for all the prototyping I've done). Usually it's one tooth retard, because it wasn't quite tight between the oil pump and the 5-8 gear.

#14

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

It only took ~4 hours (oh, my back!), but I adjusted my '86.5 5-speed to -2░ (-4░/-2░ cold).

It is difficult to retard the 5-8 side accurately because spring pressure tries to advance it to the end of the slot. Trying to retard just loosens the bolt. I finally was able to do it by retarding the timing approx. 4░, then advancing accurately to -2░. To retard, I loosened the cam bolt and clamp ring bolts, then turned the crank CW until the gear turned, but the cam was kept stationary by spring pressure. (I then torqued the cam bolt to 47ftlb, tightened the clamp ring bolts, cranked the engine by hand around to #1 0|T again, and installed the adjustment spacer.) To advance, I held with a 30mm wrench while applying slight pressure with a 17 - I left a small amount of tension on one of the clamp ring bolts to slow the movement down (this was the key in the end).

It is difficult to retard the 5-8 side accurately because spring pressure tries to advance it to the end of the slot. Trying to retard just loosens the bolt. I finally was able to do it by retarding the timing approx. 4░, then advancing accurately to -2░. To retard, I loosened the cam bolt and clamp ring bolts, then turned the crank CW until the gear turned, but the cam was kept stationary by spring pressure. (I then torqued the cam bolt to 47ftlb, tightened the clamp ring bolts, cranked the engine by hand around to #1 0|T again, and installed the adjustment spacer.) To advance, I held with a 30mm wrench while applying slight pressure with a 17 - I left a small amount of tension on one of the clamp ring bolts to slow the movement down (this was the key in the end).

#15

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Definately need to recheck after any adjustment, especially when doing the 1-4 side. (Spinning the engine with the starter is key here.) The 1-4 side is a pain because the force of adjusting changes the tension on the belt, retarding it.

I usually add 2░ advance to what I actually want on the 1-4. This time, I had to add 4░. IE I set it to zero to get -4░ after spinning the engine.

It is so nice to have it finally adjusted correctly after so many tries. When both sides looked like the picture above, I sat down on the ground and chuckled like a mad man.

I usually add 2░ advance to what I actually want on the 1-4. This time, I had to add 4░. IE I set it to zero to get -4░ after spinning the engine.

It is so nice to have it finally adjusted correctly after so many tries. When both sides looked like the picture above, I sat down on the ground and chuckled like a mad man.