Just a preview of an SC setup

#48

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Feb 2004

Location: Monterey Peninsula, CA

Posts: 2,374

Likes: 0

Received 16 Likes

on

12 Posts

Pics again from left to right..

This is the modified water bridge.. The curved piece almost serves as a cradle for the blower snout. The outlets are AN-16, and the inlet is stock for now. (I have plans for a reverse flow - heads first - cooling with an electric water pump. I would delete the stock pump by removing the impeller, installing a much beefier bearing, and not allowing the bearing to see any water. The bearing would just serve as an idler with the old WP pulley... But that will have to wait even though the modified pump was done in CAD as I have too much to do at the moment to get the car going again before I leave next two weeks for europe..)

The top view of the water bridge as you can see, is tapped for stock coolant sensors. There needs to be one more line tapped to the bridge to attach the small hose going to the coolant reservoir. (I will do this by the weekend, as I am figuring out the best spot to tap for the line..

The fuel line was modified to attach AN-8 lines for part of the system. There is a metric bubble to AN-8 on the fender wall, and an adapter fitting to the front fuel dampner. The fuel line actually goes behind the water inlet and along the cambelt cover so it can be out of the way of the SC belt etc...

The revised system I will install has all AN-8 fuel lines from the pump to the motor, but I have not plumbed it all yet, as it is not neccessary at this very second to run the car. (I will do that once the Compressor and intake is ready to be installed as I may have to juggle a few pieces etc. as I may feed the fuel line from the center of the rails to avoid pressure differences from the front to the rear of the rail, or 1-4 cyl and 5-8 cyls). That will be relatively easy as I have all the AN hoses in boxes in the garage..

Now I must go to sleep...!!!

Thanks all!

Cheers,

This is the modified water bridge.. The curved piece almost serves as a cradle for the blower snout. The outlets are AN-16, and the inlet is stock for now. (I have plans for a reverse flow - heads first - cooling with an electric water pump. I would delete the stock pump by removing the impeller, installing a much beefier bearing, and not allowing the bearing to see any water. The bearing would just serve as an idler with the old WP pulley... But that will have to wait even though the modified pump was done in CAD as I have too much to do at the moment to get the car going again before I leave next two weeks for europe..)

The top view of the water bridge as you can see, is tapped for stock coolant sensors. There needs to be one more line tapped to the bridge to attach the small hose going to the coolant reservoir. (I will do this by the weekend, as I am figuring out the best spot to tap for the line..

The fuel line was modified to attach AN-8 lines for part of the system. There is a metric bubble to AN-8 on the fender wall, and an adapter fitting to the front fuel dampner. The fuel line actually goes behind the water inlet and along the cambelt cover so it can be out of the way of the SC belt etc...

The revised system I will install has all AN-8 fuel lines from the pump to the motor, but I have not plumbed it all yet, as it is not neccessary at this very second to run the car. (I will do that once the Compressor and intake is ready to be installed as I may have to juggle a few pieces etc. as I may feed the fuel line from the center of the rails to avoid pressure differences from the front to the rear of the rail, or 1-4 cyl and 5-8 cyls). That will be relatively easy as I have all the AN hoses in boxes in the garage..

Now I must go to sleep...!!!

Thanks all!

Cheers,

#49

Addict

Rennlist Member

Rennlist Member

Richard,

I ran all new -8 AN from the back to the front, then split to -6 AN at the fuel rail. I removed both dampners, and just have a fuel pressure regulator.

I ran all new -8 AN from the back to the front, then split to -6 AN at the fuel rail. I removed both dampners, and just have a fuel pressure regulator.

#50

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Feb 2004

Location: Monterey Peninsula, CA

Posts: 2,374

Likes: 0

Received 16 Likes

on

12 Posts

Hi George,

Good to know your setup is similar.. I am planning AN-8 send and return, and I have an Aeromotive FPR as well. I was concerned about injector chatter, as well as the leaning of the cylinders from 1-4 and 5-8..

Say, have you done any data logging on fuel pressure, inlet air temperature, compressor airflow, afr and engine rpm?

I am going to need to understand what the engine likes so I can calibrate the Motec.. As you know, data patterns are going to be very helpful...

Thanks,

Good to know your setup is similar.. I am planning AN-8 send and return, and I have an Aeromotive FPR as well. I was concerned about injector chatter, as well as the leaning of the cylinders from 1-4 and 5-8..

Say, have you done any data logging on fuel pressure, inlet air temperature, compressor airflow, afr and engine rpm?

I am going to need to understand what the engine likes so I can calibrate the Motec.. As you know, data patterns are going to be very helpful...

Thanks,

#51

Addict

Rennlist Member

Rennlist Member

Richard,

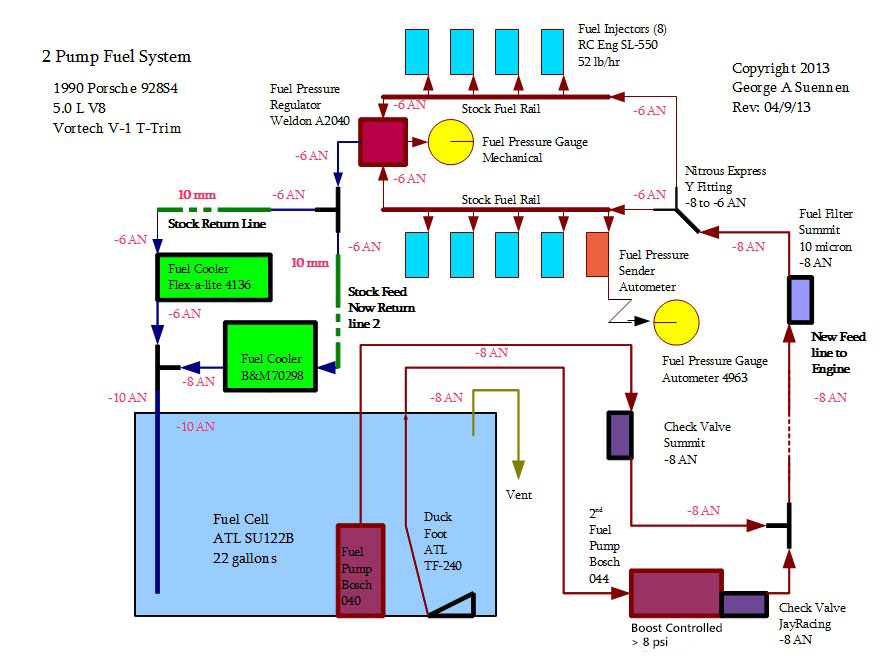

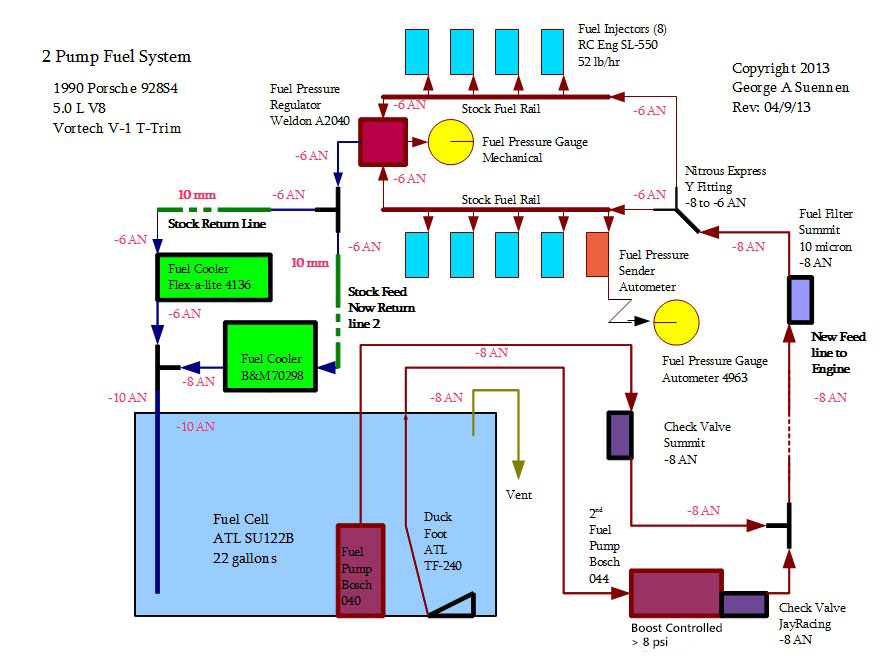

I did use a Aeromotive fuel pressure regulator, but have since switched to a Weldon A2040 (120 psi) unit. I was having trouble keeping the fuel pressure high enough, so tried a few different regulators. Of course it turned out the fuel pump couldn't pump enough fuel, so now I run two Bosch fuel pumps in parallel. Both are switched in the cabin, so I can run with 1 while cruising and 2 when under heavy load. To return the fuel, I use both the original feed line and the old return line and teeing them in the back (-10 AN) before going into the fuel cell. Here is a drawing of my current fuel system:

For what it's worth, I had originally gone to one big fuel pump, but was overheating the fuel and causing the fuel pump to cavitate. Tried another brand, and still had the problem, tried a fuel pump controller, and still had the problem. I went to a two 044 fuel pump system, added some fuel coolers, wrapped the exhaust manifold and pipe where it was close to anything fuel related, and insulated the fuel lines. Seems to be more under control, but still have some issues at 7000+ foot elevation. This year I switched out the in-tank 044 for a 040 unit and rerouted the fuel line to avoid being close to the exhaust manifold.

Hopefully this will cure my fuel problems...

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

http://928.jorj7.com

I did use a Aeromotive fuel pressure regulator, but have since switched to a Weldon A2040 (120 psi) unit. I was having trouble keeping the fuel pressure high enough, so tried a few different regulators. Of course it turned out the fuel pump couldn't pump enough fuel, so now I run two Bosch fuel pumps in parallel. Both are switched in the cabin, so I can run with 1 while cruising and 2 when under heavy load. To return the fuel, I use both the original feed line and the old return line and teeing them in the back (-10 AN) before going into the fuel cell. Here is a drawing of my current fuel system:

For what it's worth, I had originally gone to one big fuel pump, but was overheating the fuel and causing the fuel pump to cavitate. Tried another brand, and still had the problem, tried a fuel pump controller, and still had the problem. I went to a two 044 fuel pump system, added some fuel coolers, wrapped the exhaust manifold and pipe where it was close to anything fuel related, and insulated the fuel lines. Seems to be more under control, but still have some issues at 7000+ foot elevation. This year I switched out the in-tank 044 for a 040 unit and rerouted the fuel line to avoid being close to the exhaust manifold.

Hopefully this will cure my fuel problems...

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

http://928.jorj7.com

#52

Addict

Rennlist Member

Rennlist Member

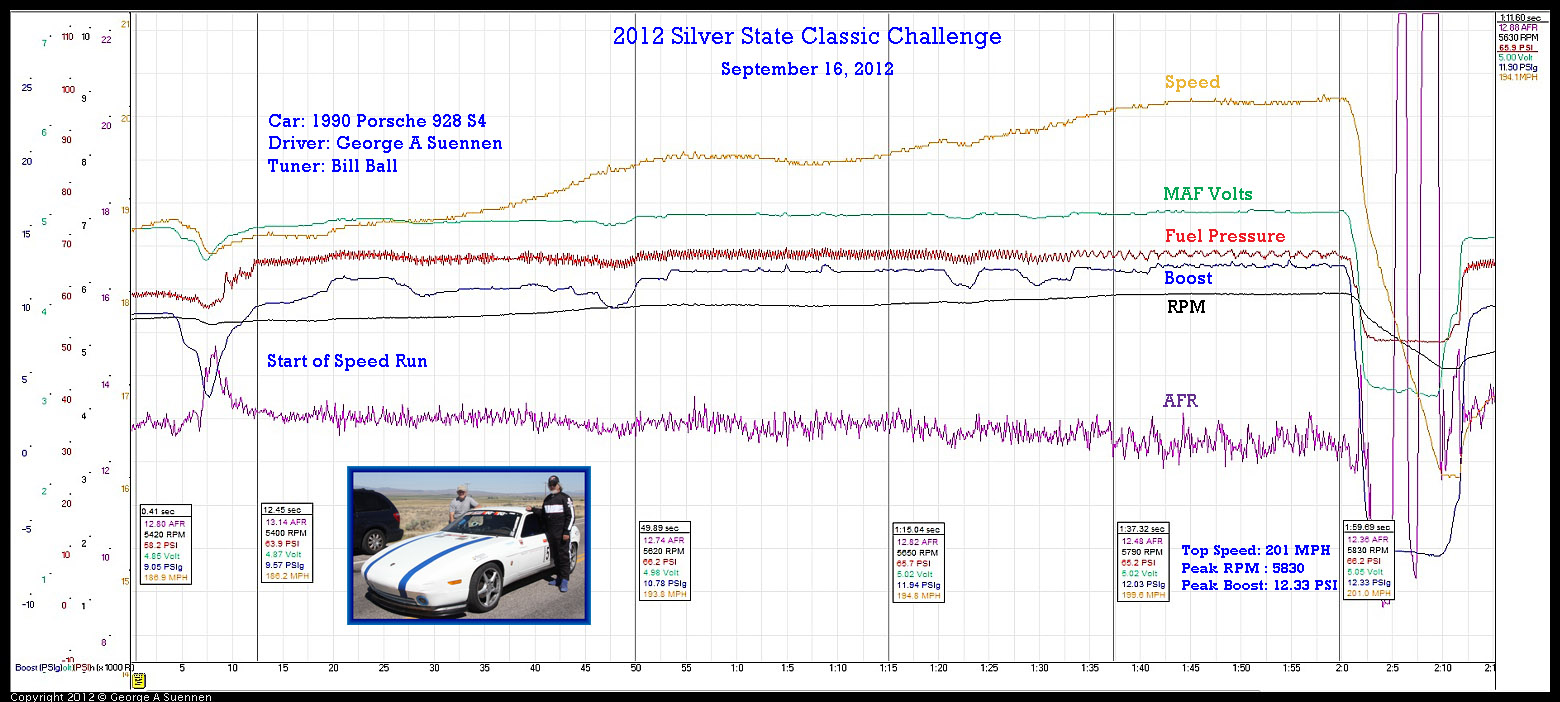

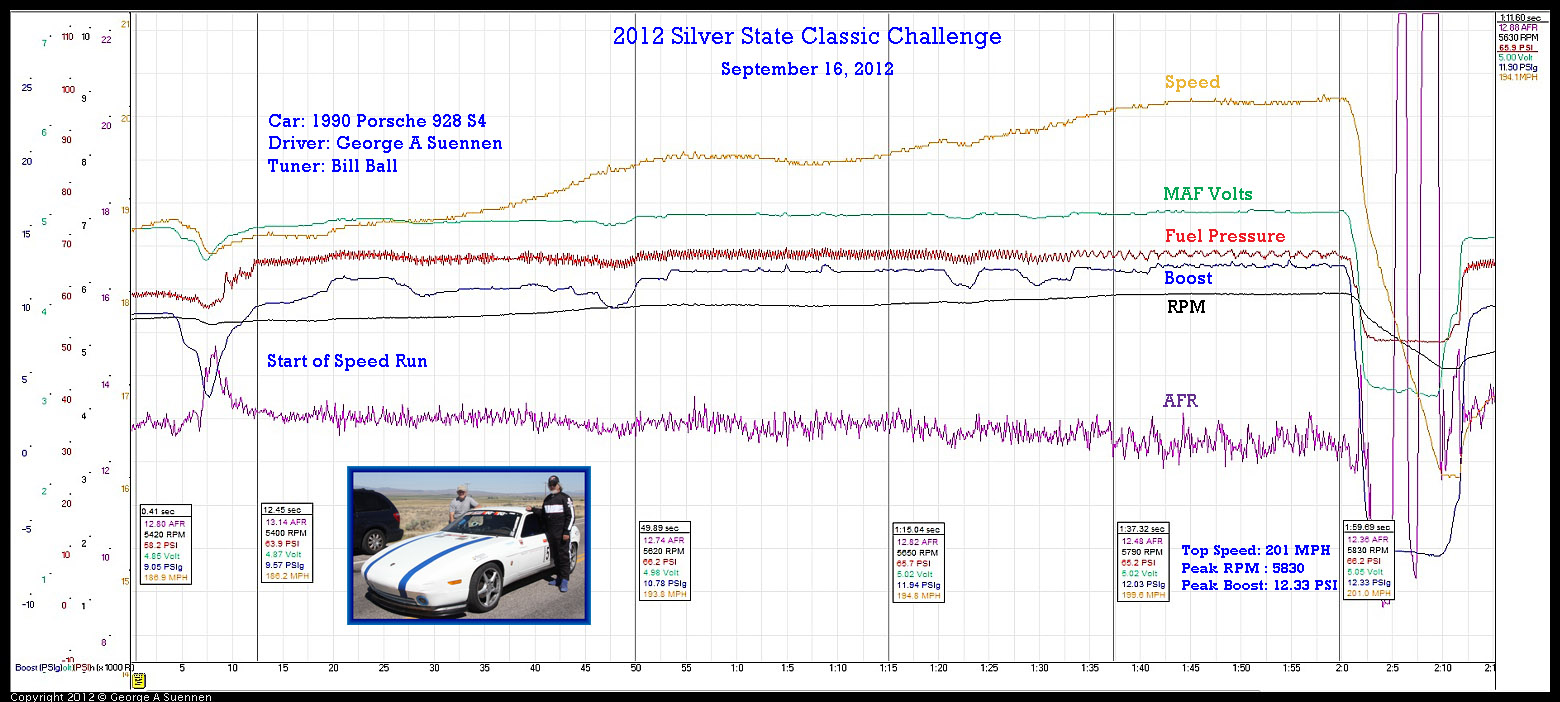

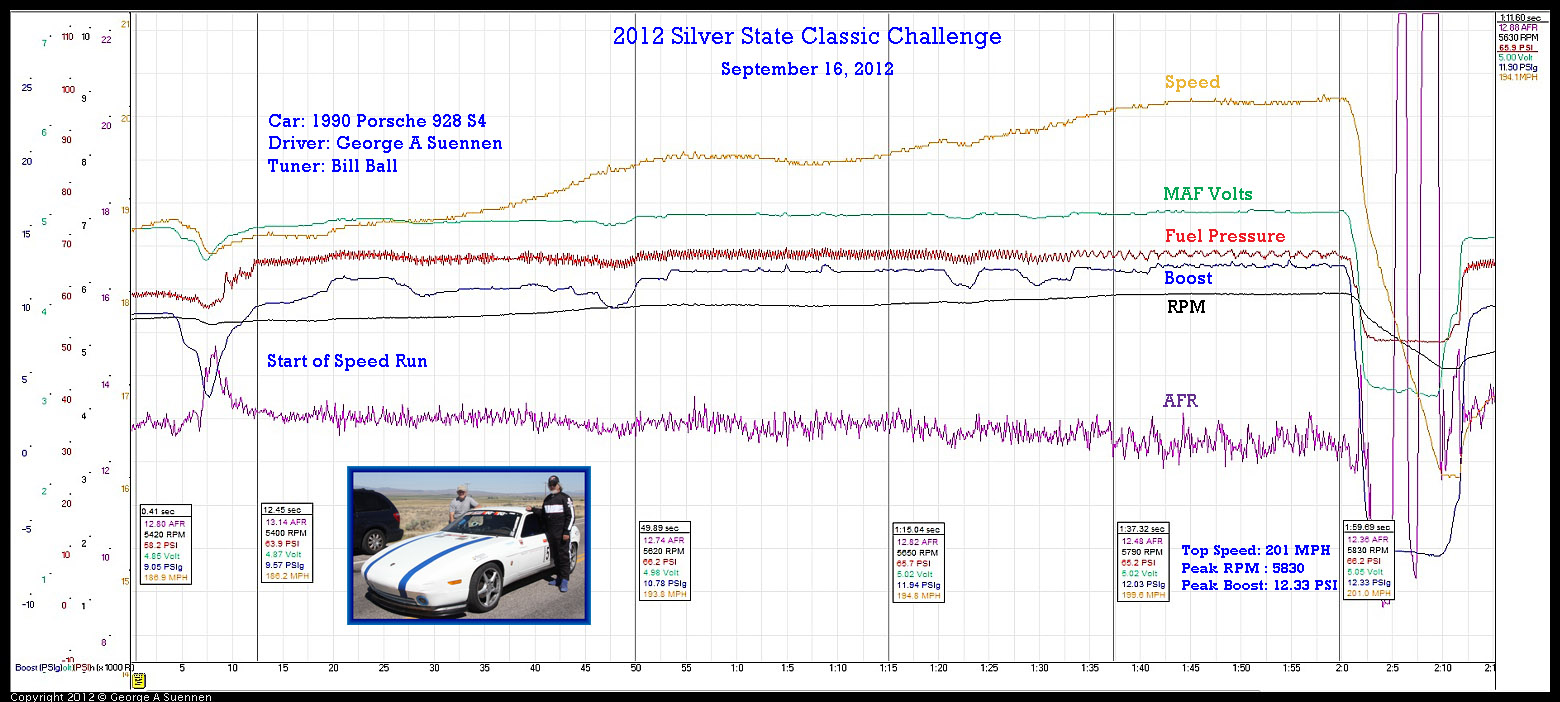

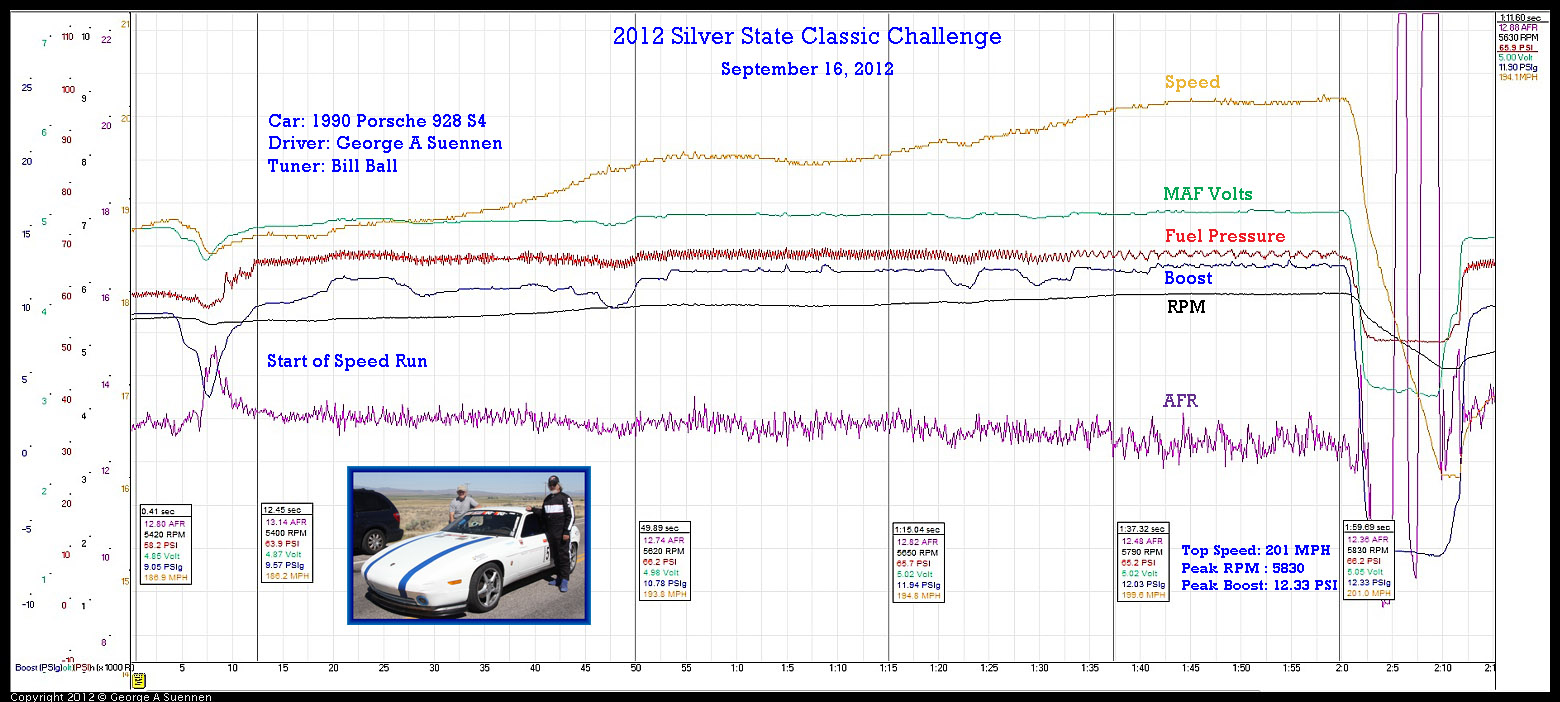

As for tuning and logs, Bill and I dyno the car a few of times a year. I log fuel pressure, MAF voltage, boost, RPM, and AFR with the LM-1/LMA-3. I monitor air intake temps (by a gauge), but don't log it. The air temp sensor is on the output of the intercooler. But since I'm also using water/methanol injection, that isn't true intake air temp. Here is the log of my last speed run from the 2012 Silver State ORR:

Bill runs the Sharktuner software on his laptop, has logs from our last few dynos. So we have more info, just not available for publication...

Bill runs the Sharktuner software on his laptop, has logs from our last few dynos. So we have more info, just not available for publication...

#54

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Feb 2004

Location: Monterey Peninsula, CA

Posts: 2,374

Likes: 0

Received 16 Likes

on

12 Posts

Hi George,

That definitely helps me to understand your system...

I am thinking of a couple of slightly different paths, but with same effect. I also want to avoid boiling the fuel by increasing the pressure too much, however, maintain an increase in flow..

I was thinking of two 044 pumps, one for each rail. With a couple check valves and an activation signal from the ECU in place of a manual switch, or even a hobbs switch, one pump per rail should suffice based on my calculations.

I hope your FP gets solved at 7000' elev..

BTW, What issues are you having? Fuel starvation, pressure drop, lean out, or? How much power is the car making now?

If a flow issue, after looking at your schematic, I would look to switch out the current rails and put in AN-8 rails...

Is the 040 pump a larger unit than the 044? (I have the 044 pump installed, and I'm pretty sure it's good to support 500HP in most conditions.)

BTW, I am also looking at running the pumps in series...

Thanks again!

That definitely helps me to understand your system...

I am thinking of a couple of slightly different paths, but with same effect. I also want to avoid boiling the fuel by increasing the pressure too much, however, maintain an increase in flow..

I was thinking of two 044 pumps, one for each rail. With a couple check valves and an activation signal from the ECU in place of a manual switch, or even a hobbs switch, one pump per rail should suffice based on my calculations.

I hope your FP gets solved at 7000' elev..

BTW, What issues are you having? Fuel starvation, pressure drop, lean out, or? How much power is the car making now?

If a flow issue, after looking at your schematic, I would look to switch out the current rails and put in AN-8 rails...

Is the 040 pump a larger unit than the 044? (I have the 044 pump installed, and I'm pretty sure it's good to support 500HP in most conditions.)

BTW, I am also looking at running the pumps in series...

Thanks again!

#55

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Feb 2004

Location: Monterey Peninsula, CA

Posts: 2,374

Likes: 0

Received 16 Likes

on

12 Posts

As for tuning and logs, Bill and I dyno the car a few of times a year. I log fuel pressure, MAF voltage, boost, RPM, and AFR with the LM-1/LMA-3. I monitor air intake temps (by a gauge), but don't log it. The air temp sensor is on the output of the intercooler. But since I'm also using water/methanol injection, that isn't true intake air temp. Here is the log of my last speed run from the 2012 Silver State ORR:

Bill runs the Sharktuner software on his laptop, has logs from our last few dynos. So we have more info, just not available for publication...

Bill runs the Sharktuner software on his laptop, has logs from our last few dynos. So we have more info, just not available for publication...

I wont be using methanol, but I do have monitoring specced for quite a few variables as well... Hard to tell what the Methanol is doing in relation to the other variables, but I guess it could be claculated out in an afternoon if you monitor the methanol use as well as the pressure etc..

Definitely Interesting stuff..

Thanks!

#56

Addict

Rennlist Member

Rennlist Member

Richard,

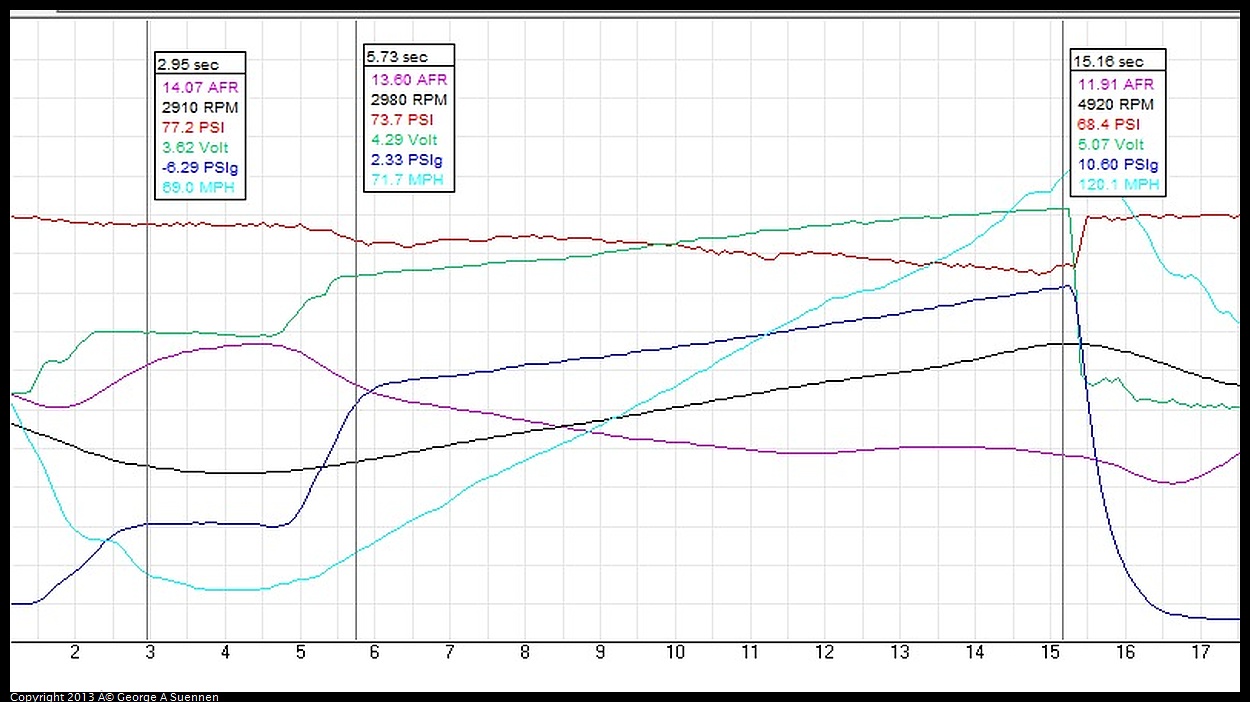

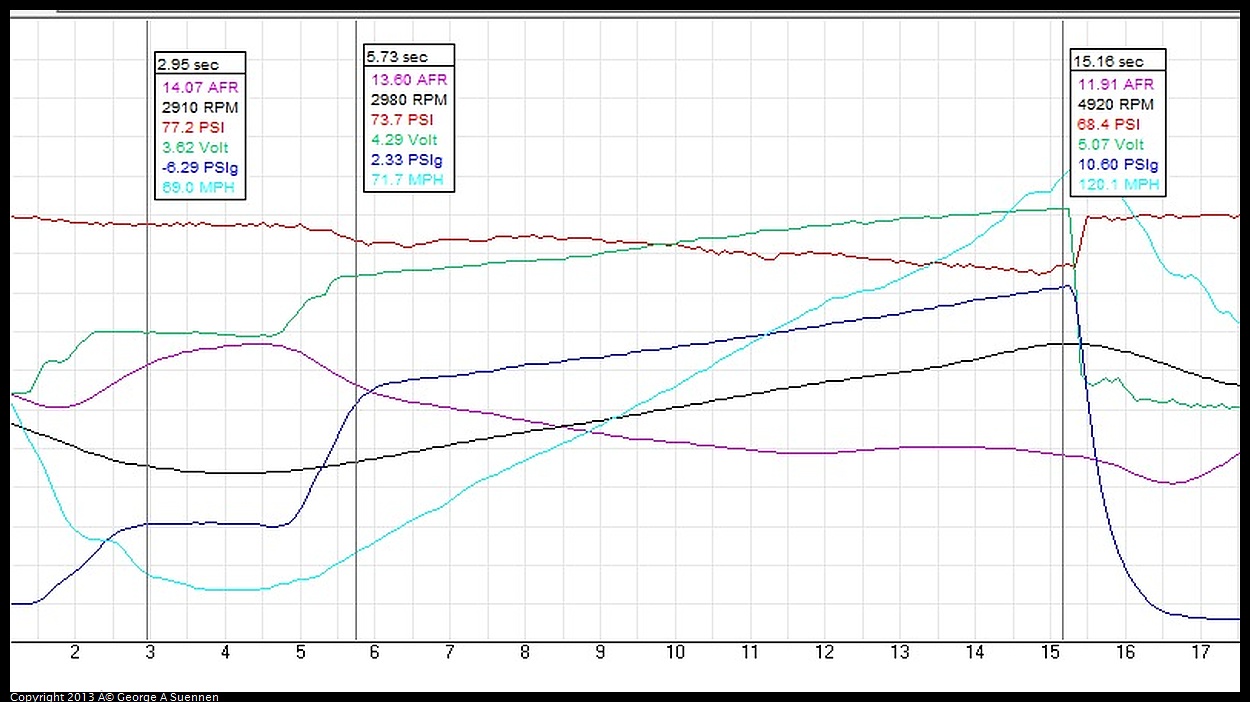

The fuel pressure was dropping as the boost increase, which is the opposite of what should have been happening. We had to increase the injector duty cycle to compensate and try to keep the AFR in the desired range. Here is a run that shows the fuel pressure drop:

Which then caused the fuel pressure to drop more...

Adding two pumps solved this problem. The Bosch 040 pump was designed to be an in-tank pump. It's rated similar to the 044, but the flow drops off faster as the fuel pressure increases.

The highest dyno run on this car measured 531 rwhp, but it was knocking a lot when under load. We've dialed back the ignition timing (a lot) and it's now making in the 460-480 rwhp range, but will run there for a long time. I hope to change the cams this summer and get it back to the 520+ rwhp range.

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

http://928.jorj7.com

The fuel pressure was dropping as the boost increase, which is the opposite of what should have been happening. We had to increase the injector duty cycle to compensate and try to keep the AFR in the desired range. Here is a run that shows the fuel pressure drop:

Which then caused the fuel pressure to drop more...

Adding two pumps solved this problem. The Bosch 040 pump was designed to be an in-tank pump. It's rated similar to the 044, but the flow drops off faster as the fuel pressure increases.

The highest dyno run on this car measured 531 rwhp, but it was knocking a lot when under load. We've dialed back the ignition timing (a lot) and it's now making in the 460-480 rwhp range, but will run there for a long time. I hope to change the cams this summer and get it back to the 520+ rwhp range.

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

http://928.jorj7.com

Hi George,

That definitely helps me to understand your system...

I am thinking of a couple of slightly different paths, but with same effect. I also want to avoid boiling the fuel by increasing the pressure too much, however, maintain an increase in flow..

I was thinking of two 044 pumps, one for each rail. With a couple check valves and an activation signal from the ECU in place of a manual switch, or even a hobbs switch, one pump per rail should suffice based on my calculations.

I hope your FP gets solved at 7000' elev..

BTW, What issues are you having? Fuel starvation, pressure drop, lean out, or? How much power is the car making now?

If a flow issue, after looking at your schematic, I would look to switch out the current rails and put in AN-8 rails...

Is the 040 pump a larger unit than the 044? (I have the 044 pump installed, and I'm pretty sure it's good to support 500HP in most conditions.)

BTW, I am also looking at running the pumps in series...

Thanks again!

That definitely helps me to understand your system...

I am thinking of a couple of slightly different paths, but with same effect. I also want to avoid boiling the fuel by increasing the pressure too much, however, maintain an increase in flow..

I was thinking of two 044 pumps, one for each rail. With a couple check valves and an activation signal from the ECU in place of a manual switch, or even a hobbs switch, one pump per rail should suffice based on my calculations.

I hope your FP gets solved at 7000' elev..

BTW, What issues are you having? Fuel starvation, pressure drop, lean out, or? How much power is the car making now?

If a flow issue, after looking at your schematic, I would look to switch out the current rails and put in AN-8 rails...

Is the 040 pump a larger unit than the 044? (I have the 044 pump installed, and I'm pretty sure it's good to support 500HP in most conditions.)

BTW, I am also looking at running the pumps in series...

Thanks again!

#57

Addict

Rennlist Member

Rennlist Member

Richard,

The water/methanol allowed me to run pump gas instead of racing gas and increase the ignition timing while still keeping knocks way down and the AFR in the 12.0-12.8 range. So it was a good move.

Sorry you can't make Sharks in the Park, it's been a while since we talked.

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

http://928.jorj7.com

The water/methanol allowed me to run pump gas instead of racing gas and increase the ignition timing while still keeping knocks way down and the AFR in the 12.0-12.8 range. So it was a good move.

Sorry you can't make Sharks in the Park, it's been a while since we talked.

George

90 S4 Grand Prix White (Murf #5)

94 GTS 5-Speed Midnight Blue

http://928.jorj7.com

Ok, got it now.. Methanol as well... Good to know that you have the logs on the laptop.. Too bad I won't be here for SITP.. I would love to look over the logs..

I wont be using methanol, but I do have monitoring specced for quite a few variables as well... Hard to tell what the Methanol is doing in relation to the other variables, but I guess it could be claculated out in an afternoon if you monitor the methanol use as well as the pressure etc..

Definitely Interesting stuff..

Thanks!

I wont be using methanol, but I do have monitoring specced for quite a few variables as well... Hard to tell what the Methanol is doing in relation to the other variables, but I guess it could be claculated out in an afternoon if you monitor the methanol use as well as the pressure etc..

Definitely Interesting stuff..

Thanks!

#58

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Boiling of the fuel has almost nothing to do with fuel pressure, especially when you have big supply and return lines (reducing resistance to flow friction). It happens because under all but WOT conditions the amount of fuel that these high flow pumps deliver WAY exceeds what is needed, so it is recirculated back to the tank over and over and over, gathering heat from the engine compartment and whatever other heat sources. The effect is more pronounced at high altitude due to the lower "boiling point", so that vapor lock is inevitable if you are just cruising along the highway. [Richard: I'm not lecturing here - I know you understand this better than I do, but it may baffle others like it did me for a long time.] We finally nailed this down by monitoring fuel temperature and watching it climb until at between 125 (Aeromotive pump) and 135F (Bosch pump) the pump would get noisy, the fuel pressure would fall until once below ~30 PSI, the injectors would no longer deliver fuel and the car would die. The only solution that worked was two fuel pumps in parallel. For everyday driving, George runs a stock pump or something close to stock. Then when he's racing, he switches on the second pump. And that's only needed at WOT. The car will cruise just fine at 150++ on one essentially stock pump. It all makes sense when you realize that except under WOT conditions, George's car uses little more horsepower than any other. We thought the Aeromotive pump controller, which is boost-controlled, would provide a solution, but it didn't. Two pumps was the answer. I've wondered why Marc and Susan didn't report similar fuel heating issues, nor is it a common issue with other cars running the Silver State. The only difference is George is seriously boosted.

#59

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

and George........nothing to say except

#60

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Feb 2004

Location: Monterey Peninsula, CA

Posts: 2,374

Likes: 0

Received 16 Likes

on

12 Posts

Hi George,

Got it now..

I agree the methanol helps a lot.. (I wanted to do something without the methanol though..)

I see the Fuel pressure go down, and the boost go up.. But I also see the AFR at 11.91... Probably better to discuss over a beer.. Ya, too bad I can't make it to SITP. It's been a while.. When I get back, I will make a trip up north and we can chat...

Good to know on the 040 being in tank... that would make a great series 1 pump with the 044 as series 2..!

Oh, congrats on the 200 club! I want to see more 928's in it...!

I want to see more 928's in it...!

Thanks again!

Got it now..

I agree the methanol helps a lot.. (I wanted to do something without the methanol though..)

I see the Fuel pressure go down, and the boost go up.. But I also see the AFR at 11.91... Probably better to discuss over a beer.. Ya, too bad I can't make it to SITP. It's been a while.. When I get back, I will make a trip up north and we can chat...

Good to know on the 040 being in tank... that would make a great series 1 pump with the 044 as series 2..!

Oh, congrats on the 200 club!

I want to see more 928's in it...!

I want to see more 928's in it...!Thanks again!