'85-'86 32V idle control valve wear

#1

Inventor

Rennlist Member

Rennlist Member

Thread Starter

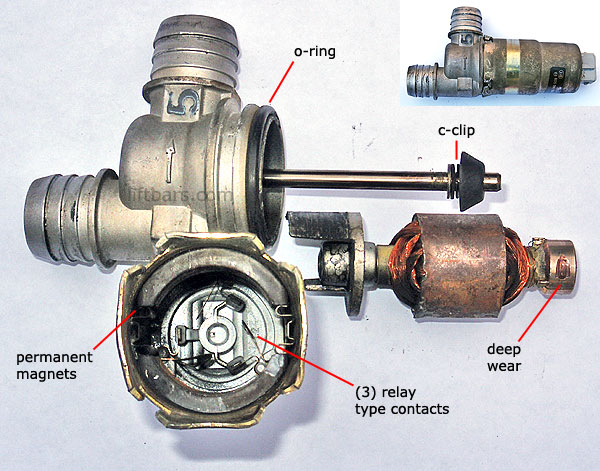

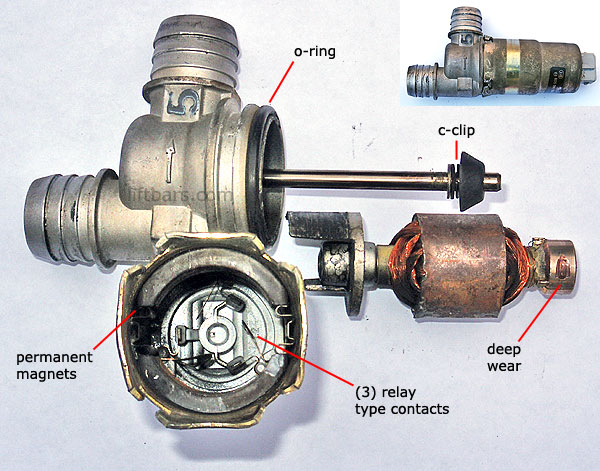

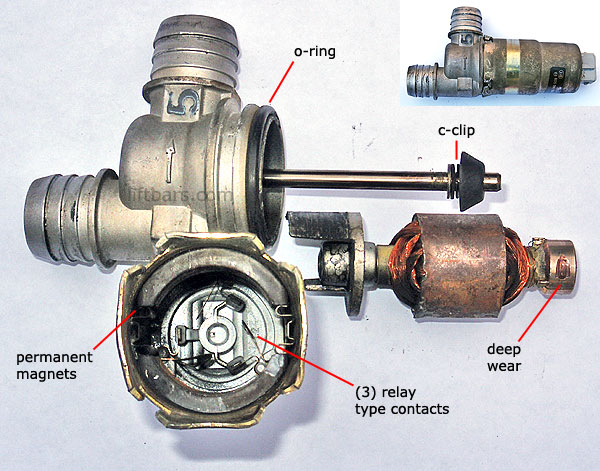

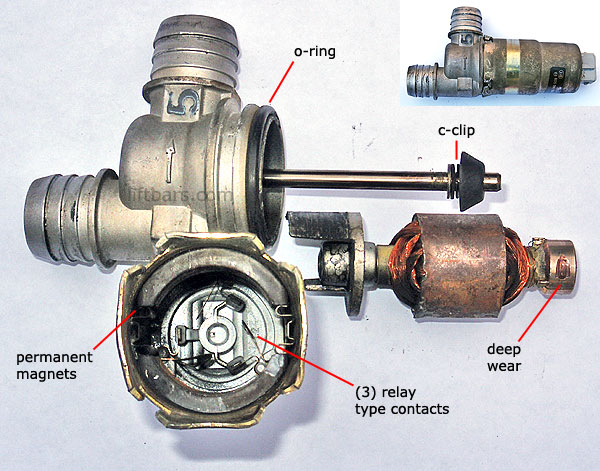

Or: Why you can't fix a 100K mile S3 ICV IAC ISV by cleaning it, or spraying it with WD-40.

If yours is original and your S3 won't idle, just buy a new one. Fuhgeddaboudit.

The LH2.2 32V ICV is a simple reversing motor which opens and closes a passage connecting the lower MAF/TB housing to the distribution pipe 'T' between the side plenums, bypassing the throttle plate. To maintain idle speed, the LH constantly pulses the valve open and closed.

Wear is indicated by difficult cold starting, high idle and/or stalling, and a drop in idle speed when the A/C is switched on.

This is a 150K+ mile ICV with deep wear (>0.5mm) grooves worn into the commutators. So deep the contacts no longer touch, just the edges of the spring arms are touching.

Also, I think that the o-ring seal could leak, and help cause the common S3 high idle?

Note that '87-up LH2.3 uses a simpler, solenoid type, ICV.

If yours is original and your S3 won't idle, just buy a new one. Fuhgeddaboudit.

The LH2.2 32V ICV is a simple reversing motor which opens and closes a passage connecting the lower MAF/TB housing to the distribution pipe 'T' between the side plenums, bypassing the throttle plate. To maintain idle speed, the LH constantly pulses the valve open and closed.

Wear is indicated by difficult cold starting, high idle and/or stalling, and a drop in idle speed when the A/C is switched on.

This is a 150K+ mile ICV with deep wear (>0.5mm) grooves worn into the commutators. So deep the contacts no longer touch, just the edges of the spring arms are touching.

Also, I think that the o-ring seal could leak, and help cause the common S3 high idle?

Note that '87-up LH2.3 uses a simpler, solenoid type, ICV.

Last edited by PorKen; 08-30-2009 at 09:26 PM. Reason: Fuhgeddaboudit.

#3

Nordschleife Master

Or: Why you can't fix a 100K mile S3 ICV IAC ISV by cleaning it, or spraying it with WD-40.

The LH2.2 32V ICV is a simple reversing motor which opens and closes a passage connecting the lower MAF/TB housing to the distribution pipe 'T' between the side plenums, bypassing the throttle plate. To maintain idle speed, the LH constantly pulses the valve open and closed.

Wear is indicated by difficult cold starting, high idle and/or stalling, and a drop in idle speed when the A/C is switched on.

This is a 150K+ mile ICV with deep wear (>0.5mm) grooves worn into the commutators. So deep the contacts no longer touch, just the edges of the spring arms are touching. I think that the o-ring seal may leak, and cause the common S3 high idle.

Note that '87-up LH2.3 uses a simpler, solenoid type, ICV.

The LH2.2 32V ICV is a simple reversing motor which opens and closes a passage connecting the lower MAF/TB housing to the distribution pipe 'T' between the side plenums, bypassing the throttle plate. To maintain idle speed, the LH constantly pulses the valve open and closed.

Wear is indicated by difficult cold starting, high idle and/or stalling, and a drop in idle speed when the A/C is switched on.

This is a 150K+ mile ICV with deep wear (>0.5mm) grooves worn into the commutators. So deep the contacts no longer touch, just the edges of the spring arms are touching. I think that the o-ring seal may leak, and cause the common S3 high idle.

Note that '87-up LH2.3 uses a simpler, solenoid type, ICV.

Thanks so much for posting this. I have wondered what the insides of these things look like. I had a pretty good idea of how they operate but its nice to see whats inside the thing and i like that your dispelling the myth that the WD-40 shot is all you need in some instances. I used WD-40 when i first got my 90 GT running and the idle went from sporadic to uncontrollable. This was unheard of at the time and i have never been able to suggest to anyone to use this idea. When a new one is $150 (I believe the 85-86 S3's are actually cheaper) then it makes sense to me to replace, especially considering the wear and the overall condition of the components inside.

Thanks again for posting pics and your thoughts. This is the content i expect when i come to this site!

#4

Inventor

Rennlist Member

Rennlist Member

Thread Starter

No carbon brushes. Just hard relay type contact buttons which easily wear into the soft copper.

The S4-up regulator has only two wires, whereas the S3 has 3; open, 12V, close.

I'm not sure if the S4-up valve is a solenoid, or a motor, but the 2.3 LH only opens(?) it. A spring closes(?) it.

The S4-up regulator has only two wires, whereas the S3 has 3; open, 12V, close.

I'm not sure if the S4-up valve is a solenoid, or a motor, but the 2.3 LH only opens(?) it. A spring closes(?) it.

#5

Nordschleife Master

As Ken says Ryan, this is only for the S3 (85/86 US)

The 97+ unit can sometimes be revived as the reason it stops responding is a build up of gunk on the piece which moves this adds binding preventing it from moving easily.

And WD-40 will not do much. WD= Water Dispersion, 40 = 40th attempt.

It is best to use something like carb cleaner, or water, or even brake clean, then a shot of penetrating oil or something like that to help keep it free and clear.

The 97+ unit can sometimes be revived as the reason it stops responding is a build up of gunk on the piece which moves this adds binding preventing it from moving easily.

And WD-40 will not do much. WD= Water Dispersion, 40 = 40th attempt.

It is best to use something like carb cleaner, or water, or even brake clean, then a shot of penetrating oil or something like that to help keep it free and clear.

#6

Nordschleife Master

Regarding cleaning, how about a bit more disassembly so we can see what sort of bearing is used between the motor and the valve, and maybe get some insight on how best to try and clean it and with what?

One reason I would skip WD40 is that the residue attracts dirt.

BTW this one looks like water got inside and rusted part of it.

One reason I would skip WD40 is that the residue attracts dirt.

BTW this one looks like water got inside and rusted part of it.

#7

Advanced

Join Date: Jun 2009

Location: Granbury, Texas

Posts: 58

Likes: 0

Received 0 Likes

on

0 Posts

Great post!

Ive been fighting idle problems in my 1986.5. I figured sense the car hunted for idle it meant that the icv was trying to open and close properly, and by cleaning the gunk out you were eliminating friction and solving the problem. As its been said before, a picture is worth a thousand words. I guess i just took a step backwards on my checklist.

------------------------------------

Black 1986.5 AT

Ive been fighting idle problems in my 1986.5. I figured sense the car hunted for idle it meant that the icv was trying to open and close properly, and by cleaning the gunk out you were eliminating friction and solving the problem. As its been said before, a picture is worth a thousand words. I guess i just took a step backwards on my checklist.

------------------------------------

Black 1986.5 AT

Trending Topics

#8

Craic Head

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Ken,

Good to know, thanks.

Does this mean the original 'Vintage' Porsche 928 ISV that I have on the shelf now isn't going to be worth something someday?

Good to know, thanks.

Does this mean the original 'Vintage' Porsche 928 ISV that I have on the shelf now isn't going to be worth something someday?

#9

Team Owner

Ken how did you pry the tabs back?

There are 8 of them I got one pried back the rest dont want to budge....

There are 8 of them I got one pried back the rest dont want to budge....

#10

Shameful Thread Killer

Rennlist Member

Rennlist Member

Can you send me that one? I may have a way to refurbish it that will keep them alive. The motor windings are presumed to be still ok. PM me if you want me to fiddle with it. I'll send you an address.

#11

Inventor

Rennlist Member

Rennlist Member

Thread Starter

I used a small sacrificial screwdriver to bend up the tabs initially. An awl might work well. If you want to put it back together, scribe the can and housing before bending up the tabs. There are no alignment marks.

I damaged the motor on the one pictured trying unsuccessfully to get it out of the housing. The chrome axle is pressed into the housing. The axle doesn't turn. The bearing on one side is the commutator, not sure what's on the other end. The armature and valve are one piece, and rotate on the axle.

This one was way too worn, but I think you could get a little more life out of one that had some material left on the spring pads. The commutators are longer that the wear area - if you could turn the can a little, you might get the 'brushes' out of their ruts. Scribe the can and housing, pry up the CCW tabs slightly, carefully rotate the can CW ~2mm somehow, without crushing, then press/tap the tabs back against the housing.

I damaged the motor on the one pictured trying unsuccessfully to get it out of the housing. The chrome axle is pressed into the housing. The axle doesn't turn. The bearing on one side is the commutator, not sure what's on the other end. The armature and valve are one piece, and rotate on the axle.

This one was way too worn, but I think you could get a little more life out of one that had some material left on the spring pads. The commutators are longer that the wear area - if you could turn the can a little, you might get the 'brushes' out of their ruts. Scribe the can and housing, pry up the CCW tabs slightly, carefully rotate the can CW ~2mm somehow, without crushing, then press/tap the tabs back against the housing.

#12

Former Vendor

Join Date: Aug 2007

Location: Danbury,CT

Posts: 957

Likes: 0

Received 0 Likes

on

0 Posts

I have one I took apart with the same issues,pm me address and I'll send it off.Ed

#13

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Doh! There is a C-clip on the end of the assembly. The armature just slides off.

Pic is updated.

Pic is updated.

#14

Team Owner

Ken i drilled small holes on each tab and then bent them out. Mine looks to be in similar condition though not as much rust on the armature. There are deep gouges on the slip ring areas.

Looks like its time for a new part.

I think they could have come up with a better way to have the contacts touching the rings.

The black plastic wedge looks like its made to spread the contacts apart, so it fits into the housing

Looks like its time for a new part.

I think they could have come up with a better way to have the contacts touching the rings.

The black plastic wedge looks like its made to spread the contacts apart, so it fits into the housing