Phenolic S3 Intake spacer?

#31

My S4 intake is long gone.

You can have anything I have designed, but the port side of my flange is only round right now - and it would need to be hand ported to match.

You can have anything I have designed, but the port side of my flange is only round right now - and it would need to be hand ported to match. But here we have Mr. Ken who has a nearly perfect match to the S3 port, which is only a bit different from the S4 intake port, but has that nice divit already designed in.

#32

Are you thinking of making lower/upper plenum and leg spacers for the S4+ intake?

No, I'm making a whole new int manifold from scratch and need to start

with the intake flanges just like Brendan is doing in his (screw it ) thread.

No, I'm making a whole new int manifold from scratch and need to start

with the intake flanges just like Brendan is doing in his (screw it ) thread.

#33

Inventor

Rennlist Member

Rennlist Member

Thread Starter

I don't have a plotter, so I can't compare it to the gasket, but I think I fixed the offset errors.

YGWYPF, YRMV, YMMV.

http://members.rennlist.org/porken/S3Intake.zip

YGWYPF, YRMV, YMMV.

http://members.rennlist.org/porken/S3Intake.zip

Last edited by PorKen; 09-07-2008 at 07:48 PM.

#34

Inventor

Rennlist Member

Rennlist Member

Thread Starter

I think next time I order some laser cutting, I'll have half a gasket made in 1/8"+ steel. I can bolt that to the intake, and use it as a guide for gasket match grinding.

#35

Thanks Ken.

#36

Inventor

Rennlist Member

Rennlist Member

Thread Starter

I zipped the DXF so the server doesn't puke on it.

Looking at PET, I wonder if the S4's thick gasket, and spacers between the nuts and manifold are for anti-vibration (like the S3's rubber buffers), or insulation, or both?

Looking at PET, I wonder if the S4's thick gasket, and spacers between the nuts and manifold are for anti-vibration (like the S3's rubber buffers), or insulation, or both?

#37

Well, its clear they were concerned over intake manifold temp, since they have a sensor in the S4 manifold for temp, and its tied into the twin fans.

#38

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

when they used a one piece manifold I think they felt they needed to allow movement for the expansion contraction of the block ....

#39

Inventor

Rennlist Member

Rennlist Member

Thread Starter

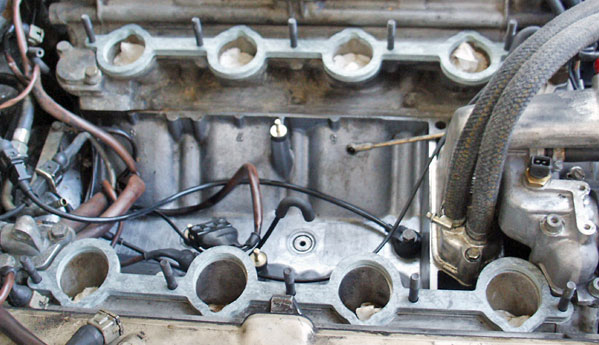

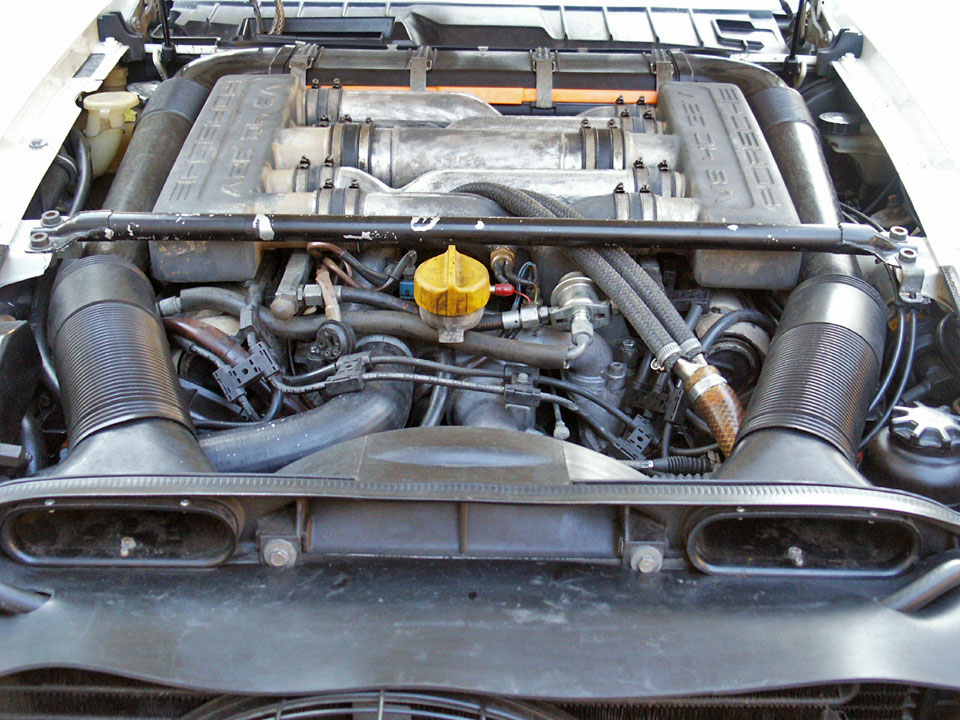

You can see most all the cold intake tricks here.

Intake spacers

No rear hood seal

Radiator(s) covered

Crank vented to atmo

Fuel damper/regulator brackets removed

Split rubber hose over the front metal fuel line

#40

Inventor

Rennlist Member

Rennlist Member

Thread Starter

The intake manifold legs were 40-50░F cooler than the head (IR gun), and it was 90░F out, today. (Unfortunately, I never wrote down what they were before.  ) The metal gas lines were cool to the touch.

) The metal gas lines were cool to the touch.

Definately makes a difference in torque on a hot day. I had the A/C on, and it still chirped the tires when it kicked down as I was getting around someone in city traffic.

I could launch from a dead stop, and the knock light never lit up - with the A/C on!

I still plan on running a hose from behind the engine and blow into the valley.

) The metal gas lines were cool to the touch.

) The metal gas lines were cool to the touch.Definately makes a difference in torque on a hot day. I had the A/C on, and it still chirped the tires when it kicked down as I was getting around someone in city traffic.

I could launch from a dead stop, and the knock light never lit up - with the A/C on!

I still plan on running a hose from behind the engine and blow into the valley.

Last edited by PorKen; 09-17-2008 at 12:37 PM.

#41

Inventor

Rennlist Member

Rennlist Member

Thread Starter

I was looking at using the 'big' empty space under the heater valve for putting a bilge blower, and I got the idea to put a cover to keep heat from rising up past the airbox. I'm not sure if has changed the airbox temps, but it makes for a nice reduction in engine noise inside the cabin at WOT! I'm keeping it.

I'm not going to put a blower under the heater valve. For cooling the intake, I'm going to have to delete the oil fill tower, and plumb a hose in that space. This will be part of some future crank evac system change.

I'm not going to put a blower under the heater valve. For cooling the intake, I'm going to have to delete the oil fill tower, and plumb a hose in that space. This will be part of some future crank evac system change.