how many 7 liter strokers are out there????

#106

Pro

There is great information in this thread of late. What would be cool, is if we could take all of the positive info and pics in this thread and add it to a Stroker Collaboration thread. So that we could see what others are doing. Set some ground rules about trash talking, and the like and keep it fact based. If you post something negative it could only be about your experience, like you tried xyz and y failed. X & Z were good though. A collaborative exchange of information. We would need mod sponsorship to keep the rennlist out of the thread.. LOL

I have tried to post any build pictures I could find here as have others.

#107

Pro

this is great input to the build, so much information in fact that I am not fully following the build spec you are pursuing

Are you building a 7.2 with this lightweight crank and NASCAR rods?

Liners are going to be a completely different approach like the type pictured which all appeared in be joined together at the top ?

If that is the case what is the objective of this approach?

#108

Rennlist Member

Join Date: Feb 2011

Location: Mostly in my workshop located in Sweden.

Posts: 2,226

Received 442 Likes

on

244 Posts

There is great information in this thread of late. What would be cool, is if we could take all of the positive info and pics in this thread and add it to a Stroker Collaboration thread. So that we could see what others are doing. Set some ground rules about trash talking, and the like and keep it fact based. If you post something negative it could only be about your experience, like you tried xyz and y failed. X & Z were good though. A collaborative exchange of information. We would need mod sponsorship to keep the rennlist out of the thread.. LOL

┼ke

#109

Rennlist Member

Join Date: Feb 2011

Location: Mostly in my workshop located in Sweden.

Posts: 2,226

Received 442 Likes

on

244 Posts

Regarding the harmonic balancer I have not come so far but it probably will be 7" ATI Super Damper part no. 917020 with my own custom made hub.

┼ke

#110

Rennlist Member

Join Date: Feb 2011

Location: Mostly in my workshop located in Sweden.

Posts: 2,226

Received 442 Likes

on

244 Posts

Hi Ake

this is great input to the build, so much information in fact that I am not fully following the build spec you are pursuing

Are you building a 7.2 with this lightweight crank and NASCAR rods?

Liners are going to be a completely different approach like the type pictured which all appeared in be joined together at the top ?

If that is the case what is the objective of this approach?

It will be bore 4.250" and stroke 3.750", 426 CI or 7.0 liter.

┼ke

#111

Pro

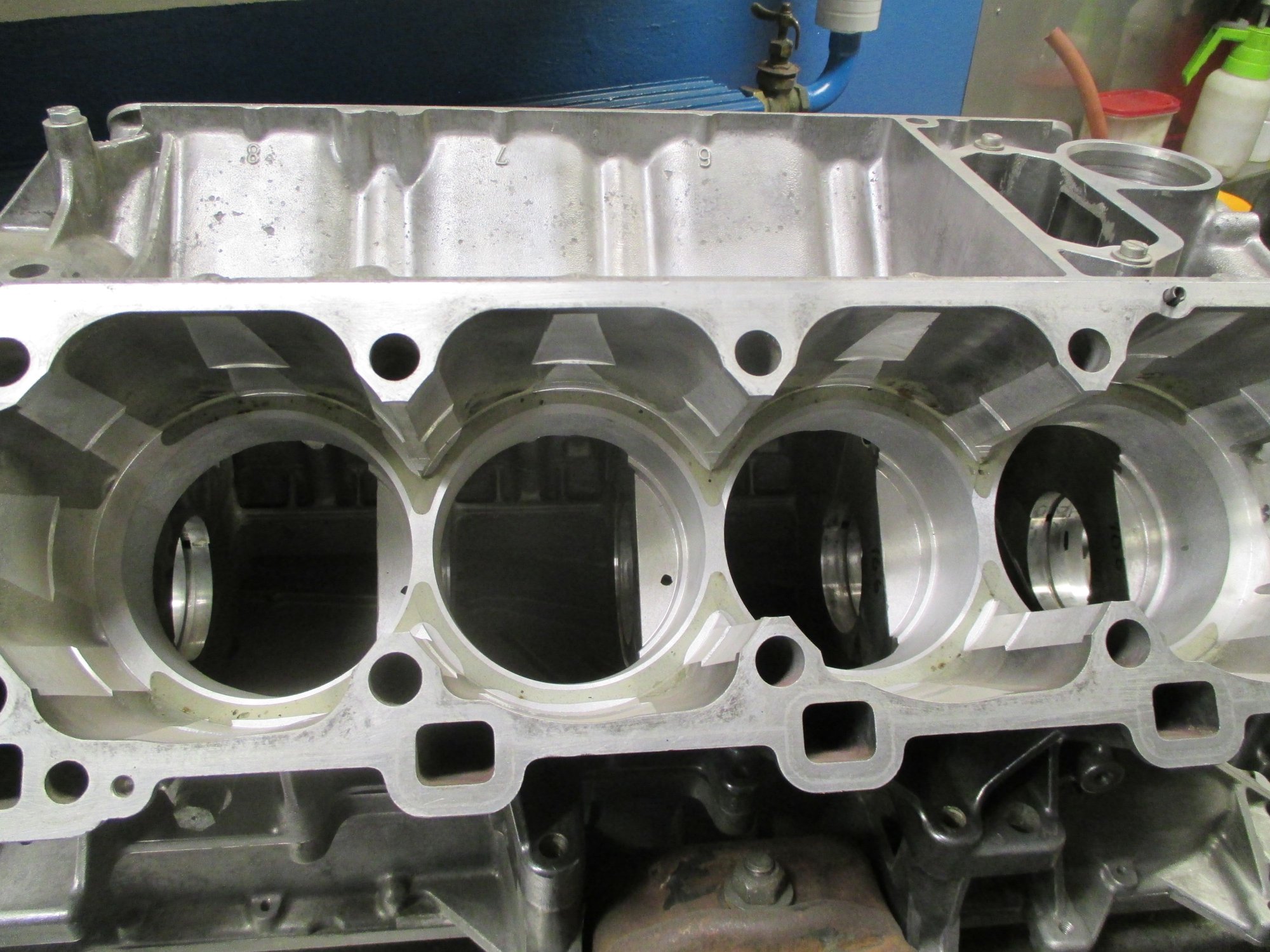

The Volvo insert cylinder block is cast iron. For the 928 I will make aluminium insert cylinder blocks having cast iron sleeves. The insert block will be made from four aluminum cylinders welded together. The advantages I can see are easy to machine and hone the cylinder bores when the insert block is out of the engine block, improved strength, same heat expansion as the engine block, no problems to heat the bulky engine block for the installation of interference fit sleeves not talking about pressing down the sleeves (post # 102).

It will be bore 4.250" and stroke 3.750", 426 CI or 7.0 liter.

┼ke

It will be bore 4.250" and stroke 3.750", 426 CI or 7.0 liter.

┼ke

#112

Nordschleife Master

In my opinion, the 928 block isn't particularly fragile. A thrust-bearing failure, severe high-boost detonation, wildly imbalanced rotating assembly, or poorly designed sleeves could get it to crack. However, since it's a cross-plane V8, it balances nicely naturally and the forces acting on the block are much smaller than in a four-banger 944 sister engines. A 3.5 liter inline four is an order of magnitude harder on the block than a 7.0 liter cross-plane V8. Just my opinion.

#113

Rennlist Member

Join Date: Feb 2011

Location: Mostly in my workshop located in Sweden.

Posts: 2,226

Received 442 Likes

on

244 Posts

To summarize what has been said so far. How many 7 liter strokers are out there? The answer is just a few. Will the bored out 7 liter engine block crack? The answer is nobody knows, just pure speculations. Time will tell when more 7 liter motors are finished and being used.

┼ke

┼ke

#114

Banned

Again, I think 7 liters is going in the wrong direction. Why is so much displacement needed to achieve more power? Although I own a 6.57L stroker that made 602hp with the custom manifold shown on my thread, it begs the question as to why the motor has to be so big to achieve that power level. As a counterpoint, I just placed an order for the Huracan Performante - 5.2L V10 normally aspirated, 640hp. Many people think this is underrated since the Performante smashed the Nurb lap time of the 918 Spyder, a much more powerful car by like 5 seconds.

I know, the new motor has DFI and a bunch of other doodads, but at the end of the day 640HP is being achieved by a motor that is smaller than that of the 928 GTS even. To me, that is a way more exciting challenge at this point - to build a super high horsepower 5.0 or 5.4.........

I know, the new motor has DFI and a bunch of other doodads, but at the end of the day 640HP is being achieved by a motor that is smaller than that of the 928 GTS even. To me, that is a way more exciting challenge at this point - to build a super high horsepower 5.0 or 5.4.........

#115

Pro

Again, I think 7 liters is going in the wrong direction. Why is so much displacement needed to achieve more power? Although I own a 6.57L stroker that made 602hp with the custom manifold shown on my thread, it begs the question as to why the motor has to be so big to achieve that power level. As a counterpoint, I just placed an order for the Huracan Performante - 5.2L V10 normally aspirated, 640hp. Many people think this is underrated since the Performante smashed the Nurb lap time of the 918 Spyder, a much more powerful car by like 5 seconds.

I know, the new motor has DFI and a bunch of other doodads, but at the end of the day 640HP is being achieved by a motor that is smaller than that of the 928 GTS even. To me, that is a way more exciting challenge at this point - to build a super high horsepower 5.0 or 5.4.........

I know, the new motor has DFI and a bunch of other doodads, but at the end of the day 640HP is being achieved by a motor that is smaller than that of the 928 GTS even. To me, that is a way more exciting challenge at this point - to build a super high horsepower 5.0 or 5.4.........

The challenges to extract super HP from a 5.0 may require complete reengineering of the engine or may never reach the limits of an engine designed yesterday.

#116

Developer

I have made the same kind of work on many, many motorcycle cylinders and cylinder blocks. Basically you make the sleeves with an interference fit, heat up the aluminum piece to well over 200 C for the sleeves to drop in. However one thing happens when it has cooled down. The aluminum shrink at a higher rate compared to the cast iron sleeves creating an air gap between the sleeve flange and the aluminum block. The upper large diameter part of Carl┤s sleeves can be seen as a very think flange. When cooled down using several tons of pressure the sleeves must be pressed down to close the air gap. Failure to press the sleeves down will result in sleeves dropping and blown head gasket.

I find it particularly difficult to perform the pressing down of the sleeves on the huge bulky 928 engine block. I have been thinking of making a special tool where the sleeves can be pressed down using a large threaded bolt.

Carl I very much want to know how you managed to do this?

┼ke

I find it particularly difficult to perform the pressing down of the sleeves on the huge bulky 928 engine block. I have been thinking of making a special tool where the sleeves can be pressed down using a large threaded bolt.

Carl I very much want to know how you managed to do this?

┼ke

On wet-wall cylinders, I have less experience, having only built the 1 so far. I understand your point and it sounds valid. I would think they would almost have to be pulled in (not pressed) individually, not in a bank of 4 at a time like we do on the dry wall liners, to insure they are fully seated before further assembly.

Beautiful machine shop, Ake!

#117

Rennlist

Basic Site Sponsor

Basic Site Sponsor

Drag racers rarely worry about piston speeds....they spent only a few tenths of seconds at rpms that would tear a road racing engine apart. Road racing is very different.

The engineers at Chevrolet found that with a 3.750 stroke engine, 7,600 rpms was the absolute limit, even with super light pistons and titanium rods ( with engines used in Trans Am racing.)

Mark Anderson's 928 race engine used an extremely "beefy" connecting rod (heavy) with relatively heavy pistons for years. He reved this engine 8,000+ for years. The only side effects were cracked blocks, pounded bearings, and rapid cylinder wear.

When we switch to a lighter rod, engine failure (rod failure) occurred very quickly. Analysis of the remaining pieces of the failed rod (not all of the pieces remained) at Carrillo found no defects or problems (with the pieces we supplied.) They said that the rod failed from excessive loading (too many rpms) and asked for any recorded data to see what rpms the rod had been subjected to. We had no such data.

Final engineering findings resulted in no changes to the design of these rods, but simply a suggestion to reduce the piston speeds (or use a lighter piston) and "gather" some recorded rpm data.

"Research" resulted in finding Chevy's information about piston speeds with a 3.750" crankshaft.

#118

Rainman

Rennlist Member

Rennlist Member

The Volvo insert cylinder block is cast iron. For the 928 I will make aluminium insert cylinder blocks having cast iron sleeves. The insert block will be made from four aluminum cylinders welded together. The advantages I can see are easy to machine and hone the cylinder bores when the insert block is out of the engine block, improved strength, same heat expansion as the engine block, no problems to heat the bulky engine block for the installation of interference fit sleeves not talking about pressing down the sleeves (post # 102).

It will be bore 4.250" and stroke 3.750", 426 CI or 7.0 liter.

┼ke

It will be bore 4.250" and stroke 3.750", 426 CI or 7.0 liter.

┼ke

Again, I think 7 liters is going in the wrong direction. Why is so much displacement needed to achieve more power? Although I own a 6.57L stroker that made 602hp with the custom manifold shown on my thread, it begs the question as to why the motor has to be so big to achieve that power level. As a counterpoint, I just placed an order for the Huracan Performante - 5.2L V10 normally aspirated, 640hp. Many people think this is underrated since the Performante smashed the Nurb lap time of the 918 Spyder, a much more powerful car by like 5 seconds.

I know, the new motor has DFI and a bunch of other doodads, but at the end of the day 640HP is being achieved by a motor that is smaller than that of the 928 GTS even. To me, that is a way more exciting challenge at this point - to build a super high horsepower 5.0 or 5.4.........

I know, the new motor has DFI and a bunch of other doodads, but at the end of the day 640HP is being achieved by a motor that is smaller than that of the 928 GTS even. To me, that is a way more exciting challenge at this point - to build a super high horsepower 5.0 or 5.4.........

that V10 does 8000rpm out of the box, and then some.

928 bottom end needs cubic dollars to survive anywhere near those RPM level. crank work, rods+pistons, dry sump oiling with windage and draining managed.

for a stock oiling system capped out at maybe 6000rpm plus a little bit, HP = CI.

#119

Pro

Again, I think 7 liters is going in the wrong direction. Why is so much displacement needed to achieve more power? Although I own a 6.57L stroker that made 602hp with the custom manifold shown on my thread, it begs the question as to why the motor has to be so big to achieve that power level. As a counterpoint, I just placed an order for the Huracan Performante - 5.2L V10 normally aspirated, 640hp. Many people think this is underrated since the Performante smashed the Nurb lap time of the 918 Spyder, a much more powerful car by like 5 seconds.

I know, the new motor has DFI and a bunch of other doodads, but at the end of the day 640HP is being achieved by a motor that is smaller than that of the 928 GTS even. To me, that is a way more exciting challenge at this point - to build a super high horsepower 5.0 or 5.4.........

I know, the new motor has DFI and a bunch of other doodads, but at the end of the day 640HP is being achieved by a motor that is smaller than that of the 928 GTS even. To me, that is a way more exciting challenge at this point - to build a super high horsepower 5.0 or 5.4.........

#120

Pro

...can you make more....

"no replacement for displacement" unless you can add RPM.

that V10 does 8000rpm out of the box, and then some.

928 bottom end needs cubic dollars to survive anywhere near those RPM level. crank work, rods+pistons, dry sump oiling with windage and draining managed.

for a stock oiling system capped out at maybe 6000rpm plus a little bit, HP = CI.

"no replacement for displacement" unless you can add RPM.

that V10 does 8000rpm out of the box, and then some.

928 bottom end needs cubic dollars to survive anywhere near those RPM level. crank work, rods+pistons, dry sump oiling with windage and draining managed.

for a stock oiling system capped out at maybe 6000rpm plus a little bit, HP = CI.