Anyone in the Kansas City area do a timing belt?

#1

Hey everyone! My 82 Weissach is really needing the timing belt done. The water pump and timing belt were quoted at $800 total....and since I will always own a 928, I would rather learn how to do it myself. I have the workshop manual, but I do not want to try it alone the first time. So, I was wondering if anyone in the KC area knew how to do it, and if they could show me? I would pay!! I have only seen 1 or 2 other 928 cars out of the entire 1.5 million population here. I guess that is good....but kind of bad.

#2

Actually, how hard is it to do the timing belt with the correct tools? I have a friend that has done them on many cars, but not the 928. Do you think it would be easy with the tools and workshop manual?

#3

Three Wheelin'

Quick answer is yes, you can do it. You'll be glad you did it yourself.

Keys are:

Patience- Don't pull it apart Saturday if you need to drive it on Monday. You may very well decide to do a few more things while the front is off. Allow time to order additional parts and do things right.

The "big three" vendors can list the basic parts for T/B W/P replacemet that you will need. Buy the flywheel lock tool. Buy the Kempf aftermarket tension tool. You'll need it now and you'll need it later for retensioning.

Print the write-ups on the websites of the "big three" of tech help (Tony, Greg Nichols, John Pirtle). Follow the steps. Take your time.

Read and respect the torque values in the manuals. In most cases, you are tightening into aluminum. Be careful.

If you have a problem or are unsure about anything, STOP and post the question or problem. Use the archives as a great source of info.

When you're ready to start, I'll email you my home and cell phone numbers. If I can help in any way, I will.

Greg

Keys are:

Patience- Don't pull it apart Saturday if you need to drive it on Monday. You may very well decide to do a few more things while the front is off. Allow time to order additional parts and do things right.

The "big three" vendors can list the basic parts for T/B W/P replacemet that you will need. Buy the flywheel lock tool. Buy the Kempf aftermarket tension tool. You'll need it now and you'll need it later for retensioning.

Print the write-ups on the websites of the "big three" of tech help (Tony, Greg Nichols, John Pirtle). Follow the steps. Take your time.

Read and respect the torque values in the manuals. In most cases, you are tightening into aluminum. Be careful.

If you have a problem or are unsure about anything, STOP and post the question or problem. Use the archives as a great source of info.

When you're ready to start, I'll email you my home and cell phone numbers. If I can help in any way, I will.

Greg

#4

Nordschleife Master

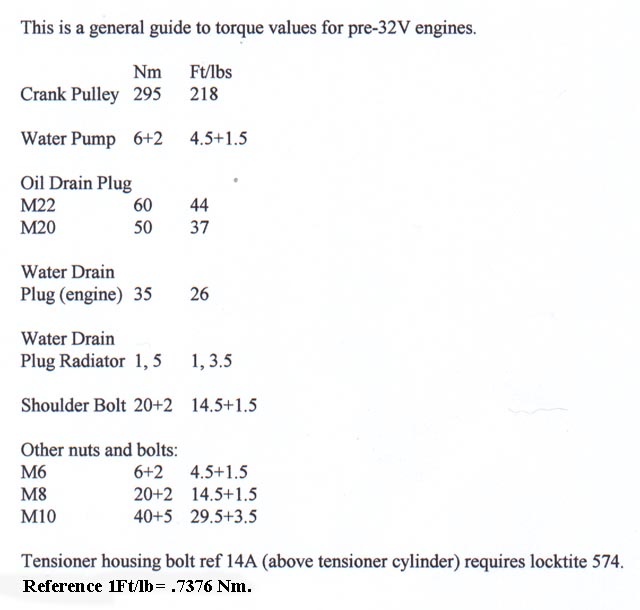

What at the tork values for what boltes on the t-belt area?

Are there any that are not related to the water pump?

I'm currently in the middle of replaceing the t-belt right now, and did not know that. I was just going to tighten them till they're good 'n snug, knowing that I was tightening into alumnium.

Removeing my 83 US spec cars t-belt has been a much to do about practicly nothing.

However, do note, I DID NOT use the flywheel lock. I have a 5-speed transmittion, a good parking brake, and a good clutch. I put it in top gear, locked the break, and went at it. It came off with out fuss. I'm going to probably use the same methoid, and a tork wrench to put it back on.

Btw, I was NOT useing jackstands or ramps, but had my car up on honest to goodness wooden seals. There was no way it could have fallen off if it moved. Heck, I don't even know if it would have gotten off if I was able to drive it.

Are there any that are not related to the water pump?

I'm currently in the middle of replaceing the t-belt right now, and did not know that. I was just going to tighten them till they're good 'n snug, knowing that I was tightening into alumnium.

Removeing my 83 US spec cars t-belt has been a much to do about practicly nothing.

However, do note, I DID NOT use the flywheel lock. I have a 5-speed transmittion, a good parking brake, and a good clutch. I put it in top gear, locked the break, and went at it. It came off with out fuss. I'm going to probably use the same methoid, and a tork wrench to put it back on.

Btw, I was NOT useing jackstands or ramps, but had my car up on honest to goodness wooden seals. There was no way it could have fallen off if it moved. Heck, I don't even know if it would have gotten off if I was able to drive it.

#5

Three Wheelin'

Important torque considerations:

Crank pully bolt

Shoulder bolt for roller

Cover bolts

Tensioner bolts

(of course) water pump

There are some others, I'll have to look.

I'll look them up and post them.

Greg

Crank pully bolt

Shoulder bolt for roller

Cover bolts

Tensioner bolts

(of course) water pump

There are some others, I'll have to look.

I'll look them up and post them.

Greg

#6

Thanks for your help Greg! I opened it all up, and have everything out. It was actually kind of fun. I do not think it is worth $800 to have someone else do it, especially on a non-interference motor. I get my timing belt tuesday. I will surley let you know what is going on. Thanks!

#7

Rennlist Member

If you can, really take your time and clean all your parts, especially if your not replacing them. It took a lot longer, but I cleaned the whole front of my engine, bolts, everything just to give it the "clean" look.

Seriously, other tip for you and others, get all your parts the FIRST time. Don't mess around. Spend the extra $$$. You don't want to do this job again anytime soon.

Seriously, other tip for you and others, get all your parts the FIRST time. Don't mess around. Spend the extra $$$. You don't want to do this job again anytime soon.

Trending Topics

#8

928 Addict

Rennlist Member

Rennlist Member

Join Date: Nov 2001

Location: IN BETWEEN A FROZEN CONCOCTION AND INDECISION

Posts: 1,741

Likes: 0

Received 1 Like

on

1 Post

Greg86andahalf,

I just wanted to take a second and applaud you for your efforts in helping other Rennlisters with their sharks and for being a Rennlist paid member and supporting this board.

[quote] I'll email you my home and cell phone numbers. If I can help in any way, I will

<hr></blockquote>

It’s people like you and this Rennlist board that makes me proud to be a shark owner!

Tim Delarm

<img src="graemlins/beerchug.gif" border="0" alt="[cheers]" />

I just wanted to take a second and applaud you for your efforts in helping other Rennlisters with their sharks and for being a Rennlist paid member and supporting this board.

[quote] I'll email you my home and cell phone numbers. If I can help in any way, I will

<hr></blockquote>

It’s people like you and this Rennlist board that makes me proud to be a shark owner!

Tim Delarm

<img src="graemlins/beerchug.gif" border="0" alt="[cheers]" />

#10

Nordschleife Master

I was realy glad when I did the timing belt on my S2. A couple of things that helped me.

1. The cams marked with a little notch on the back side of the pulley for TDC. I got tired of "looking" for this to ensure TDC was accurate. I used white out, or anything similiar, to mark the cam pulleys for easier viewing.

2. Check all your rollers - if they spin freely, then they are worn out. They should spin, but tightly. You have three rollers to look for. Tensioner, The Big Roller and the lower roller by the crank. The small lower roller can be removed by taking off the c-clip. On the lower roller, if she's bad, don't replace the whole unit (pricy), just replace the bearings.

3. You don't have to but replace the bolt that holds the roller into the H2O pump, but since your going for it, why not?. 12 ft lbs of torque I THINK. - Don't forget the locktite and to clean the threads, water pump, before installation.

4. If you don't want to spend money for the crankshaft lock, a good substitute tool is a plumbers chain. Breaker bar with a chain on it - That's what I did but BE SURE to verify TDC is on upon installation. NEVER TURN THE CRANK COUNTER CLOCKWISE

5. I didn't have room to work so I removed the Radiator - you may have to do the same. Upon installation - burping the system takes time - ensure the heater is on so H2O circulates through the heater core.

6. Label all the bolts upon removal and place them each (group of) in a seperate sandwich bag. ( I WISH I would of done this)

7. Drain the oil, you may have to remove the oil return tube and the oil dipstick. Access my friend ....Access.

8. Degreaser, when all apart....clean her up.

9. Fan - when you take the fan off, DO NOT LAY HER FLAT - She'll leak.

10. Label the Belts

I'm sorry these Ideas are not in sequencel order but Becks and I are feeling pretty good - good thing I'm not driving -

Hope these Ideas/info Help

D67

1. The cams marked with a little notch on the back side of the pulley for TDC. I got tired of "looking" for this to ensure TDC was accurate. I used white out, or anything similiar, to mark the cam pulleys for easier viewing.

2. Check all your rollers - if they spin freely, then they are worn out. They should spin, but tightly. You have three rollers to look for. Tensioner, The Big Roller and the lower roller by the crank. The small lower roller can be removed by taking off the c-clip. On the lower roller, if she's bad, don't replace the whole unit (pricy), just replace the bearings.

3. You don't have to but replace the bolt that holds the roller into the H2O pump, but since your going for it, why not?. 12 ft lbs of torque I THINK. - Don't forget the locktite and to clean the threads, water pump, before installation.

4. If you don't want to spend money for the crankshaft lock, a good substitute tool is a plumbers chain. Breaker bar with a chain on it - That's what I did but BE SURE to verify TDC is on upon installation. NEVER TURN THE CRANK COUNTER CLOCKWISE

5. I didn't have room to work so I removed the Radiator - you may have to do the same. Upon installation - burping the system takes time - ensure the heater is on so H2O circulates through the heater core.

6. Label all the bolts upon removal and place them each (group of) in a seperate sandwich bag. ( I WISH I would of done this)

7. Drain the oil, you may have to remove the oil return tube and the oil dipstick. Access my friend ....Access.

8. Degreaser, when all apart....clean her up.

9. Fan - when you take the fan off, DO NOT LAY HER FLAT - She'll leak.

10. Label the Belts

I'm sorry these Ideas are not in sequencel order but Becks and I are feeling pretty good - good thing I'm not driving -

Hope these Ideas/info Help

D67