Short belt and new bearings for engine driven fan

#1

Inventor

Rennlist Member

Rennlist Member

Thread Starter

I'm keeping the engine driven fan on the '86 for a while, and Shane was nice enough to lend me a fan with a good clutch. I couldn't find a writeup for all this info, so here ya' go.

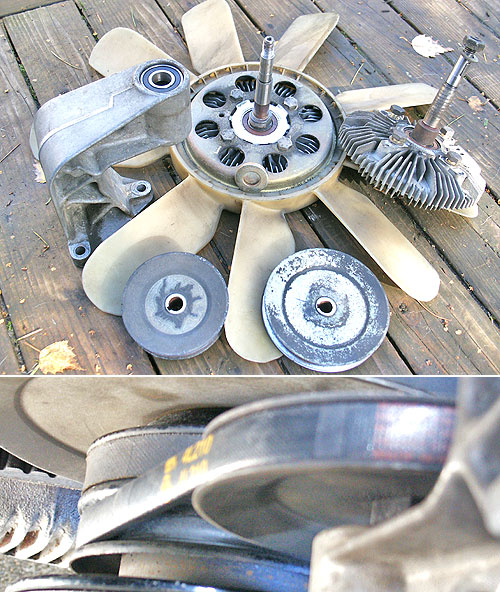

Bearings from Porsche, ~$40/~$30. Local bearing shop, $7/$16. Later fan clutches (81.5 -) spec an odd bearing with an extended hub. A 4mm spacer on one side let's you use the common bearing. I used a thick 9/16" washer.

I removed the air pump so I needed the short belt. Doing a search I found the lawnmower belt from NAPA, and I realized why some used the 20", and others the 21". If you have option M319 - higher fan speed, which usually comes with M570 - rear air, the fan pulley is smaller (86mm), so you need a 20" belt. My '86 came with a small pulley, but I swapped in a big one (106mm) from the '81.

bearings installed | 4mm spacer | late clutch + fan | early clutch

M319 86mm pulley | 106mm pulley

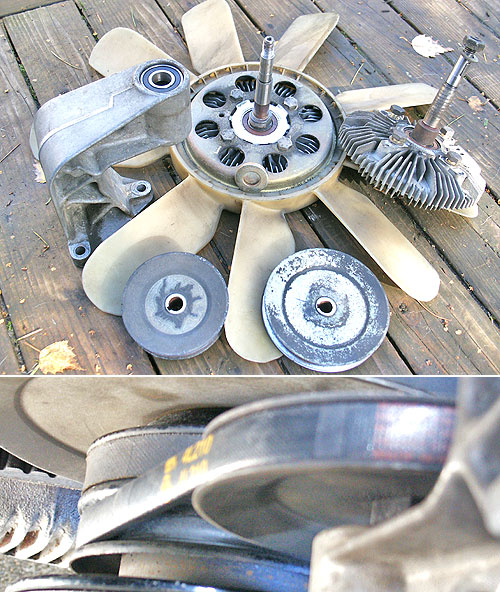

4L210 belt installed

NAPA belts:

86mm|3-3/8" pulley: 4L200

106mm|4-3/16" pulley: 4L210

Bearings:

Front/Clutch: 6202 (2RSC3) [928 106 445 02]

Rear/Pulley: 6301 (2RSC3) [928 106 441 05]

Spacer:

ID: 15mm (9/16")

OD: <= 30mm

Height: ~4mm

Bearings from Porsche, ~$40/~$30. Local bearing shop, $7/$16. Later fan clutches (81.5 -) spec an odd bearing with an extended hub. A 4mm spacer on one side let's you use the common bearing. I used a thick 9/16" washer.

I removed the air pump so I needed the short belt. Doing a search I found the lawnmower belt from NAPA, and I realized why some used the 20", and others the 21". If you have option M319 - higher fan speed, which usually comes with M570 - rear air, the fan pulley is smaller (86mm), so you need a 20" belt. My '86 came with a small pulley, but I swapped in a big one (106mm) from the '81.

bearings installed | 4mm spacer | late clutch + fan | early clutch

M319 86mm pulley | 106mm pulley

4L210 belt installed

NAPA belts:

86mm|3-3/8" pulley: 4L200

106mm|4-3/16" pulley: 4L210

Bearings:

Front/Clutch: 6202 (2RSC3) [928 106 445 02]

Rear/Pulley: 6301 (2RSC3) [928 106 441 05]

Spacer:

ID: 15mm (9/16")

OD: <= 30mm

Height: ~4mm

Last edited by PorKen; 09-19-2008 at 01:37 PM.

The following users liked this post:

kterry (11-28-2022)

#2

Inventor

Rennlist Member

Rennlist Member

Thread Starter

The bearing numbers above are a standard size among the bearing makers. Mine are ORS, made in Turkey. (You can get even cheaper bearings, without double seals. For the '81, I didn't ask for seals, and the total cost was ~$13.)

You may need a puller to remove the pulley. After it is off, remove the small Woodruff key. You'll probably also need a puller to get the clutch shaft out. (Don't get impatient and use a hammer, you'll ruin the threads... ) After that, I used a big hammer and a screwdriver through one bearing to knock out the other. An inside bearing puller would be better, here.

) After that, I used a big hammer and a screwdriver through one bearing to knock out the other. An inside bearing puller would be better, here.

Lube up the new bearings and the arm with anti-seize, then press in the bearings. I used a vice, and a thick washer, the same OD as the bearings. Slide the clutch through, tap in the Woodruff key, and install the pulley.

With the short belt, you put the belt on the pulleys, then mount the arm. It may be a little tough to get the bolts in, so watch that you don't strip the water pump holes.

You may need a puller to remove the pulley. After it is off, remove the small Woodruff key. You'll probably also need a puller to get the clutch shaft out. (Don't get impatient and use a hammer, you'll ruin the threads...

) After that, I used a big hammer and a screwdriver through one bearing to knock out the other. An inside bearing puller would be better, here.

) After that, I used a big hammer and a screwdriver through one bearing to knock out the other. An inside bearing puller would be better, here.Lube up the new bearings and the arm with anti-seize, then press in the bearings. I used a vice, and a thick washer, the same OD as the bearings. Slide the clutch through, tap in the Woodruff key, and install the pulley.

With the short belt, you put the belt on the pulleys, then mount the arm. It may be a little tough to get the bolts in, so watch that you don't strip the water pump holes.

The following users liked this post:

WestInc (11-27-2022)

#3

Burning Brakes

Join Date: Jan 2003

Location: Minneapolis MN

Posts: 773

Likes: 0

Received 0 Likes

on

0 Posts

One very simple way to run that fan w/o the air pump is to run it off the power steering pump, by offsetting the fan mount 14 mm forward. I used 3 14 mm spacers, longer bolts and a new belt (forgot the new length but 41 or 42" comes to mind). Use the power steering pump to tension the thing and you're good to go. - Ruf

#4

Inventor

Rennlist Member

Rennlist Member

Thread Starter

That's a great idea for pre-85, there's plenty of room. I'd probably do that on the '81 if I still had the fan. (I'm using just the A/C fan with a 75°c rad-switch.)

'85-'86, the PS pulley is behind the air pump/fan pulley. Also, the accelerator linkage is attached to the fan arm.

'85-'86, the PS pulley is behind the air pump/fan pulley. Also, the accelerator linkage is attached to the fan arm.

#5

Burning Brakes

Join Date: Jan 2003

Location: Minneapolis MN

Posts: 773

Likes: 0

Received 0 Likes

on

0 Posts

Oh yeah, right. I forgot about the cable on the 85 86's. Nevermind... But the idea of running a cooler switch for the AC fan is a great idea. I may have to make that mod on pure principle.- Ruf

#6

Three Wheelin'

Join Date: Dec 2003

Location: Vancouver, Canada

Posts: 1,729

Likes: 0

Received 0 Likes

on

0 Posts

I just went through this repair, replacing my fan bearings and adding the "air-pumpless" NAPA belt. Ken's info was invaluable. However, I was confused with his description of "big" and "small" pulley and ended up buying the wrong size belt. Not having both sized pulleys to compare, I guess I should have brought my pulley and fan in and compared them more carefully to the photo Ken supplied. Although my pulley looked "small" to me, I must have the "large" one, requiring the L4210 belt. For the record, the fan pulley I have measures 4" in diameter (and the corresponding pulley on the crank is about 4" in dia. as well). Ken, next time just put it on the table and measure it up, will ya!

Happy Independance Day!

Glenn

Happy Independance Day!

Glenn

#7

I am going to remove that entire belt setup...

going with an X and electric fans

here is my experimental solution...

I wanted to keep the stock throttle position for 85-86...

I bought the fan console for $10 at the wrecking yard

I sawed off the bearing then I made a holder and chucked it into a verticle mill...

going with an X and electric fans

here is my experimental solution...

I wanted to keep the stock throttle position for 85-86...

I bought the fan console for $10 at the wrecking yard

I sawed off the bearing then I made a holder and chucked it into a verticle mill...

Trending Topics

#8

Three Wheelin'

Join Date: Dec 2003

Location: Vancouver, Canada

Posts: 1,729

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by lorenolson888

I am going to remove that entire belt setup...

going with an X and electric fans

..

going with an X and electric fans

..

Glenn

#10

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Glenn,

You should know that I don't measure anything. Why do you think I have to make so many prototypes?

Did you use the plain bearing w/spacer?

You should know that I don't measure anything. Why do you think I have to make so many prototypes?

Did you use the plain bearing w/spacer?

#11

Craic Head

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Glenn,

You should have no problem getting through emissions with the crossovers and high flow cats if your car is otherwise tuned well. My air pump is there basically as a means of adjusting the fan belt right now .

.

I'm hoping to pull it out soon and replace with either electric fans or the shorter belt.

You should have no problem getting through emissions with the crossovers and high flow cats if your car is otherwise tuned well. My air pump is there basically as a means of adjusting the fan belt right now

I'm hoping to pull it out soon and replace with either electric fans or the shorter belt.

#12

Three Wheelin'

Join Date: Dec 2003

Location: Vancouver, Canada

Posts: 1,729

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by NJSharkFan

Glenn,

You should have no problem getting through emissions with the crossovers and high flow cats........

You should have no problem getting through emissions with the crossovers and high flow cats........

Glenn

#14

Inventor

Rennlist Member

Rennlist Member

Thread Starter

I think the belt driven fan is superior for A/C performance, if you drive in the city most of the time.

I just wish there was a easier/faster way to remove the throttle and fan brackets. Anytime I do anything on the front of the engine, I have to remove the air tubes, upper fan shroud, throttle bracket, and fan!

I just wish there was a easier/faster way to remove the throttle and fan brackets. Anytime I do anything on the front of the engine, I have to remove the air tubes, upper fan shroud, throttle bracket, and fan!

#15

Captain Obvious

Super User

Super User

Turkish bearings?!?!?!?!

Porken, I know you like to be cheap, just like me, but how much more would have been to get Timken or SKF instead? Ive used Romanian made bearings once and they didnt last long at all.

Nice write up by the way!

Porken, I know you like to be cheap, just like me, but how much more would have been to get Timken or SKF instead? Ive used Romanian made bearings once and they didnt last long at all.

Nice write up by the way!