Alternator voltage drop under load

#46

Three Wheelin'

Thread Starter

#47

Three Wheelin'

Thread Starter

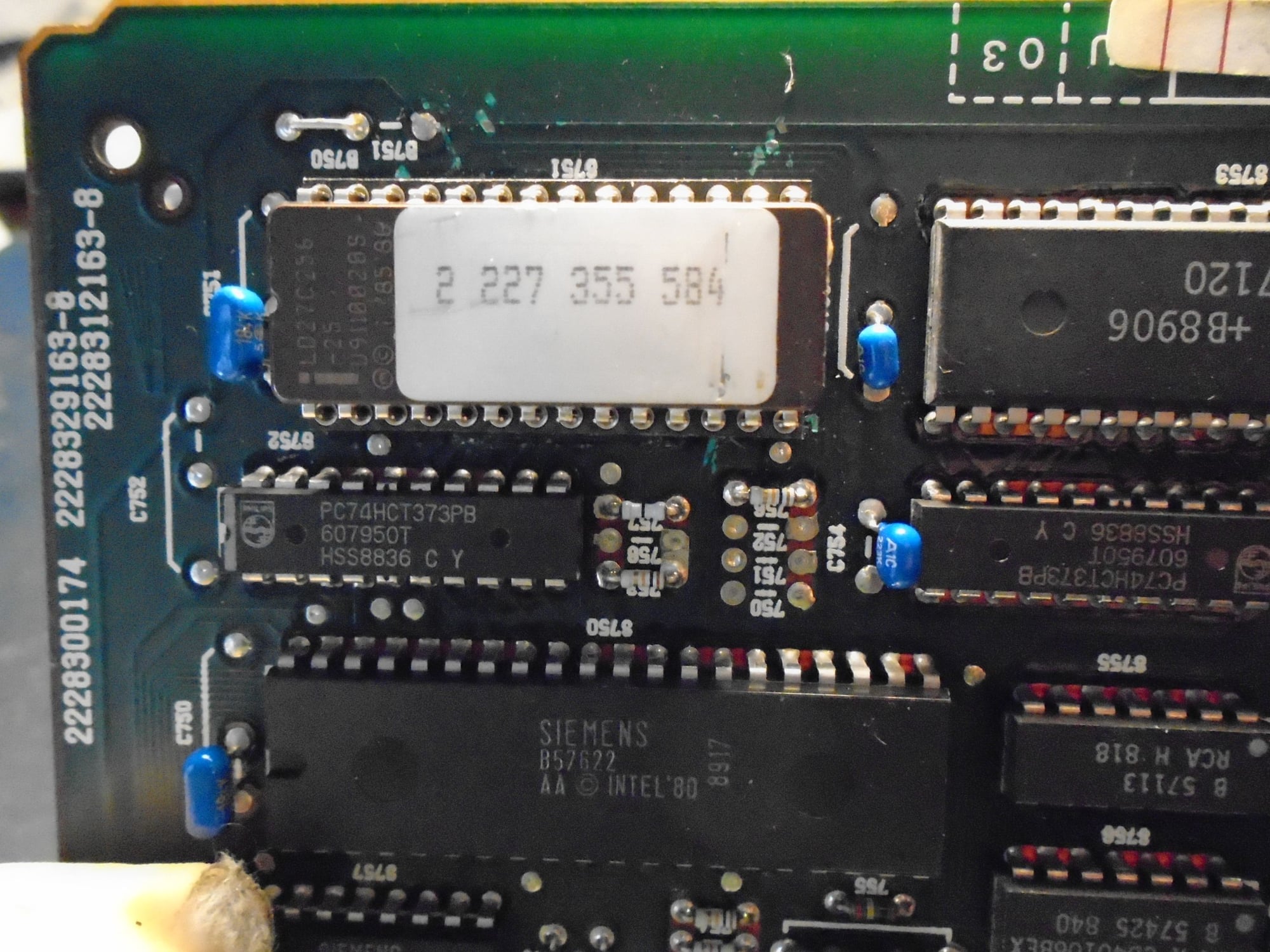

here is a photo of my chip; is this correct and original?

#48

Rennlist Member

#49

Nordschleife Master

Heat relatively speaking plays a minimal role in conductance. If we were talking about -35 to 265F, then it might be an issue, but 20-30F change shouldn't affect the circuits enough to cause wild changes in how it works. More than likely, you have an intermittent connection somewhere that fixes itself and then will degrade, and then fix, and degrade. They are very hard to find. Everyone has advised you on the ground checking, and you've done most of that, so you may have resolved it and didn't know which one was the culprit.

Finish up the ground cleaning and keep driving, see if that solved it. If not, we'll dig in some more.

Finish up the ground cleaning and keep driving, see if that solved it. If not, we'll dig in some more.

Would the metal expanding and contracting with a 20F - 30F change have much effect?

If, for example, a wire cooled and contracted and shortened up some, tightening it up a bit, pulling it tighter to the contact. Or the bolt holding it down would expand a bit as it heated, reducing the holding force.

Would/could those sorts of things be enough to make a marginal contact fail? Or be 'good', depending on the situation?

#50

Three Wheelin'

Thread Starter

Honest question:

Would the metal expanding and contracting with a 20F - 30F change have much effect?

If, for example, a wire cooled and contracted and shortened up some, tightening it up a bit, pulling it tighter to the contact. Or the bolt holding it down would expand a bit as it heated, reducing the holding force.

Would/could those sorts of things be enough to make a marginal contact fail? Or be 'good', depending on the situation?

Would the metal expanding and contracting with a 20F - 30F change have much effect?

If, for example, a wire cooled and contracted and shortened up some, tightening it up a bit, pulling it tighter to the contact. Or the bolt holding it down would expand a bit as it heated, reducing the holding force.

Would/could those sorts of things be enough to make a marginal contact fail? Or be 'good', depending on the situation?

#51

Rennlist Member

Honest question:

Would the metal expanding and contracting with a 20F - 30F change have much effect?

If, for example, a wire cooled and contracted and shortened up some, tightening it up a bit, pulling it tighter to the contact. Or the bolt holding it down would expand a bit as it heated, reducing the holding force.

Would/could those sorts of things be enough to make a marginal contact fail? Or be 'good', depending on the situation?

Would the metal expanding and contracting with a 20F - 30F change have much effect?

If, for example, a wire cooled and contracted and shortened up some, tightening it up a bit, pulling it tighter to the contact. Or the bolt holding it down would expand a bit as it heated, reducing the holding force.

Would/could those sorts of things be enough to make a marginal contact fail? Or be 'good', depending on the situation?

What folks need to understand is that once the cooling air leaves the radiator chances are it has heated up to temperatures close to 90C on a hot day when the a/c is running. Add to that the effect of the engine lump and the exhaust manifolds and it is a reasonable bet that temps under the hood are going to be close to 100C given there is no entry of ambient air and the air rush under the car is trying to suck hot air out of the engine bay, especially at higher speeds when the ground effect kicks in [about 90 mph?] assuming correct under trays are fitted. This heat does two things- the copper expands and the sheathing goes soft so it is quite conceivable that things can get a bit out of shape when wiring ages and the insulation gets brittle- and as has already been said, finding such faults must then be a night mare.

When I pulled my wiring harness to install my home build I was expecting things to be in a poor shape but it was quite an eye opener to see just how bad it really was- made me wonder how the poor thing ran. All this started when I ha instrument issues and found the cables entering the 14 pin connector were shot- some of the cores going back to the engine one could not tell what colour the cables were meant to be and the red power cables were brown with green copper corrosion inside them- given they are always live that is really scary. I have just inspected mine to see how they were holding up a year on and to check if my cable routing had caused any issues- fortunately all was excellent and I ran an extra sheath over the power cables besides the two layers of heat shrink in the sections that did not have the original orange fibre glass sheathing on- the sheathing originally supplied is brilliant and I was able to reuse it but some of the cores inside - urrrgh!

Although I still do not understand why it happened, my starter motor now takes off like Usain Bolt!

#52

Nordschleife Master

It was a general "could this be happening?" sort of question.

docmirror said that the conductivity wouldn't be affected in any real way by that sort of temp change.

Yet you still seem to have temp related issues.

So I was wondering if the temp could have an effect from a 'different angle'.

#53

Rennlist Member

Nothing specific.

It was a general "could this be happening?" sort of question.

docmirror said that the conductivity wouldn't be affected in any real way by that sort of temp change.

Yet you still seem to have temp related issues.

So I was wondering if the temp could have an effect from a 'different angle'.

It was a general "could this be happening?" sort of question.

docmirror said that the conductivity wouldn't be affected in any real way by that sort of temp change.

Yet you still seem to have temp related issues.

So I was wondering if the temp could have an effect from a 'different angle'.

#54

Shameful Thread Killer

Rennlist Member

Rennlist Member

Honest question:

Would the metal expanding and contracting with a 20F - 30F change have much effect?

If, for example, a wire cooled and contracted and shortened up some, tightening it up a bit, pulling it tighter to the contact. Or the bolt holding it down would expand a bit as it heated, reducing the holding force.

Would/could those sorts of things be enough to make a marginal contact fail? Or be 'good', depending on the situation?

Would the metal expanding and contracting with a 20F - 30F change have much effect?

If, for example, a wire cooled and contracted and shortened up some, tightening it up a bit, pulling it tighter to the contact. Or the bolt holding it down would expand a bit as it heated, reducing the holding force.

Would/could those sorts of things be enough to make a marginal contact fail? Or be 'good', depending on the situation?

Now, if we talk about that same 90F difference near the ductile limits, or the state change limits(where copper liquefies), then sure - big things happen. Hard to run current down molten copper, as it were.

The trick with conductance and cars, boats, planes is the junction of the conductive wire, with the terminal. Terminals for most cars are a Tin/Alum/Nickel alloy. Sometimes also with Copper. All those metals are pretty close together in terms of free electrons in the valence. The hassle comes in over time, that the differences eventually cause some buildup of Carbon. Now - being a human, we love carbon. But, anything that isn't a human doesn't much care for carbon. Green things expel carbon and Oxy, cars burn HC and give off nasty ole carbon, and surely - electrons HATE Carbon. as the connection draws in those Carbon atoms, resistance builds up(inverse of conductance is resistance. Hi conductance - good, hi resistance - bad). Worse, in some cases the resistance means an unstable connection, which is possibly what has happened here. Sometimes the tin-copper connection is made well, and conductance is good, other times the Carbon gets in the way, and resistance is high, conductance is low, and that's where things go pear shaped.

Overall, the temp difference we find in our cars doesn't mean too much. But - having said that, I will give credit to Fred who points out that underhood temps, can work against us just barely enough to cause things which conduct well when cool, to not conduct well when temps may be 50-60F higher. It can happen, but it is rare.

#55

Rennlist

Basic Site Sponsor

Basic Site Sponsor

How about the LH chip?

__________________

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

#56

Nordschleife Master

I didn't think it would make enough difference to matter, but I didn't know.

I had a feeling that someone on here would.

#57

Three Wheelin'

Thread Starter

NEW INFO: issue is not heat related: unusually cool morning with temps in low 60's, and only 1/4 mile from my house, with temp gauge barely off its perch, volt meter takes a dive and car stalls. immediate start up, and I pull into local restaurant, and coming to a stop, car stalls again. after a few minute stop, restart, and I cannot get the car to stall again. all good for a few hours.

first time this has happened with car cold, and outside temps cool. I wouldn't call this intermittent, but perhaps, random is a better term.

give anyone additional insight? I have ordered new battery ground strap, and large chassis to block strap from roger......

first time this has happened with car cold, and outside temps cool. I wouldn't call this intermittent, but perhaps, random is a better term.

give anyone additional insight? I have ordered new battery ground strap, and large chassis to block strap from roger......

#58

Rennlist Member

Hi Merch,

Glad you are making progress. This is a perfect opportunity for you to order Greg Brown's super alternator. It will have all top of the line components including voltage regulator.

I wish he had one for my model year.

Good luck,

Dave

Glad you are making progress. This is a perfect opportunity for you to order Greg Brown's super alternator. It will have all top of the line components including voltage regulator.

I wish he had one for my model year.

Good luck,

Dave

#59

Three Wheelin'

Thread Starter

^^^^gut feeling (not scientific and no proper deduction) is that alternator is fine. FWIW: here are some readings I just took:

testing at jump post

key off 12.62

key on 12.31 (not started)

on + lights 12.04 (not started)

running 13.84 (no accessories)

+ lights 13.76

+AC #3 13.72

+ AC #4 13.69

+hi beam 13.08 ("full" load)

these numbers are at idle 775. as I rev the car up, charging increases. I held idle up at 3k for a good minute and let go of the linkage and no drastic change in volt meter.

thought I might see a drop.....issue is random...

testing at jump post

key off 12.62

key on 12.31 (not started)

on + lights 12.04 (not started)

running 13.84 (no accessories)

+ lights 13.76

+AC #3 13.72

+ AC #4 13.69

+hi beam 13.08 ("full" load)

these numbers are at idle 775. as I rev the car up, charging increases. I held idle up at 3k for a good minute and let go of the linkage and no drastic change in volt meter.

thought I might see a drop.....issue is random...

#60

Rennlist Member

Yeah those numbers sound pretty good. Maybe try to measure again when it's misbehaving. Tough to diagnose random events.

Good luck,

Dave

Good luck,

Dave