Ben's 1982 928 S "restoration"

#46

Pro

What printer are you building? I have a Prusa i3 MK3 and have made quite a few parts out of nylon without an enclosure. Warping with nylon in my experience is no where near as bad as with ABS. The key is getting the nylon completely dry before you print. I usually pull off about twice the length of filament I need and put in in the oven at 180įF overnight. I then print really slow (10-20 mm/s). I've just about given up using ABS anymore because of warping issues. I just got a spool of PETG last week and am going to try that out for the first time. Could be a nice ABS alternative.

All told, I like the volume, but there were too many corners cut by the kit builder, and I easily doubled the price by the time it was truly usable.

The new build is a custom Core-XY that a friend and I are designing and then building a few of.

Intended build volume of 12" x 18" x ~14" Z, intended to have an external size of approximately 18" x 24" x 24" (30", allowing for some space above the motion stage for the wiring and Bowden tube to the extruder.)

We're planning on fully enclosing the printers for thermal stability and high temp plastic capability. The build plates are cut from 6mm tooling plate aluminum, and will have mains voltage heaters bonded to the bottoms.

The initial builds will be with solo extruders, but at least one is going to be upgraded to dual extrusion capability in interest of using support filaments in the future. The motion stage is designed to allow the additional needed space on the X axis.

Regarding PETG, it prints beautifully with settings that are very close to PLA. Retraction is a pain, due to how stringy it is, and likely it will need a good bit higher temps, but it still likes part cooling fans.

#47

Sooo, I worked on the 928 a bit this weekend !

Found more bolts that were lose... dry coolant tank, dry radiator, dry water hoses...

Also, there is no timing mark to set the timing !

Also, is this the oil temp sensor ?

Found the winshield washer pump was disconnected too.

I can't wait to clean all that mess !

There are too many sensors, I have to find what they do and remove what's not needed.

Also, I wil probably change my plans and use VW long nozzle injectors. That way they will sit like the K-jet injectors. They are a lot more expensive, but bigger too.

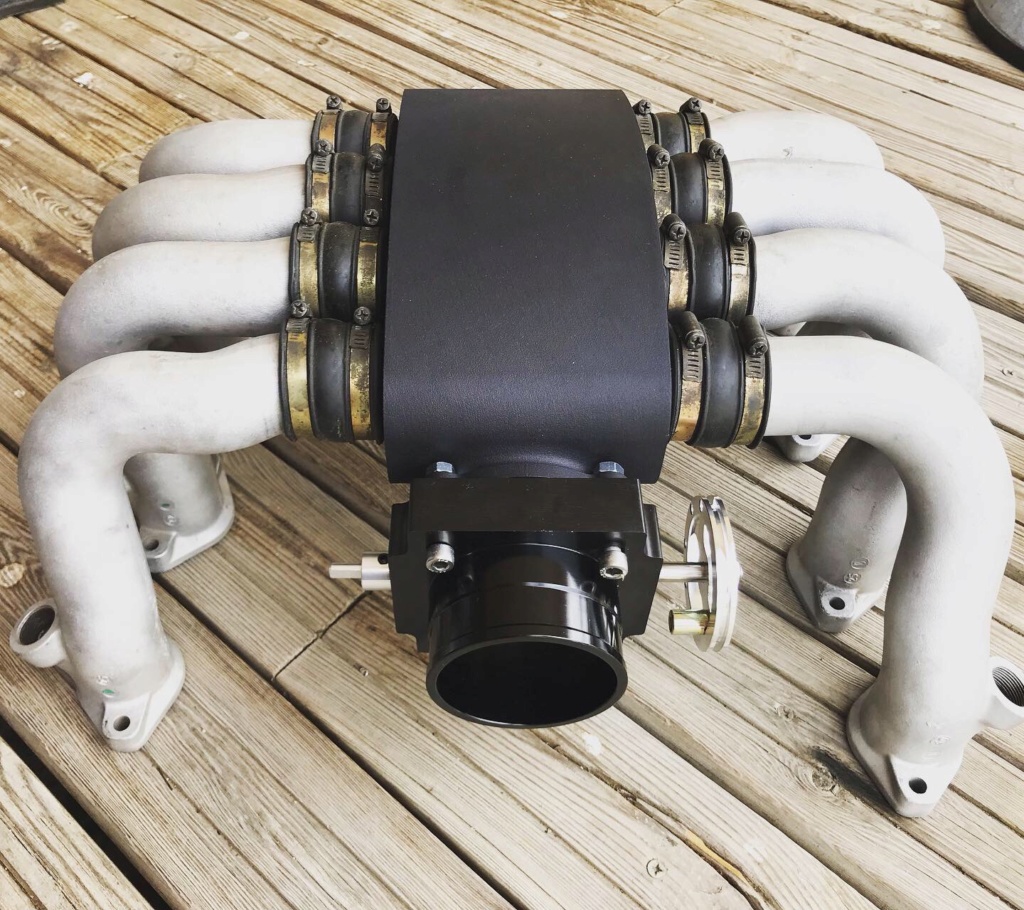

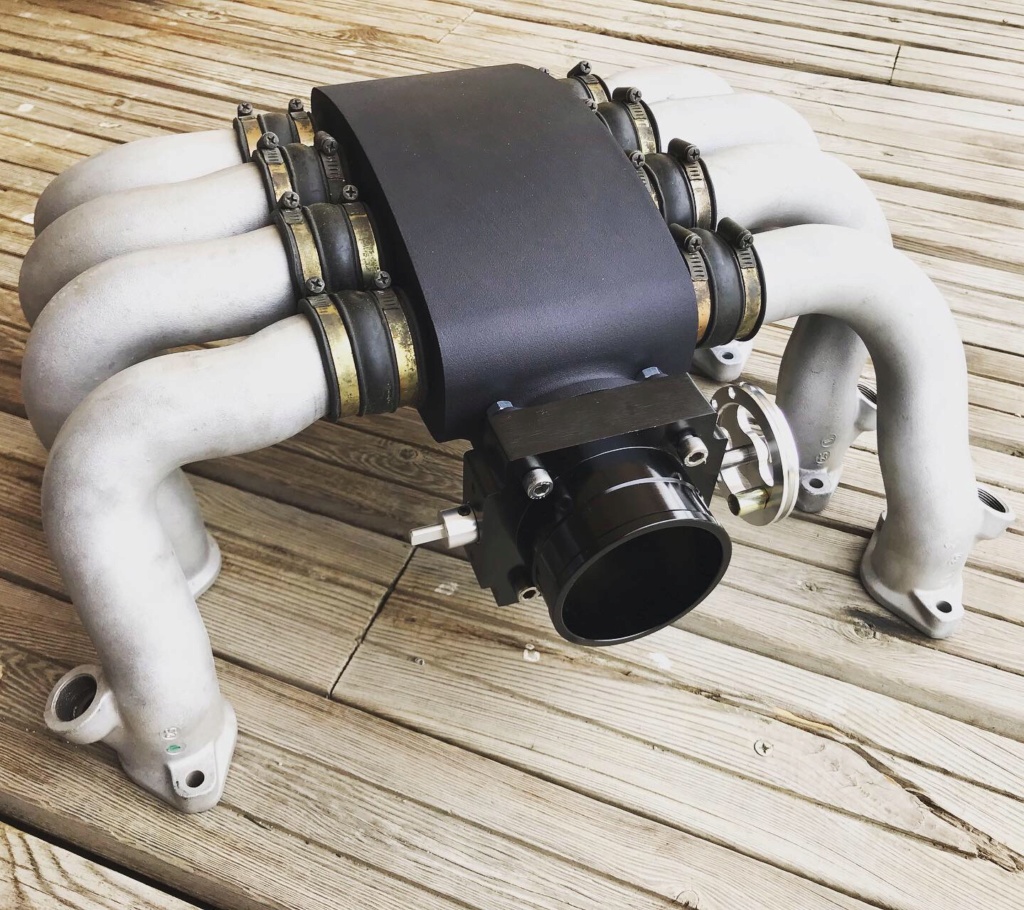

I printed a tiny version of the plenum :

In the end I dig the ribs !

Ben

Found more bolts that were lose... dry coolant tank, dry radiator, dry water hoses...

Also, there is no timing mark to set the timing !

Also, is this the oil temp sensor ?

Found the winshield washer pump was disconnected too.

I can't wait to clean all that mess !

There are too many sensors, I have to find what they do and remove what's not needed.

Also, I wil probably change my plans and use VW long nozzle injectors. That way they will sit like the K-jet injectors. They are a lot more expensive, but bigger too.

I printed a tiny version of the plenum :

In the end I dig the ribs !

Ben

#48

very cool.

#49

Some news !

I started cleaning the parts !

Surprisingly the oil filler is like new underneath the grime !

This bracket doesn't seem OEM ?

I bought a mobile scissor lift too !

It saves me a LOT of time compared to working on jack stands !

Right now the Boxster is on the lift... Getting new control arms, engine mount, brakes, tires, fan resistors...

Then I have to change the 4 Runner's clutch in a hurry, it let go this weekend and we need the car in two weeks !

And the Jag gets it's fuel pumps changed...

After all that I'll be back on the 928 with all the time I need

I started cleaning the parts !

Surprisingly the oil filler is like new underneath the grime !

This bracket doesn't seem OEM ?

I bought a mobile scissor lift too !

It saves me a LOT of time compared to working on jack stands !

Right now the Boxster is on the lift... Getting new control arms, engine mount, brakes, tires, fan resistors...

Then I have to change the 4 Runner's clutch in a hurry, it let go this weekend and we need the car in two weeks !

And the Jag gets it's fuel pumps changed...

After all that I'll be back on the 928 with all the time I need

#51

Weird, it looks homemade !

I solved the wing problem ! I found a guy with a rear hatch and a S wing that doesn't want it ! So we may swap our rear hatches around, so he gets the GT wing, and I get the S wing ! And the cars are the same colors

Tuesday I received this !!!

WEERG.com sent me a prototype as a gift !

The quality is incredible ! I can't wait to test fit it !

I solved the wing problem ! I found a guy with a rear hatch and a S wing that doesn't want it ! So we may swap our rear hatches around, so he gets the GT wing, and I get the S wing ! And the cars are the same colors

Tuesday I received this !!!

WEERG.com sent me a prototype as a gift !

The quality is incredible ! I can't wait to test fit it !

#53

Been watching your progress. As far as a fuel pressure regulator I went went with a Weldon Racing Pumps A2040-281-A-120. https://www.weldonracing.com/store/A...tors-p56722017 For pressures up to 110 PSI. I'm getting all my fuel lines done, and already have my FPR regulator mounted. I'm looking at 3D scanners. What do you use for modeling software? Did you scan the original or create your model from scratch?

81-A-12

0: use

81-A-12

0: use

#54

I donít use a 3D scanner.

Iíve been working with CAD softwares for 11 years now.

3D scanners are useful for very complex situations that canít be broken down to simple geometric shapes. Like a car body.

But when it comes to mechanical stuff that were designed by hand on a drawing board, you can usually find what reference the engineers have used to design the part and recreate it. Itís all parallelograms, triangles, and circles.

Iíve been working with CAD softwares for 11 years now.

3D scanners are useful for very complex situations that canít be broken down to simple geometric shapes. Like a car body.

But when it comes to mechanical stuff that were designed by hand on a drawing board, you can usually find what reference the engineers have used to design the part and recreate it. Itís all parallelograms, triangles, and circles.

#55

No one has created what I'm attempting to create as far as an airbox, I hand made a prototype but it is very rough and the plans are to have quite a few rounded and complese curves on it. So now that I have everything placed so it could be scanned and the modeling could be done with the data defined in the scan. I even cut a 928 hood from front to rear right down the center, so that we could create the area between the ITB's and the hood.......The design is for the top of the airbox to be a large filter that draws air in through the hood.

#56

That can be done without a scanner, you just have to be creative !

When I have to get a perfect curvature, I take a perfectly straight, mark it every few cm, lay it solidely on the surface I want to get the curve off, and measure the distance from the straight edge to the surface at every mark. Then use the same measurement on the cad software.

Then, getting the distance from the hood to the ITB's is easy too since the hood is flat

Post a photo !

Ben

When I have to get a perfect curvature, I take a perfectly straight, mark it every few cm, lay it solidely on the surface I want to get the curve off, and measure the distance from the straight edge to the surface at every mark. Then use the same measurement on the cad software.

Then, getting the distance from the hood to the ITB's is easy too since the hood is flat

Post a photo !

Ben

#57

Ben,

Sent you a PM with links as to not hijack your thread.

Sent you a PM with links as to not hijack your thread.

#58

Some news !

I started cleaning the engine.

The photo doesn't do it justice, it's actually perfect in the V !

The sides of the engine bay are looking 100x better too !

I don't want to get too agressive at once, so I'm doing small portions at the time.

I'm going to order the ECU soon !

First I have an emergency on my Toyota...

I started cleaning the engine.

The photo doesn't do it justice, it's actually perfect in the V !

The sides of the engine bay are looking 100x better too !

I don't want to get too agressive at once, so I'm doing small portions at the time.

I'm going to order the ECU soon !

First I have an emergency on my Toyota...

#60

Hi guys !

I ordered the ECU !

I ditch the speeduino idea and went with a more advanced one !

A MAXXECU Street !

It comes with it's own Bosch wideband sensor, so I'm selling my innovate MTX-L (not worth it for you guys on the other side of the atlantic...)

It's more expensive than planned... but still quite cheap for a good ECU.

I ordered the ECU !

I ditch the speeduino idea and went with a more advanced one !

A MAXXECU Street !

It comes with it's own Bosch wideband sensor, so I'm selling my innovate MTX-L (not worth it for you guys on the other side of the atlantic...)

It's more expensive than planned... but still quite cheap for a good ECU.