Euro K-Jetronic with Lamda Control

#16

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

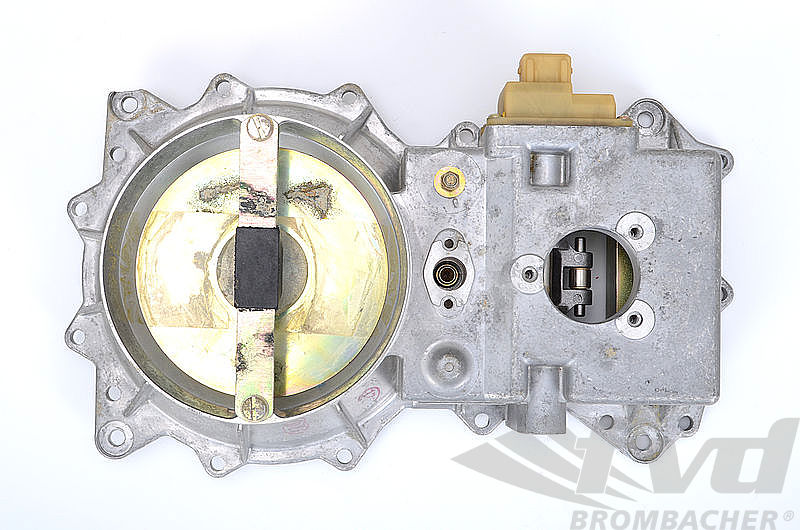

If you do in fact have a working KE-Jet system, know that the "control" for it is pure analog. The Bosch controller uses a couple of high slew rate op-amps to read the oxy sensor, and a lagged RC response damper, a couple transistors in a Darlington arrangement after an IC timer to drive the valve itself. At least 75% of the controller is dedicated to testing for bad oxy sensor and moving to a default mode that would allow the car to run. The system works well when the sensor is good and there are no wiring faults. You still need to perform basic system pressure setup, and tune the low-speed mixture with a CO sensor ahead of the catalysts with the oxy sensor disabled. Then when you reconnect, the duty cycle of the "modulating" valve should stay pretty much the same as it was in default failure mode (50-60%). At that point it will correct any small deviations in mixture, helping with fuel economy and catalyst survival. There is no real performance gain available by disconnecting or removing the system.

I built a few of these controllers from scratch for my hotrodded KE-Jet Saab Turbo back in its days. I made a couple analog boxes, with tuning pots added to adjust mixture fatter under boost. They worked OK. The last box I made was digital, with a map system similar to what we have in the LHA system cars now. It used a MAP sensor from GM, a RTD temperature element, and a rheostat on the arm.

The biggest handicap to making a good system for the turbo car was the oxy sensor itself. The pieces available at the time were reliably linear only in a very narrow range at Lambda. Else they were functionally saying "way too rich" or "way too lean", and letting the controller ramp the duty cycle towards "perfect" until it was "in range" for the sensor. No wideband sensors for consumers at the time. Remember too that primary fuel control still depended on the pancake in the venturi for 95+% of it's air flow detection. The system was a compromise that bridged the period between mechanical and, for the US 928, the barn-door-with-temp-sensor system that does a much better job of determining actual mass air flow.

I would make the original system work to maintain originality. Were it not for that consideration, I'd probably be shopping for a surplus US LH and EZF package to retrofit. The later electronic injection systems offer a lot more forgiveness in cars that aren't driven regularly. By "regularly" I mean daily to maybe weekly. CIS is amazingly dependable until it gets a little varnish and stiction in any of its several critical moving parts. Drive it regularly, or dose it up with fuel system stabilizer and Seafoam or MMO, and at least run the fuel pump for some several seconds every few days in storage. Keeps all the moving bits wet.

I built a few of these controllers from scratch for my hotrodded KE-Jet Saab Turbo back in its days. I made a couple analog boxes, with tuning pots added to adjust mixture fatter under boost. They worked OK. The last box I made was digital, with a map system similar to what we have in the LHA system cars now. It used a MAP sensor from GM, a RTD temperature element, and a rheostat on the arm.

The biggest handicap to making a good system for the turbo car was the oxy sensor itself. The pieces available at the time were reliably linear only in a very narrow range at Lambda. Else they were functionally saying "way too rich" or "way too lean", and letting the controller ramp the duty cycle towards "perfect" until it was "in range" for the sensor. No wideband sensors for consumers at the time. Remember too that primary fuel control still depended on the pancake in the venturi for 95+% of it's air flow detection. The system was a compromise that bridged the period between mechanical and, for the US 928, the barn-door-with-temp-sensor system that does a much better job of determining actual mass air flow.

I would make the original system work to maintain originality. Were it not for that consideration, I'd probably be shopping for a surplus US LH and EZF package to retrofit. The later electronic injection systems offer a lot more forgiveness in cars that aren't driven regularly. By "regularly" I mean daily to maybe weekly. CIS is amazingly dependable until it gets a little varnish and stiction in any of its several critical moving parts. Drive it regularly, or dose it up with fuel system stabilizer and Seafoam or MMO, and at least run the fuel pump for some several seconds every few days in storage. Keeps all the moving bits wet.

#17

Love these threads.

I've got a Euro '82 here that had been "federalized". Required charcoal canister is installed with two vacuum lines that go to one side of the intake to produce vacuum to the canister and the other leads to a dead end. It's got an O2 sensor installed and the wiring goes inside the car and are tucked under the CE panel with nothing connected. It might pass someones visual inspection only.

I've got a Euro '82 here that had been "federalized". Required charcoal canister is installed with two vacuum lines that go to one side of the intake to produce vacuum to the canister and the other leads to a dead end. It's got an O2 sensor installed and the wiring goes inside the car and are tucked under the CE panel with nothing connected. It might pass someones visual inspection only.

#18

Rennlist Member

my car has a multi pin socket on the side of the FD. When I got the car I had several failures to start hot - needed to cool right down before it would run. Then I found a lead hanging down one side with a plug that matched the socket, and after reconnecting the plug the hot start problem mostly went away. Have never seen anything documenting this socket.

jp 83 Euro S AT 57k

jp 83 Euro S AT 57k

#20

Intermediate

my car has a multi pin socket on the side of the FD. When I got the car I had several failures to start hot - needed to cool right down before it would run. Then I found a lead hanging down one side with a plug that matched the socket, and after reconnecting the plug the hot start problem mostly went away. Have never seen anything documenting this socket.

jp 83 Euro S AT 57k

jp 83 Euro S AT 57k

The following users liked this post:

82EUROATM (05-15-2021)