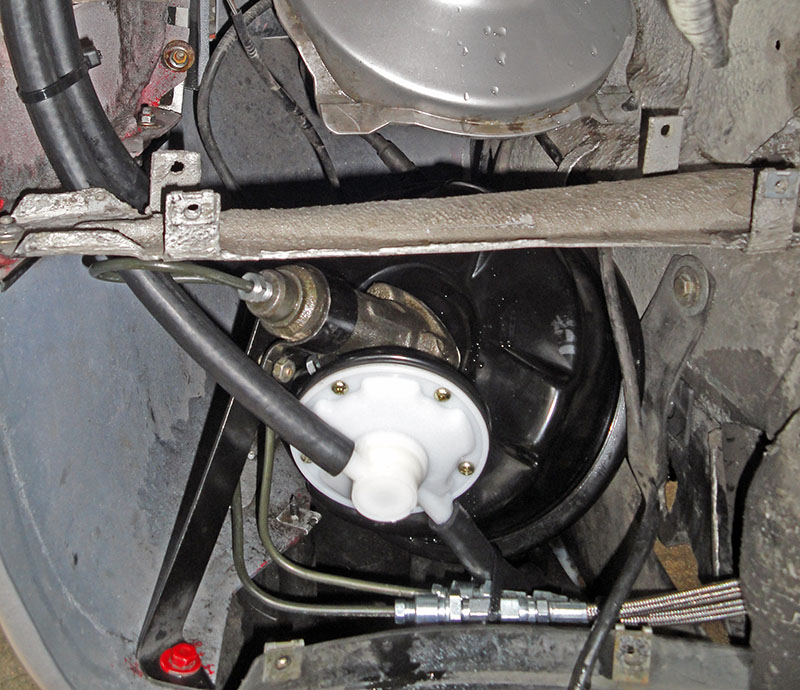

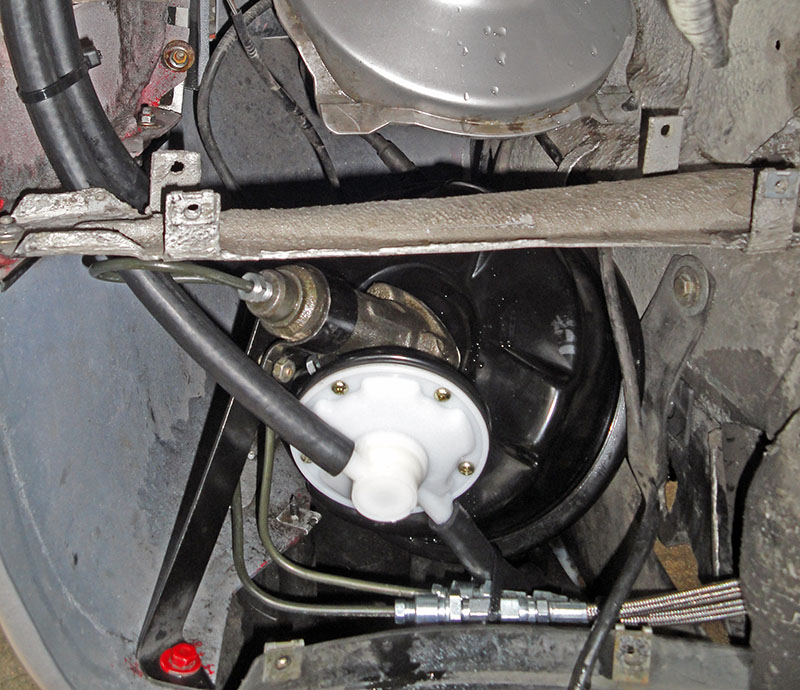

Clutch servo installed

#16

Captain Obvious

Super User

Super User

I never had any issuers holding the clutch on my '85. Is this servo disconnecting the feel of the clutch between the car and the driver? Can you feel the engagement points or you have to learn where the point is and get used to it? I never driven one with a servo clutch but hydraulic clutches always felt more disconnected than cars with cable clutches. Anything with an assist always made the car feel more disconnected.

#17

Rennlist

Basic Site Sponsor

Basic Site Sponsor

3:1 is the ticket!

So, so nice, with none of the initial-push weirdness that I had with the 2:1. Had to adjust the pre-load to zero and reduce the clutch stop so I put the pedal-spacer back in. (No helper spring.) Kept the way-back seating position though because I can pretty much operate the clutch with my tippy-toes. Much easier to feather precisely - getting going on a hill, for example.

Unboosted feels like I'm trying to push out the firewall, now!

This one came with the alternate cap for the air valve with a hose connection to the engine compartment.

Only two issues presently. First, the short sections of smaller diameter steel line into and out of the servo means it takes more effort to push the clutch very quickly (which is easier to do with the higher boost). Second, it does not hold vacuum well at shutoff.

So, so nice, with none of the initial-push weirdness that I had with the 2:1. Had to adjust the pre-load to zero and reduce the clutch stop so I put the pedal-spacer back in. (No helper spring.) Kept the way-back seating position though because I can pretty much operate the clutch with my tippy-toes. Much easier to feather precisely - getting going on a hill, for example.

Unboosted feels like I'm trying to push out the firewall, now!

This one came with the alternate cap for the air valve with a hose connection to the engine compartment.

Only two issues presently. First, the short sections of smaller diameter steel line into and out of the servo means it takes more effort to push the clutch very quickly (which is easier to do with the higher boost). Second, it does not hold vacuum well at shutoff.

I initially tried to make replacement clutch lines from -4 hose, but they proved to be too restrictive. (The higher effort required to push the clutch down quickly is from restriction.)

I had to have custom -5 hose ends made and use -5 hose to allow enough volume.

Hope this helps......

and also hope you can get your man card back......someday.

__________________

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

Last edited by GregBBRD; 10-16-2017 at 04:58 PM.

#18

Goddamn I love this place.

#19

Rainman

Rennlist Member

Rennlist Member

Even though I've spent the last week trying to figure out who could be whimpy enough to need a car with a clutch that one can push down with one finger, (my tiny 64 year old wife, who weighs 120lbs, drives these cars without any issue), I can offer you some help with line size requirements.

trying to get from chatsworth to LAX on a weekday morning can take 3 hours...

#20

Rennlist

Basic Site Sponsor

Basic Site Sponsor

#21

#22

Inventor

Rennlist Member

Rennlist Member

Thread Starter

10mm x AN4 banjos (using 3/8-24 bolts) installed. They helped quite a bit, but the restriction is still in the eight feet of -4 hose. (As Greg noted, he had trouble even with his short hose.) Going further will require -5 or -6 hoses and perhaps even (disassembling and) drilling out the ports in the servo.

It works great when used for normal driving and releases quickly, but effort goes up the faster the pedal is pressed past a certain speed - though never as much as stock effort.

The main issue now is that the servo is a vacuum pig. Used as clutch helper, the servo gobbles up almost all of its stored supply after a press or two and takes a moment to evacuate, longer at higher load. (Note it takes additional vacuum to help return the servo slave piston to its resting position.) An electric vacuum pump may help, but it may end up needing a large external tank - but where to put that!?

I think you can get 'Man Cards' at Physical Therapist offices... kind of like dentists used to give out candy.

It works great when used for normal driving and releases quickly, but effort goes up the faster the pedal is pressed past a certain speed - though never as much as stock effort.

The main issue now is that the servo is a vacuum pig. Used as clutch helper, the servo gobbles up almost all of its stored supply after a press or two and takes a moment to evacuate, longer at higher load. (Note it takes additional vacuum to help return the servo slave piston to its resting position.) An electric vacuum pump may help, but it may end up needing a large external tank - but where to put that!?

I think you can get 'Man Cards' at Physical Therapist offices... kind of like dentists used to give out candy.

#23

Rennlist

Basic Site Sponsor

Basic Site Sponsor

10mm x AN4 banjos (using 3/8-24 bolts) installed. They helped quite a bit, but the restriction is still in the eight feet of -4 hose. (As Greg noted, he had trouble even with his short hose.) Going further will require -5 or -6 hoses and perhaps even (disassembling and) drilling out the ports in the servo.

It works great when used for normal driving and releases quickly, but effort goes up the faster the pedal is pressed past a certain speed - though never as much as stock effort.

The main issue now is that the servo is a vacuum pig. Used as clutch helper, the servo gobbles up almost all of its stored supply after a press or two and takes a moment to evacuate, longer at higher load. (Note it takes additional vacuum to help return the servo slave piston to its resting position.) An electric vacuum pump may help, but it may end up needing a large external tank - but where to put that!?

I think you can get 'Man Cards' at Physical Therapist offices... kind of like dentists used to give out candy.

It works great when used for normal driving and releases quickly, but effort goes up the faster the pedal is pressed past a certain speed - though never as much as stock effort.

The main issue now is that the servo is a vacuum pig. Used as clutch helper, the servo gobbles up almost all of its stored supply after a press or two and takes a moment to evacuate, longer at higher load. (Note it takes additional vacuum to help return the servo slave piston to its resting position.) An electric vacuum pump may help, but it may end up needing a large external tank - but where to put that!?

I think you can get 'Man Cards' at Physical Therapist offices... kind of like dentists used to give out candy.

I have some custom very high flow banjo fittings that we use on Moton and JRZ shocks that are the highest flow pieces made (with a 10mm x 1.0 limitation.) The internal hole through the banjo bolt is .235". (Which is big even by -6 standards.)

These crimp directly onto high pressure -5 hose.

This is the highest flow fitting I'm aware of, in either -5 or -6 hose ends. They are pricey at Goodridge's retail price of $98.20 (low volumes used in the world, stainless steel, way more intricate than a normal banjo with bolt), but they are a real problem solver, with the built in swivel, compactness, and high flow!

If you have the room, I also have some custom stainless high flow straight fittings that go from 10 x 1.0 thread to -5 hose. Because they don't swivel, these can be a bit more cumbersome to use than the 90 degree swivel fitting (especially with long hose runs.)

However, with Goodridge's retail price of $18.79, if you can use one of these on one end of the hose, it saves some money.

Last edited by GregBBRD; 10-14-2017 at 05:40 PM.

#24

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Decided to try the factory vacuum pump (venturi-Y  ) along with a vacuum cannister. Lots of room behind the radiator S4-up, especially with Hans' fans. (I will probably attach the can to the fan shroud eventually.)

) along with a vacuum cannister. Lots of room behind the radiator S4-up, especially with Hans' fans. (I will probably attach the can to the fan shroud eventually.)

Works acceptably well even at higher loads. I noticed at those higher loads, IE. driving aggressively, I am also pressing the clutch pedal more quickly, creating higher pressure, which requires more assist, using more vacuum. With at least a larger, lower restriction output hose the servo may use less vacuum, so this vacuum supply setup may be sufficient.

) along with a vacuum cannister. Lots of room behind the radiator S4-up, especially with Hans' fans. (I will probably attach the can to the fan shroud eventually.)

) along with a vacuum cannister. Lots of room behind the radiator S4-up, especially with Hans' fans. (I will probably attach the can to the fan shroud eventually.)Works acceptably well even at higher loads. I noticed at those higher loads, IE. driving aggressively, I am also pressing the clutch pedal more quickly, creating higher pressure, which requires more assist, using more vacuum. With at least a larger, lower restriction output hose the servo may use less vacuum, so this vacuum supply setup may be sufficient.

#25

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Brake fluid drains out of the servo when opened, even without a pressure bleeder, so I took a chance and slowly drilled the outlet port to 5/32 (AN4 fitting size). Not the greatest idea but it worked, with the help of a small magnet. The canister fit perfectly up in the bumper space so it's back to a stealth install.

With better hydraulic and vacuum flow pedal action is very good. Still a touch of extra effort when pushed very quickly, but I think drilling out the servo inlet may be enough to make the system transparent enough for street use with AN4 hoses.

As you can see at (this great link), the clutch master pushes a slave piston in the servo which in turn pushes fluid to the clutch. Increasing the input flow will help push the servo slave faster.

With better hydraulic and vacuum flow pedal action is very good. Still a touch of extra effort when pushed very quickly, but I think drilling out the servo inlet may be enough to make the system transparent enough for street use with AN4 hoses.

As you can see at (this great link), the clutch master pushes a slave piston in the servo which in turn pushes fluid to the clutch. Increasing the input flow will help push the servo slave faster.

#26

Inventor

Rennlist Member

Rennlist Member

Thread Starter

BTW, one thing I've noticed when using a (Motive) pressure bleeder is that if the clutch master has gotten air into it, I have to bleed the system at the slave once, release the bleeder pressure, pump the clutch a few times, then re-pressurize and bleed again. Without releasing the pressure, air bubbles don't seem to flow out of the master.

#27

Rennlist

Basic Site Sponsor

Basic Site Sponsor

Even though I've spent the last week trying to figure out who could be whimpy enough to need a car with a clutch that one can push down with one finger, (my tiny 64 year old wife, who weighs 120lbs, drives these cars without any issue), I can offer you some help with line size requirements.

I initially tried to make replacement clutch lines from -4 hose, but they proved to be too restrictive. (The higher effort required to push the clutch down quickly is from restriction.)

I had to have custom -5 hose ends made and use -5 hose to allow enough volume.

Hope this helps......

and also hope you can get your man card back......someday.

I initially tried to make replacement clutch lines from -4 hose, but they proved to be too restrictive. (The higher effort required to push the clutch down quickly is from restriction.)

I had to have custom -5 hose ends made and use -5 hose to allow enough volume.

Hope this helps......

and also hope you can get your man card back......someday.

To my surprise, she said that she did kick off her high heals when driving one of these cars equipped with a clutch.

Before you guys/girls put vacuum boosters, extra vacuum storage containers, 12 feet of hydraulic hose, 10 feet of vacuum hose into your cars....you might want to give this a try.

#28

Rennlist Member

I am baffled the clutch in these cars is light already , the twin plate single plate , even the pedal box in the race car . the single plate in the GT you drive all day , in the city without any problem.

WHy complicate a effective design , if your clutch is heavy there is maintenance required somewhere.

WHy complicate a effective design , if your clutch is heavy there is maintenance required somewhere.

#29

Nordschleife Master

I am baffled the clutch in these cars is light already , the twin plate single plate , even the pedal box in the race car . the single plate in the GT you drive all day , in the city without any problem.

Why complicate a effective design , if your clutch is heavy there is maintenance required somewhere.

Why complicate a effective design , if your clutch is heavy there is maintenance required somewhere.

I drive a semi, and that clutch is heavy. Sitting at a long light can be a problem. I "float shift", so slow moving traffic isn't that big of a deal, but actual "stop and go" traffic gets really old fast. I go through Chicago and Boston (both through downtown) and I get lots of 'exercise' of my left leg.

I've driven cars with boosted clutches, and they are nice, in the way power brakes are nice. Low effort, but it requires a lot of finesse to use well.

I've also driven my 928 through fairly heavy traffic (Milwaukee and Oakland CA during afternoon rushes). While not "heavy", the effort gets tiring after being in slow traffic for any length of time (can't float shift the 928).

To each his (or her) own. I think it's a pretty cool setup, although I likely wouldn't get one myself. It's pretty ingenious of Ken to come up with it.

And somehow, pretty typical of "someone else" to post a few personal attacks.

#30

Inventor

Rennlist Member

Rennlist Member

Thread Starter

After a week of assisted living, the stock S4 clutch feels like a cruel joke. The clutch in my BMWs feels heavy, now.

This has turned out to be a pretty simple installation. Once I get around to redoing the bracket to hold both the servo and the vacuum tank, combined with hoses with the correct ends, the whole thing will slide into the space under the headlamp as a unit. Replace the clutch hydraulic and brake booster vacuum hoses and bleed the clutch. Done!

This has turned out to be a pretty simple installation. Once I get around to redoing the bracket to hold both the servo and the vacuum tank, combined with hoses with the correct ends, the whole thing will slide into the space under the headlamp as a unit. Replace the clutch hydraulic and brake booster vacuum hoses and bleed the clutch. Done!