S4 10:1 C/R, the big lie?

#16

Tom, where did the piston end up in relation to the top of the cylinder at TDC?

For instance; when I took my spare eng. apart, the pistons were just about flush with the top of the bore, it took a staight edga and some thin feeler guages to measure the depth.

For instance; when I took my spare eng. apart, the pistons were just about flush with the top of the bore, it took a staight edga and some thin feeler guages to measure the depth.

#17

Rennlist Member

Thread Starter

Here are some of the pics of the process.

The grease that I used to seal the plexi is similar in color to the ATF, it did not change color due to seepage.

It's great hearing everyone's input. The purpose of posting the results was to find fault in the method, so don't be shy about posting possible sources of variance in the testing. I agree that the head gasket thickness measurement is a weak point, but as Tom points out the diameter was measured with calipers at 102mm. If I get a chance, I may get a degree wheel and a proper dial gauge and redo the measurements to include a BDC measurement.

We give a lot of praise to our motors for the abuses they take (low octane/SC'ing) for a 10:1 motor, but maybe these measurements help explain a lot of that.

The grease that I used to seal the plexi is similar in color to the ATF, it did not change color due to seepage.

It's great hearing everyone's input. The purpose of posting the results was to find fault in the method, so don't be shy about posting possible sources of variance in the testing. I agree that the head gasket thickness measurement is a weak point, but as Tom points out the diameter was measured with calipers at 102mm. If I get a chance, I may get a degree wheel and a proper dial gauge and redo the measurements to include a BDC measurement.

We give a lot of praise to our motors for the abuses they take (low octane/SC'ing) for a 10:1 motor, but maybe these measurements help explain a lot of that.

#20

Rennlist Member

Dam...I hate when that happens..

2 The piston to wall when cold is less than .0008 on a decent engine, due to piston materila properties, unlike a nascar engine that used 2618 pistons where the gap is close to .004.....in other words, the piston to wall gap is insignificant.

3 the best way to measure is to drop the piston down exactly 1.0000 inches and fill the volume and subtract the 1.000 inch of volume.

Marc

DEVEK

2 The piston to wall when cold is less than .0008 on a decent engine, due to piston materila properties, unlike a nascar engine that used 2618 pistons where the gap is close to .004.....in other words, the piston to wall gap is insignificant.

3 the best way to measure is to drop the piston down exactly 1.0000 inches and fill the volume and subtract the 1.000 inch of volume.

Marc

DEVEK

#21

There it is. Adam see my post on the NW list, it's that huge dish that's not accounted for in the equation.

Marc is exactly right except that it may be easier to use 25mm down so you don't have to add in the inch/metric conversion.

Marc is exactly right except that it may be easier to use 25mm down so you don't have to add in the inch/metric conversion.

#22

Duh, I can just cut/past that here:

(btw I posted this over there bfore seeing the pics)

Here's what I come up with on this; when using a combo of

mathmatics and direct measurement there's always something

to overlook.

Figuring the cyl displacement is the same as the volume of a cylinder

100mm x 78.9mm; using 3.14 as pi this equals 619.4

( Adam got 619.7, I assume more decimal places in pi?)

This gives us the volume for a perfect cylinder, flat top and bottom.

However, when you measure the actual cc's or the area above the

piston, this takes into account the shape of the piston, which I assume

to have 4 reliefs and a fair dish to it because of the small combustion

chamber. Unless the piston is flat, you will be adding or subtracting

volume from your calculated cylinder and must compensate.

As an completely random example using Adam's numbers and

some loose assumptions lets say the piston "parks" exactly 1mm

down from the top of the cylinder at TDC. We know from the

head gasket that this is ~8cc. The remainder of 17.4 is the valve

reliefs and any piston dish. This 17.4 either has to be tossed from

the entire calculation or added back into the cylinder volume. It

would seem that either would have the same affect, but things get

a bit murky for my limited math skills:

Using Adam's measurements with my randomly generated dish/

valve relief volume;

Toss the 17.4 cc's yeilds 11.7:1 CR

Add the 17.4 cc's to displacement yeilds 9.46:1 CR

So which is right??? I don't know for sure but the former sure looks

better than the latter, and I suspect plugging the actual volume in

will yeild awfully close to 10:1 CR

Jim

1.02 mm is very close to 0.040 inches. If he used fluid to measure the top

of piston while it was in the block, that would cover the relief cuts in

the piston

crowns.

(btw I posted this over there bfore seeing the pics)

Here's what I come up with on this; when using a combo of

mathmatics and direct measurement there's always something

to overlook.

Figuring the cyl displacement is the same as the volume of a cylinder

100mm x 78.9mm; using 3.14 as pi this equals 619.4

( Adam got 619.7, I assume more decimal places in pi?)

This gives us the volume for a perfect cylinder, flat top and bottom.

However, when you measure the actual cc's or the area above the

piston, this takes into account the shape of the piston, which I assume

to have 4 reliefs and a fair dish to it because of the small combustion

chamber. Unless the piston is flat, you will be adding or subtracting

volume from your calculated cylinder and must compensate.

As an completely random example using Adam's numbers and

some loose assumptions lets say the piston "parks" exactly 1mm

down from the top of the cylinder at TDC. We know from the

head gasket that this is ~8cc. The remainder of 17.4 is the valve

reliefs and any piston dish. This 17.4 either has to be tossed from

the entire calculation or added back into the cylinder volume. It

would seem that either would have the same affect, but things get

a bit murky for my limited math skills:

Using Adam's measurements with my randomly generated dish/

valve relief volume;

Toss the 17.4 cc's yeilds 11.7:1 CR

Add the 17.4 cc's to displacement yeilds 9.46:1 CR

So which is right??? I don't know for sure but the former sure looks

better than the latter, and I suspect plugging the actual volume in

will yeild awfully close to 10:1 CR

Jim

1.02 mm is very close to 0.040 inches. If he used fluid to measure the top

of piston while it was in the block, that would cover the relief cuts in

the piston

crowns.

#25

928 Collector

Rennlist Member

Rennlist Member

well, i'm quite content that even if it ends up being a 3-litre V-7, she's kicking the butts of almost everything else out there, and remains just as drop-dead gorgeous .....

#26

Rennlist Member

sounds like the piston volume is a little high (probably do to your measuring technique.) basically, the piston volume is only going to be the volume of the valve cut outs and dish. lots of fluid can seep down to the first ring,and I dont think that is calculated in the overall volume for compression ratios. ( anyone chime in here)

41cc sounds about right for the combustion chamber, and the gasket is 7.8ccs. fix the piston volume, remove a little for your gasket. ( use 1mm hight for 7.8ccs and 20ccs for the piston face) and you then get almost exactly 10:1. that extra 5ccs is the part that is killing the calculation. anyone with a stock S4 piston can confirm this.

MK

41cc sounds about right for the combustion chamber, and the gasket is 7.8ccs. fix the piston volume, remove a little for your gasket. ( use 1mm hight for 7.8ccs and 20ccs for the piston face) and you then get almost exactly 10:1. that extra 5ccs is the part that is killing the calculation. anyone with a stock S4 piston can confirm this.

MK

Originally posted by atb

Today, before taking the last piston out of my soon-to-be stroker motor, I cc'd the piston chamber volume and the head. This is what I came up with.

The piston was brought to top dead center. I did not have a degree wheel, but I did bring the piston up in stroke to a certain distance from the top fo the cylinder (BTDC), and then brought it to the same position ATDC, then turned the crank back half way inbetween. Without the degree wheel I realize I may be off some, but I can tell you that any recipricol motion in the piston where I took my measurement was imperceptible with a depth gauge. The top of the cylinder was lightly coated with grease and sealed off with a plexi cover. A burrett was used and measured 25.4 cc's of volume. I used ATF for my measuring fluid. There was no sign of seepage under the rings after the measurement was taken.

I then lined the combustion chamber on the head with another thin film of grease, and the burrett was again used measuring 41.6 cc's of volume. The ports were checked after the measurement was taken to confirm that there was no seepage past the valves.

Lastly, the head gasket was measured. This is the only really questionable part of the calculations. The fire-ring measured 102mm across. The head gasket was the used one that came out of the motor, and the fire ring had been compressed to 1.02mm. I don't know if a smaller measurement is warrented here because the gasket wasn't compressed at the time the measurement was taken. The formula r2 x pi x h was used to calculate the head gasket volume which resulted in a calculation of 8.3 cc's for the head gasket.

Total chamber volume: 25.4 (piston) + 41.6 (head) + 8.3 = 75.3 cc's

I did not measure the cylinder volume with the piston at BDC. I went with the factory numbers of a 100mm piston and a 78.9mm stroke, and the formula set forth above, which yields a total cylinder volume of 619.7 cc's. Add the 75.3 cc's of total chamber volume to the total cylinder volume and we are left with a total volume of 695 cc's. Divide this number by the 75.3 cc's of chamber volume and you are left with a 9.23:1 C/R.

So where did the compression go? Is there something off in the measurements (particularly measuring the headgasket volume?), the math?, or is the S4 engine not truly a 10:1 C/R motor?

Thanks to Tom Middleton, Rob Fossett, and Thurston Pritchard for helping with the measuring and math for this post, we definitely were scratching our heads when all of the dust settled and we arrived at the final number.

Today, before taking the last piston out of my soon-to-be stroker motor, I cc'd the piston chamber volume and the head. This is what I came up with.

The piston was brought to top dead center. I did not have a degree wheel, but I did bring the piston up in stroke to a certain distance from the top fo the cylinder (BTDC), and then brought it to the same position ATDC, then turned the crank back half way inbetween. Without the degree wheel I realize I may be off some, but I can tell you that any recipricol motion in the piston where I took my measurement was imperceptible with a depth gauge. The top of the cylinder was lightly coated with grease and sealed off with a plexi cover. A burrett was used and measured 25.4 cc's of volume. I used ATF for my measuring fluid. There was no sign of seepage under the rings after the measurement was taken.

I then lined the combustion chamber on the head with another thin film of grease, and the burrett was again used measuring 41.6 cc's of volume. The ports were checked after the measurement was taken to confirm that there was no seepage past the valves.

Lastly, the head gasket was measured. This is the only really questionable part of the calculations. The fire-ring measured 102mm across. The head gasket was the used one that came out of the motor, and the fire ring had been compressed to 1.02mm. I don't know if a smaller measurement is warrented here because the gasket wasn't compressed at the time the measurement was taken. The formula r2 x pi x h was used to calculate the head gasket volume which resulted in a calculation of 8.3 cc's for the head gasket.

Total chamber volume: 25.4 (piston) + 41.6 (head) + 8.3 = 75.3 cc's

I did not measure the cylinder volume with the piston at BDC. I went with the factory numbers of a 100mm piston and a 78.9mm stroke, and the formula set forth above, which yields a total cylinder volume of 619.7 cc's. Add the 75.3 cc's of total chamber volume to the total cylinder volume and we are left with a total volume of 695 cc's. Divide this number by the 75.3 cc's of chamber volume and you are left with a 9.23:1 C/R.

So where did the compression go? Is there something off in the measurements (particularly measuring the headgasket volume?), the math?, or is the S4 engine not truly a 10:1 C/R motor?

Thanks to Tom Middleton, Rob Fossett, and Thurston Pritchard for helping with the measuring and math for this post, we definitely were scratching our heads when all of the dust settled and we arrived at the final number.

#27

Instructor

Join Date: Jun 2001

Location: Pasadena, CA, USA

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

Jim V, you are misunderstanding how compression is calculated.

It is the swept area of the piston plus the combustion volume divided by the combustion volume. The volume of the cylinder is measured (bore/2)^2*pi*stroke. This will give you the area that is added to the cylinder when the piston moves from TDC to BDC. In addition to that, you add the combustion volume. This is because whether the piston is at BDC or at TDC, the combustion area is still part of the equation. For a TDC calculation, you would need the piston top volume, the compression height (difference between the deck and the top of the piston, in this case these two together are 25.4cc), plus the gasket volume (8.3cc, or 7.8cc according to Mark K), plus the cylinder head volume (41.6cc). To measure BDC, you simply add the swept volume of the piston (619.7cc) because all of the other measurements remain the same.

Add them all up for the bottom dead center measurement:

619.7 + 25.4 + 8.3 + 41.6 = 695

Then, we remove the cylinder from the equation, since it is the only thing that changes from TDC to BDC.

25.4 + 8.3 + 41.6 = 75.3

The ratio of the two is the compression ratio. 695 / 75.3 = 9.23

It's possible that the piston wasn't exactly at top dead center. If the piston were half a millimeter further down in the bore than it should have been, the difference would be 4cc. That difference would mean 9.23:1 versus 9.7:1, so small changes make a big difference here, and measurement accuracy is extremely important.

It is the swept area of the piston plus the combustion volume divided by the combustion volume. The volume of the cylinder is measured (bore/2)^2*pi*stroke. This will give you the area that is added to the cylinder when the piston moves from TDC to BDC. In addition to that, you add the combustion volume. This is because whether the piston is at BDC or at TDC, the combustion area is still part of the equation. For a TDC calculation, you would need the piston top volume, the compression height (difference between the deck and the top of the piston, in this case these two together are 25.4cc), plus the gasket volume (8.3cc, or 7.8cc according to Mark K), plus the cylinder head volume (41.6cc). To measure BDC, you simply add the swept volume of the piston (619.7cc) because all of the other measurements remain the same.

Add them all up for the bottom dead center measurement:

619.7 + 25.4 + 8.3 + 41.6 = 695

Then, we remove the cylinder from the equation, since it is the only thing that changes from TDC to BDC.

25.4 + 8.3 + 41.6 = 75.3

The ratio of the two is the compression ratio. 695 / 75.3 = 9.23

It's possible that the piston wasn't exactly at top dead center. If the piston were half a millimeter further down in the bore than it should have been, the difference would be 4cc. That difference would mean 9.23:1 versus 9.7:1, so small changes make a big difference here, and measurement accuracy is extremely important.

#28

Jon,

My posts sometimes wander because I write them as I'm tossing them in my head; I should write them down, then post.

The swept volume of the cylinder; 619.7 is -calculated- and provides a perfect cylinder, flat top and bottom.

The piston however is not flat, and in this case dished and notched.

By -actually- measuring the volume above the piston at TDC, you've intruded into the -calculated- 619.7. ( My example of 17cc was just for a f'instance)

Because of the direct measurement we've now given the swept-area cylinder a top that perfectly matches the piston, so in order to maintain the volume of 619.7, the bottom must be equally shaped.

Make sense?

JimV

My posts sometimes wander because I write them as I'm tossing them in my head; I should write them down, then post.

The swept volume of the cylinder; 619.7 is -calculated- and provides a perfect cylinder, flat top and bottom.

The piston however is not flat, and in this case dished and notched.

By -actually- measuring the volume above the piston at TDC, you've intruded into the -calculated- 619.7. ( My example of 17cc was just for a f'instance)

Because of the direct measurement we've now given the swept-area cylinder a top that perfectly matches the piston, so in order to maintain the volume of 619.7, the bottom must be equally shaped.

Make sense?

JimV

#29

Instructor

Join Date: Jun 2001

Location: Pasadena, CA, USA

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

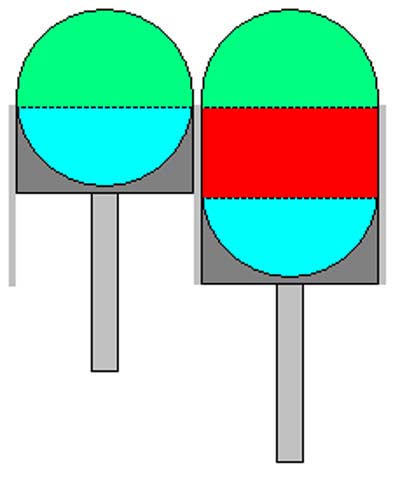

That's not correct. Remember that displacement is only the difference in the amount of volume in the cylinder when the piston is at the top versus the amount of air that is at the bottom. The difference is the displacement. Since the shape of the piston does not change, the difference is a cylinder. All you are doing is adding space in between. This is why displacement does not change with compression ratio. Perhaps this picture will help.

The displacement in this picture is the red area in the right cylinder. It is the difference in volume between the cylinder on the left and the cylinder on the right. Since the green and blue areas do not change between the two, the displacement is the space between the green and blue areas. Even if the tops of the pistons were not perpendicular to the travel of the pistons, the volume would be unchanged (since the sides of this cylinder would be the same length and distance from each other, the volume would not change, just as with a parallelogram, keeping a constant height and constant base means a constant area regardless of the angles involved).

The compression ratio in this picture would be the ratio between the total volume (green, blue, and red areas) in the right cylinder versus the total volume (green and blue areas) in the left cylinder.

The displacement in this picture is the red area in the right cylinder. It is the difference in volume between the cylinder on the left and the cylinder on the right. Since the green and blue areas do not change between the two, the displacement is the space between the green and blue areas. Even if the tops of the pistons were not perpendicular to the travel of the pistons, the volume would be unchanged (since the sides of this cylinder would be the same length and distance from each other, the volume would not change, just as with a parallelogram, keeping a constant height and constant base means a constant area regardless of the angles involved).

The compression ratio in this picture would be the ratio between the total volume (green, blue, and red areas) in the right cylinder versus the total volume (green and blue areas) in the left cylinder.

#30

Jon,

You are right and thanks (I drew a MUCH nicer picture than you :-))

Where I failed was that the volume I was concerned about is included in the 25.4 and therefore measured at both ends of the piston travel.

Normally this is seperated into 2 measurements to cover pistons that may protrude above the cylinder.

Which brings me to this question; Why are dished pistons measured down in the bore? It isn't needed as it is with domed pistons and I would think could allow more room for error that the way doing it at TDC.

Anyway, Thanks Jon

Sorry for the wasted bandwidth everyone.

You are right and thanks (I drew a MUCH nicer picture than you :-))

Where I failed was that the volume I was concerned about is included in the 25.4 and therefore measured at both ends of the piston travel.

Normally this is seperated into 2 measurements to cover pistons that may protrude above the cylinder.

Which brings me to this question; Why are dished pistons measured down in the bore? It isn't needed as it is with domed pistons and I would think could allow more room for error that the way doing it at TDC.

Anyway, Thanks Jon

Sorry for the wasted bandwidth everyone.