Need an engine shop to do an overbore - SE Michigan

#16

Just a car guy

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Jan 2002

Location: South Lyon, Michigan, Ewe Ess Eh

Posts: 9,927

Received 836 Likes

on

525 Posts

Terribly sorry to hear this mate. It's a fear I have as well, to the point where I consider re-using rings on the alusil bores.

*can you guess or do you know what went wrong?*

Somewhere on the forums a couple years ago I read a "success" story of a 2.5 n/a owner boring only 1 cyl, 1 or 2 sizes larger with no noticeable effect on balance.

*can you guess or do you know what went wrong?*

Somewhere on the forums a couple years ago I read a "success" story of a 2.5 n/a owner boring only 1 cyl, 1 or 2 sizes larger with no noticeable effect on balance.

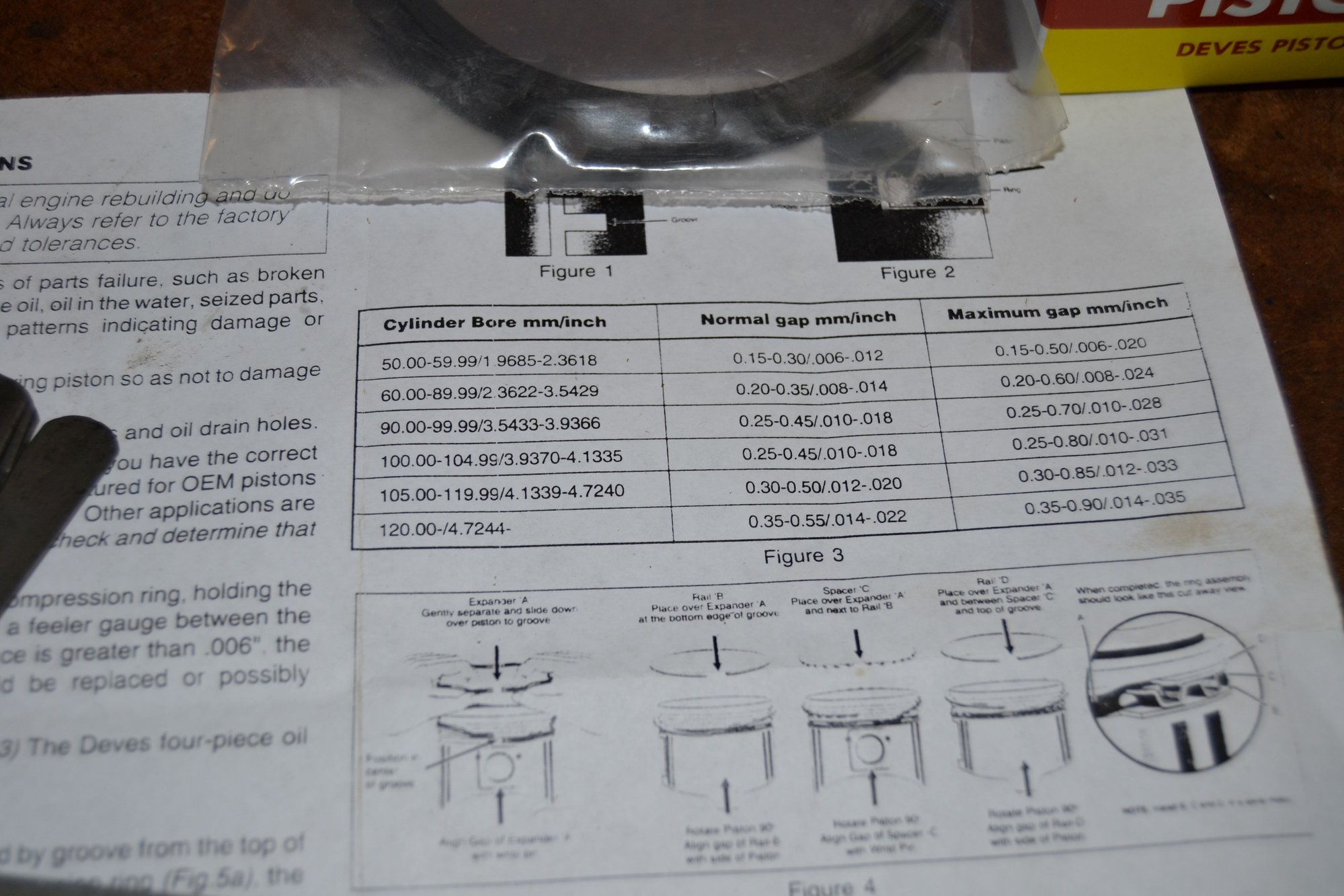

This necessitated buying new rings. Not a big deal. It's just the product I picked, turned out to be crap. Deves from Pelican. Nothing against Pelican - they are great. But this product was not specifically too good. I ground the top two rings in each bore to 0.33mm gap. About the middle of the spec. The instructions that came with the rings claimed that the oil rings did not need to be gapped at all. The problem was the four-piece oil ring set. It was nearly impossible to get the two expander and spacer rings to sit in the ring groove between the two rails. So at least one (#4) never did get seated properly. I must have forced this in and damaged the bore. I'll post a few pics of that mess soon. I haven't taken everything back apart yet - but I did see damage at the top of cylinder #2 as well. I'm going to place some of the blame on my ring compressor tool as well. Though I have used it many times in the past for other engine builds (though none with an aluminum block).

You are correct, the factory service manual does specifically state that it is possible to do just one overbore as the mass of oversize pistons are the same as the standard size. However, if I have to do two, I might do well to have them all done.

This is nothing that money can't fix. But it sure is kick in the nuts.

#18

Developer

Scott, a "rule of thumb" (pun intended) is to drag your thumbnail along the cylinder wall. Generally speaking, your thumbnail will glide over scratches smaller than .010" of and inch, and will catch on those 0.010" of an inch and larger.

Take a look at these pics of Cayenne damage that we repair:

https://928motorsports.com/services/...ock_repair.php

and see what I mean about the pistons. When the cylinder walls are deeply damaged, you can bet the pistons are too. To fix the cylinders and put the original pistons back in would only scar up the cylinders again.

Take a look at these pics of Cayenne damage that we repair:

https://928motorsports.com/services/...ock_repair.php

and see what I mean about the pistons. When the cylinder walls are deeply damaged, you can bet the pistons are too. To fix the cylinders and put the original pistons back in would only scar up the cylinders again.

#19

Developer

Block restoration kits for 944's are as follows:

Nikasil without boring: $1141 OR

Nikasil with boring (for engines with deep cylinder gouges) gouges $1391

4 forged pistons .020" over, with gapless piston rings compatible with Nikasil, and wrist pins

compatible with the stock con rods $1217

Then we ship everything back to you and you are ready to assemble your new motor.

Nikasil without boring: $1141 OR

Nikasil with boring (for engines with deep cylinder gouges) gouges $1391

4 forged pistons .020" over, with gapless piston rings compatible with Nikasil, and wrist pins

compatible with the stock con rods $1217

Then we ship everything back to you and you are ready to assemble your new motor.

#21

Developer

The cast piston alloys are softer than those alloys used in a forged piston. But even more to the point is the piston coatings, usually on the skirts. You will note that there are no coatings on the skirts of the stock cast piston in an alusil bore, and we have to request a nikasil-compatible coating (or none) when the piston will go in to Nikasil.

Nikasil has terrific scratch resistance, and makes a great addition to the strength of the Alusil block. You probably already know that Alusil is a hypereutectic alloy and has terrific strength and wear characteristics. Its Achilles's heal is that Alusil is easily scratched. A plating of Nikasil on top of the Alusil solves this one weakness, and makes a great engine.

Nikasil has terrific scratch resistance, and makes a great addition to the strength of the Alusil block. You probably already know that Alusil is a hypereutectic alloy and has terrific strength and wear characteristics. Its Achilles's heal is that Alusil is easily scratched. A plating of Nikasil on top of the Alusil solves this one weakness, and makes a great engine.

#22

Just a car guy

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Jan 2002

Location: South Lyon, Michigan, Ewe Ess Eh

Posts: 9,927

Received 836 Likes

on

525 Posts

Scott, a "rule of thumb" (pun intended) is to drag your thumbnail along the cylinder wall. Generally speaking, your thumbnail will glide over scratches smaller than .010" of and inch, and will catch on those 0.010" of an inch and larger.

Take a look at these pics of Cayenne damage that we repair:

https://928motorsports.com/services/...ock_repair.php

and see what I mean about the pistons. When the cylinder walls are deeply damaged, you can bet the pistons are too. To fix the cylinders and put the original pistons back in would only scar up the cylinders again.

Take a look at these pics of Cayenne damage that we repair:

https://928motorsports.com/services/...ock_repair.php

and see what I mean about the pistons. When the cylinder walls are deeply damaged, you can bet the pistons are too. To fix the cylinders and put the original pistons back in would only scar up the cylinders again.

Thanks for all the information. I'll try your thumb nail "test", but I think I can safely say, I've got serious enough damage that an overbore will be required.

What is different in my case, is that the pistons are probably still fine. The rings are what caused the damage to the bores. I failed at getting the oil rings properly situated in the lower groove. I then forced the pistons into the bore and created the gouges. While the pistons may still be OK, they will not be usable with an overbore.

I have been in a very foul mood because of this and have also been trying to get rid of a serious cold. Maybe this weekend I will feel up to taking some more photos and begin disassembly of everything (again).

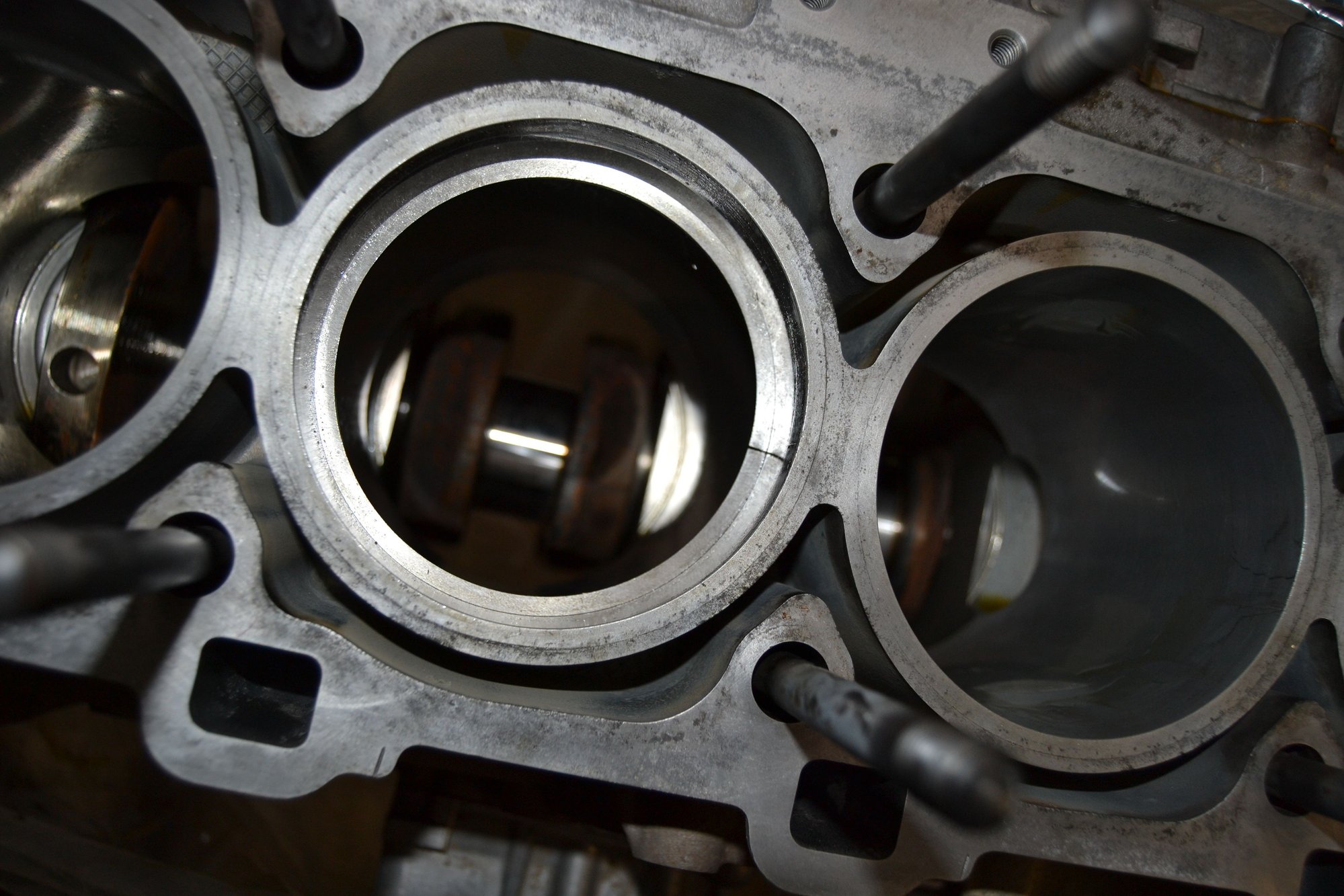

In the meantime, if you look closely at cylinder #2 in this photo - you can see damage to the bore. This is not as bad as #4 - which had not been installed at the time of this shot. Regardless the damage is probably enough, that even if this were the worst, it would need attention. Even #3 shows signs of distress.

#23

Just a car guy

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Jan 2002

Location: South Lyon, Michigan, Ewe Ess Eh

Posts: 9,927

Received 836 Likes

on

525 Posts

Block restoration kits for 944's are as follows:

Nikasil without boring: $1141 OR

Nikasil with boring (for engines with deep cylinder gouges) gouges $1391

4 forged pistons .020" over, with gapless piston rings compatible with Nikasil, and wrist pins

compatible with the stock con rods $1217

Then we ship everything back to you and you are ready to assemble your new motor.

Nikasil without boring: $1141 OR

Nikasil with boring (for engines with deep cylinder gouges) gouges $1391

4 forged pistons .020" over, with gapless piston rings compatible with Nikasil, and wrist pins

compatible with the stock con rods $1217

Then we ship everything back to you and you are ready to assemble your new motor.

I've got a few questions about removing all of the steel pieces.

1) Why is this necessary? I can understand the head studs, but what about all of the guide pins, etc? The studs for the lower crankcase would need to remain, correct?

2) How easy are these pieces to remove?

3) Would they get damaged on removal?

4) Are there kits to replace all of these pieces, should they indeed get damaged? I've not noticed them listed at the usual places - but then again, I haven't consciously been looking.

5) If I need to pay to have these pieces removed, approximately how much is this likely to be?

6) Can you explain the gapless rings? Are they installed in the pistons already?

I'll probably have a hundred other questions as I progress. But I expect there is a high probability I will need to employ your services. Thank you for all of the help so far.

#24

Developer

All the steel has to be removed from the block because this is an electrostatic charged vat process with an anode and a cathode. The ferrous metal conducts way to well and disturbs the proper plating of the aluminum.

Most of the metal like the head locating pins are not too hard to get out. We use a MAP gas torch to warm the aluminum and a vise-grip. Not rocket science. If the part does not come out easily, leave it rather than wreck it. We can "paint" the steel parts with a special wax compound before they are dipped and protect the steel bits that way.

I am a big fan of Total Seal rings and I would suggest you go to their site to read up on the benefits of gapless rings. They can explain it better than I can. I use them on every engine I can, I have seen the benefits in lower crankcase pressures and higher HP output many many times.

Your overbore will come in at a unique size and the only rings that will be available are file-to-fit rings. Because of this, The rings will not come on the pistons.

If you do not want to file your piston rings and install them on your pistons, we could do that for you here before we ship you the block.

For us to do that for you, you would have to send us the Con Rods because it is better to mount the piston on to the con rod and install the wrist pin keepers before installing the piston rings. Then we could check and file the 6 rings per cylinder to fit, and install them on the pistons for you. This way you would receive the block with a set of pistons on their rods and piston rings on their pistons. You take it from there. Figure 2 hours per cylinder at our shop rate of $90/hr if you want us to do this.

Most of the metal like the head locating pins are not too hard to get out. We use a MAP gas torch to warm the aluminum and a vise-grip. Not rocket science. If the part does not come out easily, leave it rather than wreck it. We can "paint" the steel parts with a special wax compound before they are dipped and protect the steel bits that way.

I am a big fan of Total Seal rings and I would suggest you go to their site to read up on the benefits of gapless rings. They can explain it better than I can. I use them on every engine I can, I have seen the benefits in lower crankcase pressures and higher HP output many many times.

Your overbore will come in at a unique size and the only rings that will be available are file-to-fit rings. Because of this, The rings will not come on the pistons.

If you do not want to file your piston rings and install them on your pistons, we could do that for you here before we ship you the block.

For us to do that for you, you would have to send us the Con Rods because it is better to mount the piston on to the con rod and install the wrist pin keepers before installing the piston rings. Then we could check and file the 6 rings per cylinder to fit, and install them on the pistons for you. This way you would receive the block with a set of pistons on their rods and piston rings on their pistons. You take it from there. Figure 2 hours per cylinder at our shop rate of $90/hr if you want us to do this.

#25

Just a car guy

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Jan 2002

Location: South Lyon, Michigan, Ewe Ess Eh

Posts: 9,927

Received 836 Likes

on

525 Posts

OK - I figured there had to be an electrostatic process involved or you wouldn't care about the steel parts. What about the lower crankshaft studs? Don't they need to stay in place to reduce deflection by having the lower bolted in place during the boring process? Maybe the process is not so heat intensive as say an iron block?

No problem on the rings. I can do this myself. The term "gapless" seemed odd. I didn't see anything at their site explaining that meaning. There would still be a specification for a gap, correct? Thermal expansion dictates this.

Thanks for the continued help. Maybe I will feel up to messing with this soon. Still trying to fight off what I believe is the flu.

No problem on the rings. I can do this myself. The term "gapless" seemed odd. I didn't see anything at their site explaining that meaning. There would still be a specification for a gap, correct? Thermal expansion dictates this.

Thanks for the continued help. Maybe I will feel up to messing with this soon. Still trying to fight off what I believe is the flu.

#26

Racer

Join Date: Sep 2012

Location: Greenville New York

Posts: 444

Likes: 0

Received 0 Likes

on

0 Posts

Other steel parts to remove; balance shaft cover locating dowels, front main bearing locating roll pin, oil galley plugs(3), bell housing dowels, lower crankcase locating dowel. Then pray the shop gets piston to wall clearance correct. Good luck to you.

#28

Racer

Join Date: Sep 2012

Location: Greenville New York

Posts: 444

Likes: 0

Received 0 Likes

on

0 Posts

I didn't go the plating route in the end so no first hand experience with this.

#29

Developer

Don't it let it cause you too much concern. Pull the locating pins that are easy and don't worry about it. When your block gets here we will try to remove the ones you leave, and if we cannot get them out, we mark them to be sealed with wax before they are dipped. No worries.

)

)