DME Repaired w/pics

#1

Addict

Rennlist Member

Rennlist Member

Thread Starter

Ok, fingers crossed, I think I repaired my DME tonight.

Symptoms:

- Car would die suddenly and intermittently

- Shaking the DME would get it running again (even going down the road a couple of times!)

- Frequency of problem was increasing

After a fair bit of searching on the list I surmised that it must be a cracked solder joint in the DME. I found several threads but no pictures.

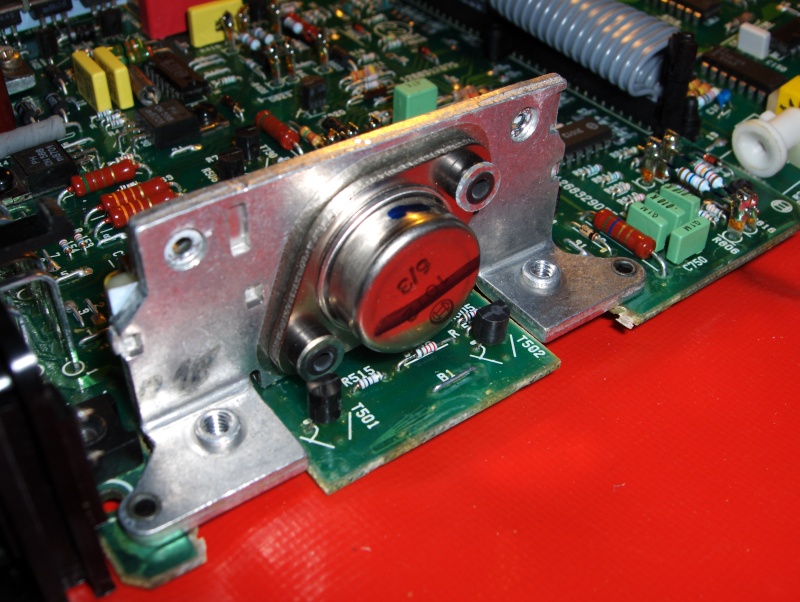

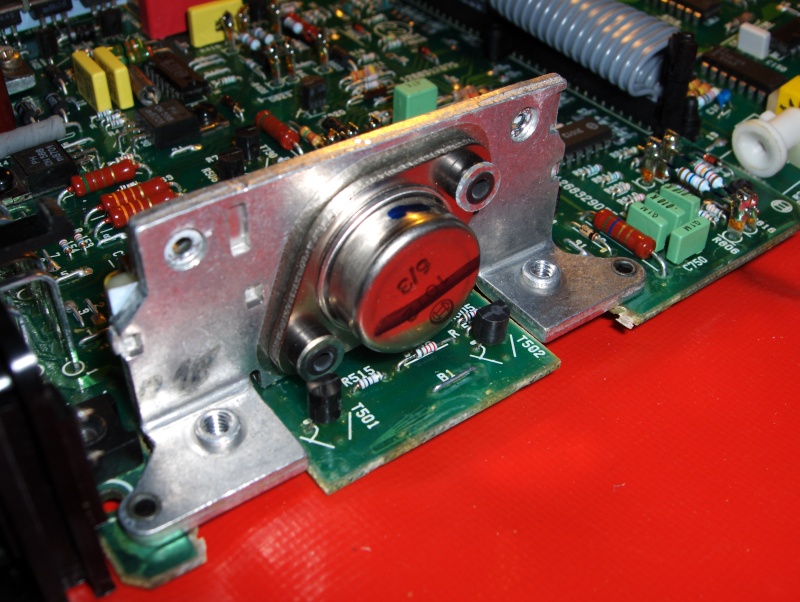

Based on what I read, the failure was typically on the leads from 'the big silver transistor'. Here's what that looks like:

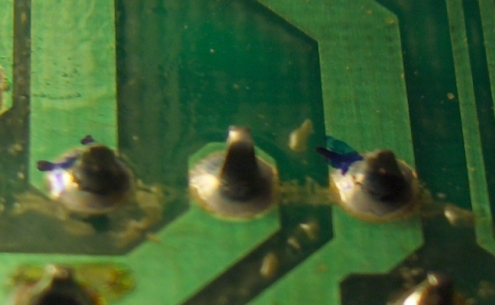

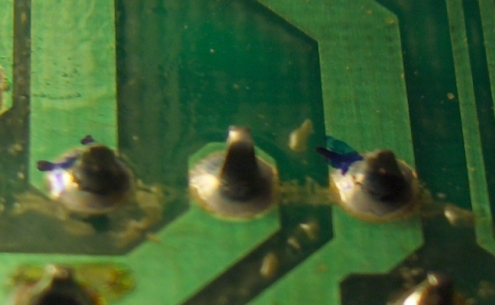

There are three leads that come off this transistor and here is what they looked like on the bottom of the board. Notice the tiny cracks on the two outside posts?

Out with the trusty soldering iron, melt the solder joints and then let it 'freeze' and life is good. Only time will tell of course if this really was the fix but it had died several times on me earlier today and so far this evening it's running like a champ.

The hardest part was soldering with my fingers crossed

For a thread on repairing early DME's Click Here

Keywords for future searchers: DME stall die sudden solder crack transistor repair intermittent

Symptoms:

- Car would die suddenly and intermittently

- Shaking the DME would get it running again (even going down the road a couple of times!)

- Frequency of problem was increasing

After a fair bit of searching on the list I surmised that it must be a cracked solder joint in the DME. I found several threads but no pictures.

Based on what I read, the failure was typically on the leads from 'the big silver transistor'. Here's what that looks like:

There are three leads that come off this transistor and here is what they looked like on the bottom of the board. Notice the tiny cracks on the two outside posts?

Out with the trusty soldering iron, melt the solder joints and then let it 'freeze' and life is good. Only time will tell of course if this really was the fix but it had died several times on me earlier today and so far this evening it's running like a champ.

The hardest part was soldering with my fingers crossed

For a thread on repairing early DME's Click Here

Keywords for future searchers: DME stall die sudden solder crack transistor repair intermittent

Last edited by gregeast; 11-10-2006 at 09:23 AM.

#3

Advanced

Originally Posted by gregeast

Out with the trusty soldering iron, melt the solder joints and then let it 'freeze' and life is good. Only time will tell of course if this really was the fix but it had died several times on me earlier today and so far this evening it's running like a champ.

The hardest part was soldering with my fingers crossed

The hardest part was soldering with my fingers crossed

I believe the correct way is to remove the old solder and replace it with fresh. That's what all the electronics repair guys do when repairing/replacing components on circuit boards.

Good luck, hope it goes well for you.

Cheers

Rob

#4

I would take care with the level of heat transferred to the Transistor itself - although the correct way is probably to replace the solder I would think what you did will fix it satisfactorily and obviously you haven't overheated the transistor as it works.

Thanks for thr info and the pics.

Bill Babe

Thanks for thr info and the pics.

Bill Babe

#5

I would take care with the level of heat transferred to the Transistor itself - although the correct way is probably to replace the solder I would think what you did will fix it satisfactorily and obviously you haven't overheated the transistor as it works.

Thanks for the info and the pics.

Bill Babe

Thanks for the info and the pics.

Bill Babe

#6

Defending the Border

Rennlist Member

Rest In Peace

Rennlist Member

Rest In Peace

Excellent job Greg! You really wouldn't think that transistor could move much, except for thermal excursions.

"Stunning photography" **** - Rennlist Technical Forums.

Ditto on fresh solder and heat transfer.

"Stunning photography" **** - Rennlist Technical Forums.

Ditto on fresh solder and heat transfer.

#7

Addict

Rennlist Member

Rennlist Member

Thread Starter

I didn't remove the old solder but I did flow some new in on top of what was there. The leads to that transistor are fairly long, ~1/2", with a 90 bend in them so heat transfer is probably less of a concern than normal.

Thanks guys, please keep your fingers crossed for me.

Thanks guys, please keep your fingers crossed for me.

Trending Topics

#10

Burning Brakes

Join Date: Mar 2006

Location: Orlando,FL (formerly UK)

Posts: 1,215

Likes: 0

Received 0 Likes

on

0 Posts

I've been a professional service engineer for almost 30 years, and while it IS preferable to remove all old solder, it's by no means essential.

The important thing is that the solder joints are not dull and crystalline-looking (which is usually caused by the pieces moving as the solder cools through it's "eutectic region" -the transitional stage as it cools from a liquid to a solid.) when you've finished.

Basically, if the joint looks shiny and isn't 'balled-up' away from the circuit board or away from the component lead -i.e. it's clinging nicely to both- then it's a good joint. -If the old joint 'hisses and pops' a lot as you melt the old solder, it was porous and has moisture in it. -You should remove it, but as long as it boils off, you'll probably get another 10-20 years out of it once you add the new solder.

More info with pictures is here: http://dragon.herts.ac.uk/~eleqdml/t...eral/soldering

As regards not overheating the transistor, -yes that's true but that transistor can take a fair amoun of heat (it gets hot during regular use, hence it's being mounted to a heatsink) and it also has long leads, but still it's best to be mindful of not keeping the iron on the joint for more than ten seconds between cooling periods.

As a rule, these types of 'crack-line' joint failures occur at places where there's a lot of un-relieved stress or flex on the leads. Often a dab of "hot-snot" plastic glue-gun goo to strengthen or reinforce the mass of the component or heatsink at the corner where it meets the circuit board will help prevent re-occurence.

Keith

The important thing is that the solder joints are not dull and crystalline-looking (which is usually caused by the pieces moving as the solder cools through it's "eutectic region" -the transitional stage as it cools from a liquid to a solid.) when you've finished.

Basically, if the joint looks shiny and isn't 'balled-up' away from the circuit board or away from the component lead -i.e. it's clinging nicely to both- then it's a good joint. -If the old joint 'hisses and pops' a lot as you melt the old solder, it was porous and has moisture in it. -You should remove it, but as long as it boils off, you'll probably get another 10-20 years out of it once you add the new solder.

More info with pictures is here: http://dragon.herts.ac.uk/~eleqdml/t...eral/soldering

As regards not overheating the transistor, -yes that's true but that transistor can take a fair amoun of heat (it gets hot during regular use, hence it's being mounted to a heatsink) and it also has long leads, but still it's best to be mindful of not keeping the iron on the joint for more than ten seconds between cooling periods.

As a rule, these types of 'crack-line' joint failures occur at places where there's a lot of un-relieved stress or flex on the leads. Often a dab of "hot-snot" plastic glue-gun goo to strengthen or reinforce the mass of the component or heatsink at the corner where it meets the circuit board will help prevent re-occurence.

Keith

#11

Addict

Rennlist Member

Rennlist Member

Thread Starter

Based on how sturdily this transistor is mounted (I wish I'd taken a pic of the other side too) and the fact that the leads are making a 90 degree bend and so are not supporting the mass of the transistor my guess is that the cracks are the result of heat cycling, not of mechanical breakage. Which is why I wanted to add a bit of new solder to the mix.

Like VWAddict said, if I get 20 more years out of it I'll be quite happy

Like VWAddict said, if I get 20 more years out of it I'll be quite happy

#12

Rennlist Member

When the DME is running, that transistor can get so hot it will burn your skin (ask me how I know). I assume that adds to the stress seen at the joints.

#13

Addict

Rennlist Member

Rennlist Member

Thread Starter

Originally Posted by aribop

FINALLY a post that adds value to this forum!

Thanks, Greg!!

Thanks, Greg!!