#2 cylinder not firing 944S2

#16

Racer

Thread Starter

I have a question. When you started the post you said the #2 cylinder was 180 psi. The latest compression showed it at 130. What has changed? Was the lifter on cylinder #2 making a knocking noise when you noticed this problem? Usually when I've had a faulty lifter, it was very noisy. If it wasn't making a lot of noise, then I'm wondering if it might be a bad valve or something else in the cylinder like a bad ring, cylinder head gasket, bad seal around spark plug, etc.

Iíll run a leak-down test before before pulling the valve cover though.

#17

Racer

As the title says, Iím down a cylinder. Compression shows 180psi on cyl #2, the #2 plug fires fine with a strong spark, I cleaned all injectors and all four spray well (I even swapped injectors between cylinders), and I see 12V on each lead for the #2&3 injectors. However, thereís no fuel in cyl #2 even after running the engine.

I think thereís an issue with firing the injector, but Iím not sure what. How does the injector firing work? Does one of the injector leads get grounded to complete the circuit?

Thanks,

Camelman

I think thereís an issue with firing the injector, but Iím not sure what. How does the injector firing work? Does one of the injector leads get grounded to complete the circuit?

Thanks,

Camelman

#18

As the title says, Iím down a cylinder. Compression shows 180psi on cyl #2, the #2 plug fires fine with a strong spark, I cleaned all injectors and all four spray well (I even swapped injectors between cylinders), and I see 12V on each lead for the #2&3 injectors. However, thereís no fuel in cyl #2 even after running the engine.

I think thereís an issue with firing the injector, but Iím not sure what. How does the injector firing work? Does one of the injector leads get grounded to complete the circuit?

Thanks,

Camelman

I think thereís an issue with firing the injector, but Iím not sure what. How does the injector firing work? Does one of the injector leads get grounded to complete the circuit?

Thanks,

Camelman

#19

Rennlist Member

There's a good discussion of the various firing methods here: https://members.rennlist.com/951_rac...atchFiring.pdf

#20

Rennlist Member

I think the difference came from the hydraulic tappet working, and then not working. The engine had operated with cyl #2 intermittently firing before, which was noticeable as a power surge when the cylinder fired. There was a very loud tapping when that occurred, but there’s no noticeable tapping now.

#21

Sorry to take this thread sideways. If it was my S2. It would be towed to the nearest mechanic for some immediate help before I caused myself 3000.00 more in damage to it. Just throwing that out there.

#22

Racer

Thread Starter

Otto, thanks for the info.

Stevie, a failed tappet is not uncommon, nor a failure of its cousin, the "lifter", in pushrod engines. A failure isn't a huge problem as far as damage is concerned, but will cause operational issues such as reduced power output. The hydraulic tappet is a robust unit that has an internal oil gallery that gets "pumped up" to expand the tappet to the correct height. Oil doesn't flow quickly through the unit, so there's a chance for sludge to build up in it. With enough sludge, the intake hole can get blocked, or the adjustment portion can get stuck, and then the tappet won't be pumped up to be tall enough to fill the space between the valve and the camshaft. That creates a situation where the camshaft will slap into the hydraulic tappet instead of maintaining a constant contact with it. Since the hydraulic tappet/lifter is pretty robust, it can take a lot of this slapping, but you'll want to fix it soon. The best way to remedy this is to DRIVE YOUR CAR!!! Seriously, drive that sucker, change the oil when it's time, and maybe run a cleaner through the oil every so often. I consider hydraulic lifters/tappets to be wear items, so I'm not bothered with having to change mine. I just wish I didn't have to.

Seriously, drive that sucker, change the oil when it's time, and maybe run a cleaner through the oil every so often. I consider hydraulic lifters/tappets to be wear items, so I'm not bothered with having to change mine. I just wish I didn't have to.

Camelman

Stevie, a failed tappet is not uncommon, nor a failure of its cousin, the "lifter", in pushrod engines. A failure isn't a huge problem as far as damage is concerned, but will cause operational issues such as reduced power output. The hydraulic tappet is a robust unit that has an internal oil gallery that gets "pumped up" to expand the tappet to the correct height. Oil doesn't flow quickly through the unit, so there's a chance for sludge to build up in it. With enough sludge, the intake hole can get blocked, or the adjustment portion can get stuck, and then the tappet won't be pumped up to be tall enough to fill the space between the valve and the camshaft. That creates a situation where the camshaft will slap into the hydraulic tappet instead of maintaining a constant contact with it. Since the hydraulic tappet/lifter is pretty robust, it can take a lot of this slapping, but you'll want to fix it soon. The best way to remedy this is to DRIVE YOUR CAR!!!

Seriously, drive that sucker, change the oil when it's time, and maybe run a cleaner through the oil every so often. I consider hydraulic lifters/tappets to be wear items, so I'm not bothered with having to change mine. I just wish I didn't have to.

Seriously, drive that sucker, change the oil when it's time, and maybe run a cleaner through the oil every so often. I consider hydraulic lifters/tappets to be wear items, so I'm not bothered with having to change mine. I just wish I didn't have to.Camelman

#23

I'm a bit confused, Can not anyone else see the Elephant in the room, THERE IS NO FUEL GETTING TO NO.2 CYLINDER, This has to be the priority regardless of poor compression,

To answer a previous question, the S2 "batch fires" the injectors, you could mock up some jumper leads and have no.1 injector plug diverted to no.2 and visa versa, that way if the misfire goes to no.1 you know it's the wiring either, ballast resistor I mention earlier, Wiring in harness where it joins the 4 injectors to the one output from the DME, or possibly the injector plug,

Good news is, it is not the DME

To answer a previous question, the S2 "batch fires" the injectors, you could mock up some jumper leads and have no.1 injector plug diverted to no.2 and visa versa, that way if the misfire goes to no.1 you know it's the wiring either, ballast resistor I mention earlier, Wiring in harness where it joins the 4 injectors to the one output from the DME, or possibly the injector plug,

Good news is, it is not the DME

#24

Racer

Thread Starter

Aussie, I donít think itís a fuel delivery issue after all. Sorry for not clearing that up.

The inconsistent compression numbers had me chasing my tail at first. Iím still not 100% on whatís going on, but the injectors are firing, spark plugs are firing, and compression is low. I am going to do a leak down test, and also investigate the hydraulic tappet that had been giving me fits earlier.

The inconsistent compression numbers had me chasing my tail at first. Iím still not 100% on whatís going on, but the injectors are firing, spark plugs are firing, and compression is low. I am going to do a leak down test, and also investigate the hydraulic tappet that had been giving me fits earlier.

#26

Racer

Otto, thanks for the info.

Stevie, a failed tappet is not uncommon, nor a failure of its cousin, the "lifter", in pushrod engines. A failure isn't a huge problem as far as damage is concerned, but will cause operational issues such as reduced power output. The hydraulic tappet is a robust unit that has an internal oil gallery that gets "pumped up" to expand the tappet to the correct height. Oil doesn't flow quickly through the unit, so there's a chance for sludge to build up in it. With enough sludge, the intake hole can get blocked, or the adjustment portion can get stuck, and then the tappet won't be pumped up to be tall enough to fill the space between the valve and the camshaft. That creates a situation where the camshaft will slap into the hydraulic tappet instead of maintaining a constant contact with it. Since the hydraulic tappet/lifter is pretty robust, it can take a lot of this slapping, but you'll want to fix it soon. The best way to remedy this is to DRIVE YOUR CAR!!! Seriously, drive that sucker, change the oil when it's time, and maybe run a cleaner through the oil every so often. I consider hydraulic lifters/tappets to be wear items, so I'm not bothered with having to change mine. I just wish I didn't have to.

Seriously, drive that sucker, change the oil when it's time, and maybe run a cleaner through the oil every so often. I consider hydraulic lifters/tappets to be wear items, so I'm not bothered with having to change mine. I just wish I didn't have to.

Camelman

Stevie, a failed tappet is not uncommon, nor a failure of its cousin, the "lifter", in pushrod engines. A failure isn't a huge problem as far as damage is concerned, but will cause operational issues such as reduced power output. The hydraulic tappet is a robust unit that has an internal oil gallery that gets "pumped up" to expand the tappet to the correct height. Oil doesn't flow quickly through the unit, so there's a chance for sludge to build up in it. With enough sludge, the intake hole can get blocked, or the adjustment portion can get stuck, and then the tappet won't be pumped up to be tall enough to fill the space between the valve and the camshaft. That creates a situation where the camshaft will slap into the hydraulic tappet instead of maintaining a constant contact with it. Since the hydraulic tappet/lifter is pretty robust, it can take a lot of this slapping, but you'll want to fix it soon. The best way to remedy this is to DRIVE YOUR CAR!!!

Seriously, drive that sucker, change the oil when it's time, and maybe run a cleaner through the oil every so often. I consider hydraulic lifters/tappets to be wear items, so I'm not bothered with having to change mine. I just wish I didn't have to.

Seriously, drive that sucker, change the oil when it's time, and maybe run a cleaner through the oil every so often. I consider hydraulic lifters/tappets to be wear items, so I'm not bothered with having to change mine. I just wish I didn't have to.Camelman

#27

Racer

Thread Starter

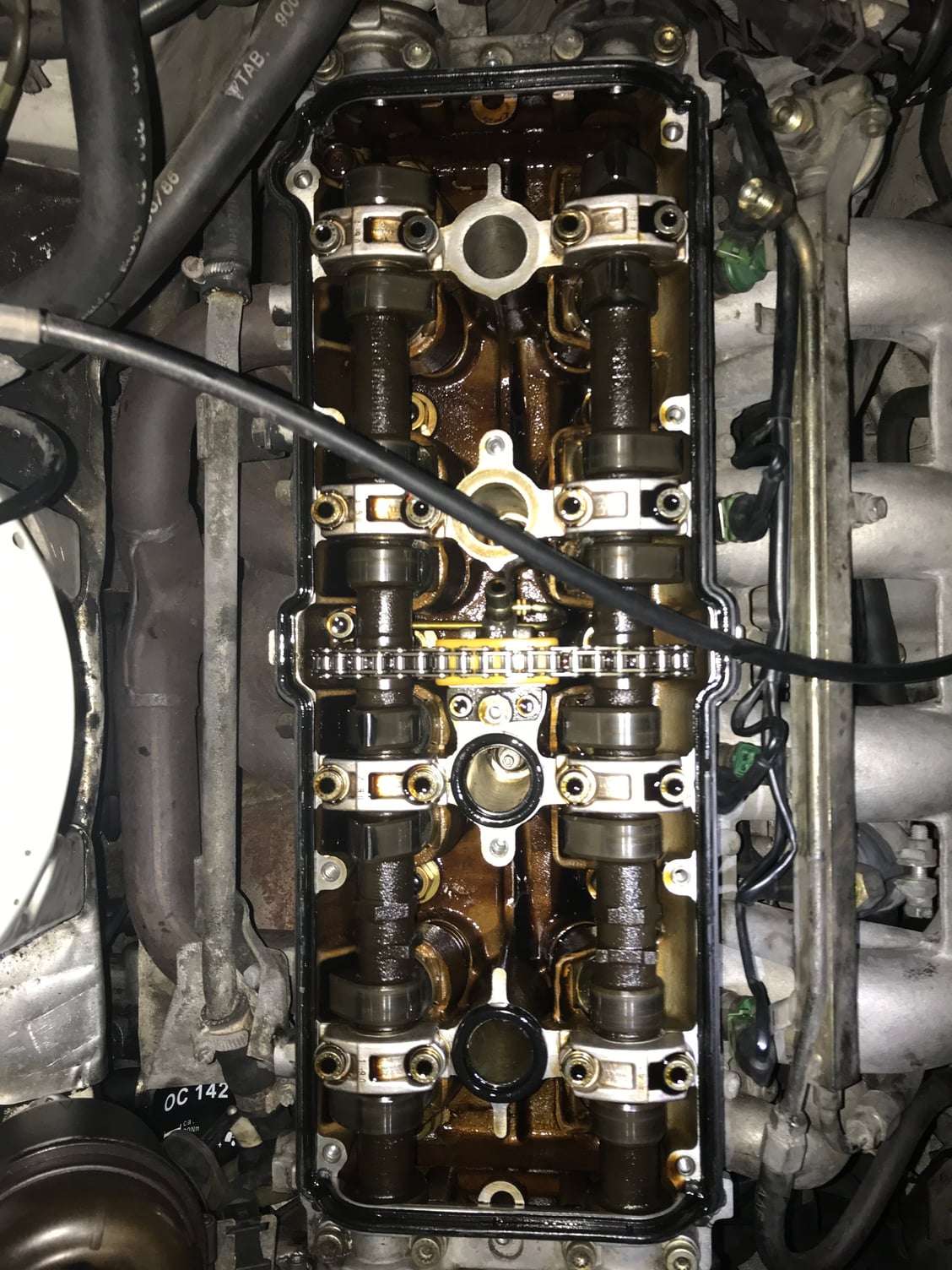

I pulled the valve cover and checked cam lobe to lifter clearances with feeler gauges tonight. I also rotated the crank pulley as necessary to unload the valve springs. None of the lifters allowed even a .0015Ē feeler to pass. Can anyone confirm if what I did is a legit way to test the lifters? Do I need to pull the lifters out to see the undersides to verify if they are collapsed? I also pushed on the #2 cylinder lifters to see if theyíd budge, but they were firm.

Iíll get a leak down tester to test everything this weekend.

I donít feel confident with my feeler gauge test for the lifters.

#28

Racer

Thread Starter

I pulled the head and everything looks good. 7/16 lifters were soft though, so Iím thinking itís time to clean them all.

Will install all new rubber seals in the head and valve cover along with new bolts. The big question is if I send the head off for new valve guides, etc by Lindsey Racing (or other), or just clean it and reassemble. I had to drill out some cam cover bolts, so will definitely need a cleaning. A full refresh will be about $1600 including shipping to Lindsey.

A refresh would include new valve guides and seals.

Car has 167k miles.

Camelman

Will install all new rubber seals in the head and valve cover along with new bolts. The big question is if I send the head off for new valve guides, etc by Lindsey Racing (or other), or just clean it and reassemble. I had to drill out some cam cover bolts, so will definitely need a cleaning. A full refresh will be about $1600 including shipping to Lindsey.

A refresh would include new valve guides and seals.

Car has 167k miles.

Camelman

Last edited by camelman; 03-19-2019 at 02:53 AM.

#29

FWIW all those compression numbers seem low, with #2 obviously having the biggest issue. MY S2 was around 205-210psi across all four cylinders the last time I checked it. Might be a good idea to have the whole thing refreshed at this point.

#30

Race Car

It's impossible to comment on OP's compression numbers without knowing the altitude where the test was performed.

For each 1000 feet, air density has a .2 affect on CR.

Statically, the swept volume from BDC to TDC, expecting all valves closed precisely at that degree, coupled with the negative cc area of the combustion chamber should yield 10.9:1 CR or 160.23 psi at sea level.

Because valve events are included in spinning an engine over, this is called dynamic compression ratio, and it's always less than the mathematical static compression because the seat time of the valve are in play.

An engine could achieve more than 10.9:1 X 14.7 (psi atmospheric at sea level) with 100+% VE or re-compression of residual gas not cleared on previous cycle.

Or a faulty gauge

T

For each 1000 feet, air density has a .2 affect on CR.

Statically, the swept volume from BDC to TDC, expecting all valves closed precisely at that degree, coupled with the negative cc area of the combustion chamber should yield 10.9:1 CR or 160.23 psi at sea level.

Because valve events are included in spinning an engine over, this is called dynamic compression ratio, and it's always less than the mathematical static compression because the seat time of the valve are in play.

An engine could achieve more than 10.9:1 X 14.7 (psi atmospheric at sea level) with 100+% VE or re-compression of residual gas not cleared on previous cycle.

Or a faulty gauge

T