The front girdle dowel that wasn't used on the 944

#17

Three Wheelin'

Seems to me that they did this for a reason, They left that locating pin out on purpose, the side-to-to side is determined by the bearings, and the fore/aft is determined by the oil pump. If you add a "force" locator as determined by a bolt hole, In my opinion that is asking for trouble. I have taken apart 200,000 mile motors, race motors, and engines with blown headgaskets. I have never, seen really bad mains...Ever.. only bad no 2 rod bearings.. I personally would let it find its home on its own, and once that loctite is dry and the Girdle is locked down there is no way it can move unless you knock a counterweight off the crank...

#18

Seems to me that they did this for a reason, They left that locating pin out on purpose, the side-to-to side is determined by the bearings, and the fore/aft is determined by the oil pump. If you add a "force" locator as determined by a bolt hole, In my opinion that is asking for trouble. I have taken apart 200,000 mile motors, race motors, and engines with blown headgaskets. I have never, seen really bad mains...Ever.. only bad no 2 rod bearings.. I personally would let it find its home on its own, and once that loctite is dry and the Girdle is locked down there is no way it can move unless you knock a counterweight off the crank...

#19

Rennlist Member

Seems to me that they did this for a reason, They left that locating pin out on purpose, the side-to-to side is determined by the bearings, and the fore/aft is determined by the oil pump. If you add a "force" locator as determined by a bolt hole, In my opinion that is asking for trouble. I have taken apart 200,000 mile motors, race motors, and engines with blown headgaskets. I have never, seen really bad mains...Ever.. only bad no 2 rod bearings.. I personally would let it find its home on its own, and once that loctite is dry and the Girdle is locked down there is no way it can move unless you knock a counterweight off the crank...

The main bearings/crank isn't the best way to locate or stabilize the girdle's location relative to the block when building an engine that will be pushed hard. I'm sure that's why shops such as Lindsey's offer the service of installing additional alignment pins. But for the vast majority of street dwelling 944s the original design seems to work fine.

#20

Just a car guy

Rennlist Member

Rennlist Member

Join Date: Jan 2002

Location: South Lyon, Michigan, Ewe Ess Eh

Posts: 9,927

Received 835 Likes

on

524 Posts

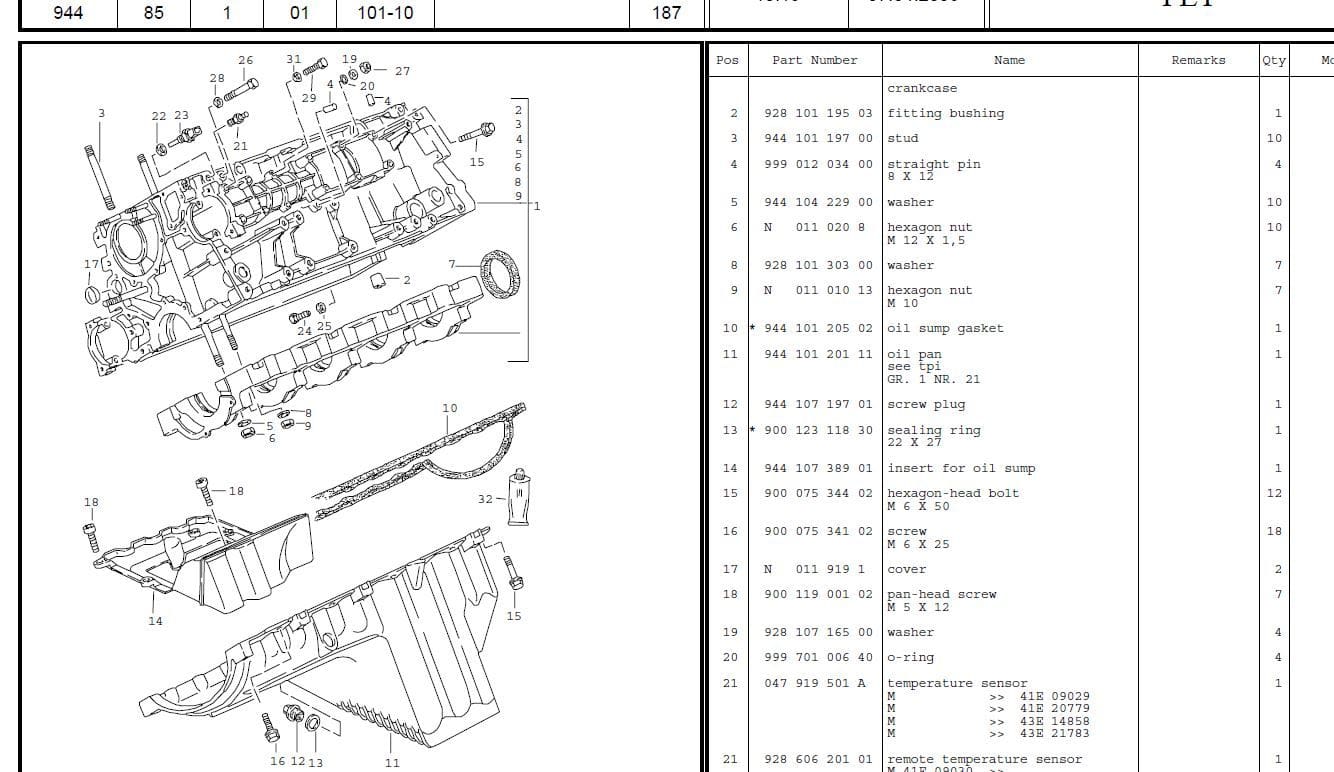

This image is from the early years. My experience with the older years is also consistent with this diagram. See item #2.

#22

Instructor

I will also add the number one main bearing is a full concentric bearing and it does have a locating pin to establish its position in relation to the block/girdle. My first mach8ne shop noticed this and put in a dowel he had in stock in the front position. I would think the concentric bearing as well as the oil pump on the front of the block with main studs should provide an almost perfect alignment. The same machine shop installed the girdle to check for main bearing out of round and didn’t use the bearings and then called me and asked how I ever was able to get this engine to run? I showed him the bearings and oil pump and not long after we decided to part ways and I picked up m6 engine and went to a proper race engine machine shop to continue.

#23

I will also add the number one main bearing is a full concentric bearing and it does have a locating pin to establish its position in relation to the block/girdle. My first mach8ne shop noticed this and put in a dowel he had in stock in the front position. I would think the concentric bearing as well as the oil pump on the front of the block with main studs should provide an almost perfect alignment. The same machine shop installed the girdle to check for main bearing out of round and didnít use the bearings and then called me and asked how I ever was able to get this engine to run? I showed him the bearings and oil pump and not long after we decided to part ways and I picked up m6 engine and went to a proper race engine machine shop to continue.

The second dowel is not needed. I mounted mine on Monday.

#24

Rennlist Member

I will also add the number one main bearing is a full concentric bearing and it does have a locating pin to establish its position in relation to the block/girdle. My first mach8ne shop noticed this and put in a dowel he had in stock in the front position. I would think the concentric bearing as well as the oil pump on the front of the block with main studs should provide an almost perfect alignment. The same machine shop installed the girdle to check for main bearing out of round and didnít use the bearings and then called me and asked how I ever was able to get this engine to run? I showed him the bearings and oil pump and not long after we decided to part ways and I picked up m6 engine and went to a proper race engine machine shop to continue.

#25

Race Car

I always mock up just my bare pump housing right after setting girdle and before any bolts are torqued.

I only insert oil pump bolts that don't engage with girdle, just the ones in the block attachment area.

Tighten slightly with 1/4 drive set just several inch pounds.

The manual has a procedure for planing the block flush for misaligned block/girdle fit where the oil pump overlaps both parts, using abrasive stone.

If you have @ or less than .020" overhang, the 574 will fill that gap.

T

I only insert oil pump bolts that don't engage with girdle, just the ones in the block attachment area.

Tighten slightly with 1/4 drive set just several inch pounds.

The manual has a procedure for planing the block flush for misaligned block/girdle fit where the oil pump overlaps both parts, using abrasive stone.

If you have @ or less than .020" overhang, the 574 will fill that gap.

T

#28

Race Car

It's kind of a "feel" thing. If one was way off, I wouldn't crank down on it, I'd rather match it with the stone.

Like I said though .020 or less isn't going to be a problem, that's within the spec of film sealing capability of the Loctite.

Man, you should have seen Eon past weekend wrestling a 968 against one of the country's top tier SP3 cars.

Car he had was on Koni street car shocks in the front.....passed for the lead twice in one sprint and only didn't finish P1 because the guy dive bombed him on the brakes 2 laps from the end.

T