Racing

#46

Rennlist Member

Which only goes to show that if they can have their own forum, why can't "the rest of us"

#47

Race Car

Thread Starter

I have the software packs and when I first started this, I was actually going to buy a 3 or 4 axis machine.

Boeing is currently selling off some of their machinery in Washington state, so clean, well maintained stuff. I also have an owner/operator trucking friend.

Then, I figured, I'd just have these two guys (software and machinist) make my own personal ones and not worry about making them available, with the exception of sharing my design file for anybody that wanted to replicate them near their own locale with their own CNC "guy".

That said, at the tracks themselves, racers come around asking a lot of questions, "what did you do for this", "how did you resolve this". I get racers show up at the next year annual at some of the tracks we race and show me an item that they copied off our car. At the NOLA PCA race, we actually had even the weekend track photographer that came by Sunday during load up and talk for a while, state that he had been all around the track with his press credentials and our car stood out as the best handling car there. So, I think, why shouldn't I profit from this information sharing, be it parts, service, whatever.

Mainly, I'm just too busy. Too many irons in the fire already.

My oulet for sharing some info and experiences is here. When I disappear from here periodically, I just don't have any more time to give.

I work a weekly job, overtime pretty regularly, work on a select customer base's 944s, build some racing manuals and do 3-4 side line automatic transmissions a month. Build and improve our own race cars., etc., etc.

I'm about to build a new two story custom house from the ground up, with me being the general contractor.

If people are interested, after I present these finished arms, I will link them up with the guy that did mine and they can buy them through him if they wish. This guy has built some of the most repeatedly accurate rifles in the country and makes custom gears for the most well known gear related business in the Baton Rouge area.

I'll tell you, with the projects I have, I almost...., came very close to just purchasing existing ones...., I contacted a vendor/friend about it that I will leave nameless. When the returned price link was equal to no relief, I stated that I would build them myself.

The last push for me to do this was his comment in an email reply - "a lot of folks have attempted it....but".

Well...., guess what....?

I aint "a lot of folks".

I will have two working billet arms just like I described here and said I would do.

And they are going to be on the car at the front of the field.

I promise.

T

#48

Rennlist Member

"Then, I figured, I'd just have these two guys (software and machinist) make my own personal ones and not worry about making them available, with the exception of sharing my design file for anybody that wanted to replicate them near their own locale with their own CNC "guy"."

Sure. Absolutely. These software "machinist" guys would just do that stuff for you because you're such a great person?

T, we do this sort of thing for money and also a certain amount of respect. You sort of missed the "respect" part.

Sure. Absolutely. These software "machinist" guys would just do that stuff for you because you're such a great person?

T, we do this sort of thing for money and also a certain amount of respect. You sort of missed the "respect" part.

Last edited by Otto Mechanic; 09-26-2017 at 03:22 PM.

#49

Race Car

Thread Starter

"Then, I figured, I'd just have these two guys (software and machinist) make my own personal ones and not worry about making them available, with the exception of sharing my design file for anybody that wanted to replicate them near their own locale with their own CNC "guy"."

Sure. Absolutely. These software "machinist" guys would just do that stuff for you because you're such a great person?

T, we do this sort of thing for money and also a certain amount of respect. You sort of missed the "respect" part.

Sure. Absolutely. These software "machinist" guys would just do that stuff for you because you're such a great person?

T, we do this sort of thing for money and also a certain amount of respect. You sort of missed the "respect" part.

He owns the most notorious diesel repair shop in a three parish (that;s county to you guys) area.

They call me for help on light and medium truck transmissions from time to time.

I have quite a few "friends" that would jump over a couple of hurdles to help me out.

Plus, he loves my son too and would do almost anything to help him if it's within his capability.

I have two great kids, and as mush as my son excels on the track, he's the same in everything he does.

There are more than a few RL'ers that lurk these threads and read the stuff I write that would vouch for this 100%.

T

#50

Rennlist Member

#51

Rennlist Member

Just have someone with experience and knowledge of welding high strength steels do the work. I don't know enough to be certain of anything, but am always concerned with the weakened heat effected zones on high carbon alloy steels. Not sure if a simple post weld treatment is adequate to eliminate residual stresses.

#52

Race Car

Thread Starter

A lot of projects and things going on, so I'm just now getting a new ball joint in the same arm just to get car off trailer so I didn't have to limp it off on a floor jack.

Quick shout out for the Sloan Kwik Load trailer too while I'm at it. It would have been pretty much impossible for the roll back wrecker to place the car on the trailer without further damage if it hadn't been for the roll back style trailer I have.

Anyways, the culprit - 17mm extended length ball joint pin.

Snapped immediately below the spindle pinch bolt, not at the tapered radius where the stem meets the ball where it's cross section's diameter is lessened during machining.

The way the two broken pieces fit back together, aligns with the chain of events my son recalled before it completely failed - steering wheel off center before it broke.

T

Quick shout out for the Sloan Kwik Load trailer too while I'm at it. It would have been pretty much impossible for the roll back wrecker to place the car on the trailer without further damage if it hadn't been for the roll back style trailer I have.

Anyways, the culprit - 17mm extended length ball joint pin.

Snapped immediately below the spindle pinch bolt, not at the tapered radius where the stem meets the ball where it's cross section's diameter is lessened during machining.

The way the two broken pieces fit back together, aligns with the chain of events my son recalled before it completely failed - steering wheel off center before it broke.

T

#53

Rennlist Member

I ask because I just rebuilt the ball joints on my aluminum arms. Mine weren't "extended" though, I used the Renbay kit. If you don't mind explaining, what's the purpose of the "extended" pins?

Regards,

#54

Rennlist Member

Another control arm/pin comment, for what it's worth:

Years ago, over 20 at least..... I had spoke with Dave or Jeff Stone (don't recall anymore which one) at Kelly Moss about control arm failures. They had said to retorque the pinch bolt before every event. Replace it anytime it is removed (this is somewhat obvious, as the bolt bends a little when it is torqued down), and to replace it every year. Very apparent that they believed a loose knuckle to ball joint connection would lead to catastrophe.

Now they put a lot of race miles on a car over a single season (with the S2s running endurance races in the IMSA Firestone Firehawk Series), and to this day I still don't replace the bolts annually. But I never reuse them and have the suspension apart often enough that I have gone thru several sets of the pinch bolts/nuts over the years.

Just mentioning here, as it is one more component to keep an eye on when these cars are driven hard.

Years ago, over 20 at least..... I had spoke with Dave or Jeff Stone (don't recall anymore which one) at Kelly Moss about control arm failures. They had said to retorque the pinch bolt before every event. Replace it anytime it is removed (this is somewhat obvious, as the bolt bends a little when it is torqued down), and to replace it every year. Very apparent that they believed a loose knuckle to ball joint connection would lead to catastrophe.

Now they put a lot of race miles on a car over a single season (with the S2s running endurance races in the IMSA Firestone Firehawk Series), and to this day I still don't replace the bolts annually. But I never reuse them and have the suspension apart often enough that I have gone thru several sets of the pinch bolts/nuts over the years.

Just mentioning here, as it is one more component to keep an eye on when these cars are driven hard.

#55

Rennlist Member

Another control arm/pin comment, for what it's worth:

Years ago, over 20 at least..... I had spoke with Dave or Jeff Stone (don't recall anymore which one) at Kelly Moss about control arm failures. They had said to retorque the pinch bolt before every event. Replace it anytime it is removed (this is somewhat obvious, as the bolt bends a little when it is torqued down), and to replace it every year. Very apparent that they believed a loose knuckle to ball joint connection would lead to catastrophe.

Now they put a lot of race miles on a car over a single season (with the S2s running endurance races in the IMSA Firestone Firehawk Series), and to this day I still don't replace the bolts annually. But I never reuse them and have the suspension apart often enough that I have gone thru several sets of the pinch bolts/nuts over the years.

Just mentioning here, as it is one more component to keep an eye on when these cars are driven hard.

Years ago, over 20 at least..... I had spoke with Dave or Jeff Stone (don't recall anymore which one) at Kelly Moss about control arm failures. They had said to retorque the pinch bolt before every event. Replace it anytime it is removed (this is somewhat obvious, as the bolt bends a little when it is torqued down), and to replace it every year. Very apparent that they believed a loose knuckle to ball joint connection would lead to catastrophe.

Now they put a lot of race miles on a car over a single season (with the S2s running endurance races in the IMSA Firestone Firehawk Series), and to this day I still don't replace the bolts annually. But I never reuse them and have the suspension apart often enough that I have gone thru several sets of the pinch bolts/nuts over the years.

Just mentioning here, as it is one more component to keep an eye on when these cars are driven hard.

The front suspension was upper and lower control arms fabricated from cold rolled seamless steel tubing (All_American made). The lower control arm was fabricated to accept a Moog ball joint. The upper control arm was fabricated with a threaded insert for a high misalignment hemi spherical bearing joint. The spindle was a Pinto. The front tires were 13 x15 and the rear tires were 17x15, Goodyear Racing Slicks.

We had one ball joint failure on the right hand side. All the road racing courses had significantly more right hand corners than left hand corners. The ball joint failed in the taper about 3/4 inch below the castle nut. The ball joint failure was caused by movement in the lower tapered mounting block of the Pinto spindle.

A crew member had not torque the ball joint to 125 ft-lb, but probably the torque from pulling on a 1/2 inch ratchet wrench. Thus the ball joint was not seated for the spring and torsion bar downward force applied to the inside tire (right side) when the car rolled to the left to load the outside tire in a right hand corner. The ball joint diameter near the top elongated and failed in tension.

Just my 0.02

#56

Race Car

Thread Starter

Well guys, racing was the title even though this thread went in a few different directions.

Have another tale to tell.

Hadn't raced the 944 in the 1st post in quite a while and it still sits with a damaged fender, plans in action to take it to Barber is several weeks but it isn't the topic of this racing post.

A friend of mine bought a former race 968 that was in pretty bad shape, so he, my son (driver) and myself started a long journey not long after I started this thread in totally disassembling the car and slowly rebuilding it over 9+ months. It was intended to be a DE car for my friend and occasionally raced so we opted out of complexity and went with the Koni 474 front shock, converted by True Choice for ride height, bump and rebound adjustability. Koni aluminum body inverted 3012s at the rear.

I went through the transmission, new bearings and synchros (pinion bearing noise) and finished it, installed and tested the entire car 1 week before the 2018 NOLA PCA race at Circuit Grand Bayou.

We had a fuel starvation problem there and found that the used tank we installed while removing a bad fuel cell install by previous owner had a displaced baffle top.

So we threw the car back on scales to recheck all settings, removed transmission again to repair tank, et, etc., stuck some vinyl on the car and dropped it at the track.

My friend's eyesight took a turn for the worse, so my son signed up to race the car instead of his SP2 944.

My son Eon (RL 87_944S) races SP2 so this would be his first SP3 race.

He's a top driver in his own class and there were 9 SP3 cars there ranging from S2s, 944T and one other 968...., 2 time 944 Super Cup champ.

Needless to say, it'd be tough going beating the rest of the cars on a first outing with a barely tested stock bodied car...., on Koni street shocks in the front, no belly pan or batwing and the side gates from the stock 968 rear wing missing.....but to be second and attempt a challenge on a full blown nationally renowned top tier car would be equivalent to David killing Goliath with a slingshot and some stones....

Eon gave it a run for the money, propping this car up with 2.0sec per lap on driving skill alone.

Here's how it went.

T

Have another tale to tell.

Hadn't raced the 944 in the 1st post in quite a while and it still sits with a damaged fender, plans in action to take it to Barber is several weeks but it isn't the topic of this racing post.

A friend of mine bought a former race 968 that was in pretty bad shape, so he, my son (driver) and myself started a long journey not long after I started this thread in totally disassembling the car and slowly rebuilding it over 9+ months. It was intended to be a DE car for my friend and occasionally raced so we opted out of complexity and went with the Koni 474 front shock, converted by True Choice for ride height, bump and rebound adjustability. Koni aluminum body inverted 3012s at the rear.

I went through the transmission, new bearings and synchros (pinion bearing noise) and finished it, installed and tested the entire car 1 week before the 2018 NOLA PCA race at Circuit Grand Bayou.

We had a fuel starvation problem there and found that the used tank we installed while removing a bad fuel cell install by previous owner had a displaced baffle top.

So we threw the car back on scales to recheck all settings, removed transmission again to repair tank, et, etc., stuck some vinyl on the car and dropped it at the track.

My friend's eyesight took a turn for the worse, so my son signed up to race the car instead of his SP2 944.

My son Eon (RL 87_944S) races SP2 so this would be his first SP3 race.

He's a top driver in his own class and there were 9 SP3 cars there ranging from S2s, 944T and one other 968...., 2 time 944 Super Cup champ.

Needless to say, it'd be tough going beating the rest of the cars on a first outing with a barely tested stock bodied car...., on Koni street shocks in the front, no belly pan or batwing and the side gates from the stock 968 rear wing missing.....but to be second and attempt a challenge on a full blown nationally renowned top tier car would be equivalent to David killing Goliath with a slingshot and some stones....

Eon gave it a run for the money, propping this car up with 2.0sec per lap on driving skill alone.

Here's how it went.

T

#59

Race Car

Thread Starter

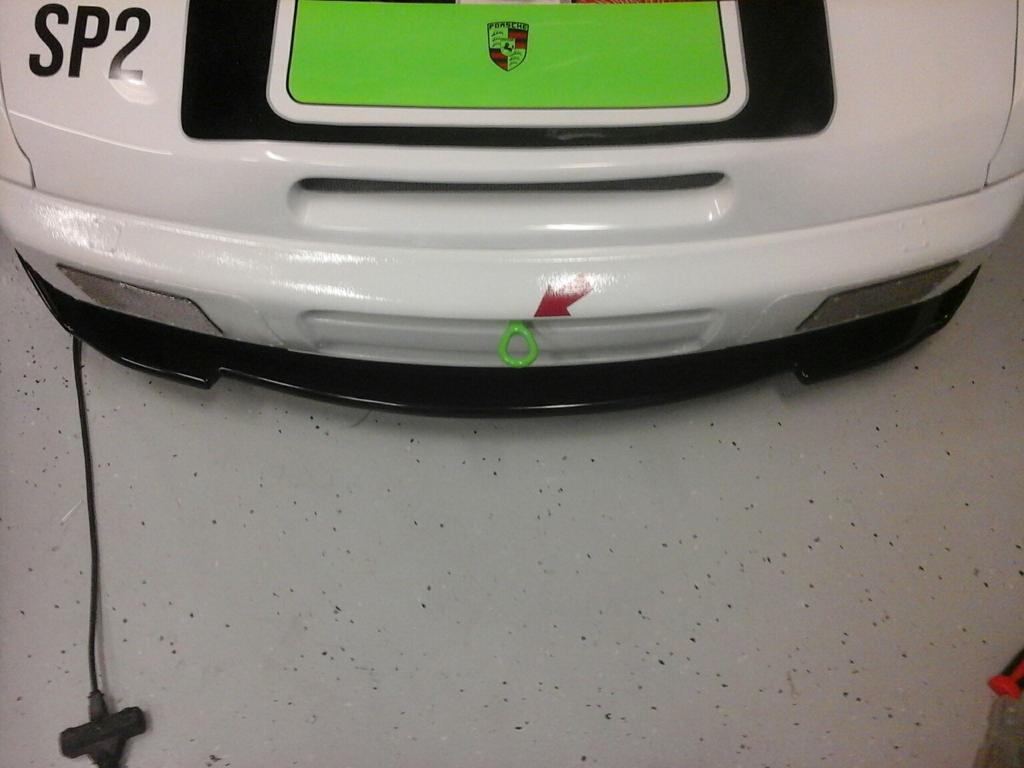

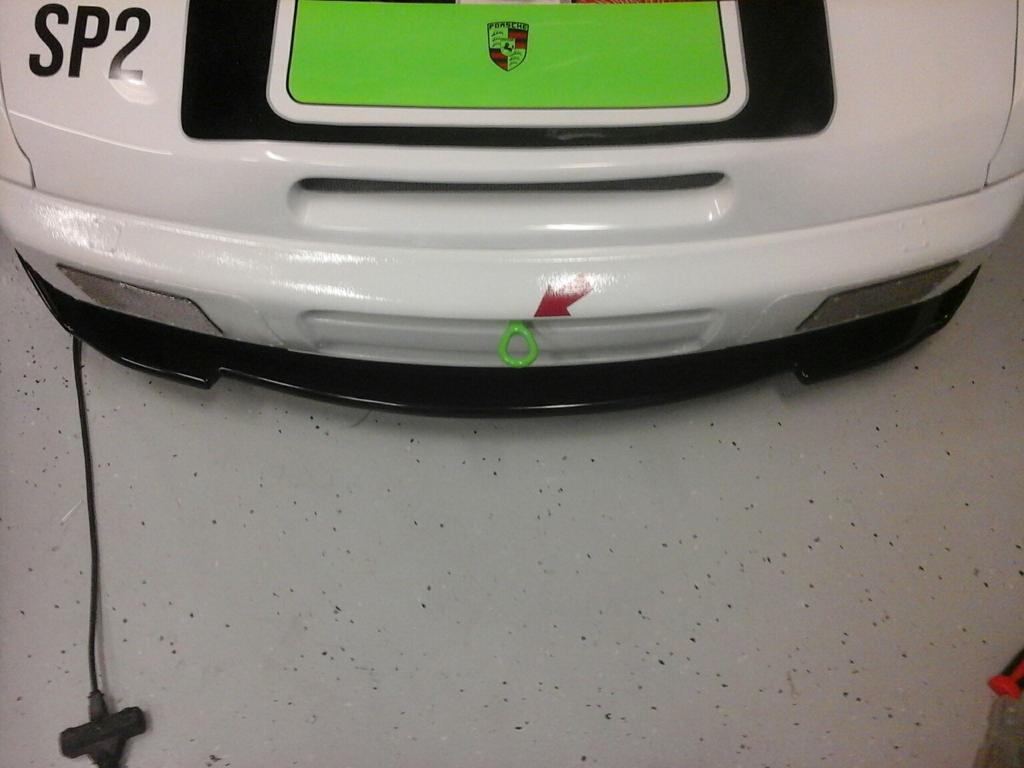

Well, where this thread left off, we substituted the main race car for the 968 for a one off race at NOLA Motorsports in another class up (vid above) because our 944NA SP2 car had snapped a ball joint and dmaged the LF fender, need the LSD redone, etc., etc.

Well, after finishing the transmission, upgraded to the Turbo S thicker clutch discs by surface grinding the pressure rings to make room for the increased thickness, I decided to convert the front end to 944T using parts I already had.

Car uses the "humped" vented nose panel designed for the stacked intercoolers so we could delete the headlight covers/pivots completely, so I turned that into a ram air for the stock airbox.

I had designed and reconfigured a GT Racing T/S2 splitter years ago and had it laying around so we used it on this car for better cooling and front aero.

It has a set back center and side gates to limit the front air spillage.

Here's a close up of the wing side plates that are hand molded fiberglass additions to the GT splitter.

The front bumper cover was a stock piece originally, with the fog and signal light pockets cut out.

It's coated with rock (chip) guard, the same product as the stock rocker panels, to reduce the chances of stone chips from track use.

A textured surface is also more aero friendly...

The side marker fillers are 16 gauge steel, painted body color with a backup washer and nut inside.

.

.

T

Well, after finishing the transmission, upgraded to the Turbo S thicker clutch discs by surface grinding the pressure rings to make room for the increased thickness, I decided to convert the front end to 944T using parts I already had.

Car uses the "humped" vented nose panel designed for the stacked intercoolers so we could delete the headlight covers/pivots completely, so I turned that into a ram air for the stock airbox.

I had designed and reconfigured a GT Racing T/S2 splitter years ago and had it laying around so we used it on this car for better cooling and front aero.

It has a set back center and side gates to limit the front air spillage.

Here's a close up of the wing side plates that are hand molded fiberglass additions to the GT splitter.

The front bumper cover was a stock piece originally, with the fog and signal light pockets cut out.

It's coated with rock (chip) guard, the same product as the stock rocker panels, to reduce the chances of stone chips from track use.

A textured surface is also more aero friendly...

The side marker fillers are 16 gauge steel, painted body color with a backup washer and nut inside.

.

.T

#60

Race Car

Thread Starter

Just noticed, in the last pic, you can see the sister car to this one, outside the shop door, identical body work except it's in orange/wht/blk as opposed to green/why/blk.

This is my 210bhp 944S 16V engined SP3 project.

T

This is my 210bhp 944S 16V engined SP3 project.

T