1979/80 924 German car, Crank No Start

#1

All, new to the forum as I just bout a 1979/80 924 as very much a project.

The car sat from 2000 to 2014 and again from 2014-2017. The previous owner tried a few things to get it started including draining the tank and rebuilding the fuel dizzy.

I have managed to get the car started once but had to keep the key turned to the "Run" position to keep it running. Is it possible there are relays for both ignition and running? I have a 1978 MGB with a system like this and the failure of the "Run" relay will result in that condition.

FUEL:

The Fuel Pump Relay in the car does not appear to work. I have tested it using the Clark's Garage method. I have also jumped the 87 and 30 on the fuse panel and that does energize the fuel pump. Fuel reaches the dizzy. Leaving the jumper in also allows fuel to get past the banjo fittings - this makes me think I have good pressure. I have a fuel pressure tester but haven't figured out how to hook it up to this system yet. Any thoughts?

The gas seems fresh and does not smell like old/bad gas.

I have not tested injector pulse.

IGNITION:

The plugs are older but gapped to .030. I have spark on the #1 plug - it is not fat but can be seen in normal light.

The firing order is 1342 but I don't believe it is timed properly. I'm in the process of setting static timing - flywheel to "OT," camshaft dimple and pointer, and will line up mark on dizzy body with rotor button.

I found TDC with the cam and pointer and screwdriver in the number 1 plug and the rotor is pointing at the 1 o'clock position as viewed looking down from the passenger (US) fender. I would have expected it to be pointing at the number 1 cylinder or close.

I have spark and have fuel but it seems the quality is suspect.

I'm not new to cars but I'm new to Porsches. I have lurked here and 924.org as well as Clark's Garage. Any new thoughts would be greatly appreciated!

Thanks!

Erik

The car sat from 2000 to 2014 and again from 2014-2017. The previous owner tried a few things to get it started including draining the tank and rebuilding the fuel dizzy.

I have managed to get the car started once but had to keep the key turned to the "Run" position to keep it running. Is it possible there are relays for both ignition and running? I have a 1978 MGB with a system like this and the failure of the "Run" relay will result in that condition.

FUEL:

The Fuel Pump Relay in the car does not appear to work. I have tested it using the Clark's Garage method. I have also jumped the 87 and 30 on the fuse panel and that does energize the fuel pump. Fuel reaches the dizzy. Leaving the jumper in also allows fuel to get past the banjo fittings - this makes me think I have good pressure. I have a fuel pressure tester but haven't figured out how to hook it up to this system yet. Any thoughts?

The gas seems fresh and does not smell like old/bad gas.

I have not tested injector pulse.

IGNITION:

The plugs are older but gapped to .030. I have spark on the #1 plug - it is not fat but can be seen in normal light.

The firing order is 1342 but I don't believe it is timed properly. I'm in the process of setting static timing - flywheel to "OT," camshaft dimple and pointer, and will line up mark on dizzy body with rotor button.

I found TDC with the cam and pointer and screwdriver in the number 1 plug and the rotor is pointing at the 1 o'clock position as viewed looking down from the passenger (US) fender. I would have expected it to be pointing at the number 1 cylinder or close.

I have spark and have fuel but it seems the quality is suspect.

I'm not new to cars but I'm new to Porsches. I have lurked here and 924.org as well as Clark's Garage. Any new thoughts would be greatly appreciated!

Thanks!

Erik

#2

Three Wheelin'

1. engine timing

2. spark coming out of the plugs (all of them)

3. fuel coming out of the injectors (all of them)

4. spark timing

5. vacuum leaks

1: Take the cam cover off, go to the passenger side and lean over closer to the cam sprocket and look down the direction of the belt goes.

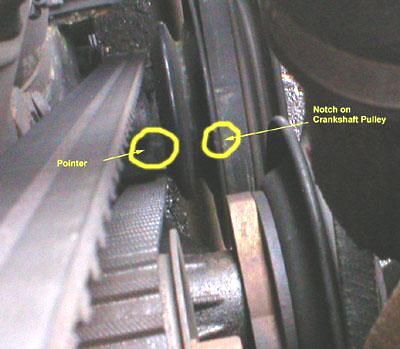

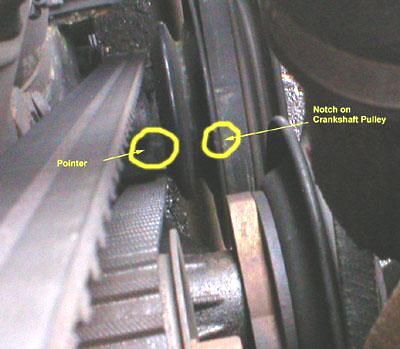

Look for the pointer (V shaped) on the oil pump casing and for the notch/cut in the crankshaft pulley.

Rotate the engine by hand or put the car in 5th gear and push it until you align the notch in the crank shaft pulley with the pointer on the oil pump casing.

When you have this, check for camshaft sprocket notch against the camshaft cover but be careful to look from the back of the engine towards the front of the car, see pics below.

2: take all plugs out and lay them on the cam cover, ofcourse still connected to the leads. Crank the engine and check that they produce sparks.

3: Take out the air filter to have access to the air metering plate(you will have to manually move it up and down). Pull straight up on the injectors (they have o-ring seals and they should pop out if you apply sufficient force). put each of them in the neck of a 2L bottle and do the jumper trick to activate the fuel pump.

No significant amount of fuel should come out. Then reach for the air metering plate and move it by hand, the more you open the air plate the more fuel should be sprayed by the injectors. Spray pattern should be a clear myst like cone and continuous.

4: With the engine at TDC, like explained in point 1, remove the spark dizzy cap and look at where the rotor is pointing, it should be roughly in the direction of the lead in the cap that goes to cyl nr1 then in a clockwise direction next lead on the cap should go to cyl nr3 then 2 then 4. Make sure that at TDC the rotor points towards the cap port that takes the lead to cyl 1.

5: when you have done all the above, make SURE that all the rubber pieces and vacuum hooses are tight on their ports, have no craks or splits and especially the tubes that go from the air metering unit to the throttle body are tight, not cracked and not damaged in any way.

Your engine should start and run if you do all these checks...especially if the car ran before.

2. spark coming out of the plugs (all of them)

3. fuel coming out of the injectors (all of them)

4. spark timing

5. vacuum leaks

1: Take the cam cover off, go to the passenger side and lean over closer to the cam sprocket and look down the direction of the belt goes.

Look for the pointer (V shaped) on the oil pump casing and for the notch/cut in the crankshaft pulley.

Rotate the engine by hand or put the car in 5th gear and push it until you align the notch in the crank shaft pulley with the pointer on the oil pump casing.

When you have this, check for camshaft sprocket notch against the camshaft cover but be careful to look from the back of the engine towards the front of the car, see pics below.

2: take all plugs out and lay them on the cam cover, ofcourse still connected to the leads. Crank the engine and check that they produce sparks.

3: Take out the air filter to have access to the air metering plate(you will have to manually move it up and down). Pull straight up on the injectors (they have o-ring seals and they should pop out if you apply sufficient force). put each of them in the neck of a 2L bottle and do the jumper trick to activate the fuel pump.

No significant amount of fuel should come out. Then reach for the air metering plate and move it by hand, the more you open the air plate the more fuel should be sprayed by the injectors. Spray pattern should be a clear myst like cone and continuous.

4: With the engine at TDC, like explained in point 1, remove the spark dizzy cap and look at where the rotor is pointing, it should be roughly in the direction of the lead in the cap that goes to cyl nr1 then in a clockwise direction next lead on the cap should go to cyl nr3 then 2 then 4. Make sure that at TDC the rotor points towards the cap port that takes the lead to cyl 1.

5: when you have done all the above, make SURE that all the rubber pieces and vacuum hooses are tight on their ports, have no craks or splits and especially the tubes that go from the air metering unit to the throttle body are tight, not cracked and not damaged in any way.

Your engine should start and run if you do all these checks...especially if the car ran before.

Last edited by morghen; 04-15-2017 at 09:46 AM.

#3

Thanks Morghen! I did the static timing using another method I found on a board and my rotor was most definitely not even close to pointing to the front. I will try again today and see what I come up with. I don't think the dizzy is 180 out though which is good. The cam cover needs painting anyway!

I pulled the plugs last night and found that the number 3 had been repaired with a Save a Thread. Not happy about that but it seemed fine - at least the plug wasn't beat up or showing signs of detonation.

Thanks again!

I pulled the plugs last night and found that the number 3 had been repaired with a Save a Thread. Not happy about that but it seemed fine - at least the plug wasn't beat up or showing signs of detonation.

Thanks again!

#4

Three Wheelin'

As far as I remember the dizzy housing has to be in a specific orientation as well. Look for a notch on the housings as well.

Go trough the points I mentioned above and you should be fine.

Go trough the points I mentioned above and you should be fine.

#5

Got TDC using the method Morghen provided (oil pump pointer and crank mark aligned, pointer on valve cover and cam sprocket lined up) and rotor button is still pointing at the 1 o'clock position. Verified I have spark to all four cylinders and fitting order is 1342.

Pulled the injectors and got nothing. The fuel leaks at the distributor but doesn't appear to get to the injector except in dribbles. Pulled all four injectors and soaked them in carb cleaner. Also discovered that the number two line was actually broken at the banjo fitting.

Thanks for the ongoing input!

Pulled the injectors and got nothing. The fuel leaks at the distributor but doesn't appear to get to the injector except in dribbles. Pulled all four injectors and soaked them in carb cleaner. Also discovered that the number two line was actually broken at the banjo fitting.

Thanks for the ongoing input!

#6

Three Wheelin'

Then leave the spark alone, if it worked before it should work now and if the cam and crank align that's already a good sign.

What did you do to test the injectors? did you follow the steps I described above? Did you lift the air metering plate up by hand?

You would be lucky to get away with just injectors being clogged(perhaps try ultrasonic cleaning)...lets hope you don't have to rebuild the fuel dizzy. Get the banjo fitting sorted and post some pics.

What did you do to test the injectors? did you follow the steps I described above? Did you lift the air metering plate up by hand?

You would be lucky to get away with just injectors being clogged(perhaps try ultrasonic cleaning)...lets hope you don't have to rebuild the fuel dizzy. Get the banjo fitting sorted and post some pics.

#7

Sorry, I spent a couple of days working on my MGB and just got back to the 924 yesterday.

Yes, I used your method of moving the air meter up and down and still got nothing to the injectors (I actually only had one injector hooked up at a time, the other lines were all in bottles with no injector. Some lines got fuel, others did not.) When I move the air meter there is definitely fuel "rushing" in. I can hear it and, as I said, fuel does get to the end of some lines. I sprayed carb cleaner in the lines and it appears to come out the other end nicely so I don't believe they are blocked.

I tried to test the fuel delivery rate but could not get the return line separated just below the brake booster so I ran a test off of a smaller line. Because of the smaller diameter I did not get 750cc but did get 180cc in 30 seconds. I also checked for flow at the banjo bolt on the return line - based on the volume I collected there I am willing to bet I would get 750cc in 30 seconds if I could get the return line off (but I don't want to break a fitting on a gas line.)

Fuel leaks past the copper crush washers on one of the lines on top of the dizzy (the fitting at the 7 o'clock position as you face the car) and I tightened down the three screws which keep the two halves together. It doesn't look like the washers have ever been replaced and so it might be worth a few dollars to try new washers while I'm replacing the broken line.

According to the previous owner, the fuel dizzy has been rebuilt - I even have an extra including an air meter. Of course, the PO failed to mention the helicoil repair on #3, so...

I'm okay with having the dizzy rebuilt if there is a place to get it done and if that is the problem.

Yes, I used your method of moving the air meter up and down and still got nothing to the injectors (I actually only had one injector hooked up at a time, the other lines were all in bottles with no injector. Some lines got fuel, others did not.) When I move the air meter there is definitely fuel "rushing" in. I can hear it and, as I said, fuel does get to the end of some lines. I sprayed carb cleaner in the lines and it appears to come out the other end nicely so I don't believe they are blocked.

I tried to test the fuel delivery rate but could not get the return line separated just below the brake booster so I ran a test off of a smaller line. Because of the smaller diameter I did not get 750cc but did get 180cc in 30 seconds. I also checked for flow at the banjo bolt on the return line - based on the volume I collected there I am willing to bet I would get 750cc in 30 seconds if I could get the return line off (but I don't want to break a fitting on a gas line.)

Fuel leaks past the copper crush washers on one of the lines on top of the dizzy (the fitting at the 7 o'clock position as you face the car) and I tightened down the three screws which keep the two halves together. It doesn't look like the washers have ever been replaced and so it might be worth a few dollars to try new washers while I'm replacing the broken line.

According to the previous owner, the fuel dizzy has been rebuilt - I even have an extra including an air meter. Of course, the PO failed to mention the helicoil repair on #3, so...

I'm okay with having the dizzy rebuilt if there is a place to get it done and if that is the problem.

Trending Topics

#8

Sorry, I spent a couple of days working on my MGB and just got back to the 924 yesterday.

Yes, I used your method of moving the air meter up and down and still got nothing to the injectors (I actually only had one injector hooked up at a time, the other lines were all in bottles with no injector. Some lines got fuel, others did not.) When I move the air meter there is definitely fuel "rushing" in. I can hear it and, as I said, fuel does get to the end of some lines. I sprayed carb cleaner in the lines and it appears to come out the other end nicely so I don't believe they are blocked.

I tried to test the fuel delivery rate but could not get the return line separated just below the brake booster so I ran a test off of a smaller line. Because of the smaller diameter I did not get 750cc but did get 180cc in 30 seconds. I also checked for flow at the banjo bolt on the return line - based on the volume I collected there I am willing to bet I would get 750cc in 30 seconds if I could get the return line off (but I don't want to break a fitting on a gas line.)

Fuel leaks past the copper crush washers on one of the lines on top of the dizzy (the fitting at the 7 o'clock position as you face the car) and I tightened down the three screws which keep the two halves together. It doesn't look like the washers have ever been replaced and so it might be worth a few dollars to try new washers while I'm replacing the broken line.

According to the previous owner, the fuel dizzy has been rebuilt - I even have an extra including an air meter. Of course, the PO failed to mention the helicoil repair on #3, so...

I'm okay with having the dizzy rebuilt if there is a place to get it done and if that is the problem.

Yes, I used your method of moving the air meter up and down and still got nothing to the injectors (I actually only had one injector hooked up at a time, the other lines were all in bottles with no injector. Some lines got fuel, others did not.) When I move the air meter there is definitely fuel "rushing" in. I can hear it and, as I said, fuel does get to the end of some lines. I sprayed carb cleaner in the lines and it appears to come out the other end nicely so I don't believe they are blocked.

I tried to test the fuel delivery rate but could not get the return line separated just below the brake booster so I ran a test off of a smaller line. Because of the smaller diameter I did not get 750cc but did get 180cc in 30 seconds. I also checked for flow at the banjo bolt on the return line - based on the volume I collected there I am willing to bet I would get 750cc in 30 seconds if I could get the return line off (but I don't want to break a fitting on a gas line.)

Fuel leaks past the copper crush washers on one of the lines on top of the dizzy (the fitting at the 7 o'clock position as you face the car) and I tightened down the three screws which keep the two halves together. It doesn't look like the washers have ever been replaced and so it might be worth a few dollars to try new washers while I'm replacing the broken line.

According to the previous owner, the fuel dizzy has been rebuilt - I even have an extra including an air meter. Of course, the PO failed to mention the helicoil repair on #3, so...

I'm okay with having the dizzy rebuilt if there is a place to get it done and if that is the problem.

#9

Three Wheelin'

If the fuel dizzy was rebuilt and you have no fuel at the injectors its clear...the PO did a **** job "rebuilding" it. You clearly cant start the car if you don't have fuel going to the injectors.

Ask Dan(ideola) for help, he may sell you a working fuel dizzy or could guide you to rebuild yours.

garage.ideola.com

Ask Dan(ideola) for help, he may sell you a working fuel dizzy or could guide you to rebuild yours.

garage.ideola.com

#10

I just wanted to follow up on this one. I pulled the fuel dizzy and, as Morghen suggested, the rebuild was awful. The o rings were stretched out and not even close to the right size - anywhere in the dizzy. It was bad. The diaphragm had tears in it. It was clean, however.

I ordered the Salvox rebuild kit from Salvox and I'm waiting patiently for its arrival. In the meantime I've re-cleaned the dizzy and painted it black.

Any thoughts on if the injector lines can be cleaned and painted? They are braided and I thought they might be paintable.

Thanks!

I ordered the Salvox rebuild kit from Salvox and I'm waiting patiently for its arrival. In the meantime I've re-cleaned the dizzy and painted it black.

Any thoughts on if the injector lines can be cleaned and painted? They are braided and I thought they might be paintable.

Thanks!