Dan's Ultimate 931 Build

#1

Former Vendor

Thread Starter

I have started a series of threads at 924board.org on a complete ground-up monster 931 build I've been working on for a while. Since there are a few 931 enthusiasts who drop by here that don't frequent the other forum, I thought it might be useful to post links to those threads here. The threads have spawned a whole bunch of very interesting, and sometimes enlightening discussions on maxing out the 2.0L turbos, so hopefully this cross post will provide some additional value to Rennlisters. Enjoy!

Turkey Shoot Open Invitation: Dan's Ultimate 931 Build

Short Block Internals for Dan's Ultimate 931 Build

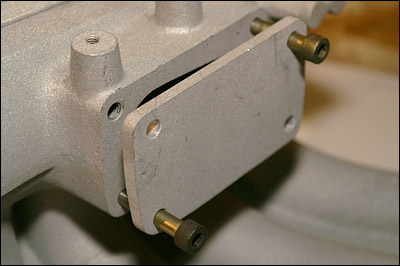

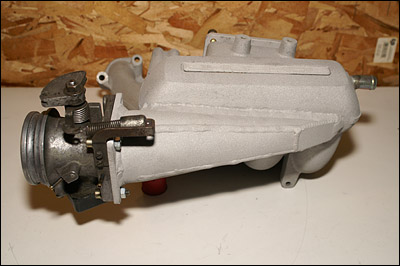

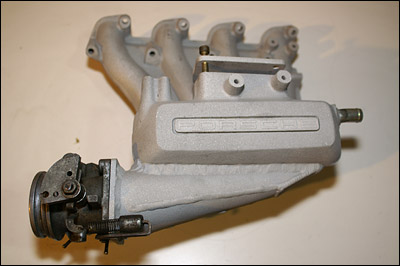

Intake Modification Concept for Dan's Ultimate 931 Build

Hybrid Turbo for Dan's Ultimate 931 Build

Intercooling for Dan's Ultimate 931 Build

Turkey Shoot Open Invitation: Dan's Ultimate 931 Build

Short Block Internals for Dan's Ultimate 931 Build

Intake Modification Concept for Dan's Ultimate 931 Build

Hybrid Turbo for Dan's Ultimate 931 Build

Intercooling for Dan's Ultimate 931 Build

#2

Formula One Spin Doctor

Rennlist Member

Rennlist Member

Hello ,

Interesting links and project ,

A stock 951 intercooler will reach your target BHP goal with no issues nor need for modifications. At the prices they are currently trading for used , it would be your most cost effective choice....

The assumptions on intercooling effect, i would have to disagree with, as the temperature drop will be less in respect to the shortest distance traveled, you want the air to travel the longest path thru the core for the most effect. Hence the 951 style type cooler will have a longer core path , with more temperature drop than the top /bottom shorter core path intercooler you are considering......

The crower rods where custom ( nice) made for your application ? did you have them drilled for piston cooling ?

Last edited by A.Wayne; 02-24-2008 at 01:50 AM.

#3

Former Vendor

Thread Starter

Re: the stock 951 IC, there are three concerns:

1) the area of the charge air face is smaller than it should be for the BHP targets I want to achieve

2) the end tanks are highly restrictive and ideally should be re-engineered to allow for better flow

3) the thinner IC (e.g. 3" deep) would be better for cooling than the 5" depth of the stock unit

All told, however, going with a modified unit (like one from Lindsey Racing) would probably suffice, and would be better than having a big 3"x10"x18" unit in front of the rad.

Re: the Crower rods, are they custom? Yes & no...they were custom made to accommodate my increased stroke, and they are not an off-the-shelf item. However, they maintain the stock length, as well as the stock diameters for the big and little ends. Therefore, they can be used as a direct replacement for stock rods. The big advantage of the Crower rods is that they are lighter, stronger, and have a lower profile at the crank end, which allows for increased stroke without requiring the block to be clearanced.

As for integral squirters, David Crower specifically recommneded against them because they would weaken the rod itself. To replace the stock squirter functionality, the top of the rod journal faces have been notched on both sides to allow oil to be squirted up onto the bottom of the pistons.

1) the area of the charge air face is smaller than it should be for the BHP targets I want to achieve

2) the end tanks are highly restrictive and ideally should be re-engineered to allow for better flow

3) the thinner IC (e.g. 3" deep) would be better for cooling than the 5" depth of the stock unit

All told, however, going with a modified unit (like one from Lindsey Racing) would probably suffice, and would be better than having a big 3"x10"x18" unit in front of the rad.

Re: the Crower rods, are they custom? Yes & no...they were custom made to accommodate my increased stroke, and they are not an off-the-shelf item. However, they maintain the stock length, as well as the stock diameters for the big and little ends. Therefore, they can be used as a direct replacement for stock rods. The big advantage of the Crower rods is that they are lighter, stronger, and have a lower profile at the crank end, which allows for increased stroke without requiring the block to be clearanced.

As for integral squirters, David Crower specifically recommneded against them because they would weaken the rod itself. To replace the stock squirter functionality, the top of the rod journal faces have been notched on both sides to allow oil to be squirted up onto the bottom of the pistons.

#4

Formula One Spin Doctor

Rennlist Member

Rennlist Member

Re: the stock 951 IC, there are three concerns:

1) the area of the charge air face is smaller than it should be for the BHP targets I want to achieve

2) the end tanks are highly restrictive and ideally should be re-engineered to allow for better flow

3) the thinner IC (e.g. 3" deep) would be better for cooling than the 5" depth of the stock unit

.

1) the area of the charge air face is smaller than it should be for the BHP targets I want to achieve

2) the end tanks are highly restrictive and ideally should be re-engineered to allow for better flow

3) the thinner IC (e.g. 3" deep) would be better for cooling than the 5" depth of the stock unit

.

Dan,

If your target goal is 350 bhp , a stock intercooler will suffice, unless at 350 bhp your turbo discharge temps are off the charts. even so 350 bhp is easily obtainable with a stock 951 intercooler without mods.

Using a 951 style setup will free up the front of the car for better oil and radiator cooling......

#5

Former Vendor

Thread Starter

I know the 951 IC will work, the question is, is it an ideal configuration, can it be improved. In terms of the charge air face, the depth of the core, and the end tank design, I believe it is less than ideal...according the engineers at Bell Intercoolers, the charge air face ought to be larger. Also, bear in mind, this is not going on a 2.5L motor...in order to achieve 300+ BHP on the 2.0L motor, it will be necessary to be running fairly high levels of boost, which adds heat, etc. A more efficient design would be better. I'm fairly confident that adding the low pressure exit duct like Steve (aka Bass GT) has done will improve the cooling efficiency.

My biggest complaint with the stock 951 unit is the design of the end tanks...first of all, they are a documented flaw because of how they restrict the flow, and secondly, they are not oriented correctly for my application. So in any event, I'll probably modify the stock unit if I go that route. The huge advantage, of course, is being able to mount it above the rad instead of in front. Space for oil cooling is no issue because I have an ultra wide body kit, and there is ducting on the side of the front facia to accommodate a large, oversize oil cooler.

My biggest complaint with the stock 951 unit is the design of the end tanks...first of all, they are a documented flaw because of how they restrict the flow, and secondly, they are not oriented correctly for my application. So in any event, I'll probably modify the stock unit if I go that route. The huge advantage, of course, is being able to mount it above the rad instead of in front. Space for oil cooling is no issue because I have an ultra wide body kit, and there is ducting on the side of the front facia to accommodate a large, oversize oil cooler.

Trending Topics

#8

Former Vendor

Thread Starter

Water-cooled Hybrid Turbo for the 931 UWB arrived last week from Majestic. For those that haven't been following closely, we discovered during the process that the 951 water-cooled bearing housing is a direct, bolt-on replacement for the stock 931 bearing housing. Considering the common failure mode (seized bearings due to oil coking from heat soak) of the stock 931 unit, the water cooled bearing housing should be a big improvement to longevity, if nothing else.

Also, for those who aren't familiar with the 931 K26 turbo unit, you need to be aware that the turbine housing has a unique 3-bolt flange that cannot be gotten around without building a VERY expensive custom exhaust manifold. So, this approach provides a very inexpensive path to retain stock manifold, stock turbine housing, water cooled bearing housing, mated to a modern K27 compressor housing and wheel capable of pushing 600+ CFM.

Related threads at 924board.org:

Hybrid Turbo for Dan's Ultimate 931 Build

Bolt-in off-the-shelf water-cooled turbo for 931

Click pix for larger images

Ceramic-coated exhaust manifold (series II)

Ceramic-coated J-Pipe

Here are the components:

Stock 931 Turbine housing, shaft & wheel

Stock 944 K26 water-cooled bearing housing

K27 compressor housing (5327-101-5079)

- machined to accommodate wheel

- 2" outlet / 2.75" inlet

K27 compressor wheel (part number unknown)

Total cost:

- Rebuild: $335

- New compressor wheel: $125

- Bearing housing trade: $65

- Compressor housing trade & machining: $140

Total cost from Majestic: $665

(not including ceramic coating and shipping)

Also, for those who aren't familiar with the 931 K26 turbo unit, you need to be aware that the turbine housing has a unique 3-bolt flange that cannot be gotten around without building a VERY expensive custom exhaust manifold. So, this approach provides a very inexpensive path to retain stock manifold, stock turbine housing, water cooled bearing housing, mated to a modern K27 compressor housing and wheel capable of pushing 600+ CFM.

Related threads at 924board.org:

Hybrid Turbo for Dan's Ultimate 931 Build

Bolt-in off-the-shelf water-cooled turbo for 931

Click pix for larger images

Ceramic-coated exhaust manifold (series II)

Ceramic-coated J-Pipe

Here are the components:

Stock 931 Turbine housing, shaft & wheel

Stock 944 K26 water-cooled bearing housing

K27 compressor housing (5327-101-5079)

- machined to accommodate wheel

- 2" outlet / 2.75" inlet

K27 compressor wheel (part number unknown)

Total cost:

- Rebuild: $335

- New compressor wheel: $125

- Bearing housing trade: $65

- Compressor housing trade & machining: $140

Total cost from Majestic: $665

(not including ceramic coating and shipping)

#9

Three Wheelin'

I wouldnt use the Stock manifold.

Ive been working on a custom equal length headers that puts the turbo where the A/C compressor was(though you could put the turbo near the stock position. Dont know when im going to get the chance to finish it, but ive mocked it up in mild steel.

Ive been working on a custom equal length headers that puts the turbo where the A/C compressor was(though you could put the turbo near the stock position. Dont know when im going to get the chance to finish it, but ive mocked it up in mild steel.

#10

Former Vendor

Thread Starter

I wouldnt use the Stock manifold.

Ive been working on a custom equal length headers that puts the turbo where the A/C compressor was(though you could put the turbo near the stock position. Dont know when im going to get the chance to finish it, but ive mocked it up in mild steel.

Ive been working on a custom equal length headers that puts the turbo where the A/C compressor was(though you could put the turbo near the stock position. Dont know when im going to get the chance to finish it, but ive mocked it up in mild steel.

I concluded the best option was to use a good, uncracked series II manifold (which has been ceramic coated), retain the stock turbine housing (also ceramic coated), and do the custom work from the bearing housing out. The water-cooled 944 bearing housing should significantly improve the turbo longevity, and the K27 cold side will produce the 600 CFM required for my application. By all accounts, the stock log-style manifold is really quite good for this application...re-routing to the other side introduces a set of very concerning variables, particularly with respect to exhaust temps (arguably the most important element of proper spooling of the turbine). So I feel pretty good about this setup. Only time on the dyno will truly tell if it was the best decision...it seems at this point to be the best compromise of performance increase and budget.

#11

Instructor

Dan,

I woud love to say there was a years worth of science, including 12 weeks solid using Big Blue to calc it all out, but my manifold was created out of a design requirement. I didn't want to put the turbo on the other side of the motor due to the runner length, and inherent heat dissipation issues and also i didn't believe i had the clearance under the sump, as although i have dry sumped the motor, i'm using a modified OEM sump, not the low profile factory item, which gave the required clearance for the runners behind the oil scavenge chamber, but an equal length was just not possible in the area i wanted to use. So a compromise had to be made. Smaller shorter runners for velocity, heat retention & plumbing ease, and the ability to fit a WG under it if required. I think the only huge downside with the OEM manifold is that the WG connection is at the wrong end. Now i think there may be a difference between LHD &RHD manifolds, as those i've seen from your side of the pond seem to have a runner from the collector to the WG. My OEM header draws the WG from behind Cyl #4, which is not good with the reversion ect. I think this is because of steering column clearance issues on the RHD models

The only other option was OOTB's proposed Chinese Puzzle equal length manifold, which worked in theory, but never made it into the real world,.

The manifold

The ITB's

Thrown together to get it up & running

Steve

I woud love to say there was a years worth of science, including 12 weeks solid using Big Blue to calc it all out, but my manifold was created out of a design requirement. I didn't want to put the turbo on the other side of the motor due to the runner length, and inherent heat dissipation issues and also i didn't believe i had the clearance under the sump, as although i have dry sumped the motor, i'm using a modified OEM sump, not the low profile factory item, which gave the required clearance for the runners behind the oil scavenge chamber, but an equal length was just not possible in the area i wanted to use. So a compromise had to be made. Smaller shorter runners for velocity, heat retention & plumbing ease, and the ability to fit a WG under it if required. I think the only huge downside with the OEM manifold is that the WG connection is at the wrong end. Now i think there may be a difference between LHD &RHD manifolds, as those i've seen from your side of the pond seem to have a runner from the collector to the WG. My OEM header draws the WG from behind Cyl #4, which is not good with the reversion ect. I think this is because of steering column clearance issues on the RHD models

The only other option was OOTB's proposed Chinese Puzzle equal length manifold, which worked in theory, but never made it into the real world,.

The manifold

The ITB's

Thrown together to get it up & running

Steve

Last edited by Bass GT3; 07-04-2008 at 09:42 PM.

#12

Former Vendor

Thread Starter

I had a couple of welders take a look at this approach, but I ruled it out because the cost of the materials alone would have approached $1000, to say nothing of the fabrication and welding expense. It also greatly complicates matters because you have to have the car sitting at the welder's shop with engine installed if you really hope to properly mock up and fabricate the header without causing fitment issues and having to potentially re-do very expensive fabrication work. In the end, it just wasn't feasible economically, especially when the hybrid route I took cost well under $1000 for everything, while still easily achieving the CFM requirements I was shooting for.

#13

Instructor

Hi Dan,

When planning my manifold, i kept refering to Peter's site, to see if it would work for me. The problems i hit were once again, my steering column is a problem, my dry sump pipe work wouldn't go into the block witht he turbo moved back so much, and finally, the benefit of mounting the turbo so high overcame the inherent oil drain issue. It also allows me to change turbo's in a matter of minutes should i ever decide to run different units to cater for different venues. The major downside with mine is that i doubt it would work with a road car, especially with pop up lights.

And looking at your stock manifold, yes, there is a deffinate WG tube from the collector going rearwrds. On RHD cars, that tube is not present, so the WG is plumbed out of cylinder #4. This is a major downside, and makes the WG control very so-so.

Steve

When planning my manifold, i kept refering to Peter's site, to see if it would work for me. The problems i hit were once again, my steering column is a problem, my dry sump pipe work wouldn't go into the block witht he turbo moved back so much, and finally, the benefit of mounting the turbo so high overcame the inherent oil drain issue. It also allows me to change turbo's in a matter of minutes should i ever decide to run different units to cater for different venues. The major downside with mine is that i doubt it would work with a road car, especially with pop up lights.

And looking at your stock manifold, yes, there is a deffinate WG tube from the collector going rearwrds. On RHD cars, that tube is not present, so the WG is plumbed out of cylinder #4. This is a major downside, and makes the WG control very so-so.

Steve

#14

Former Vendor

Thread Starter

It's been a while since I've updated here...slow but steady progress has been made since the last time I posted.

I've started a new thread to document the body work:

Body Work for Dan's Ultimate 931 Build

Highlights include:

A custom fabricated front upper cross member to strengthen the front end and provide mounting points for a 951 FMIC and Wizard Racing aluminum 951 radiator:

A custom fabricated cage for an E85-safe FuelSafe ED115 fuel cell:

Installation of an AutoPower bolt-in bar and U-Weld-It cage customized for better form, fit and function:

For details of all of the dimensions and build considerations, visit the aforementioned thread on 924board.org. One word of warning...the orientation of this particular fuel cell install will probably NOT work on an Audi-equipped 944 due to the length of the gearbox. My car will be running an LSD-equipped snailshell, so there is plenty of room. But hopefully, the execution will provide some valuable views of the rear hatch area completely deconstructed, as well as some design and construction considerations for anyone considering a fuel cell in a 944.

I've started a new thread to document the body work:

Body Work for Dan's Ultimate 931 Build

Highlights include:

A custom fabricated front upper cross member to strengthen the front end and provide mounting points for a 951 FMIC and Wizard Racing aluminum 951 radiator:

A custom fabricated cage for an E85-safe FuelSafe ED115 fuel cell:

Installation of an AutoPower bolt-in bar and U-Weld-It cage customized for better form, fit and function:

For details of all of the dimensions and build considerations, visit the aforementioned thread on 924board.org. One word of warning...the orientation of this particular fuel cell install will probably NOT work on an Audi-equipped 944 due to the length of the gearbox. My car will be running an LSD-equipped snailshell, so there is plenty of room. But hopefully, the execution will provide some valuable views of the rear hatch area completely deconstructed, as well as some design and construction considerations for anyone considering a fuel cell in a 944.

#15

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member