Projects on my new, to me, 1974 914-6

#151

Racer

Thread Starter

Great news today. John Forbes, of Black Forest Racing, called me this afternoon to tell me the motor is running, and running well. He did a leak down test and it was 2% on all cylinders. According to John, the leak down test should be done on a warm motor. Since he wanted to know what he had before he put the motor back in the car, he did the test on a stone cold motor. He thinks the leak down percentages would be closer to zero had the engine been warm. He said the engine sounds great and is very responsive.

His son is the computer guy who runs the dyno. He is out of town this week so it will be next week before we can put it on the dyno.

After installing the shifter, it was really stiff. John noticed that as well and they fixed that. He said it now shifts well. Now that the motor is back in the car, John is having the State Police come to his shop to inspect it since it has an out of state title. Once he has that done, I will be driving there (about fifty miles) to pick up the paperwork and get it registered. And...to hear that motor run!!!

His son is the computer guy who runs the dyno. He is out of town this week so it will be next week before we can put it on the dyno.

After installing the shifter, it was really stiff. John noticed that as well and they fixed that. He said it now shifts well. Now that the motor is back in the car, John is having the State Police come to his shop to inspect it since it has an out of state title. Once he has that done, I will be driving there (about fifty miles) to pick up the paperwork and get it registered. And...to hear that motor run!!!

#153

Racer

Thread Starter

I visited John's shop today to give him some money and to, hopefully, drive the car. Since is was raining, we passed on the driving but I did take a couple videos of the engine running. It sounded great!!

John has been driving it as he is fine tuning the shifter adjustments. He says it is very strong as currently configured. Should be even stronger after some fine tuning. It is difficult to start when cold but John's son, Cody, says it needs to have the fuel enrichment increased when cold. Cody will be back next week to fine tune it and then do some dyno runs. He typically videos the dyno runs so I should have some more video next week. I may have to hook up the Go-Pro for the drive home!!

John commented that first and second gear are vey close. Ed had the transmission geared this way for autocrossing. It effectively makes it a four speed as you can take off in second gear. Second, third, and fourth are very close while fifth is an overdrive gear.

John has been driving it as he is fine tuning the shifter adjustments. He says it is very strong as currently configured. Should be even stronger after some fine tuning. It is difficult to start when cold but John's son, Cody, says it needs to have the fuel enrichment increased when cold. Cody will be back next week to fine tune it and then do some dyno runs. He typically videos the dyno runs so I should have some more video next week. I may have to hook up the Go-Pro for the drive home!!

John commented that first and second gear are vey close. Ed had the transmission geared this way for autocrossing. It effectively makes it a four speed as you can take off in second gear. Second, third, and fourth are very close while fifth is an overdrive gear.

#154

Racer

Thread Starter

No car yet. John's son Cody returned from his trip and dyno tuned the engine last week. He did not make a power run which he is planning to do this week. While tuning it, he was having some issues with the left bank and right bank having different fuel mixtures. There is only one O2 sensor so he wasn't sure what the problem was. So he called Electromotive, the makers of the computer. They worked it out and now everything is as is should be.

There have been a couple other issues that John and Cody have worked on. One was the tach not working. Turns out I did wire it correctly but the signal put out by the computer was too weak to work with a factory tach. John has an amplifier adapter on the way to remedy that.

Before I took the car to John's shop, there was a small leak on the transmission. Running the car revealed an even larger leak on the left side around the output seal. John has fixed those as well. Brad Mayeur built that transmission back in 2006. I discussed the leaks with him and he said he was having a problem with the rear case leak at that time. He said he would pay for the repair. He was not having an issue with the output seals at that time but would talk to John about it. Not too many people would back up work they did 13 years ago!! Tells you a lot about Brad's character.

The temperature gauge was also not working and John is tracking that down.

The most vexing issue has been the shifter. John worked for days trying to get the aftermarket shifter to work. Despite many adjustment attempts, he could either have 2nd and 4th or 1st and 5th, but never all of them. After some discussions, we decided to try a completely stock shifter. Same results. John had never run into this situation before. So he shined a light down the tunnel and used a mirror to see if there were any obstructions. There was one. When I installed the right seat belt receptacle, I had used a bolt that was too long. It protruded into the tunnel just enough to keep the rod from moving far enough to the right to engage gears. In all of his time working on 914's, John had never run into this before. At out last discussion, he was going to adjust the stock shifter to make sure everything worked so he could give the car back to Cody to do the dyno runs. Once that is done, he will re-install the aftermarket shifter and see how that works.

Despite this has being an expensive exercise, I am glad I had to take the car to John. I would have gone crazy trying to figure out the shifter and the tach. Plus I now have the EFI properly tuned. I am excited about getting the car back. May not be this week as they are very busy there with race prep for their customers. Plus we are going the Outer Banks for a week in our motorhome and leaving this Sunday.

There have been a couple other issues that John and Cody have worked on. One was the tach not working. Turns out I did wire it correctly but the signal put out by the computer was too weak to work with a factory tach. John has an amplifier adapter on the way to remedy that.

Before I took the car to John's shop, there was a small leak on the transmission. Running the car revealed an even larger leak on the left side around the output seal. John has fixed those as well. Brad Mayeur built that transmission back in 2006. I discussed the leaks with him and he said he was having a problem with the rear case leak at that time. He said he would pay for the repair. He was not having an issue with the output seals at that time but would talk to John about it. Not too many people would back up work they did 13 years ago!! Tells you a lot about Brad's character.

The temperature gauge was also not working and John is tracking that down.

The most vexing issue has been the shifter. John worked for days trying to get the aftermarket shifter to work. Despite many adjustment attempts, he could either have 2nd and 4th or 1st and 5th, but never all of them. After some discussions, we decided to try a completely stock shifter. Same results. John had never run into this situation before. So he shined a light down the tunnel and used a mirror to see if there were any obstructions. There was one. When I installed the right seat belt receptacle, I had used a bolt that was too long. It protruded into the tunnel just enough to keep the rod from moving far enough to the right to engage gears. In all of his time working on 914's, John had never run into this before. At out last discussion, he was going to adjust the stock shifter to make sure everything worked so he could give the car back to Cody to do the dyno runs. Once that is done, he will re-install the aftermarket shifter and see how that works.

Despite this has being an expensive exercise, I am glad I had to take the car to John. I would have gone crazy trying to figure out the shifter and the tach. Plus I now have the EFI properly tuned. I am excited about getting the car back. May not be this week as they are very busy there with race prep for their customers. Plus we are going the Outer Banks for a week in our motorhome and leaving this Sunday.

#155

Racer

Thread Starter

And then there were more problems!

John works on the air cooled motors while son Cody works with modern electronics. Due to a miscommunication, John had told me that Cody had the issues worked out on the fuel injection. That wasn't the case. He was still having problems tuning it. It was not responding well to changes he made on the setup and it was till spitting back through the stacks on part throttle. At wide open throttle it was looking pretty good but there were issues with the transition on part throttle. Cody had spent quite a bit of time conversing with Richard Clewett about the issues but they could not get it to respond the way it should.

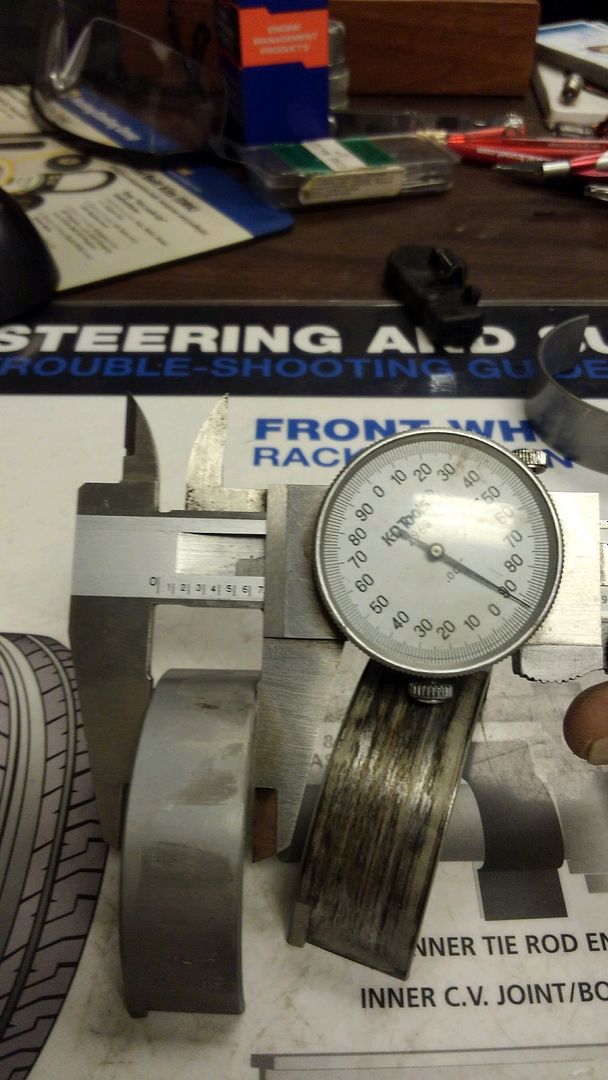

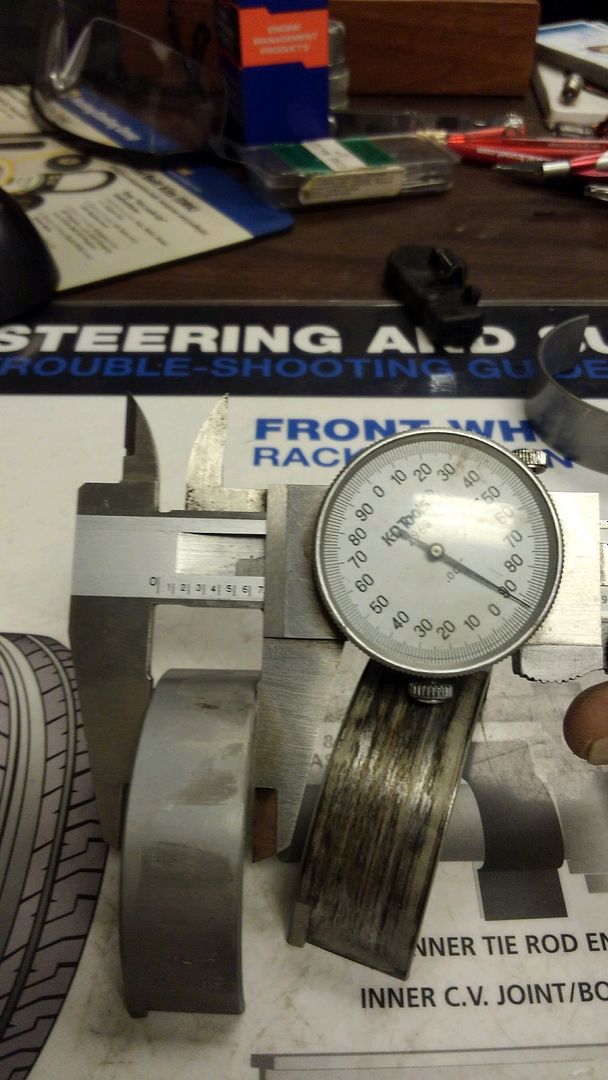

This prompted Cody and John to begin looking at the overall health of the motor. They had done a leakdown test prior to installing the motor and it was good. They decided they should do a compression test. Cody got about 120 and John read about 130 on each of their respective compression testers. As their gauges were far from new, they each decided to order a new compression tester from Snap-On so they could check it again. This was on Monday a week ago. The gauges were to come in on Wednesday.

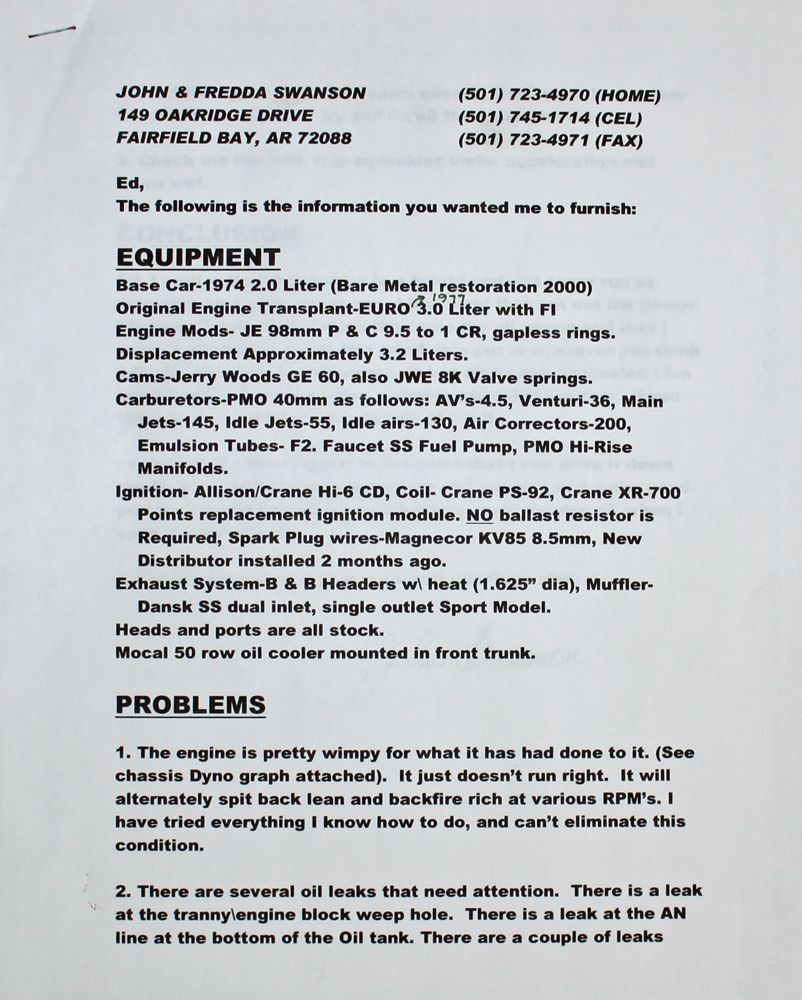

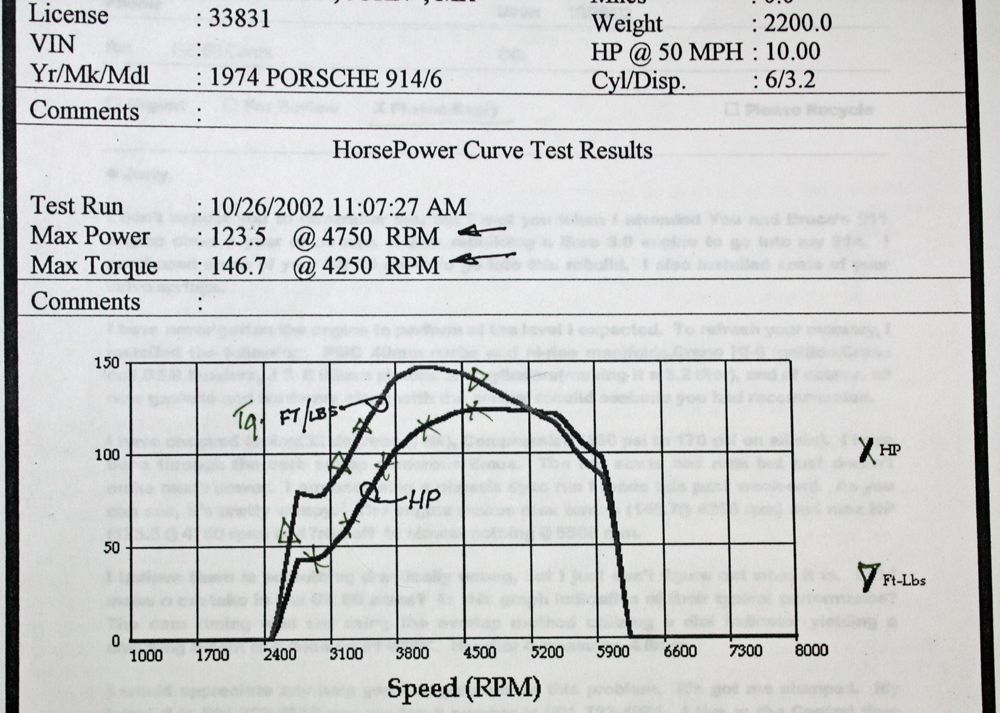

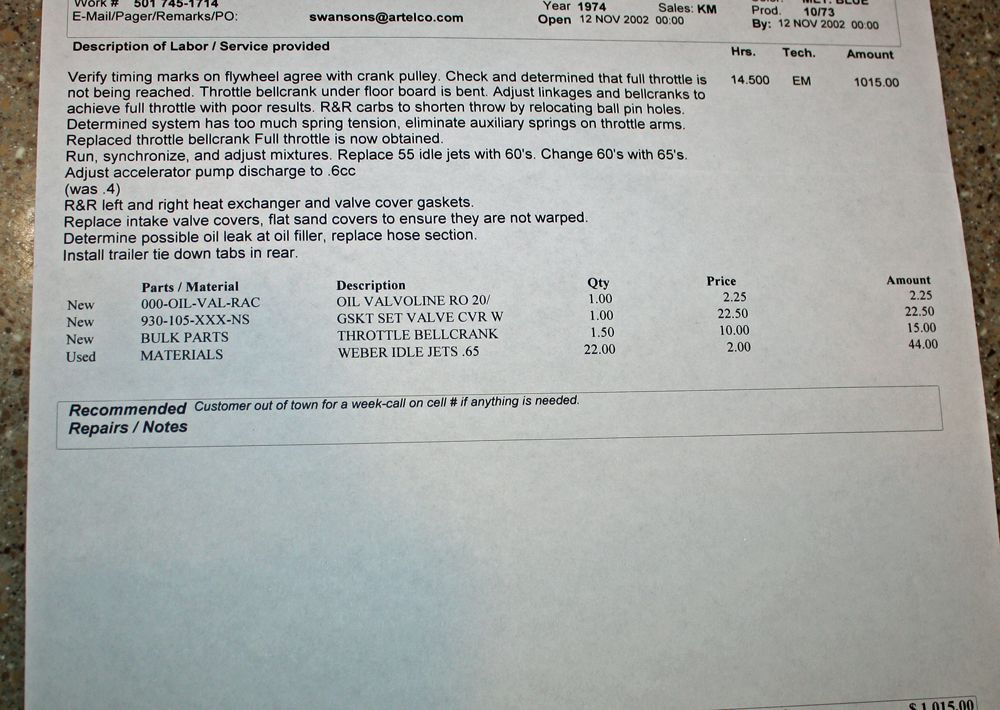

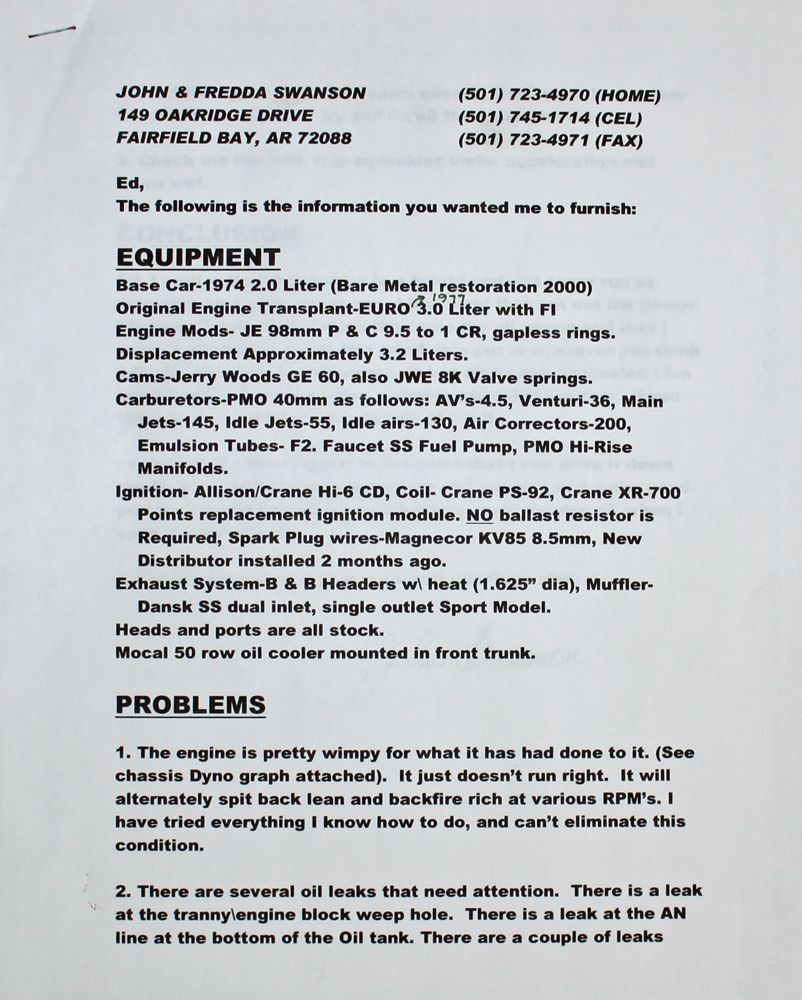

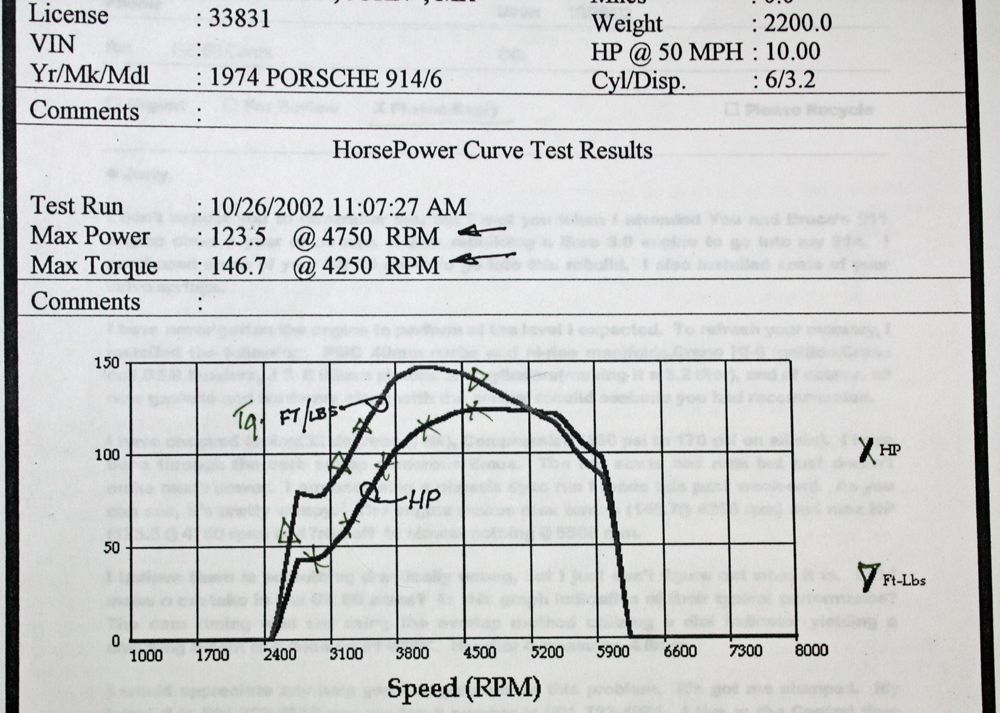

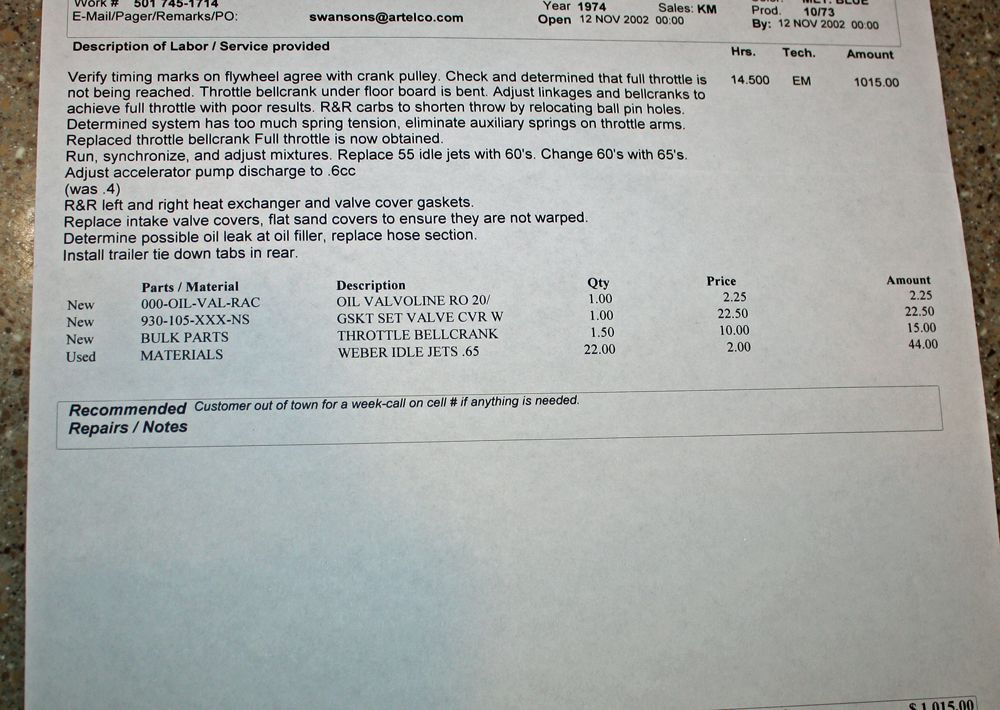

The car had come with a large box of records which I had gone through nearly a year ago when I first got the car. John and Cody's issues with spitting and not having the power they thought the engine should have sounded familiar. I dug through the records and found some documents showing that the original builder of the motor had these very same issues. Below is a letter from him to Ed Mayo in Dallas concerning these issues along with a dyno report showing only 125hp at the wheels. Also below is the bill from Ed Mayo outlining some of the things he found. None of these were going to restore lots of power but, evidently, made it better.

I had some business to take care of near John's shop so I headed there with these documents. Upon reading them, John thanked me for bringing them as there were going out of their minds trying to tune the car. Shortly, the Snap-On truck arrived and John immediately did a compression test. The new gauge showed 135. John commented that not only was it low but the way it moved the needle on the gauge was telling. Normally it jumps to the reading where here it was a somewhat gradual climb. He said it should be at least 150 and that his race motors will typically be 180.

John's best guess was that the car had the wrong pistons. I told him to do whatever he had to do to find out what was wrong. Cody and he were taking their 30's Ford roadster with a flathead V8 to a big car show in Maggie Valley, NC last weekend. so nothing happened on the motor until this week. John called me on Thursday to tell me that he was right about the pistons.

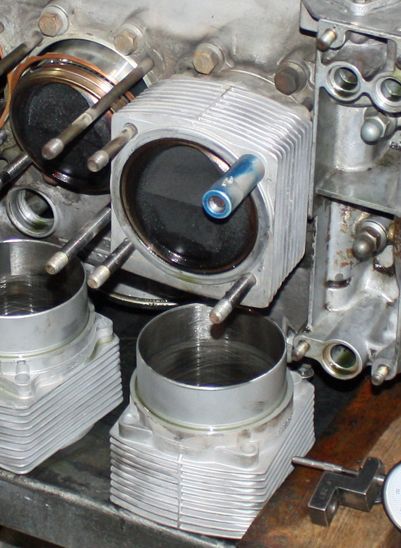

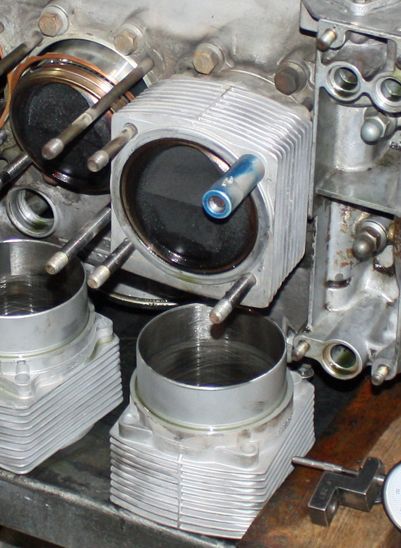

I drove over there Friday morning to give John some more money and to see what he had found. It is a little out of focus in the photo below but, when at top dead center, the piston is not flush with the top edge of the cylinder. It's not off my much but enough to make a big difference.

The pistons are J&E marked 96P. They are in excellent shape as were the rings, which explains why the leakdown test was good.

John talked to J&E about these pistons. The engine had been running very rich with the carburetors and they wanted to see one of the pistons cleaned up so they could check for numbers. There were no other numbers besides the 96P. One their current pistons there are numbers showing when it was made and other tracking information. Evidently they were not doing this back in 2002.

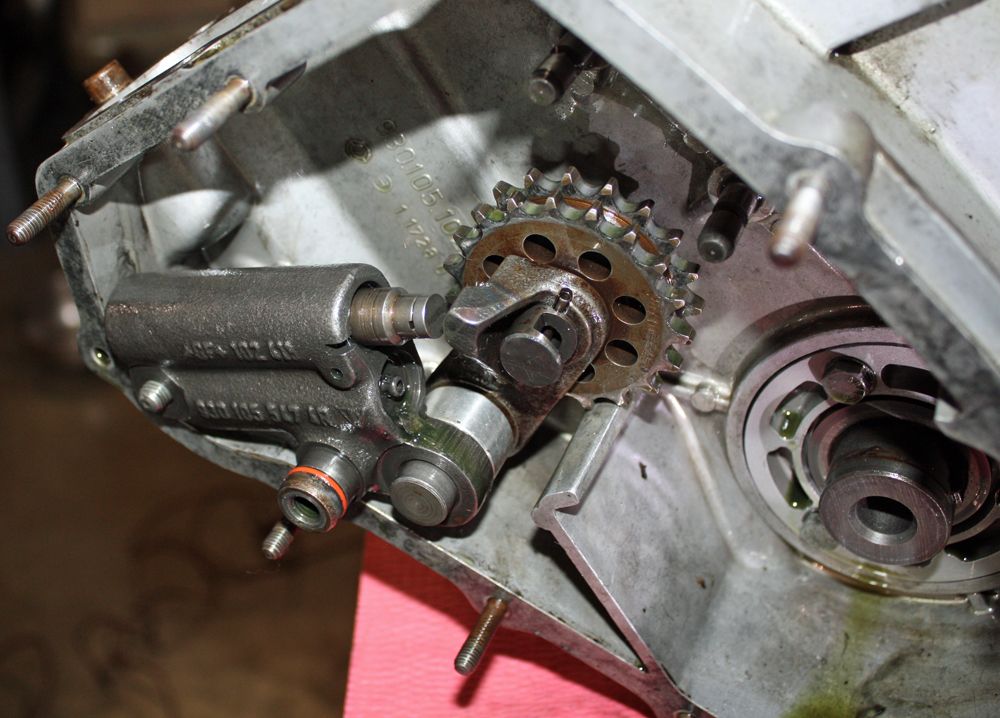

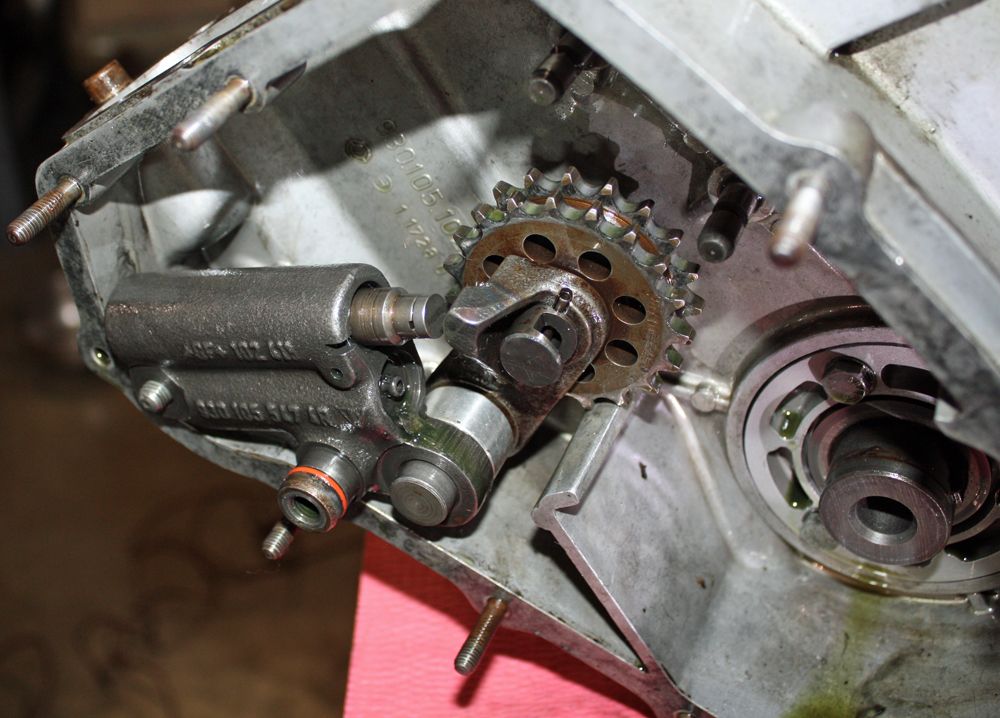

The cylinders looked great with the crosshatching still showing. The guy who had this car redone back in 2002 also built the motor. He had attended a class put on by Bruce Anderson and Jerry Woods and then built the motor. I believe it was his first attempt. John found some other disturbing items. One was the lack of a spacer on the chain sprocket at the chain tensioner on the right side. John had not had this side apart previously as my boo boo was on the other side. The first photo below shows what it looked like before they took it apart. The other photos show a spacer, from John's inventory, in place. John said that on the later cars the sprocket assembly was different with the part being built in such a way that no spacer was needed. John didn't recall this issue on the other side as would have noticed it.

There was also an issue with the chain guides as there were five of one type and one of the other instead of them being evenly divided with uppers and lowers.

The rod bolts were stock but John said he would have used competition bolts and nuts on a motor putting out the power this one should. He also found the use of crush washers where wave washers should have been used. Because of all of these issues, he said the case should come apart so they can check everything. And that is where we are at today.

John works on the air cooled motors while son Cody works with modern electronics. Due to a miscommunication, John had told me that Cody had the issues worked out on the fuel injection. That wasn't the case. He was still having problems tuning it. It was not responding well to changes he made on the setup and it was till spitting back through the stacks on part throttle. At wide open throttle it was looking pretty good but there were issues with the transition on part throttle. Cody had spent quite a bit of time conversing with Richard Clewett about the issues but they could not get it to respond the way it should.

This prompted Cody and John to begin looking at the overall health of the motor. They had done a leakdown test prior to installing the motor and it was good. They decided they should do a compression test. Cody got about 120 and John read about 130 on each of their respective compression testers. As their gauges were far from new, they each decided to order a new compression tester from Snap-On so they could check it again. This was on Monday a week ago. The gauges were to come in on Wednesday.

The car had come with a large box of records which I had gone through nearly a year ago when I first got the car. John and Cody's issues with spitting and not having the power they thought the engine should have sounded familiar. I dug through the records and found some documents showing that the original builder of the motor had these very same issues. Below is a letter from him to Ed Mayo in Dallas concerning these issues along with a dyno report showing only 125hp at the wheels. Also below is the bill from Ed Mayo outlining some of the things he found. None of these were going to restore lots of power but, evidently, made it better.

I had some business to take care of near John's shop so I headed there with these documents. Upon reading them, John thanked me for bringing them as there were going out of their minds trying to tune the car. Shortly, the Snap-On truck arrived and John immediately did a compression test. The new gauge showed 135. John commented that not only was it low but the way it moved the needle on the gauge was telling. Normally it jumps to the reading where here it was a somewhat gradual climb. He said it should be at least 150 and that his race motors will typically be 180.

John's best guess was that the car had the wrong pistons. I told him to do whatever he had to do to find out what was wrong. Cody and he were taking their 30's Ford roadster with a flathead V8 to a big car show in Maggie Valley, NC last weekend. so nothing happened on the motor until this week. John called me on Thursday to tell me that he was right about the pistons.

I drove over there Friday morning to give John some more money and to see what he had found. It is a little out of focus in the photo below but, when at top dead center, the piston is not flush with the top edge of the cylinder. It's not off my much but enough to make a big difference.

The pistons are J&E marked 96P. They are in excellent shape as were the rings, which explains why the leakdown test was good.

John talked to J&E about these pistons. The engine had been running very rich with the carburetors and they wanted to see one of the pistons cleaned up so they could check for numbers. There were no other numbers besides the 96P. One their current pistons there are numbers showing when it was made and other tracking information. Evidently they were not doing this back in 2002.

The cylinders looked great with the crosshatching still showing. The guy who had this car redone back in 2002 also built the motor. He had attended a class put on by Bruce Anderson and Jerry Woods and then built the motor. I believe it was his first attempt. John found some other disturbing items. One was the lack of a spacer on the chain sprocket at the chain tensioner on the right side. John had not had this side apart previously as my boo boo was on the other side. The first photo below shows what it looked like before they took it apart. The other photos show a spacer, from John's inventory, in place. John said that on the later cars the sprocket assembly was different with the part being built in such a way that no spacer was needed. John didn't recall this issue on the other side as would have noticed it.

There was also an issue with the chain guides as there were five of one type and one of the other instead of them being evenly divided with uppers and lowers.

The rod bolts were stock but John said he would have used competition bolts and nuts on a motor putting out the power this one should. He also found the use of crush washers where wave washers should have been used. Because of all of these issues, he said the case should come apart so they can check everything. And that is where we are at today.

#156

Racer

Thread Starter

While I was at the shop, I took the fan shroud with me. It has some paint issues that I had not addressed as I didn't want to tear down the motor to the extent needed to remove the shroud. I bought some very mild plastic bead for my bead blaster, turned down the air pressure and removed the old paint. After cleaning everything, I hit it with some primer. I will do a bit of sanding on that and then add the color coat.

#157

Racer

Thread Starter

On the good news side, my son's car arrived at his house from the body shop. Adam, from Backyard Legends in Concord, NC, delivered it in his closed trailer. Adam has prepared cars for Amelia and does fantastic work. The paint quality cannot be seen in photos. It has to be seen in person. The complete bottom and the engine and trunk bays are painted with a matching color bedliner material.

Last summer Hendrick Porsche of Charlotte hosted a 70th birthday party for Porsche. Numerous cars were on display with one of them being a RSR that Adam had recently completed in a stunning orange.

I struck up a conversation with Adam and told him about Matt's project putting the Tesla motor into a 1979 911. He was interested from the get go and said he wanted to be involved with the car. I put him and Matt together and the result is stunning. The first photo below shows the car as Matt bought it. It was a roller that had been flooded during Katrina. Matt had some rust repair to do before he could begin modifying it for the Tesla motor installation.

Last summer Hendrick Porsche of Charlotte hosted a 70th birthday party for Porsche. Numerous cars were on display with one of them being a RSR that Adam had recently completed in a stunning orange.

I struck up a conversation with Adam and told him about Matt's project putting the Tesla motor into a 1979 911. He was interested from the get go and said he wanted to be involved with the car. I put him and Matt together and the result is stunning. The first photo below shows the car as Matt bought it. It was a roller that had been flooded during Katrina. Matt had some rust repair to do before he could begin modifying it for the Tesla motor installation.

#158

Racer

Thread Starter

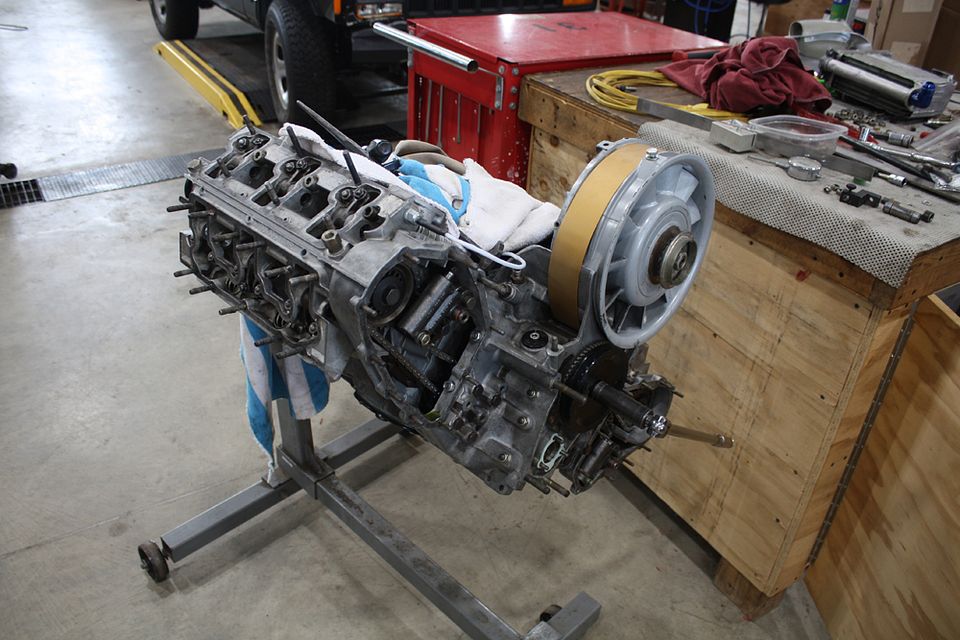

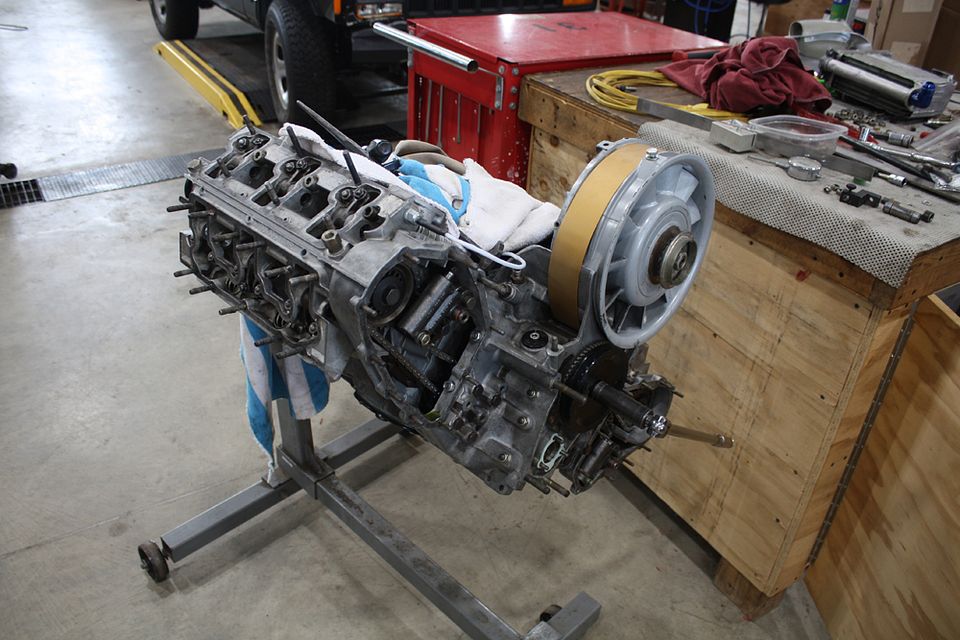

John's wife had surgery on her shoulder recently. Besides taking her in for surgery, he has had to take her in for rehabilitation. Also, his sister passed last week so he had a funeral to attend. I visited the shop today. John was gone with his wife but I did see the motor. It is nearly all the way apart. I left a message for him to call me when he gets a chance.

After working with the shroud, I decided it needed a fresh coat of gelcoat. I have it at a boat company to have that done. They are busy so I am at their mercy.

About seven years ago, I did a full body-off restoration on a '64 Corvette coupe. I did that entire project in nine months. And that was with me breaking my wrist about two months into the project resulting in my not being able to work on it for about six weeks. This 914 has been my most frustrating project to date. Everything is taking longer than I expected it to. One of these days it will be finished.

On the other hand, my son's 911 Tesla project is moving right along. He has it mostly complete. On Sunday the body shop guy came to Matt's house and we installed the doors, bumpers, hood, and deck lid. It looks fantastic!!

After working with the shroud, I decided it needed a fresh coat of gelcoat. I have it at a boat company to have that done. They are busy so I am at their mercy.

About seven years ago, I did a full body-off restoration on a '64 Corvette coupe. I did that entire project in nine months. And that was with me breaking my wrist about two months into the project resulting in my not being able to work on it for about six weeks. This 914 has been my most frustrating project to date. Everything is taking longer than I expected it to. One of these days it will be finished.

On the other hand, my son's 911 Tesla project is moving right along. He has it mostly complete. On Sunday the body shop guy came to Matt's house and we installed the doors, bumpers, hood, and deck lid. It looks fantastic!!

#159

Racer

Thread Starter

I am still waiting on the motor rebuild. John's other sister is dying as well. He recently spent a week in New Jersey with her and other family. Both his sister who passed and this ill sister were/are in their sixties and both were heavy smokers. It is hitting John hard. I visited with him this past week. He asked if I had seen some of the commercials that show people's faces distorted from cancer surgery. He said both of his sisters looked like those in the ads. Pretty tough. He said he was getting his head wrapped around all of this and was ready to get back to working on my motor. Not much I could say under the circumstances except to offer my condolences.

On the plus side, my son's car made its debut today at the Charlotte Cars and Cappuccino. And it was a huge hit. A local outlaw Porsche builder wanted to know if Matt would build more cars like his as this guy thinks he could sell them. The number he threw out was $150K. Some friends of mine were there and were duly impressed. I was a proud father. I actually talked to more people about the car than my son did as he is a reluctant public speaker. Having spent most of my career in sales, being a reluctant speaker is not one of my traits!!

On the plus side, my son's car made its debut today at the Charlotte Cars and Cappuccino. And it was a huge hit. A local outlaw Porsche builder wanted to know if Matt would build more cars like his as this guy thinks he could sell them. The number he threw out was $150K. Some friends of mine were there and were duly impressed. I was a proud father. I actually talked to more people about the car than my son did as he is a reluctant public speaker. Having spent most of my career in sales, being a reluctant speaker is not one of my traits!!

The following users liked this post:

Gmanscott (07-31-2019)

#160

Racer

Thread Starter

And the saga continues. Last week I visited John and found that nothing had been done on the engine. More excuses. Today I performed an intervention and brought everything home!! I hooked up my utility trailer to my Audi Allroad to haul the engine and transmission. Everything else went inside in various tubs. A call to AAA soon had a roll-back there to take the car to my house. The car had been at John's for five months!!!

Once I decided that I wanted to do this I began thinking about where I was going to take the motor. Because of the fuel injection I wanted someone working on it who understands that system. The obvious choice would have been Richard Clewett but California is a long way from North Carolina.

Then I remembered talking with my 40 year plus buddy about his PCA race car while we were in Florida this past winter. He has basically this identical motor in his car with Richard's injection system. And it was built by a 30 plus year friend in Elkhart, Indiana. I called my friend with the race car to see if my other friend was still building motors. Turns out he had just rebuilt the race car motor this past spring. And I also discovered that my engine builder friend had built another engine with this configuration for another friend of mine.

So I called my engine builder friend. After some get acquainted talk, we got down to business. At one time he was the lead technician at the local Porsche dealership. That job was followed by him owning an independent Porsche repair shop. When I lived in Indiana, he used to come over to help me on projects and taught me much of what I know. In 1989, he built a 944 motor at my house that I ran in a track car for five years, followed by my son having that car for another four years. Never had a bit of trouble with that motor.

His path to working on cars began with the vocational school he attended while in high school. That vocational school had asked him for some advice and he ended up volunteering there while had he his independent business. One day the school asked if he would be interested in becoming an instructor. He wasn't making all that much money with his shop and the new job came with great benefits. He has been there for fourteen years now...and loves it.

He was more than willing to build the motor. And then he asked if I would be OK with him using the motor in his classroom. He has eight seniors this year who would be thrilled to work on a Porsche motor. My friend would be overseeing them to make sure everything was correct. I agreed. He is very excited about his kids working on the motor as it isn't likely they would be working on this type of motor in their future careers. They normally build a small block Chevy so this would be quite different.

I am taking the car and motor to him next Monday. We are leaving on a nearly two month motorhome trip just before Labor Day so they can work on it while I am gone. This won't be a quick turnaround but the motor will be with someone that I trust. While he is working on the motor, my other friend will be storing the car in one of his buildings. I just may get this thing back together!

Once I decided that I wanted to do this I began thinking about where I was going to take the motor. Because of the fuel injection I wanted someone working on it who understands that system. The obvious choice would have been Richard Clewett but California is a long way from North Carolina.

Then I remembered talking with my 40 year plus buddy about his PCA race car while we were in Florida this past winter. He has basically this identical motor in his car with Richard's injection system. And it was built by a 30 plus year friend in Elkhart, Indiana. I called my friend with the race car to see if my other friend was still building motors. Turns out he had just rebuilt the race car motor this past spring. And I also discovered that my engine builder friend had built another engine with this configuration for another friend of mine.

So I called my engine builder friend. After some get acquainted talk, we got down to business. At one time he was the lead technician at the local Porsche dealership. That job was followed by him owning an independent Porsche repair shop. When I lived in Indiana, he used to come over to help me on projects and taught me much of what I know. In 1989, he built a 944 motor at my house that I ran in a track car for five years, followed by my son having that car for another four years. Never had a bit of trouble with that motor.

His path to working on cars began with the vocational school he attended while in high school. That vocational school had asked him for some advice and he ended up volunteering there while had he his independent business. One day the school asked if he would be interested in becoming an instructor. He wasn't making all that much money with his shop and the new job came with great benefits. He has been there for fourteen years now...and loves it.

He was more than willing to build the motor. And then he asked if I would be OK with him using the motor in his classroom. He has eight seniors this year who would be thrilled to work on a Porsche motor. My friend would be overseeing them to make sure everything was correct. I agreed. He is very excited about his kids working on the motor as it isn't likely they would be working on this type of motor in their future careers. They normally build a small block Chevy so this would be quite different.

I am taking the car and motor to him next Monday. We are leaving on a nearly two month motorhome trip just before Labor Day so they can work on it while I am gone. This won't be a quick turnaround but the motor will be with someone that I trust. While he is working on the motor, my other friend will be storing the car in one of his buildings. I just may get this thing back together!

#161

Racer

Thread Starter

My boat guy who was going to apply new gelcoat to the fan shroud also did not work out. John owes me some money and, as partial payment, he gave me a fan shroud. I drilled out the rivets and painted the shroud and the metal part separately.

The carburetor hats had a few scratches before I took it to John. There were a few more when I got them back. Nothing terrible but enough that I blasted them and took them ot my powder coater yesterday. I picked them up today with a cost of $20.

The fins on the alternator housing were rusty. After doing some sanding, I painted them with a high temp paint.

I did an inventory yesterday and found that the only part that was missing was the band that retains the fan. I drove over to John's this morning and got it. Now that it was apart, I blasted it and painted it gold.

Now all I have to do is pack everything to prepare it for transporting in the truck next Monday.

The carburetor hats had a few scratches before I took it to John. There were a few more when I got them back. Nothing terrible but enough that I blasted them and took them ot my powder coater yesterday. I picked them up today with a cost of $20.

The fins on the alternator housing were rusty. After doing some sanding, I painted them with a high temp paint.

I did an inventory yesterday and found that the only part that was missing was the band that retains the fan. I drove over to John's this morning and got it. Now that it was apart, I blasted it and painted it gold.

Now all I have to do is pack everything to prepare it for transporting in the truck next Monday.

The following users liked this post:

Gmanscott (08-09-2019)

#162

Racer

Thread Starter

I have an update. As a refresher, the engine came out of a Euro Carrera and began as a 3.0 liter. Marty told me to order a SC basic rebuild kit with standard bearings. I also ordered ARP studs and rod bolts. When Marty began to assemble the bottom end, he discovered the bearings were too small. This is the bearing that came in the kit.

This is the bearing that was in the motor.

I bought the kit from Vertex. After getting together with Vertex's owner, he and Marty came to the conclusion that the engine, while a 3.0 liter, had 2.7 rods. Marty knew there were some differences between the Euro Carrera motor and a SC motor, but did not know about the rod issue. The Euro 3.0 has the aluminum case rather than the magnesium case of the 2.7. Marty now has the correct bearings.

When Marty inspected the pistons, he discovered one had bolt thread marks on the top of the piston where a bolt had been squeezed between the piston and the head. I did read where the guy who built the motor dropped a bolt into the engine and had to disassemble the part of the motor to get to it. Evidently the engine was hand cranked before the bolt was removed. Marty also noticed that it appeared the cylinders had been honed. He is concerned that the Nikasil lining had been compromised.

The pistons and cylinders were sent to EBS. This is their assessment.

"Just a quick note to let you know that we have received your pistons and cylinders. The JE pistons are very old. No job number stamped on the inside of the piston. Without the job number it's impossible to know exactly what they are. JE has significantly improved their 911 air cooled pistons and ring pack since then. I would recommend going with a new set of JE pistons 98mm 9.5:1CR. They will be correct for the application, a slight bump in compression ratio for a bit more performance, coated piston skirts and lightweight wrist pins. Cylinders have had something done to them. I would recommend plating the cylinders to make sure that everything is 100% correct. They might be within spec but I do not know what process they used to hone the cylinders. We can have them inspected and measured, cost is $100/set. Attached is a copy of your quote. Let me know if you have any questions. If you would like us to measure and inspect the cylinders allow 7-10 days."

I will be calling EBS later today to give them some money. And that is where I am at to this date.

This is the bearing that was in the motor.

I bought the kit from Vertex. After getting together with Vertex's owner, he and Marty came to the conclusion that the engine, while a 3.0 liter, had 2.7 rods. Marty knew there were some differences between the Euro Carrera motor and a SC motor, but did not know about the rod issue. The Euro 3.0 has the aluminum case rather than the magnesium case of the 2.7. Marty now has the correct bearings.

When Marty inspected the pistons, he discovered one had bolt thread marks on the top of the piston where a bolt had been squeezed between the piston and the head. I did read where the guy who built the motor dropped a bolt into the engine and had to disassemble the part of the motor to get to it. Evidently the engine was hand cranked before the bolt was removed. Marty also noticed that it appeared the cylinders had been honed. He is concerned that the Nikasil lining had been compromised.

The pistons and cylinders were sent to EBS. This is their assessment.

"Just a quick note to let you know that we have received your pistons and cylinders. The JE pistons are very old. No job number stamped on the inside of the piston. Without the job number it's impossible to know exactly what they are. JE has significantly improved their 911 air cooled pistons and ring pack since then. I would recommend going with a new set of JE pistons 98mm 9.5:1CR. They will be correct for the application, a slight bump in compression ratio for a bit more performance, coated piston skirts and lightweight wrist pins. Cylinders have had something done to them. I would recommend plating the cylinders to make sure that everything is 100% correct. They might be within spec but I do not know what process they used to hone the cylinders. We can have them inspected and measured, cost is $100/set. Attached is a copy of your quote. Let me know if you have any questions. If you would like us to measure and inspect the cylinders allow 7-10 days."

I will be calling EBS later today to give them some money. And that is where I am at to this date.

#163

Racer

Thread Starter

Covid-19 update.

At least for now, the school where my friend works is having students back in class next week. The heads have been sent out to be redone. Once everything is back, the plan is to finish up the engine build. As part of their training, the class will install the motor and tranny. They now have a dyno at the school. Once it is back in the car and running , my friend will tune the car on the dyno.

As we all know with this pandemic, nothing is certain. If they have issues and transition to online learning, my friend will finish the build on the motor. I will probably head up there to help him install the drivetrain and we will put it on the dyno to tune it.

At least for now, the school where my friend works is having students back in class next week. The heads have been sent out to be redone. Once everything is back, the plan is to finish up the engine build. As part of their training, the class will install the motor and tranny. They now have a dyno at the school. Once it is back in the car and running , my friend will tune the car on the dyno.

As we all know with this pandemic, nothing is certain. If they have issues and transition to online learning, my friend will finish the build on the motor. I will probably head up there to help him install the drivetrain and we will put it on the dyno to tune it.

#164

Racer

Thread Starter

Due to COVID issues with the machine shop employees, I finally got the heads back in January.

So Marty was all set to proceed. And then things turned around in a hurry. Marty's wife had a bout with cancer about five years ago. She was due for her annual checkup back in November but, due to COVID, that checkup did not happen. She was feeling poorly the first part of January with back issues. They saw a doctor who thought she had a slipped disc and was medicating for that. But her health deteriorated to a point that Marty took her to the emergency room last month. The cancer had come back and her kidneys were shutting down. Three days later she passed. As you can imagine, the last thing on Marty's mind is building a motor. And that is the last thing I am concerned about as well. I feel so sorry for Marty. He was devastated.

Better news is that my son has taken a new job. He has worked for Toyota Racing Development for the past 10 years with his latest promotion was to head of vehicle dynamics. About a year ago, he was approached by a head hunter. Great Wall Motors, located in Baoding, China, primarily builds SUV's and trucks. They want to get into racing and were looking for someone to build a racing program from scratch. Matt was their choice and, had it not been for COVID, he might have moved to China last spring. They are paying him big bucks and furnishing him with an apartment.

As it was, he flew out of Charlotte to LA on January 24th where he had to pass a COVID test before flying to a port city in China. He then was quarantined for 14 days in a government owned hotel. After he flew from that city to Baoding, he had to quarantine for another 21 days in another government owned hotel!!! They are super serious about COVID in China!

Last week was his first week of work!! He is very excited about the opportunity to build a race program from scratch. Long days as they go in at 8:30 and leave around 8:30 in the evening. However, they do have nap time in the afternoon. There are mats spread out and everyone lies down. He said it reminded him of kindergarten but it is refreshing. He says the people are super nice and very polite. So far, so good.

We visited with him just before he left and the told me that I was not to sell the 914 until I gave him a chance to buy it. He has always loved 914's and wants to own the car. His contract is for three years with renewal options, so it will be awhile before he is back. So no pressure to finish the car.

So Marty was all set to proceed. And then things turned around in a hurry. Marty's wife had a bout with cancer about five years ago. She was due for her annual checkup back in November but, due to COVID, that checkup did not happen. She was feeling poorly the first part of January with back issues. They saw a doctor who thought she had a slipped disc and was medicating for that. But her health deteriorated to a point that Marty took her to the emergency room last month. The cancer had come back and her kidneys were shutting down. Three days later she passed. As you can imagine, the last thing on Marty's mind is building a motor. And that is the last thing I am concerned about as well. I feel so sorry for Marty. He was devastated.

Better news is that my son has taken a new job. He has worked for Toyota Racing Development for the past 10 years with his latest promotion was to head of vehicle dynamics. About a year ago, he was approached by a head hunter. Great Wall Motors, located in Baoding, China, primarily builds SUV's and trucks. They want to get into racing and were looking for someone to build a racing program from scratch. Matt was their choice and, had it not been for COVID, he might have moved to China last spring. They are paying him big bucks and furnishing him with an apartment.

As it was, he flew out of Charlotte to LA on January 24th where he had to pass a COVID test before flying to a port city in China. He then was quarantined for 14 days in a government owned hotel. After he flew from that city to Baoding, he had to quarantine for another 21 days in another government owned hotel!!! They are super serious about COVID in China!

Last week was his first week of work!! He is very excited about the opportunity to build a race program from scratch. Long days as they go in at 8:30 and leave around 8:30 in the evening. However, they do have nap time in the afternoon. There are mats spread out and everyone lies down. He said it reminded him of kindergarten but it is refreshing. He says the people are super nice and very polite. So far, so good.

We visited with him just before he left and the told me that I was not to sell the 914 until I gave him a chance to buy it. He has always loved 914's and wants to own the car. His contract is for three years with renewal options, so it will be awhile before he is back. So no pressure to finish the car.

#165

Racer

Thread Starter

My good friend Dave and I both turned 75 abut three weeks apart this spring. One of Dave's two sons bought four tickets to the vintage races at Road America and rented a four bedroom house. They asked me to be the fourth person. As you can imagine, I said yes to that proposition. That all happened this past weekend and we had a great time. We also bumped into our old friend Ben whom we had not seen for some time.

After accepting, I called Marty to let him know I would be in Indiana and wondered how he was coming on the motor and if I could be of assistance while I am there. He said he was close on the motor and that I should bring work clothes.

This morning we picked up the car from my friend Harry's building and took it to the Elkhart Career Center. I hooked up the alternator and installed the other shroud wiring. Marty then did the cam timing. We are meeting tomorrow morning to button up the motor and may put it in the car if all goes well. Progress!!

After accepting, I called Marty to let him know I would be in Indiana and wondered how he was coming on the motor and if I could be of assistance while I am there. He said he was close on the motor and that I should bring work clothes.

This morning we picked up the car from my friend Harry's building and took it to the Elkhart Career Center. I hooked up the alternator and installed the other shroud wiring. Marty then did the cam timing. We are meeting tomorrow morning to button up the motor and may put it in the car if all goes well. Progress!!