Porsche 993: Why is My Suspension Creaking When I Turn the Steering Wheel?

A creaking noise when turning can be quite annoying. However, when your car makes noise, it is often trying to tell you something. In the case of a front suspension noise, it is a good idea to listen and inspect components of the steering and suspension system to prevent a failure that could result in an accident.

This article applies to the Porsche 993 (1993-1998).

A creaking noise when turning the steering wheel is often an indication of a failing component in the steering and suspension system. Luckily, components of the steering and suspension system are easily accessible and can quickly be examined for wear and tear. When a worn or failed component is discovered, it is an opportune time to install upgrades to the front suspension to improve handling and ride quality. This article will examine several components in the steering and suspension system that have the potential to squeak and creak when turning the steering wheel in a Porsche 993.

Materials Needed

- Floor jack and jack stands

- Tire iron for wheel removal

- Pry bar

Tie Rod Ball Joints

The first component to inspect when experiencing a creaking noise while turning the steering wheel are the tie rod ball joints. The steering rack is connected to the suspension upright (also known as a steering knuckle) by way of the tie rod ball joints. The ball joints pivot back and forth to allow for smooth operation between the steering rack and suspension uprights as the steering wheel is turned. The ball joints can become contaminated with dirt, debris, and moisture which can cause them to fail. Similarly, the grease inside the ball joints can dry up over time and not allow the ball joints to move as freely as they should. Inspect the condition of the ball joints and their rubber boots. If there is excessive play or the rubber boots are torn, replace the tie rod assembly.

(Related article: How to Replace Tie Rods in a Porsche 993 - Rennlist.com)

Figure 1. Tie rod outer ball joint.

Figure 2. Example of torn ball joint boot.

Lower Control Arm Ball Joint

Similar to the tie rods, the front lower control arms also utilize a ball joint to connect the control arm to the suspension upright. The suspension upright rotates on this ball joint as the steering wheel is turned. The ball joint is under a lot of stress as it is continually pivoting as the suspension moves up and down while driving. As with the tie rod ball joints, the lower control arm ball joint can corrode and dry out if a rubber boot is torn and begin to creak or squeak when turning. Inspect the ball joint for excessive play or a torn boot and replace if necessary.

(Related Article: How to Replace Front Lower Ball Joint in a Porsche 993 - Rennlist.com)

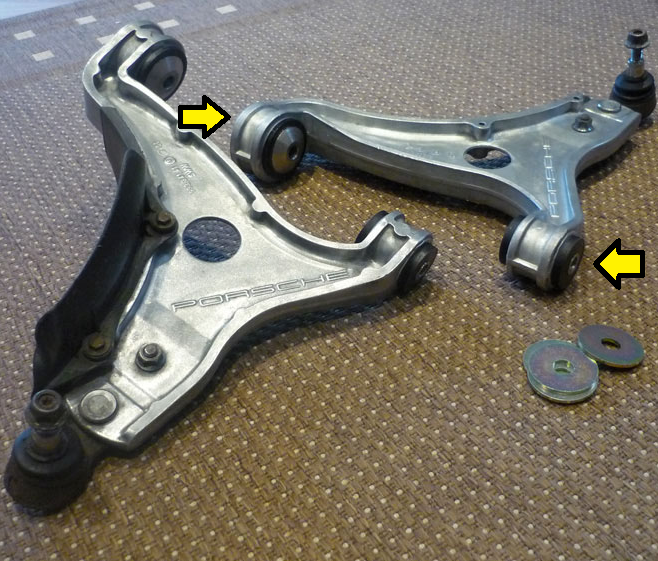

Lower Control Arm Bushings

The lower control arms on the 993 pivot on rubber bushings where they are mounted to the chassis. Owners have complained of squeaking and creaking noises when driving over bumps as the control arms work up and down. The rubber bushings can dry out and become hardened over time, which can lead to noisy suspension, vibration, and poor vehicle control. This is a very common issue with the 993 and most owners opt to upgrade to a harder urethane bushing for improved handling precision and cornering. Some owners have lubricated the dried rubber bushing with some success in limiting noise. It is worth noting, if you have or plan to install urethane bushing in the lower control arms, that these bushings are known to make a squeaking noise even when new. Control arm bushings can be visually inspected from under the car. They can also be tested for excessive play by placing a pry bar between the control arm and chassis and applying force while examining the amount of deflection.

Figure 4. Lower control arm bushing inspection.

Figure 5. Additional view of LCA bushings.

Suspension Struts

The original struts (aka coilovers) fitted to the 993 from the factory typically have a short lifespan of around 30,000 to 40,000 miles before performance begins to degrade or strut failure occurs. Several components of the strut can cause a creaking noise when the car is being driven. It is not a bad idea to install a new or upgraded set of struts if any of your factory components are suspect as new units will greatly improve handling and ride quality of the 993.

- Springs - A broken coil spring can create a lot of suspension creaking noise. Inspect the spring, paying close attention to the top and bottom portions for cracks or breaks. Also, owners have reported a creaking when the spring was not properly seated in the top mount. If the spring snags or gets hung up and cannot freely rotate when turning, it will creak and groan.

- Top mount - The strut top mount has bearings and rubber hats that can also make noise when turning. If moisture and grime enter the bearings, the bearings can corrode and not allow the strut to rotate freely. Additionally, the underside of the top mount has a rubber hat that the coil spring rides in. If the rubber is damaged or hardened, the spring will be noisy when the front wheels are being turned. Inspect the components for wear and tear and replace if necessary. Owners with monoball top mounts have also had failures, but this typically produces a clunking noise as opposed to a creak or squeak.

(Related Article: How to Replace Front Struts in a Porsche 993 - Rennlist.com)

Figure 6. Inspecting front strut.

Figure 7. Top and bottom view of stock top mount.

Roll Bar Bushings

The rubber anti-roll bar bushings that secure the the roll bar to the chassis are a known source for squeaking and creaking noises. Rubber bushings do a good job of absorbing minor vibrations and noises all while providing decent rigidity. However, as with most other rubber components, the bushings can age, dry out and deteriorate. When cornering, the torsional flex of the roll bar in a hardened or worn bushing can become noisy. Additionally, a worn out bushing can cause excessive body roll and reduce the tires' contact with the road. Porsche issued a service bulletin that explained the need to lubricate the bushing with Vaseline to prevent squeaking noises. Luckily, the bushing can be easily inspected and replaced if necessary.

Related Discussions

- Suspension Squeak - Rennlist.com

- Help with Suspension Noise - Rennlist.com

- Suspension Noise - Rennlist.com