What exactly is ‘Finished leather’?

#1

Burning Brakes

Thread Starter

Join Date: Dec 2006

Location: London,UK / Florida US State- Dazed & Confused

Posts: 863

Likes: 0

Received 4 Likes

on

4 Posts

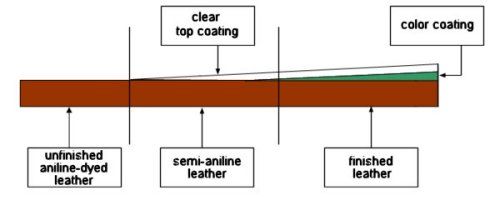

Section through finished leather - Diagram by Advanced Leather Solutions

Be cognizant that you’re dealing with the finished coating on the leather and not with the leather hide itself

Research

Information regarding the care of leather is scarce, often contradictory, misleading, or simply wrong. Misinformation can lead to inadvertent damage to your vehicles leather upholstery; my goal is to present clear, concise, accurate information.

There is a great deal of conflicting information on leather care being put out by leather experts themselves who use baffling pseudo scientific techno speak as another marketing ploy, which makes it difficult to find a definitive, unbiased answer. It had always confounded me that such a simple subject has been made into something so complicated.

After various meetings and discussions with leather tanners, fat liquoring formulators, their chemists and many leather care product manufacturers I’ve gained an understanding of this versatile material on both a practical and scientific level.

I have always thought that the more facts and information you have at hand the easier it is to judge what information you are being given. After all, how can you fully understand and properly use any product unless you have all the facts? In the final analysis; it’s your vehicle, your hard earned money and your choice

History

Prior to 1939 leathers produced were solely vat dyed. Usually these colors faded quickly and developed into strange shades of greens or browns after exposure to the sun. Although the surfaces did not crack and chip as badly, the leather still became dry and stiff.

After 1945 new technology created new demands and brighter colors quickly became popular with the availability of nitrocellulose resin emulsion lacquers. Leathers that were vat dyed were now surface coated as well. In the early 1980’s nitrocellulose lacquers gave way to the resin-base dyes in use today.

Before 1980 most automotive leather upholstery used was high quality top grain full grain leather with a pigmented solvent-based Nitrocellulose lacquer coating and their unstable plasticizers would easily migrate in the heat from sun exposure and again create 'fogging' on the internal surfaces of the windows. As a result of this plasticizer migration the use of oil-based products that contained solvents to keep them from becoming brittle and cracking, creams, waxes and oils were needed in aftercare products to try and bring the suppleness back into the leather

By applying an oil-based conditioner and allowing time for it to work in a heated environment. This can be accomplished by covering the seats with a plastic bag to help retain the heat and them leave overnight will ensure the oils permeate the lacquer and reach the leather hide. This process can also be used for equestrian tack; bridles, harnesses’, saddle and leather chaps and riding boots.

This nitrocellulose resin conditioning methodology for some reason has been carried over to modern finished leather. Even though urethane’s only requirement is to be kept clean and hydrated, it doesn’t require conditioning. Products such as leather (Saddle) soaps, oil-based Conditioners, Neat-foot oil, and Hide Food still prevail as top sellers, albeit most are made for equestrian tack.

These are very different leathers with drastically differing care requirements. The exact reason for this type of misapplication is unclear.

It’s possible that there is an association with old world quality (i.e. European automobiles with unfinished leather upholstery and real burl wood interiors) with these types of products, despite the fact that the automotive industry has been using aqueous (water- based) urethane covered pigmented leather since 1980.

Modern Leather Surface Technology

Automotive leather surfaces have undergone major technological improvements over the past decade. The complex tanning process of chromed tanned hides results in the fat liquoring and oils necessary to keep the hide soft and pliable being locked in, this is further sealed by a durable urethane covering to protect the hide from abrasion, entering and exiting the vehicle well as the dust / dirt introduced by the vehicle’s AC system.

The leather used for modern automotive upholstery is finished leather; the ‘finish’ applied to the leather hide is a pigmented (colour) urethane protective layer and a clear abrasion resistant topcoat.

Materials Technology

Automotive OEM technology is becoming more and more complex requiring educated and skilled technicians to work on them. As the materials used are constantly changing we must maintain our knowledge base and utilize the correct products and application methodologies to keep up with emerging technologies.

Automobile manufacturers have blurred the distinguishing lines on what exactly leather is. There are many so-called ‘leathers’ that are actually the bottom split (the fibrous part of the hide) which are covered with a vinyl or urethane coating. Diagnosis is the key, not guess work. Before deciding on what products to use, you need to ascertain the grade of leather and the type of leather finish applied

Be cognizant that the leather and finishes used for automotive upholstery varies from leather industry standard descriptions and although the names are similar the type of leather, pigmentation and finish are often very different. So it is very important to be able to recognise the various finishes and materials used by OEM’s as they all require different methodologies and products for proper care and maintenance.

Unfinished vs. Finished leather

a) Unfinished leather - the appeal of this type of leather is its initial "natural" look and the soft, supple texture. The downside is aesthetic vulnerability; due to the porous nature of untreated leather, it stains easily and it is sensitive to ultra violet (UV) light, which means that the colour is subject to photochemical degradation (bleaching, (fading), discoloration, chalking, brittleness and cracking) all indications of UV deterioration. The porous nature of unfinished leather will allow a water- or oil-based solution to permeate the leather.

b) Finished or micro pigmented leather - is commonly used for automobile as these resins create a film that protects the leather. The water-based urethane pigmented (colour) coat and the clear topcoat provides abrasion and stain resistance. This type of leather finish is the most durable and easiest to care for but tends to be stiffer than both unfinished and micro pigmented leather. When Ford first introduced its King Ranch leather in their F-Series trucks it had unfinished leather, later they adopted a micro pigment type finish

Using advanced micro pigments this finishing technique makes the finish rigorous enough to stand up to the conditions it would be subjected to in an automobile. Generally speaking micro pigment style leathers come in very earthy natural colours, incorporating a small quantity of pigment (a thin clear sealant that provides a uniform colour and affords some protection) but not so much as to conceal the natural characteristics of the hide so it will still retain the soft hand of Aniline leather. This type of leather is also used for perforated leather finishes.

Now virtually 95% of leather in domestic (American) and Imported (Asian ) vehicles use finished (urethane coated) upholstery Among European car makers aniline and recently semi-aniline (micro pigmented) leather upholstery is still much more common than with domestic models, but urethane finished leather is becoming more prevalent

Automobile model ranges use different materials for their vehicles interiors; there are also various finishes applied -

• Aniline Leather (Immersion Dyed)

• Semi-aniline (Micro pigment) leather

• Finished leather

As well as various grades of leather hide, full-grain, top-grain and split –grain, along with artificial leather such as MB-Tex and unfinished materials like Synthetics and Alcantara, and sometimes combinations of products (Alcantara seat inserts on leather seating)

Using any product not specifically designed for your leather finish can cause staining and permanent damage.

The applied finish - consists of two or three aqueous (water- based) pigmented base coat applications, and then a clear aqueous (water- based) top coat is applied as the final stage of the finishing process, which usually includes additives to give it a soft feel (patina) and abrasion resistance, as well as a limited amount of ‘slide’ to assist in entering and exiting the vehicle

Cross-linking enhances the physical properties of water-based pigmentation (colour) and the urethane coating, which proceeds to form a chemical bond between the molecules, creating a resilient and very durable finish.

Topcoat - an extremely hard wearing water-based clear urethane is used to improve abrasion resistance and colour fastness, making the surface much easier to clean and less prone to staining, while increasing resistance to perspiration, grease and oil. It greatly increases surface durability and also improves surface texture giving it a smooth, soft and silky feel.

It also has micro-pores that allow transpiration, i.e. evaporation and hydration (the passage of water vapour through a membrane or pore) they are not sealed per se. Urethane pigmented finished leather won't absorb liquids because of the protective properties of the finish making for easier clean-up.

A simple test – place a drop of moisture on the surface of the leather - if it soaks into the leather you have unfinished leather (sometimes called aniline style)

If there is a very light colour or clear coat on top of aniline-dyed leather, it is often referred to as “semi-aniline.” Semi-aniline leather offers modest protection while retaining much of the aesthetic beauty of unfinished aniline-dyed leather but still remain absorbent to moisture.

If the moisture sits on the surface and does not soak in and darken the material you have finished leather.

Pigmented leather won't absorb liquids because of the protective properties of the finish making for easier clean-up.

Since the leather hide has a pigmented urethane layer and clear topcoat finish, when treating the leather, so you are in fact dealing with a urethane (to all intents and purposes, a ~150 µ (micron) thick plastic surface coating, about the same thickness as automobile clear coat paint; that simply needs to be kept clean and hydrated…it really is that simple.

A simple concept that been stated a million times and still some will swear that treating finished leather with a conditioner is beneficial. But if you feel 50USD plus and approx 2-3 hours work is a worthwhile investment of time / money to treat a urethane pigmented covering, that’s your choice

I hope you’ve found this article both informative and helpful.

TOGWT® Autopia Detailing Wiki Articles[COLOR="Blue"]

1. “Unfinished leather” - http://www.autopia.org/forum/autopia...ml#post1543547

2. “Leather Upholstery Type Surface Identification” - http://www.autopia.org/forum/autopia...fication.html#

3. “Leather Articles Hyperlinks” -http://www.autopia.org/forum/autopia-detailing-wiki/141973-leather-articles-hyperlinks.html

If you have any questions about automotive leather, its care or renovation techniques, please let me know

Last edited by TOGWT; 06-26-2013 at 07:40 PM.

#2

Thank you for your very informative post. So, what type of leather is Espresso and how should it be cleaned and conditioned (hopefully with product suggestions). I am guessing its semi-aniline (micro pigment) leather. Thanks again.

#3

Burning Brakes

Thread Starter

Join Date: Dec 2006

Location: London,UK / Florida US State- Dazed & Confused

Posts: 863

Likes: 0

Received 4 Likes

on

4 Posts

TOGWT Detailing Wiki Articles Index- Leather Care Index - #4 in the series.

Everything you’ll ever want to know about automotive leather upholstery; but were too afraid to ask.

Aniline (Immersion Dyed) Leather - http://togwt1980.blogspot.co.uk/2015...e-leather.html

Everything you’ll ever want to know about automotive leather upholstery; but were too afraid to ask.

Aniline (Immersion Dyed) Leather - http://togwt1980.blogspot.co.uk/2015...e-leather.html

#4

Thank you. I have read much of your information on various sites and it is very informative. But my question still remains - do you know what type of leather Porsche's "natural" leathers are? From the information I am reading (nothing from Porsche yet) I am guessing it is semi-aniline (micro pigmented). Your help is appreciated.

#5

Burning Brakes

Thread Starter

Join Date: Dec 2006

Location: London,UK / Florida US State- Dazed & Confused

Posts: 863

Likes: 0

Received 4 Likes

on

4 Posts

Aniline leather – (this is a misnomer; aniline is a transparent dye not a type of leather) its absorbent and is dyed with an immersion type process rather than having a pigmentation added, the dye provides an even overall colour and, so that the original grain surface can be seen completely unhindered it is then protected with a very thin layer of completely transparent, abrasion resistant urethane (unprotected Aniline is rarely use for automobile upholstery)

Immersion dyed top-grain leather is used in prestige European automobiles - Aston Martin, Audi, Bentley, Ferrari, Jaguar, Lotus, Lexus,, Range Rover and Rolls Royce, US - Cadillac and high-end German automobiles such as Audi, BMW, Daimler AG, Mercedes-Benz and Porsche

Immersion dyed top-grain leather is used in prestige European automobiles - Aston Martin, Audi, Bentley, Ferrari, Jaguar, Lotus, Lexus,, Range Rover and Rolls Royce, US - Cadillac and high-end German automobiles such as Audi, BMW, Daimler AG, Mercedes-Benz and Porsche

#7

Several other things. My car is two years old but new to me. The leather appears to be in excellent condition. The car will be used about 9,000 miles per year, and I live in very hot, humid central Florida. Many thanks.

Trending Topics

#8

Burning Brakes

Thread Starter

Join Date: Dec 2006

Location: London,UK / Florida US State- Dazed & Confused

Posts: 863

Likes: 0

Received 4 Likes

on

4 Posts

Simple cleaning, hydration and protection are the three steps that will prolong the life of Micro pigment finished leather. Always pretest the product on a hidden area. Shake the foam container thoroughly. Spray the product at a distance of 12 inches from the leather to one section at a time, and allow product to remain in place for approximately 15 to 30 seconds.

Finished leather doesn’t require conditioning or rejuvenation; always keep in mind that you’re dealing with the finished coating on the leather and not with the leather hide itself

1. Clean - there are two cleaning-related factors that can cause your leather to wear prematurely. The first is dirt, and the second is oil, combined they become very abrasive, as dirt / grit and subsequent friction cause the finish to wear

Remove surface dirt and dust, cleaning the seams periodically is important as dirt / grit will abrade the stitching causing them to fail, prise them apart, then use a soft brush, vacuum and then use a foam cleaner, one section at a time, and then finally wipe off with a clean, damp 100% cotton micro fibre towel

The advantage of foam over liquid is the minimum amount of moisture, very important for cleaning absorbent, perforated and moisture sensitive leathers.

Use a foam cleaner, which should be given dwell time and then gentle agitation with a medium stiff bristled brush to get the product into the materials surface, the low moisture content of foam can then be easily rinsed and the surface dried. Remove excess product and debris with a clean, damp 100% cotton micro fibre towel. If the foam is allowed to dry the soil will be re-deposited to the surface.

Check the results and repeat process as necessary

For heavily soiled areas use a foam cleaner (Leather Master™ Foam Cleaner) that contains a surfactant that will lift dirt and soil, allow react time to do its work and then use a soft brush to agitate and loosen the dirt (Swissvax Leather Brush) especially on light coloured leathers; this enables the cleaning of the micro pores and creases and lifts the dirt out and reveal any further work that needs doing (dye transfer, stains, etc.)

2. Hydrated – when leather tanner’s talk about conditioning leather they are referring to its moisture content, re-hydration is used to restore or maintain fluid balance (transpiration and evaporation of moisture); not the replenishment or replacement of the fat liquoring, oils and / or waxes.

Moisture balance is a sine qua non (an indispensable and essential action) in leather care. Leather naturally absorbs and retains moisture vapour, meaning it’s also susceptible to losing the moisture necessary to keep it pliant and soft. One of major attribute is its ability for transpiration (allowing the movement of moisture back and forth (evaporation and hydration), which it does even better than wool.

Repetitive heat cycling causes the leather to lose moisture, resulting in the formation of creasing or surface cracks, which may lead to the leather contracting; however the urethane remains stable, which may lead to it delaminating.

A regular wipe down with a damp towel on a regular basis is all you need to condition and / or hydrate finished leather, and by using aqueous (water- based) products that do not contain oils and/or waxes, check the label if they do then don't use them. Leather should be hydrated on a regular basis and is somewhat climate dependent.

3. Protected - is essential as it will protect the surface finish, without hindering transpiration, while acting as a sacrificial layer; this way you are not actually cleaning the Leather's original surface, but cleaning from the surface of the protection. It also makes dirt easier to clean off

Leather Master™ - Protection Cream (a Scotchgard™ type product specifically formulated for lather) the polymers penetrate the surface of finished leather and cross-link to form a durable protective film that is breathable, allowing transpiration and keeps the leather supple. Being aqueous (water- based) it restores moisture to finished leather and provides a protective sacrificial barrier against all kinds of soiling, water, oil, alcohol-based stains and perspiration marks, so you are cleaning the protective layer

Patina(softness) - used to improve and maintain the tactile feel and lustre to ensure the leather remains soft and supple; apply Leather Master™ Soft Touch and allow to dry for approx. 20 minutes, finally using a clean dry 100% cotton micro fibre towel buff to a matte sheen.

This product is NOT a conditioner per se but is used to restore the softness to hard finished leather; place the car in a sunny location and roll down the windows. Allow the car to sit in the sun for one or two hours to warm the surfaces

Maintenance:

Monthly hydration of leather upholstery in most southern states; Florida, Texas and Arizona, and etc. especially during the summer months, would not be out of line

Finished leather doesn’t require conditioning or rejuvenation; always keep in mind that you’re dealing with the finished coating on the leather and not with the leather hide itself

1. Clean - there are two cleaning-related factors that can cause your leather to wear prematurely. The first is dirt, and the second is oil, combined they become very abrasive, as dirt / grit and subsequent friction cause the finish to wear

Remove surface dirt and dust, cleaning the seams periodically is important as dirt / grit will abrade the stitching causing them to fail, prise them apart, then use a soft brush, vacuum and then use a foam cleaner, one section at a time, and then finally wipe off with a clean, damp 100% cotton micro fibre towel

The advantage of foam over liquid is the minimum amount of moisture, very important for cleaning absorbent, perforated and moisture sensitive leathers.

Use a foam cleaner, which should be given dwell time and then gentle agitation with a medium stiff bristled brush to get the product into the materials surface, the low moisture content of foam can then be easily rinsed and the surface dried. Remove excess product and debris with a clean, damp 100% cotton micro fibre towel. If the foam is allowed to dry the soil will be re-deposited to the surface.

Check the results and repeat process as necessary

For heavily soiled areas use a foam cleaner (Leather Master™ Foam Cleaner) that contains a surfactant that will lift dirt and soil, allow react time to do its work and then use a soft brush to agitate and loosen the dirt (Swissvax Leather Brush) especially on light coloured leathers; this enables the cleaning of the micro pores and creases and lifts the dirt out and reveal any further work that needs doing (dye transfer, stains, etc.)

2. Hydrated – when leather tanner’s talk about conditioning leather they are referring to its moisture content, re-hydration is used to restore or maintain fluid balance (transpiration and evaporation of moisture); not the replenishment or replacement of the fat liquoring, oils and / or waxes.

Moisture balance is a sine qua non (an indispensable and essential action) in leather care. Leather naturally absorbs and retains moisture vapour, meaning it’s also susceptible to losing the moisture necessary to keep it pliant and soft. One of major attribute is its ability for transpiration (allowing the movement of moisture back and forth (evaporation and hydration), which it does even better than wool.

Repetitive heat cycling causes the leather to lose moisture, resulting in the formation of creasing or surface cracks, which may lead to the leather contracting; however the urethane remains stable, which may lead to it delaminating.

A regular wipe down with a damp towel on a regular basis is all you need to condition and / or hydrate finished leather, and by using aqueous (water- based) products that do not contain oils and/or waxes, check the label if they do then don't use them. Leather should be hydrated on a regular basis and is somewhat climate dependent.

3. Protected - is essential as it will protect the surface finish, without hindering transpiration, while acting as a sacrificial layer; this way you are not actually cleaning the Leather's original surface, but cleaning from the surface of the protection. It also makes dirt easier to clean off

Leather Master™ - Protection Cream (a Scotchgard™ type product specifically formulated for lather) the polymers penetrate the surface of finished leather and cross-link to form a durable protective film that is breathable, allowing transpiration and keeps the leather supple. Being aqueous (water- based) it restores moisture to finished leather and provides a protective sacrificial barrier against all kinds of soiling, water, oil, alcohol-based stains and perspiration marks, so you are cleaning the protective layer

Patina(softness) - used to improve and maintain the tactile feel and lustre to ensure the leather remains soft and supple; apply Leather Master™ Soft Touch and allow to dry for approx. 20 minutes, finally using a clean dry 100% cotton micro fibre towel buff to a matte sheen.

This product is NOT a conditioner per se but is used to restore the softness to hard finished leather; place the car in a sunny location and roll down the windows. Allow the car to sit in the sun for one or two hours to warm the surfaces

Maintenance:

Monthly hydration of leather upholstery in most southern states; Florida, Texas and Arizona, and etc. especially during the summer months, would not be out of line

#12

One of the biggest things that people fail to do when cleaning their leather is flushing the surface of both dirt & chemical remnants. Cleaners will break down the soiling and just doing a wipe of the surface isn't enough to get the surface totally clean. If you don't flush the surface the dirt and chemical remains and creates rapid resoiling and further harm to the surface.

Just take a bucket of clean water and completely submerge a clean towel (cotton or MF).

Wring out the excess wetness:

Gently wipe the surface:

Constantly keep dipping your towel into the bucket of water to flush the contaminants. You'll be amazed at how much soiling will get transferred into your bucket. This will also greatly help hydrate your surface.

These pics were part of a greater thread on Autopia where I give a tutorial on proper interior cleaning on a 1963 Aston Martin DR4 with original Connolly Leather. http://www.autopia.org/forums/detail...ighlight=aston

Just take a bucket of clean water and completely submerge a clean towel (cotton or MF).

Wring out the excess wetness:

Gently wipe the surface:

Constantly keep dipping your towel into the bucket of water to flush the contaminants. You'll be amazed at how much soiling will get transferred into your bucket. This will also greatly help hydrate your surface.

These pics were part of a greater thread on Autopia where I give a tutorial on proper interior cleaning on a 1963 Aston Martin DR4 with original Connolly Leather. http://www.autopia.org/forums/detail...ighlight=aston