RMS seal has ridges on it - normal?

#16

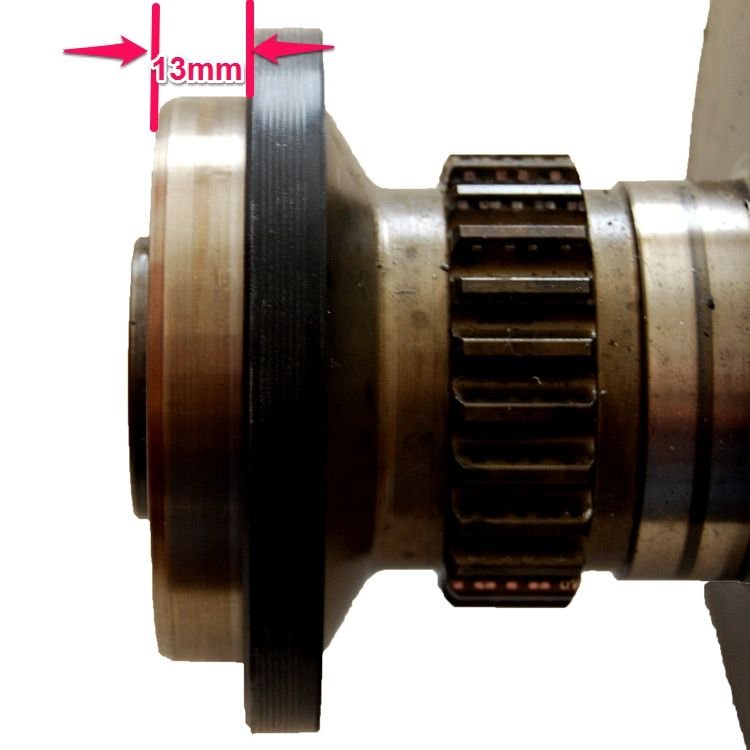

It may be obvious but from the replies these points were not emphasized. The proper tool serves two purposes:

1) To push in the RMS as squarely as possible (with respect to the crank)

2) Ensure the RMS sits at the proper depth and equal depth all around the edge. If you examine an opened engine case halves, you will understand why it's 13mm and not 12 or 14mm because 13mm is the only depth that makes sense.

Any pipe coupler with the proper diameter can achieve 1) but you will have to eyeball 2), kinda like trying to draw a straight line free hand. Given how picky the RMS is (not supposed to touch the seal by bare hands and you need the $500 factory tool ensure it's straight), it's always good to be careful.

The purpose of the machined delrin tool is to achieve the above two points with accuracy....in case someone thinks the tool is dumb and can be replaced by or compared with a $2 coupler

http://www.cheetahonline.com/technic...orsche-engine/

1) To push in the RMS as squarely as possible (with respect to the crank)

2) Ensure the RMS sits at the proper depth and equal depth all around the edge. If you examine an opened engine case halves, you will understand why it's 13mm and not 12 or 14mm because 13mm is the only depth that makes sense.

Any pipe coupler with the proper diameter can achieve 1) but you will have to eyeball 2), kinda like trying to draw a straight line free hand. Given how picky the RMS is (not supposed to touch the seal by bare hands and you need the $500 factory tool ensure it's straight), it's always good to be careful.

The purpose of the machined delrin tool is to achieve the above two points with accuracy....in case someone thinks the tool is dumb and can be replaced by or compared with a $2 coupler

http://www.cheetahonline.com/technic...orsche-engine/

#17

Racer

Thread Starter

Join Date: Aug 2015

Location: Montreal, QC, Canada

Posts: 261

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the link.

Still not clear where from calculate that 13mm. My old one sits at 13.4mm but I measure up to the surface where round notches are and not the most outer ridge.

I thought of using end plug method plus a stopper, some sort of a smaller pipe resting on the crank. Just need to figure it,s exact length and cut it dead square.

Still confused about that blue thing. I remove it prior to placing the seal onto crank. Or I use it to somehow transfer the seal from it onto the crank? Article above mentions something but it's not clear to me. And the "plastic insert" , what they call it there, does not look like mine.

Still not clear where from calculate that 13mm. My old one sits at 13.4mm but I measure up to the surface where round notches are and not the most outer ridge.

I thought of using end plug method plus a stopper, some sort of a smaller pipe resting on the crank. Just need to figure it,s exact length and cut it dead square.

Still confused about that blue thing. I remove it prior to placing the seal onto crank. Or I use it to somehow transfer the seal from it onto the crank? Article above mentions something but it's not clear to me. And the "plastic insert" , what they call it there, does not look like mine.

#20

"Still confused about that blue thing. I remove it prior to placing the seal onto crank. "

In the link below the 3rd photo from the top it says "Place the open end of the plastic insert onto the crankshaft end. This should fit on as shown. ". Looks like your blue insert is put in backwards though. Did it come like that from Porsche? I can check mine tonight.

In the link below the 3rd photo from the top it says "Place the open end of the plastic insert onto the crankshaft end. This should fit on as shown. ". Looks like your blue insert is put in backwards though. Did it come like that from Porsche? I can check mine tonight.

#22

Racer

Join Date: Dec 2009

Location: South of Vancouver

Posts: 315

Likes: 0

Received 0 Likes

on

0 Posts

That delrin tool from Cheeta is really nice for $60 and I would have bought one if I knew about it. I balked at the $500 factory tool for obvious reasons. But Ahsai is right - it has to be done with precision.

Mine is still leak-free, but I'm an artsy type so I can draw a straight line freehand

Mine is still leak-free, but I'm an artsy type so I can draw a straight line freehand

#23

Captain Obvious

Super User

Super User

Why can't one touch the seal with your bare hands?

This seal is no different that other main seals for other engines. Believe it or not, they can tolerate quiet a bit of being not square in the hole but one should try to get the seal in as square as possible. I think it's more important NOT to put the new seal exactly where the old one was than to keep the 13mm distance.

This seal is no different that other main seals for other engines. Believe it or not, they can tolerate quiet a bit of being not square in the hole but one should try to get the seal in as square as possible. I think it's more important NOT to put the new seal exactly where the old one was than to keep the 13mm distance.

#24

It may be obvious but from the replies these points were not emphasized. The proper tool serves two purposes:

Given how picky the RMS is (not supposed to touch the seal by bare hands...

http://www.cheetahonline.com/technic...orsche-engine/

Given how picky the RMS is (not supposed to touch the seal by bare hands...

http://www.cheetahonline.com/technic...orsche-engine/

#25

Racer

Thread Starter

Join Date: Aug 2015

Location: Montreal, QC, Canada

Posts: 261

Likes: 0

Received 0 Likes

on

0 Posts

Btw, where exactly we draw that "straight line" ? MS Paint anyone?

In my understanding, I simply use the back end of a measuring caliper to do a "stair step" between flywheel mating surface and highest point of the seal.

In my understanding, I simply use the back end of a measuring caliper to do a "stair step" between flywheel mating surface and highest point of the seal.

#26

Why can't one touch the seal with your bare hands?

This seal is no different that other main seals for other engines. Believe it or not, they can tolerate quiet a bit of being not square in the hole but one should try to get the seal in as square as possible. I think it's more important NOT to put the new seal exactly where the old one was than to keep the 13mm distance.

This seal is no different that other main seals for other engines. Believe it or not, they can tolerate quiet a bit of being not square in the hole but one should try to get the seal in as square as possible. I think it's more important NOT to put the new seal exactly where the old one was than to keep the 13mm distance.

Search for the word "touch" in this article and you'll see that mentioned multiple times http://www.callasrennsport.com/wp-co...of-M96-Woe.pdf

As to why and being counter-intuitive, I agree but you have to ask Porsche

The tool is just there to make it easier, faster, and more foolproof.

The tool is just there to make it easier, faster, and more foolproof.

#27

Racer

Thread Starter

Join Date: Aug 2015

Location: Montreal, QC, Canada

Posts: 261

Likes: 0

Received 0 Likes

on

0 Posts

Ashai - the tool gives me a reading, a digital one up to tenth of mm. So once it reads 13.00mm taken from multiple spots across the the circle - I guess I'm good

Unless we're not seeing the things same way....

I'll take a pic tomorrow

Unless we're not seeing the things same way....

I'll take a pic tomorrow

#28

#30

Rennlist Member