Broken clutch fork?

#1

Intermediate

Thread Starter

Join Date: Jan 2005

Location: NW New Jersey

Posts: 47

Likes: 0

Received 0 Likes

on

0 Posts

So I am having some problems shifting and getting into gear.

here are he symptoms:

The pedal feels funny even after bleeding, it has more travel before resistance and it is softer.

I cannot shift into any gear with the engine running.

If I try to push the pedal further to the floor I hear a grinding sound, not unlike the shift fork engaging the ring gear.

The roll pin is still in operation.

The master and slave cylinder have been recently replaced and show no signs of leaking.

Are these symptoms of a broken or cracked shift fork? How could I tell without disconnecting the engine from the transmission?

Is it really possible change the fork out without dropping the engine?

thank you in advance

__________________

Ken

'89 C4 Coupe

'88 Mazda MX6

here are he symptoms:

The pedal feels funny even after bleeding, it has more travel before resistance and it is softer.

I cannot shift into any gear with the engine running.

If I try to push the pedal further to the floor I hear a grinding sound, not unlike the shift fork engaging the ring gear.

The roll pin is still in operation.

The master and slave cylinder have been recently replaced and show no signs of leaking.

Are these symptoms of a broken or cracked shift fork? How could I tell without disconnecting the engine from the transmission?

Is it really possible change the fork out without dropping the engine?

thank you in advance

__________________

Ken

'89 C4 Coupe

'88 Mazda MX6

#4

Technical Guru

Rennlist Member

Rennlist Member

Originally Posted by Ken964

I cannot shift into any gear with the engine running.

(although unlikely...)

Originally Posted by Ken964

If I try to push the pedal further to the floor I hear a grinding sound, not unlike the shift fork engaging the ring gear.

The master and slave cylinder have been recently replaced and show no signs of leaking.

The master and slave cylinder have been recently replaced and show no signs of leaking.

Originally Posted by Ken964

Are these symptoms of a broken or cracked shift fork?

Originally Posted by Ken964

How could I tell without disconnecting the engine from the transmission?

There is also an inspection port on the bottom of the transmission bellhousing meant for checking the amount of clutch disc wear but you should be able to look through it and check the front of the ring gear for score marks.

Originally Posted by Ken964

Is it really possible change the fork out without dropping the engine?

#5

Intermediate

Thread Starter

Join Date: Jan 2005

Location: NW New Jersey

Posts: 47

Likes: 0

Received 0 Likes

on

0 Posts

Thank you for the ideas, I will take a look in the inspection port and readjust the pedal travel. Hopefully I did not do too much damage.

The clutch has about 16k miles on it and the fork and associated hardware are also listed as being replaced by the PO's mechanic.

If the pedal was incorrectly adjusted so the release bearing was always engaged I guess that would explain the disintegrated bearing there.

I will keep everyone posted on any progress.

take care

__________________

Ken

'89 C4 Coupe

'88 Mazda MX6

The clutch has about 16k miles on it and the fork and associated hardware are also listed as being replaced by the PO's mechanic.

If the pedal was incorrectly adjusted so the release bearing was always engaged I guess that would explain the disintegrated bearing there.

I will keep everyone posted on any progress.

take care

__________________

Ken

'89 C4 Coupe

'88 Mazda MX6

#7

Intermediate

Thread Starter

Join Date: Jan 2005

Location: NW New Jersey

Posts: 47

Likes: 0

Received 0 Likes

on

0 Posts

It turns out my pressure plate was cracked:

https://rennlist.com/forums/964-forum/322497-cracked-pressure-plate.html

Everything came out without too much trouble, a stuck PDAS actuator and rounded out cheese heads were the worst.

The release bearing was still in good operating condition and spun nice and smoothly. The release fork was also fine and the bushings were operational although they required some pounding to remove the operating shaft.

Ken

____________

'89 C4 Coupe

'97 Volvo 960 Estate

https://rennlist.com/forums/964-forum/322497-cracked-pressure-plate.html

Everything came out without too much trouble, a stuck PDAS actuator and rounded out cheese heads were the worst.

The release bearing was still in good operating condition and spun nice and smoothly. The release fork was also fine and the bushings were operational although they required some pounding to remove the operating shaft.

Ken

____________

'89 C4 Coupe

'97 Volvo 960 Estate

Trending Topics

#8

Just saw Jason's pic of the broken transmission (pic from bell housing end)...

This is exactly what mine did - clutch fork pivot bearing seized, spun inside the transmission 'ears' and finally broke one...

My mechanic / me are having a tough time getting this sorted:

- can't source a replacement front trans casting

- can re-weld though don't have the dimensions to re-machine

- complete replacement trans seems a bit of a waste...

Any ideas?? Anyone have dimensions for re-machining the shift fork pivot??

Thanks much,

andrew

This is exactly what mine did - clutch fork pivot bearing seized, spun inside the transmission 'ears' and finally broke one...

My mechanic / me are having a tough time getting this sorted:

- can't source a replacement front trans casting

- can re-weld though don't have the dimensions to re-machine

- complete replacement trans seems a bit of a waste...

Any ideas?? Anyone have dimensions for re-machining the shift fork pivot??

Thanks much,

andrew

#9

What our local welding shop guy did was pretty clever. He asked me for an old, junk release fork pivot axle. He put it in position, then just welded around it. Aluminum weld does not stick to steel. Then he justed pulled out the junk axle, and voila, we had a correctly sized hole. No machining. It works fine.

#10

Technical Guru

Rennlist Member

Rennlist Member

Originally Posted by And

Anyone have dimensions for re-machining the shift fork pivot??

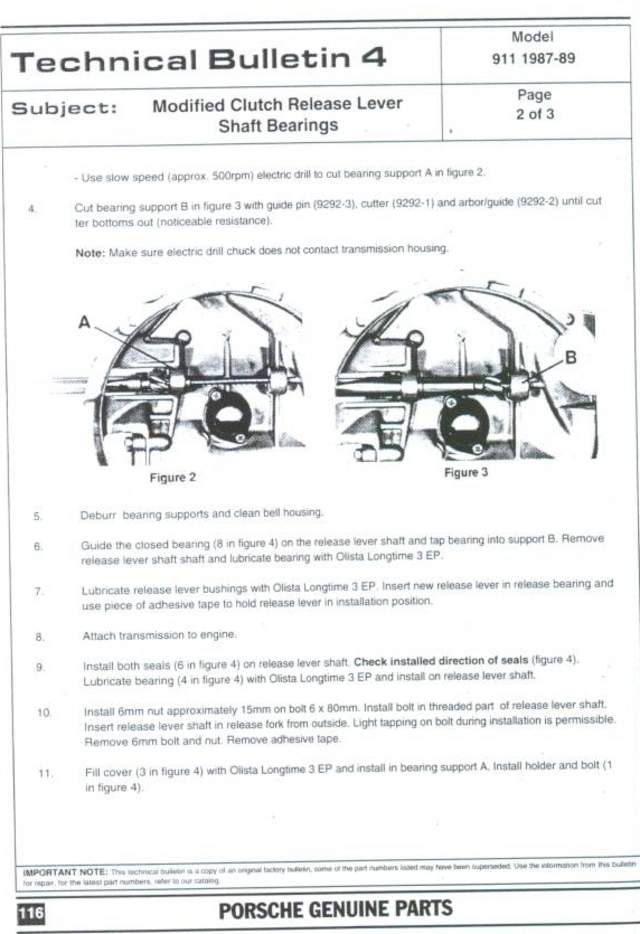

Here are some photos of the welding with a little dremel tool grinding but before the boring.

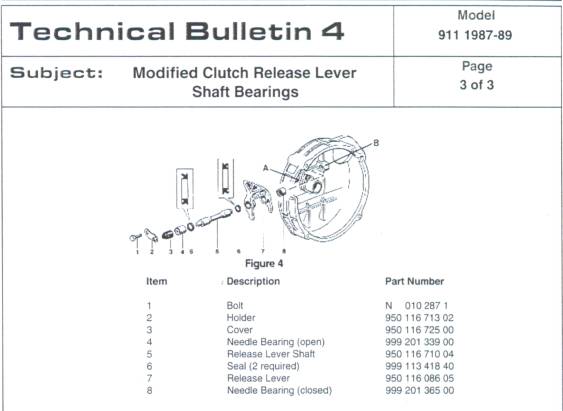

and here is the TSB from Porsche.