Torque tube rebuild pictures and tools

#16

Drifting

Cool, looks like BJ didn't remove it after all. I could refine it some after more experience but I hope it helps some of you out there in 928 land. Any questions, feel free to call me at 801-487-6733/Shop and I'll be glad to help.

Dave

Motorsport

Dave

Motorsport

#17

Dean of Rennlist, "I'm Listening"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Dave, since you're currently in the process of rebuilding my torque tube as we speak, if you want to take some pics of the process and post them, I don't mind.

#18

Drifting

I wouldn't want to bare it's underside to everyone, it's not that kind of lady. Now a fast and easy car like mine would love to show it all off. Yours is too classy of a lady. Mine wears a thong, yours is dressed in silk, mine likes Tequila shooters, yours prefers a good Merlot. Man I could go on and on........but mine's *** isn't as wide as yours is. I'm not sure that's a good thing though in this case.

BTW, give me a call when you get a chance for an update on your lady's surgery.

Dave

Dave

BTW, give me a call when you get a chance for an update on your lady's surgery.

Dave

Dave

#19

Addict

Rennlist Member

Rennlist Member

Thread Starter

Justin and Scott, '78 shifter wasn't vibrating noticeably at any particular rpm range. Center bearing is noisy and all three are original. Now is good time to change them when gearbox is out. As for '92, I don't know. Haven't ever driven it, bought it with broken engine and now slowly rebuilding almost entire car. Bearings sound and feel fine when rotating center shaft and 3rd bearings (have it out now) inner race. They are 13 years old already and I don't feel like taking TT out ever again when this rebuild is over. Total time and cost of the job is very small compared to overall work needed. IMHO it would be stupid not to change bearings.

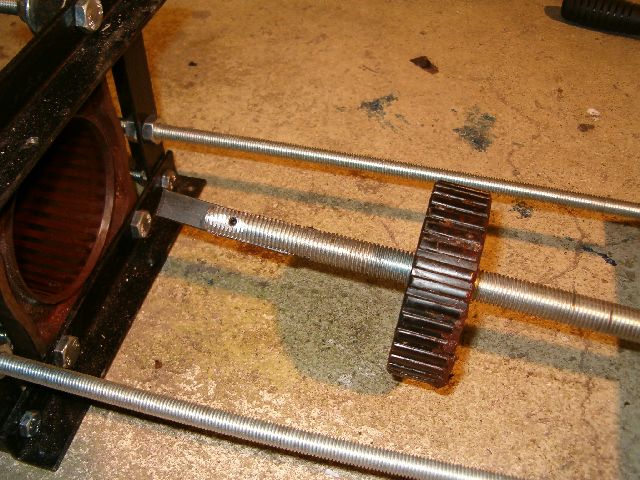

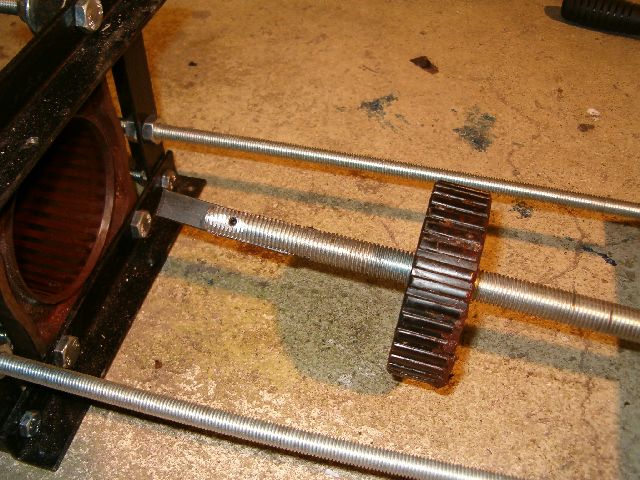

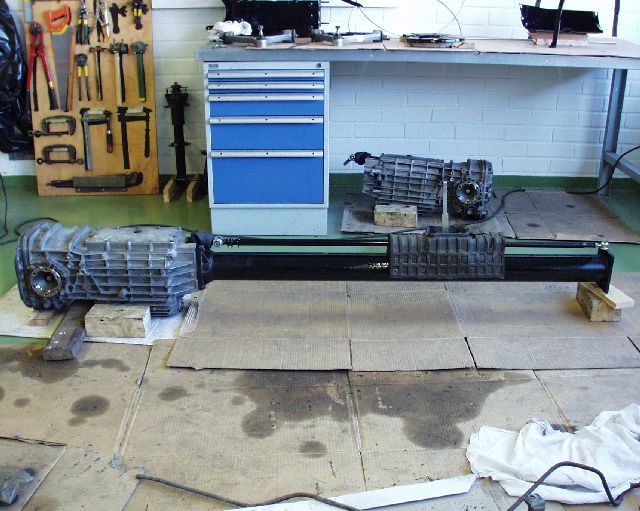

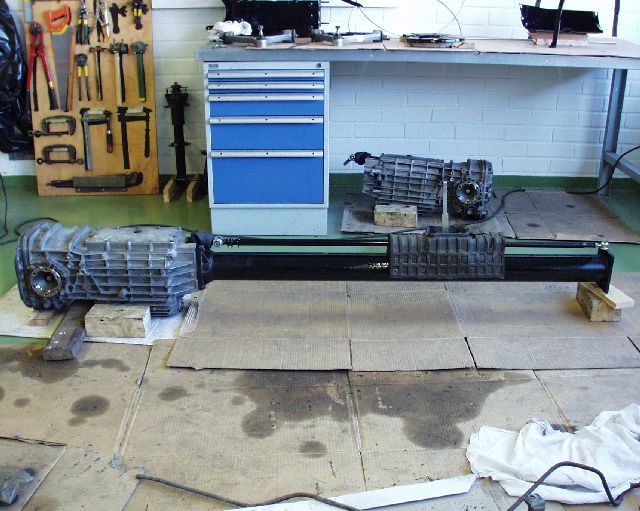

Here's few more more pictures of support structure just for Dave while it's been used on '92 center shaft.

I was before we started and still am fully aware all that could be replaced by just one flat iron twisted to U shape plus U's ends made to small hooks for making them grap behind/against TT end plate. Whole point of this exercise is (for me at least) fact that it's possible to take out tube internals and put them back together without using sledgehammer. Not competition who can make needed tools with least amount of materials. More generally, goal is to do rebuild without force and violence towards the parts.

Shaft passing through 3rd bearing.

'78 shaft already out and '92 on the way.

Notch at rear bore of '78 was made when we installed '85 G28.10 gearbox to give room for input shaft clamp bolt.

Here's few more more pictures of support structure just for Dave while it's been used on '92 center shaft.

I was before we started and still am fully aware all that could be replaced by just one flat iron twisted to U shape plus U's ends made to small hooks for making them grap behind/against TT end plate. Whole point of this exercise is (for me at least) fact that it's possible to take out tube internals and put them back together without using sledgehammer. Not competition who can make needed tools with least amount of materials. More generally, goal is to do rebuild without force and violence towards the parts.

Shaft passing through 3rd bearing.

'78 shaft already out and '92 on the way.

Notch at rear bore of '78 was made when we installed '85 G28.10 gearbox to give room for input shaft clamp bolt.

#20

Addict

Rennlist Member

Rennlist Member

Thread Starter

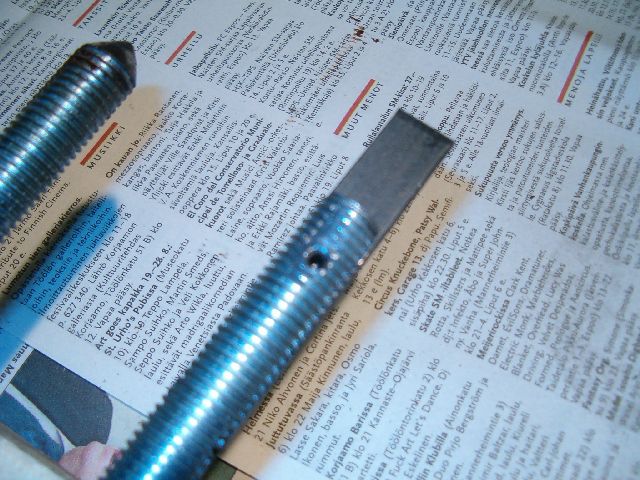

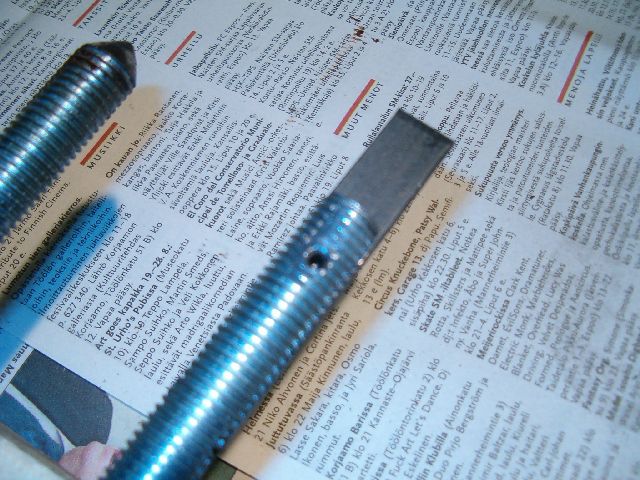

Mysterious bearing fishing hook. This is the one in Dave's drawing. I'm not sure who came up this tool first. All I know it certainly wasn't me. Can remember mentions of such device made years ago in one of the Porsche mailing lists. This must have been way before Rennlist. PorscheFans was name of the one now long gone list I think. I sure have seen that Dave's picture before but couldn't find the link during previous conversations. Would have helped explaining how it works. This is what we did, it's not pretty.

There is small threaded pin holding flat iron in place. Hole drilled to side of threaded bar has threads in it and flat iron moves freely except it can't rotate full circle. Gravity keeps it aligned with threaded bar when bar is held correct way around and rotate it sideways when bar is turned 180 degrees.

There is small threaded pin holding flat iron in place. Hole drilled to side of threaded bar has threads in it and flat iron moves freely except it can't rotate full circle. Gravity keeps it aligned with threaded bar when bar is held correct way around and rotate it sideways when bar is turned 180 degrees.

#21

Addict

Rennlist Member

Rennlist Member

Thread Starter

Hook in action on 3rd (rearmost) bearing on '92 TT

On '78 TT 3rd bearing support made nice plowing marks to grease and dirt inside torque tube. 2nd and 1st bearing are still inside the tube.

On '78 TT 3rd bearing support made nice plowing marks to grease and dirt inside torque tube. 2nd and 1st bearing are still inside the tube.

#22

Addict

Rennlist Member

Rennlist Member

Thread Starter

Bearing support has clearly changed some time between '78 (early Euro model made summer of '77) and '92 (Euro made March of that year). '78 is more rubbery where '92 looks and feels plastic. This is 3rd bearing from '92. Will get comparison pictures when parts are clean.

This is little late now but it's very important to take measurements before anything is moved. Still when putting all back in these measurements shouldn't be followed blindly as parts might have moved a lot over the years. On both center shafts there are signs where black plastic tubes had resided. We plan to use these as guides where to put bearings back.

On '92 there is harmonic vibration damper between 2nd and 3rd bearing. If 3rd starts to move forward with center shaft this might cause small problems at taking 3rd out but it shouldn't prevent it totally. On '78, 1st bearing moved with center shaft some 7" and is now almost out. This is worrying as it should be black plastic pipe and center shaft that have lowest friction against each other, not tube wall and bearing support. Otherwise entire support is inclined to move when shaft expands and contracts little when heated up by exhaust.

'78 tube walls shows some signs that all three bearing supports had moved forward about 5 mm. We plan to set them and center shaft along them back to correct position. Not sure what we're going to do with worn rear bores on it. Perhaps have more metal welded to shaft and new bores made to it.

Current situation is that center shaft and 3rd bearing are out on both tubes. Job will progress some time during next few weeks.

This is little late now but it's very important to take measurements before anything is moved. Still when putting all back in these measurements shouldn't be followed blindly as parts might have moved a lot over the years. On both center shafts there are signs where black plastic tubes had resided. We plan to use these as guides where to put bearings back.

On '92 there is harmonic vibration damper between 2nd and 3rd bearing. If 3rd starts to move forward with center shaft this might cause small problems at taking 3rd out but it shouldn't prevent it totally. On '78, 1st bearing moved with center shaft some 7" and is now almost out. This is worrying as it should be black plastic pipe and center shaft that have lowest friction against each other, not tube wall and bearing support. Otherwise entire support is inclined to move when shaft expands and contracts little when heated up by exhaust.

'78 tube walls shows some signs that all three bearing supports had moved forward about 5 mm. We plan to set them and center shaft along them back to correct position. Not sure what we're going to do with worn rear bores on it. Perhaps have more metal welded to shaft and new bores made to it.

Current situation is that center shaft and 3rd bearing are out on both tubes. Job will progress some time during next few weeks.

#23

Drifting

Great pics! I sure could have used them in 2002 when I tore into mine for the first time. This will help any of the DIY'ers out there scared to tackle it themselves.

I do not know who came up with the idea for the tool but I can say I didn't copy it from anything I had ever seen but it is my drawing. It's a common tool design probably figured out by a monkey centuries ago to fix his 928........

BTW, when you reassemble, make sure the direction of the bearing inserts will allow you to insert the shaft without pushing the bearings out of the carriers or the inserts out of the bearings. Also, I have seen a couple of the vibration damper's come apart and cause a nasty rattle while going over bumps in the road. And make sure the shaft is very clean when you reinsert it, makes it slide through the bearing inserts much easier and minimizes the chance of moving the bearing carriers. Oh yeah, I lube the tube with silicone spray when removing the bearing carriers, helps them come out much easier.

Dave

Motorsport

I do not know who came up with the idea for the tool but I can say I didn't copy it from anything I had ever seen but it is my drawing. It's a common tool design probably figured out by a monkey centuries ago to fix his 928........

BTW, when you reassemble, make sure the direction of the bearing inserts will allow you to insert the shaft without pushing the bearings out of the carriers or the inserts out of the bearings. Also, I have seen a couple of the vibration damper's come apart and cause a nasty rattle while going over bumps in the road. And make sure the shaft is very clean when you reinsert it, makes it slide through the bearing inserts much easier and minimizes the chance of moving the bearing carriers. Oh yeah, I lube the tube with silicone spray when removing the bearing carriers, helps them come out much easier.

Dave

Motorsport

#28

Addict

Rennlist Member

Rennlist Member

Thread Starter

AFAIK 05 came '80 in middle of production year meaning first Euro S still got 03. Not sure if some 4.5 engine cars (mainly Euros) use 03 up to end of '82 or if they also have 05.

TT lenght difference comes from different gearboxes and rear subframe. Subframe and TT was changed at same time to move gearbox 30mm forward. Difference isn't very obvious in pictures but it's there.

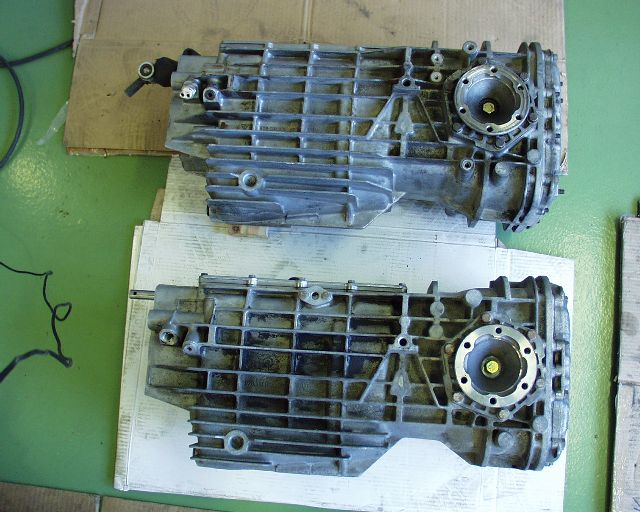

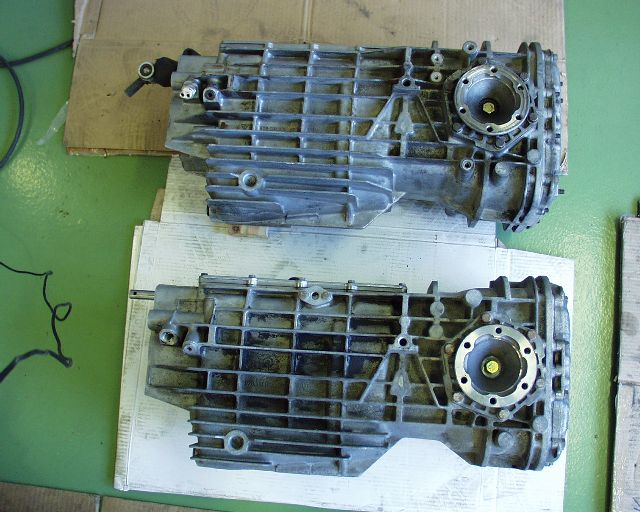

G28.10 on top, G28.03 bottom.

Two threaded holes between joint flange and gearbox mount hole are for mounting vibration damper support. Other end of damper mounts to rear subframe. Later subframes have mounting ear left over in casting to allow subframe to be used on these old cars and there was no point in changing casting mould anyway. AFAIK gearbox dampers were deleted either when battery box was integrated to body for '79 model year or engine mounts were changed from square to round style in '83, probably already in '79. Engine dampers were deleted same time as engine mounts changed. AFAIK there are unused threads in lower suspension supporting bows at least up to '87 but not in '92 anymore even though it's possible to make these as support casting is still the same. When ever factory had a chance they used same casting while end result changed. This saves lot of money and keeps number of different part types down.

10 and all boxes after it have large nut on center of the right side. Under it is adjustment for lever counter spring. All earlier versions have different system where there are two springs around inner shifter rod. On G28.12 lever that later type spring (under large nut) pushes was changed and this makes gear lever stay between 2-3 when in neutral. AFAIK all boxes up to '86 should have gear lever between 4-5 and two of springs, weak between 4-5 to 2-3 and stronger between 2-3 to R-1. On many early boxes weaker spring is so weak that it has no effect and it's possible to make lever stay between 2-3 by setting lever front ball cup joint slanted.

G28.03 on top, G28.10 bottom.

03 has two holes in this left side also for vibration damper support. Rest of the holes around joint flange are for '78 model year only battery box. End flange has studs also for the box.

10 has completely new system for keeping lever on gears and neutral compared to older boxes. Aluminium piece at this side, left from center of box just below top, is part of it.

When we installed 10 to '78 we had to modify it somewhat. It obviously didn't have all those mounting holes for vibration dampers and battery box. We had to improvise one support as there's no material in casting below joint flange on 10 like 03 has. Used next one towards rear and piece of flat iron. Has worked fine for past four years.

There was at least one change to TT within 03 years. '78 cars have gear shift rod bearing bracket mounted to body when all later cars have it on central tube. Quess idea behind first version was to have gear lever fixed to body so it wouldn't move when engine-TT-gearbox package moves slightly. On '78 when engine and gearbox mounts sag this twists lever and in general makes removing TT and adjusting gear lever more difficult. We added mounting support on top of central shaft for bearing bracket and adjusted lever on floor before mounting TT-gearbox package to car.

Now these are down again as gear lever is extremely sloppy. Probably broken spring under large nut on the side. We'll do total rebuild so that we don't have to touch them ever again.

gruffalo, good catch. They're exacly that from http://www.helsinginsanomat.fi. We do not discriminate any pages. GTS cams on top of traffic pages and Carrera GT test drive article.

They're exacly that from http://www.helsinginsanomat.fi. We do not discriminate any pages. GTS cams on top of traffic pages and Carrera GT test drive article.

PS. Here's other faster method for fishing bearings out. I like slow one by one way and this all at once approach wouldn't work very well with '90 and later tubes because of vibration damper between 2nd and 3rd bearing. It would mean five times resistance when pulling than taking them one by one and vibration damper can stay in on slower method.

http://www.clarks-garage.com/shop-manual/susp-16.htm

TT lenght difference comes from different gearboxes and rear subframe. Subframe and TT was changed at same time to move gearbox 30mm forward. Difference isn't very obvious in pictures but it's there.

G28.10 on top, G28.03 bottom.

Two threaded holes between joint flange and gearbox mount hole are for mounting vibration damper support. Other end of damper mounts to rear subframe. Later subframes have mounting ear left over in casting to allow subframe to be used on these old cars and there was no point in changing casting mould anyway. AFAIK gearbox dampers were deleted either when battery box was integrated to body for '79 model year or engine mounts were changed from square to round style in '83, probably already in '79. Engine dampers were deleted same time as engine mounts changed. AFAIK there are unused threads in lower suspension supporting bows at least up to '87 but not in '92 anymore even though it's possible to make these as support casting is still the same. When ever factory had a chance they used same casting while end result changed. This saves lot of money and keeps number of different part types down.

10 and all boxes after it have large nut on center of the right side. Under it is adjustment for lever counter spring. All earlier versions have different system where there are two springs around inner shifter rod. On G28.12 lever that later type spring (under large nut) pushes was changed and this makes gear lever stay between 2-3 when in neutral. AFAIK all boxes up to '86 should have gear lever between 4-5 and two of springs, weak between 4-5 to 2-3 and stronger between 2-3 to R-1. On many early boxes weaker spring is so weak that it has no effect and it's possible to make lever stay between 2-3 by setting lever front ball cup joint slanted.

G28.03 on top, G28.10 bottom.

03 has two holes in this left side also for vibration damper support. Rest of the holes around joint flange are for '78 model year only battery box. End flange has studs also for the box.

10 has completely new system for keeping lever on gears and neutral compared to older boxes. Aluminium piece at this side, left from center of box just below top, is part of it.

When we installed 10 to '78 we had to modify it somewhat. It obviously didn't have all those mounting holes for vibration dampers and battery box. We had to improvise one support as there's no material in casting below joint flange on 10 like 03 has. Used next one towards rear and piece of flat iron. Has worked fine for past four years.

There was at least one change to TT within 03 years. '78 cars have gear shift rod bearing bracket mounted to body when all later cars have it on central tube. Quess idea behind first version was to have gear lever fixed to body so it wouldn't move when engine-TT-gearbox package moves slightly. On '78 when engine and gearbox mounts sag this twists lever and in general makes removing TT and adjusting gear lever more difficult. We added mounting support on top of central shaft for bearing bracket and adjusted lever on floor before mounting TT-gearbox package to car.

Now these are down again as gear lever is extremely sloppy. Probably broken spring under large nut on the side. We'll do total rebuild so that we don't have to touch them ever again.

gruffalo, good catch.

They're exacly that from http://www.helsinginsanomat.fi. We do not discriminate any pages. GTS cams on top of traffic pages and Carrera GT test drive article.

They're exacly that from http://www.helsinginsanomat.fi. We do not discriminate any pages. GTS cams on top of traffic pages and Carrera GT test drive article.

PS. Here's other faster method for fishing bearings out. I like slow one by one way and this all at once approach wouldn't work very well with '90 and later tubes because of vibration damper between 2nd and 3rd bearing. It would mean five times resistance when pulling than taking them one by one and vibration damper can stay in on slower method.

http://www.clarks-garage.com/shop-manual/susp-16.htm

#29

Hi Erkka, could you tell me please what is the internal diameter for the torque tube? I got 93 mm, is this correct as I had to contend with the shaft being in the way at the time.

#30

Addict

Rennlist Member

Rennlist Member

Thread Starter

93 mm is very close. Haven't measured it yet when center shaft is out and can't remember for sure what we saw before we started. Took measurement for the fishing tool and it might have been few mm more, something like 95mm perhaps. Will get accurate number next time. You might try to derive it by measuring distance to center shaft x 2 + thickness of shaft if you need it fast.