Devek Sway bar instructions

#1

Rennlist Member

Thread Starter

Much appreciate if anyone can post or send me a copy of the instructions for how to set up the Devek bar.

Been doing a bit of servicing on mine and something does not quite look right in that with the car in the air on the passenger side the steering tie rod end sits on the bar arm- no idea why ti should do that on one side and not the other- all things being equal.

Rgds

Fred

Been doing a bit of servicing on mine and something does not quite look right in that with the car in the air on the passenger side the steering tie rod end sits on the bar arm- no idea why ti should do that on one side and not the other- all things being equal.

Rgds

Fred

#3

Rennlist Member

Thread Starter

#4

Drifting

Happy Thanksgiving my friend!!

#6

Rennlist Member

Thread Starter

Andrew,

Thanks for trying- floor open to other offers- if anyone can wrtie down the correct procedure that would be great.

I seem to remember you have to set the turnbuckle on the link such that when the suspension is settled there is no pre-load on the bolt if that makes sense. I also seem to remember that there is a requirement to initially run with only one side connected bizarrre as thatmay sound.

Rgds

Fred

Thanks for trying- floor open to other offers- if anyone can wrtie down the correct procedure that would be great.

I seem to remember you have to set the turnbuckle on the link such that when the suspension is settled there is no pre-load on the bolt if that makes sense. I also seem to remember that there is a requirement to initially run with only one side connected bizarrre as thatmay sound.

Rgds

Fred

#7

Rennlist Member

Okay...Not installation instructions, but I do have the DEVEK front anti-sway bar on my 94 GTS.

First what anti-sway bars do. When a car turns the weight wants to keep going straight so the car body wants to roll in the opposite direction of the turn. The sway bar connects the left and right sprung suspension parts, wheel, tire, etc. together so when the body tries to roll it must also lift part of the weight of the suspension parts on the opposite side of the car. The stiffer the anti-sway bar the less the car will roll, but also the harsher the ride because the more the bumpyness of the road on one side of the car will effect the other side of the car.

The turnbuckle itself does not effect the stiffness of the anti-sway bar. There are two purposes for the adjustability of the turnbuckle.

One is to adjust the position of the swaybar arm so it does not interfere with the other suspension components like the tie rod you mentioned. Not as important with the wheels off the ground, but very important during normal suspension travel. Mine was not adjusted properly when I got the car and had bent the driver's side tie rod messing up the alignment. Don't know exactly what adjustments were made as the mechanic I took it to for alignment re-adjusted the turnbuckle to keep it from happening again when he replaced the bent tie rod.

The other is to balance, or pre-load the sway-bar in one direction or the other. Balance means with the car settled on flat and level there is no load on the anti-sway bar (NORMAL). This means they should be loose like you mentioned. Pre-load means you can set the the anit-sway bar so one or the other wheel is pushing that corner of the car up. Preload is typically used in specific racing applications. Example would be drag racing. The tendency is for the torque of the motor and drivetrain to twist the car. Preloading the sway bars can help keep all four tires loaded to help keep the weight balanced between both rear tires so one does not start losing traction before the other. In applications like NASCAR the preload is done so the car is set up to keep the weight on the tires more balanced while turning left. The preload can also help keep the car balanced if one side of the car is heavier than the other. And example would be if you are autocrossing or tracking the car with only a driver in the car makes the left side of the car heavier.

The length of the sway bar arm is a different setting altogether.

It is like adjusting the size of the bar. The front is adjusted along with the rear sway bar to adjust the effect body roll has on front to rear weight balance as the car transitions and is turning. The preferred balance is different depending on driving style and average corner radius. An example would be if you turn hard to the right and the car pushes or understeers. The front is getting less traction compared to there rear. You will typically notice while understeering the left or outside rear of the car is lower and the right front of the car is higher. If you stiffen the rear sway bar it will help keep the weight on the front right corner giving it more traction and reduce understeer. These adjustments depend on driving style because it is very dynamic and not only has to do with when the car is turning but also if the car is maintaining speed, accelerating, or decelerating and how quickly and/or abruptly it is accelerating or decelerating.

Hope not too confusing and gives enough general understanding that you can adjust your DEVEK bar so it does not hit other suspension components AND maintain any preload if any.

First what anti-sway bars do. When a car turns the weight wants to keep going straight so the car body wants to roll in the opposite direction of the turn. The sway bar connects the left and right sprung suspension parts, wheel, tire, etc. together so when the body tries to roll it must also lift part of the weight of the suspension parts on the opposite side of the car. The stiffer the anti-sway bar the less the car will roll, but also the harsher the ride because the more the bumpyness of the road on one side of the car will effect the other side of the car.

The turnbuckle itself does not effect the stiffness of the anti-sway bar. There are two purposes for the adjustability of the turnbuckle.

One is to adjust the position of the swaybar arm so it does not interfere with the other suspension components like the tie rod you mentioned. Not as important with the wheels off the ground, but very important during normal suspension travel. Mine was not adjusted properly when I got the car and had bent the driver's side tie rod messing up the alignment. Don't know exactly what adjustments were made as the mechanic I took it to for alignment re-adjusted the turnbuckle to keep it from happening again when he replaced the bent tie rod.

The other is to balance, or pre-load the sway-bar in one direction or the other. Balance means with the car settled on flat and level there is no load on the anti-sway bar (NORMAL). This means they should be loose like you mentioned. Pre-load means you can set the the anit-sway bar so one or the other wheel is pushing that corner of the car up. Preload is typically used in specific racing applications. Example would be drag racing. The tendency is for the torque of the motor and drivetrain to twist the car. Preloading the sway bars can help keep all four tires loaded to help keep the weight balanced between both rear tires so one does not start losing traction before the other. In applications like NASCAR the preload is done so the car is set up to keep the weight on the tires more balanced while turning left. The preload can also help keep the car balanced if one side of the car is heavier than the other. And example would be if you are autocrossing or tracking the car with only a driver in the car makes the left side of the car heavier.

The length of the sway bar arm is a different setting altogether.

It is like adjusting the size of the bar. The front is adjusted along with the rear sway bar to adjust the effect body roll has on front to rear weight balance as the car transitions and is turning. The preferred balance is different depending on driving style and average corner radius. An example would be if you turn hard to the right and the car pushes or understeers. The front is getting less traction compared to there rear. You will typically notice while understeering the left or outside rear of the car is lower and the right front of the car is higher. If you stiffen the rear sway bar it will help keep the weight on the front right corner giving it more traction and reduce understeer. These adjustments depend on driving style because it is very dynamic and not only has to do with when the car is turning but also if the car is maintaining speed, accelerating, or decelerating and how quickly and/or abruptly it is accelerating or decelerating.

Hope not too confusing and gives enough general understanding that you can adjust your DEVEK bar so it does not hit other suspension components AND maintain any preload if any.

Trending Topics

#8

Rennlist Member

Thread Starter

My problem is quite simple in that all I wanted to do was re-grease the mount bushings. I undid the mounts but when I tried to put them back I could not get the bolts both sides to align- probably because there is no weight on the wheels.

I then found another problem in that the hex bolt that fastens the drop link rose joint to the adjustable arm appears to be a strange size. A 8mm hex wrench is too small and a 10mmhex is too big and I have never seen a 9mm hex wrench but apparently they exist and the size I measured is consistent with this. If anyone can test/confirm on their Devek bar much appreciated.

There is a very specific procedure to fit these but I cannot remember the specific details- I seem to remember that initially you attach one side until the car settles but even that does not make much sense.

The adjustable piston simply changes the lever arm and thus the effective stiffness of the bar as a whole. shortening the piston makes the bar stiffer, lengthening it makes the bar softer thus how one tunes the handling. With stock wheels it is a waste of time as the last thing a stock 928 needs is more understeer. Different matter when you have wide/grippy rubber up front.

Rgds

Fred

I then found another problem in that the hex bolt that fastens the drop link rose joint to the adjustable arm appears to be a strange size. A 8mm hex wrench is too small and a 10mmhex is too big and I have never seen a 9mm hex wrench but apparently they exist and the size I measured is consistent with this. If anyone can test/confirm on their Devek bar much appreciated.

There is a very specific procedure to fit these but I cannot remember the specific details- I seem to remember that initially you attach one side until the car settles but even that does not make much sense.

The adjustable piston simply changes the lever arm and thus the effective stiffness of the bar as a whole. shortening the piston makes the bar stiffer, lengthening it makes the bar softer thus how one tunes the handling. With stock wheels it is a waste of time as the last thing a stock 928 needs is more understeer. Different matter when you have wide/grippy rubber up front.

Rgds

Fred

Last edited by FredR; 11-29-2015 at 04:31 PM. Reason: Confirmed size is 9mm

#9

Rennlist Member

My problem is quite simple in that all I wanted to do was re-grease the mount bushings. I undid the mounts but when I tried to put them back I could not get the bolts both sides to align- probably because there is no weight on the wheels.

I then found another problem in that the hex bolt that fastens the drop link rose joint to the adjustable arm appears to be a strange size. A 8mm hex wrench is too small and a 10mmhex is too big and I have never seen a 9mm hex wrench but apparently they exist and the size I measured is consistent with this. If anyone can test/confirm on their Devek bar much appreciated.

There is a very specific procedure to fit these but I cannot remember the specific details- I seem to remember that initially you attach one side until the car settles but even that does not make much sense.

The adjustable piston simply changes the lever arm and thus the effective stiffness of the bar as a whole. shortening the piston makes the bar stiffer, lengthening it makes the bar softer thus how one tunes the handling. With stock wheels it is a waste of time as the last thing a stock 928 needs is more understeer. Different matter when you have wide/grippy rubber up front.

Rgds

Fred

I then found another problem in that the hex bolt that fastens the drop link rose joint to the adjustable arm appears to be a strange size. A 8mm hex wrench is too small and a 10mmhex is too big and I have never seen a 9mm hex wrench but apparently they exist and the size I measured is consistent with this. If anyone can test/confirm on their Devek bar much appreciated.

There is a very specific procedure to fit these but I cannot remember the specific details- I seem to remember that initially you attach one side until the car settles but even that does not make much sense.

The adjustable piston simply changes the lever arm and thus the effective stiffness of the bar as a whole. shortening the piston makes the bar stiffer, lengthening it makes the bar softer thus how one tunes the handling. With stock wheels it is a waste of time as the last thing a stock 928 needs is more understeer. Different matter when you have wide/grippy rubber up front.

Rgds

Fred

generally, mid span on the adjustment is good for street and race cars with lighter that you would normally have on a race car springs set up. rain becomes an even lighter setting and with really stiff racing springs, very little bar is needed. almost stock might work. generally, most race cars work better with a little softer spring as well.

#10

Rennlist Member

good description.

Okay...Not installation instructions, but I do have the DEVEK front anti-sway bar on my 94 GTS.

First what anti-sway bars do. When a car turns the weight wants to keep going straight so the car body wants to roll in the opposite direction of the turn. The sway bar connects the left and right sprung suspension parts, wheel, tire, etc. together so when the body tries to roll it must also lift part of the weight of the suspension parts on the opposite side of the car. The stiffer the anti-sway bar the less the car will roll, but also the harsher the ride because the more the bumpyness of the road on one side of the car will effect the other side of the car.

The turnbuckle itself does not effect the stiffness of the anti-sway bar. There are two purposes for the adjustability of the turnbuckle.

One is to adjust the position of the swaybar arm so it does not interfere with the other suspension components like the tie rod you mentioned. Not as important with the wheels off the ground, but very important during normal suspension travel. Mine was not adjusted properly when I got the car and had bent the driver's side tie rod messing up the alignment. Don't know exactly what adjustments were made as the mechanic I took it to for alignment re-adjusted the turnbuckle to keep it from happening again when he replaced the bent tie rod.

The other is to balance, or pre-load the sway-bar in one direction or the other. Balance means with the car settled on flat and level there is no load on the anti-sway bar (NORMAL). This means they should be loose like you mentioned. Pre-load means you can set the the anit-sway bar so one or the other wheel is pushing that corner of the car up. Preload is typically used in specific racing applications. Example would be drag racing. The tendency is for the torque of the motor and drivetrain to twist the car. Preloading the sway bars can help keep all four tires loaded to help keep the weight balanced between both rear tires so one does not start losing traction before the other. In applications like NASCAR the preload is done so the car is set up to keep the weight on the tires more balanced while turning left. The preload can also help keep the car balanced if one side of the car is heavier than the other. And example would be if you are autocrossing or tracking the car with only a driver in the car makes the left side of the car heavier.

The length of the sway bar arm is a different setting altogether.

It is like adjusting the size of the bar. The front is adjusted along with the rear sway bar to adjust the effect body roll has on front to rear weight balance as the car transitions and is turning. The preferred balance is different depending on driving style and average corner radius. An example would be if you turn hard to the right and the car pushes or understeers. The front is getting less traction compared to there rear. You will typically notice while understeering the left or outside rear of the car is lower and the right front of the car is higher. If you stiffen the rear sway bar it will help keep the weight on the front right corner giving it more traction and reduce understeer. These adjustments depend on driving style because it is very dynamic and not only has to do with when the car is turning but also if the car is maintaining speed, accelerating, or decelerating and how quickly and/or abruptly it is accelerating or decelerating.

Hope not too confusing and gives enough general understanding that you can adjust your DEVEK bar so it does not hit other suspension components AND maintain any preload if any.

First what anti-sway bars do. When a car turns the weight wants to keep going straight so the car body wants to roll in the opposite direction of the turn. The sway bar connects the left and right sprung suspension parts, wheel, tire, etc. together so when the body tries to roll it must also lift part of the weight of the suspension parts on the opposite side of the car. The stiffer the anti-sway bar the less the car will roll, but also the harsher the ride because the more the bumpyness of the road on one side of the car will effect the other side of the car.

The turnbuckle itself does not effect the stiffness of the anti-sway bar. There are two purposes for the adjustability of the turnbuckle.

One is to adjust the position of the swaybar arm so it does not interfere with the other suspension components like the tie rod you mentioned. Not as important with the wheels off the ground, but very important during normal suspension travel. Mine was not adjusted properly when I got the car and had bent the driver's side tie rod messing up the alignment. Don't know exactly what adjustments were made as the mechanic I took it to for alignment re-adjusted the turnbuckle to keep it from happening again when he replaced the bent tie rod.

The other is to balance, or pre-load the sway-bar in one direction or the other. Balance means with the car settled on flat and level there is no load on the anti-sway bar (NORMAL). This means they should be loose like you mentioned. Pre-load means you can set the the anit-sway bar so one or the other wheel is pushing that corner of the car up. Preload is typically used in specific racing applications. Example would be drag racing. The tendency is for the torque of the motor and drivetrain to twist the car. Preloading the sway bars can help keep all four tires loaded to help keep the weight balanced between both rear tires so one does not start losing traction before the other. In applications like NASCAR the preload is done so the car is set up to keep the weight on the tires more balanced while turning left. The preload can also help keep the car balanced if one side of the car is heavier than the other. And example would be if you are autocrossing or tracking the car with only a driver in the car makes the left side of the car heavier.

The length of the sway bar arm is a different setting altogether.

It is like adjusting the size of the bar. The front is adjusted along with the rear sway bar to adjust the effect body roll has on front to rear weight balance as the car transitions and is turning. The preferred balance is different depending on driving style and average corner radius. An example would be if you turn hard to the right and the car pushes or understeers. The front is getting less traction compared to there rear. You will typically notice while understeering the left or outside rear of the car is lower and the right front of the car is higher. If you stiffen the rear sway bar it will help keep the weight on the front right corner giving it more traction and reduce understeer. These adjustments depend on driving style because it is very dynamic and not only has to do with when the car is turning but also if the car is maintaining speed, accelerating, or decelerating and how quickly and/or abruptly it is accelerating or decelerating.

Hope not too confusing and gives enough general understanding that you can adjust your DEVEK bar so it does not hit other suspension components AND maintain any preload if any.

#11

Rennlist Member

Thread Starter

Gents,

I think I have worked it out having studied the layout a bit more yesterday. The first step is to ensure the sway bar can rotate OK in its mounts when fastened with the drop links not connected. You then set the drop link adjustment on one side only with the car sat on its wheels such that the tie rod is well clear of the bar, presumably with the turnbuckle somewhere around mid range. You then take the car for a ride to settle the suspension and then connect the other tie-rod with no pre-load on the bar.

After that, if for any specific reason you want to induce some pre-load on one side relative to the other you can then adjust both turnbuckles [up or down] to achieve a degree of bias should you wish to. That would fit in with Rich's excellent description I suspect. Perhaps the kind of thing oval racers do because they only turn in one direction- but probably the kind of thing one wants to avoid on a street/conventional track car.

Rgds

Fred

I think I have worked it out having studied the layout a bit more yesterday. The first step is to ensure the sway bar can rotate OK in its mounts when fastened with the drop links not connected. You then set the drop link adjustment on one side only with the car sat on its wheels such that the tie rod is well clear of the bar, presumably with the turnbuckle somewhere around mid range. You then take the car for a ride to settle the suspension and then connect the other tie-rod with no pre-load on the bar.

After that, if for any specific reason you want to induce some pre-load on one side relative to the other you can then adjust both turnbuckles [up or down] to achieve a degree of bias should you wish to. That would fit in with Rich's excellent description I suspect. Perhaps the kind of thing oval racers do because they only turn in one direction- but probably the kind of thing one wants to avoid on a street/conventional track car.

Rgds

Fred

#13

Rennlist Member

Thread Starter

Thanks for that- sounds as though I have it cracked- just came back from my local tool store [not too many over here] and found a hex wrench that was 5/16th-close to what I need and was just about to walk out the store when I spotted some more wrenches round the corner and found a 9mm wrench with good leverage so that will be another tick in the box this afternoon.

Rgds

Fred

#14

Rennlist Member

Thread Starter

So, I reinstalled the Devek bar this afternoon and came across an interesting finding- hopefully correct.

What I found was that one has to adjust the length of the connected link very carefully to avoid a clash of the various components at full lock. I just about managed to achieve this but this was with the stiffness adjustment piston at mid range. If I were to pull it fully stiff then if the suspension was at full lock and the wheel went airborne the tie rod would hammer down on the roll bar. Seems to me this is unavoidable no matter how it adjusted if you run at full stiffness.

That being said I would think it is highly unlikely that a wheel is going to be airborne at full lock but if it does I can well understand how and why it could damage the tie rod as Rich experienced in his post.

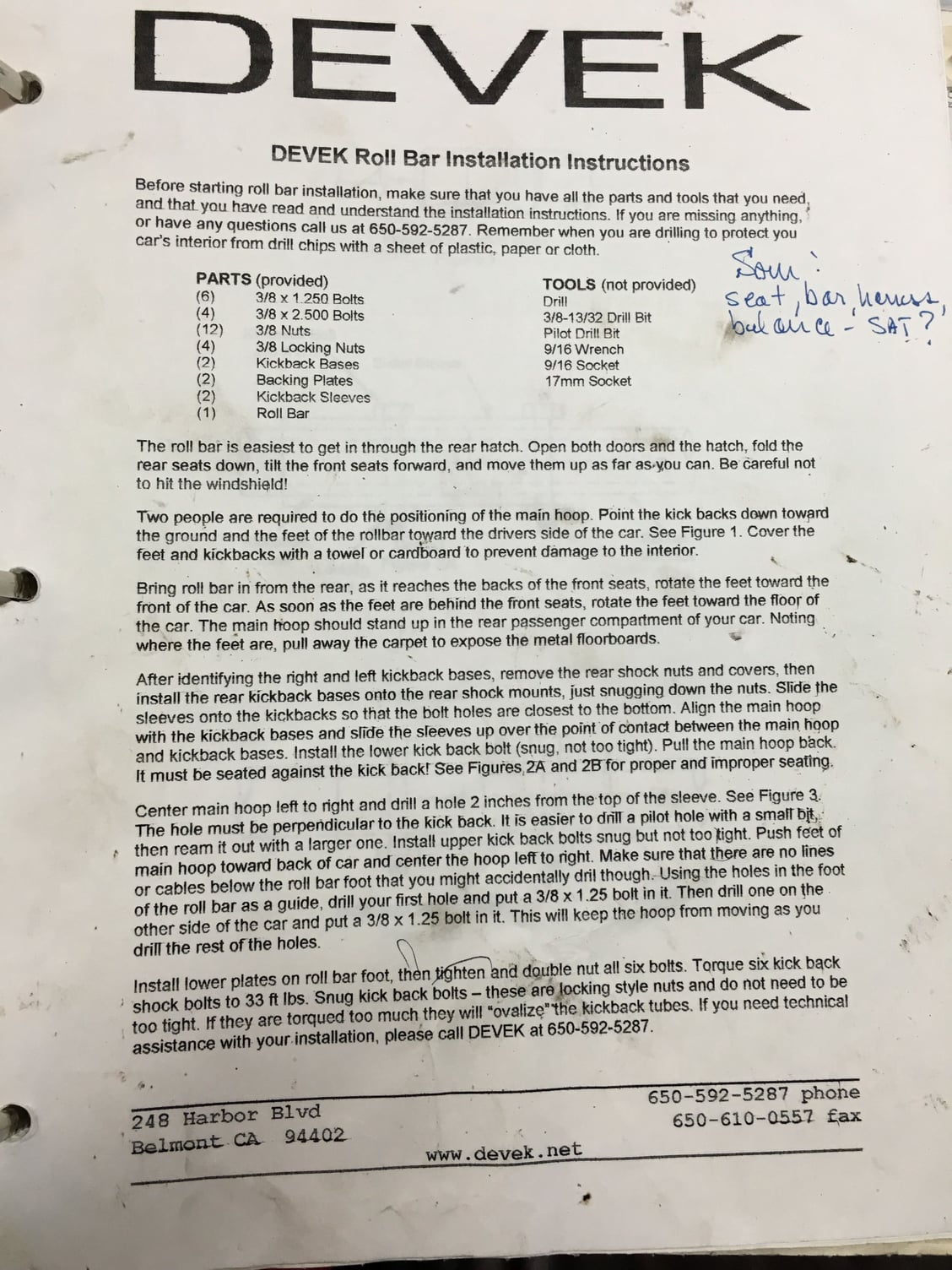

The attached photo shows how tight it is [best angle I could shoot] plus a shot of the Devek bar for those that do not know what they look like. The bar itself was in great condition with most of the paint solid and the rose joints still tight. I just cleaned and re-greased the joints and put it back in.

The other point I remembered is that the original instructions called for the bolt that holds the lower rose joint to the adjustment piston to be Loctited. It took quite an effort to undo the passenger side joint so I left the driver side as I found it. that proved to be somewhat tricky when it came to re-installation.

I did this by attaching the driver side turnbuckle and then tried to attach the passenger side bracket. To get it all aligned I had to play with the driver side turnbuckle until it all kind of aligned. Doing this job single handed from jack stands under the car is not easy and I had to provide support for the bar using a scissor jack otherwise a single pair of hands would not have worked. Far better to undo both drop links I suspect.

Whilst adjusting the drop links to clear the steering tie rod, you could feel the turnbuckle getting stiffer with more turns and similarly as one proceeded to adjust the turnbuckle on the other side it would start out stiff and gradually go easy as the number of turns on the turnbuckle was equalised- this tells me I have it more or less right and maybe no need to do the final joint with the car back on its wheels after all- jury still out on that one.

The other point I noted was that the bolt that holds the rose joint to the bar is not metric- my original estimate that it is a 3/8 inch hex would seem to be correct. A 9mm wrench took it but I feared something might round.

Rgds

Fred

What I found was that one has to adjust the length of the connected link very carefully to avoid a clash of the various components at full lock. I just about managed to achieve this but this was with the stiffness adjustment piston at mid range. If I were to pull it fully stiff then if the suspension was at full lock and the wheel went airborne the tie rod would hammer down on the roll bar. Seems to me this is unavoidable no matter how it adjusted if you run at full stiffness.

That being said I would think it is highly unlikely that a wheel is going to be airborne at full lock but if it does I can well understand how and why it could damage the tie rod as Rich experienced in his post.

The attached photo shows how tight it is [best angle I could shoot] plus a shot of the Devek bar for those that do not know what they look like. The bar itself was in great condition with most of the paint solid and the rose joints still tight. I just cleaned and re-greased the joints and put it back in.

The other point I remembered is that the original instructions called for the bolt that holds the lower rose joint to the adjustment piston to be Loctited. It took quite an effort to undo the passenger side joint so I left the driver side as I found it. that proved to be somewhat tricky when it came to re-installation.

I did this by attaching the driver side turnbuckle and then tried to attach the passenger side bracket. To get it all aligned I had to play with the driver side turnbuckle until it all kind of aligned. Doing this job single handed from jack stands under the car is not easy and I had to provide support for the bar using a scissor jack otherwise a single pair of hands would not have worked. Far better to undo both drop links I suspect.

Whilst adjusting the drop links to clear the steering tie rod, you could feel the turnbuckle getting stiffer with more turns and similarly as one proceeded to adjust the turnbuckle on the other side it would start out stiff and gradually go easy as the number of turns on the turnbuckle was equalised- this tells me I have it more or less right and maybe no need to do the final joint with the car back on its wheels after all- jury still out on that one.

The other point I noted was that the bolt that holds the rose joint to the bar is not metric- my original estimate that it is a 3/8 inch hex would seem to be correct. A 9mm wrench took it but I feared something might round.

Rgds

Fred

#15

Rennlist Member

drop the bar down a bit. it shouldnt be that close.

then attach one side.leaving the adjusters loose on the other side. lower the car and reach under to adjust to match the height to the swaybar bolt hole.. thread it in and torque. raise car and tighten the height adjusters.

then attach one side.leaving the adjusters loose on the other side. lower the car and reach under to adjust to match the height to the swaybar bolt hole.. thread it in and torque. raise car and tighten the height adjusters.