Pulling the in tank fuel pump

#1

Rennlist Member

Thread Starter

Doing some general maintenance work at the moment now the weather is a very pleasant 30C day time temps - somewhat different to the UK where I was last week - non stop winds and rain for 8 days- loved it!].

I want to pull the in tank pump and fit the GB hose hose kit. My in tank hose is bound to be on its last legs if not gone already.

Took a look at the task today and saw that the tank cradle is very much in the way so presumably has to be dropped. Has anyone seen a good post/write up about doing this? Cannot find anything to date.

Need to drain the tank - intend to jumper the pump and use it to evacuate the tank into a bucket [currently lowish level]. Can then use the petrol to help de-grease the drive shafts.

I think it may be a good idea to squeeze the boss with a jubilee clip to help stop the insert turning- any thoughts? Any other tips/suggestions appreciated.

Rgds

Fred

I want to pull the in tank pump and fit the GB hose hose kit. My in tank hose is bound to be on its last legs if not gone already.

Took a look at the task today and saw that the tank cradle is very much in the way so presumably has to be dropped. Has anyone seen a good post/write up about doing this? Cannot find anything to date.

Need to drain the tank - intend to jumper the pump and use it to evacuate the tank into a bucket [currently lowish level]. Can then use the petrol to help de-grease the drive shafts.

I think it may be a good idea to squeeze the boss with a jubilee clip to help stop the insert turning- any thoughts? Any other tips/suggestions appreciated.

Rgds

Fred

#2

Just undo the two rearward cradle bolts and you will have enough room. For emptying the tank, I just pull the hose off the pump and put it over a bucket/gas can.

#4

Archive Gatekeeper

Rennlist Member

Rennlist Member

Like Sean says-

Remove the rear cradle bolts (prepare for the shower of dust and dirt...) and get after it with the 36 mm socket in your new 3/4" drive tool collection.

If you're worried about the health of the metal knurled insert that the in-tank pump screws into, it's cheap insurance to tighten a hose clamp around the OD of the flange in the tank that the pump screws into, so while you're torquing on the pump you lessen the risk of breaking loose the knurled insert.

Remove the rear cradle bolts (prepare for the shower of dust and dirt...) and get after it with the 36 mm socket in your new 3/4" drive tool collection.

If you're worried about the health of the metal knurled insert that the in-tank pump screws into, it's cheap insurance to tighten a hose clamp around the OD of the flange in the tank that the pump screws into, so while you're torquing on the pump you lessen the risk of breaking loose the knurled insert.

#5

Rennlist Member

Thread Starter

Like Sean says-

Remove the rear cradle bolts (prepare for the shower of dust and dirt...) and get after it with the 36 mm socket in your new 3/4" drive tool collection.

If you're worried about the health of the metal knurled insert that the in-tank pump screws into, it's cheap insurance to tighten a hose clamp around the OD of the flange in the tank that the pump screws into, so while you're torquing on the pump you lessen the risk of breaking loose the knurled insert.

Remove the rear cradle bolts (prepare for the shower of dust and dirt...) and get after it with the 36 mm socket in your new 3/4" drive tool collection.

If you're worried about the health of the metal knurled insert that the in-tank pump screws into, it's cheap insurance to tighten a hose clamp around the OD of the flange in the tank that the pump screws into, so while you're torquing on the pump you lessen the risk of breaking loose the knurled insert.

Thanks for the inputs- indeed the new socket sets both have 36mm sockets whereas my 1/2 inch drive set tops out at 32mm. Seems my new breaker bar is similar to the one on Rob's avatar and the one in the socket set [stiff as King Kong's private part] is even better.

I am kind of nervous about touching the in-tank pump so any assurance is welcome but given the in-tank hose has been in service for some 9 years if it has not gone already it must be about to. Hope to fit Greg's kit and forgot about it until the pump packs up [probably a week later!].

What is the torque setting for that 36mm fitting- obviously it is not going to be much and correct torque is most important. Not sure if the torque spec is in the manual for that item- either way wlll take a look tomorrow.

Rgds

Fred

#6

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Fred--

Start drowning that fitting now with Kroil or atf/acetone, giving it a fighting chanceat coming loose for you in a day or two.

Start drowning that fitting now with Kroil or atf/acetone, giving it a fighting chanceat coming loose for you in a day or two.

#7

Rennlist Member

If you pull the sender from the top of the tank then you can get a look at the strainer end of the pump, maybe more. If it is sitting at a wonky angle, then the hose is gone for sure.

Soak the fitting in penetrating oil as Bob mentioned, but I would also absolutely fit a thin jubilee clamp before putting any torque on it. Cost is almost nothing, and while there is no guarantee I've had no spun fittings when the clamp was put in place first.

One thread: https://rennlist.com/forums/928-foru...l#post11611542

(See next post for pictures)

This was a repair after the insert spun and came out (no clamp), and shows the clamp I used to reinforce the plastic mounting-boss.

That in-tank pump has been in and out a couple of times for checking and fitting of better hose, no troubles. When I pulled the strainer on our '88 (to fit a in-tank pump), put the clamp on first. It was tight coming out (there was some corrosion after 27 years) but no troubles. It is amazing what a little metal reinforcement will do for plastic.

WSM says 25 NM (18 ft-lbs). New gasket, always. And I would advise silver anti-seize on the threads, there was some left on the threads years later in spite of the fuel-soaked environment.

Trending Topics

#8

Archive Gatekeeper

Rennlist Member

Rennlist Member

18 ft-lbs is the torque value, or 0.03 horsepower-seconds on the Kibort scale.

#9

using the hose clamp around the threaded area is genius. I went with the Tim Murphy solution with the larger tank billet tank ID part , and the 044 pump with the larger inlet ID fitting.... Quality parts... none better...oh and the larger hose as well..

#10

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

#11

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

and FWIW, this hose replacement is on my winter to-do list now that we actually have a winter. Have the new in-tank pump, but need to grab the strainer, and get the little intermediate hose from Greg.

#12

Rennlist Member

Thread Starter

Gents,

As usual great advice- just had a "sod it" moment when I realised that I did not order a new gasket for the in tank pump.

Must get after that Roger chappy to put one in the GB kit for the benefit of cretins like me! Gives me time to spray it a few times with some penetrating fluid- won't do any harm. Indeed I could take a look through the top hatch when the tank is drained to see if there is continuity on the hose but then it wll not really change anything and the probably needs a gasket as well!

It never ends on these dammed cars!

Rgds

Fred

As usual great advice- just had a "sod it" moment when I realised that I did not order a new gasket for the in tank pump.

Must get after that Roger chappy to put one in the GB kit for the benefit of cretins like me! Gives me time to spray it a few times with some penetrating fluid- won't do any harm. Indeed I could take a look through the top hatch when the tank is drained to see if there is continuity on the hose but then it wll not really change anything and the probably needs a gasket as well!

It never ends on these dammed cars!

Rgds

Fred

#13

Fred,

Terry removed my in tank pump whilst my car was in Dubai, so giving him a call may help. My in tank pump was in reasonable state once I had a chance to review it afterwards.

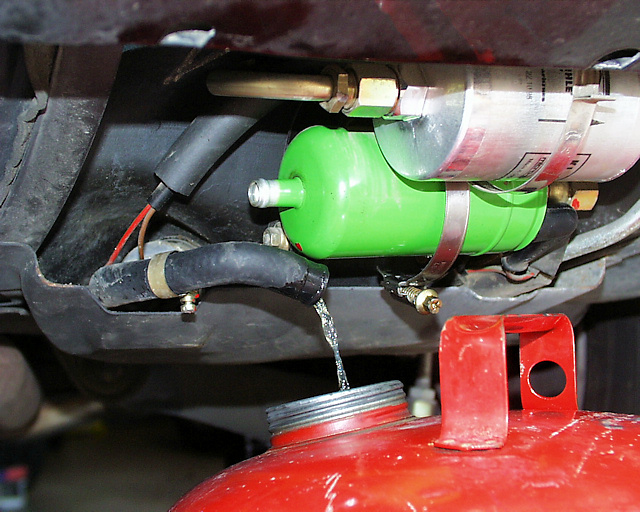

One word of warning, if you change the main fuel pump check valve at the same time ensure you change the small pipe between the pump and the filter, otherwise it is a near impossible task to refit without a leak.

Terry removed my in tank pump whilst my car was in Dubai, so giving him a call may help. My in tank pump was in reasonable state once I had a chance to review it afterwards.

One word of warning, if you change the main fuel pump check valve at the same time ensure you change the small pipe between the pump and the filter, otherwise it is a near impossible task to refit without a leak.

#14

Rennlist Member

Thread Starter

Fred,

Terry removed my in tank pump whilst my car was in Dubai, so giving him a call may help. My in tank pump was in reasonable state once I had a chance to review it afterwards.

One word of warning, if you change the main fuel pump check valve at the same time ensure you change the small pipe between the pump and the filter, otherwise it is a near impossible task to refit without a leak.

Terry removed my in tank pump whilst my car was in Dubai, so giving him a call may help. My in tank pump was in reasonable state once I had a chance to review it afterwards.

One word of warning, if you change the main fuel pump check valve at the same time ensure you change the small pipe between the pump and the filter, otherwise it is a near impossible task to refit without a leak.

I should be calling Terry soon so a good reason to do so

Interesting comment about the check valve job. I replaced mine on the late 90 S4 and everything went back without a hitch. Just the fickle nature of these things I suppose.

Rgds

Fred

#15

Rennlist Member

Thread Starter

Well I finally got round to the in tank pump today.

Removal was straight forward- very little torque required to move it so my main concern was mitigated- whether or not the dousings with releasing fluid helped no idea but it sure came out easy.

To my surprise the piece of pipe was still in tact but it was more like hard plastic than rubber so a timely intervention I suspect.

First mistake I made was to not test the pump before doing anything as will be obvious later.

I checked all the connections- they looked sound and taking great care went to fit the GB hose kit. The clamp fitted fine over the hose but I found it was somewhat tight once the pipe ballooned over the barbs. I found the lug clamps would not slide over the expanded section so started to help persuade it to move with a screwdriver. Damm thing slipped and next thing I know one of the cables broke away from the soldered nipple- durrgh!

Out came the soldering iron- not that I am very good with one. Decided to go the whole hog and solder two new cables- not sure that was a good idea but eventually I managed to do it and also some heat shrink sleeves - noted that the plastic did not like my heat gun and to be very careful. Fitted the GB hose and lug clamps [sort of] and before going to refit the pump tested it- nothing- durrgh. Found tha tone of my joints was no good so had to pull everything off and start again.

Eventually go it all fitted together and running but had to omit the lug clamps that had been compressed [slightly] so could not get them on this time. Decided to run with push fit- just have to see how it goes but now not worried about taking it all out again later.

At least I used the experience to then repair the spare in tank pump I have from my S4 that had a broken cable already so now have two in tank pumps available.

Interestingly the hose from the tank to the main pump was showing signs of cracking and the seal around the in tank pump was showing signs of failing but interestingly from the outside in. So a good intervention I feel as long as I can get everything working tickety boo.

Regards

Fred

Removal was straight forward- very little torque required to move it so my main concern was mitigated- whether or not the dousings with releasing fluid helped no idea but it sure came out easy.

To my surprise the piece of pipe was still in tact but it was more like hard plastic than rubber so a timely intervention I suspect.

First mistake I made was to not test the pump before doing anything as will be obvious later.

I checked all the connections- they looked sound and taking great care went to fit the GB hose kit. The clamp fitted fine over the hose but I found it was somewhat tight once the pipe ballooned over the barbs. I found the lug clamps would not slide over the expanded section so started to help persuade it to move with a screwdriver. Damm thing slipped and next thing I know one of the cables broke away from the soldered nipple- durrgh!

Out came the soldering iron- not that I am very good with one. Decided to go the whole hog and solder two new cables- not sure that was a good idea but eventually I managed to do it and also some heat shrink sleeves - noted that the plastic did not like my heat gun and to be very careful. Fitted the GB hose and lug clamps [sort of] and before going to refit the pump tested it- nothing- durrgh. Found tha tone of my joints was no good so had to pull everything off and start again.

Eventually go it all fitted together and running but had to omit the lug clamps that had been compressed [slightly] so could not get them on this time. Decided to run with push fit- just have to see how it goes but now not worried about taking it all out again later.

At least I used the experience to then repair the spare in tank pump I have from my S4 that had a broken cable already so now have two in tank pumps available.

Interestingly the hose from the tank to the main pump was showing signs of cracking and the seal around the in tank pump was showing signs of failing but interestingly from the outside in. So a good intervention I feel as long as I can get everything working tickety boo.

Regards

Fred