Melted #17 Fuse

#1

Instructor

Thread Starter

So the AC and Blower went out yesterday on the trip down from Chicago to St. Louis. I checked the #17 fuse and it was melted to the box!!! So I have two questions: One, how would one remove the melted fuse safely (I already tried the needle nose pliers). And two, is there a deeper issue that I should look into here?

#2

I had something like this happen to me.

Two fuses melted the contacts and the surrounding plastic into one giant ball.

I guess you can replace the block of 5 fuse holders....but that might be a pain with the grey spaghetti on the back of the panel. I didn't do this.

I went ahead and got a used CE panel from 928 Intl, all new GOOD fuses from one of the 3 known reliable 928 suppliers (cheap Chinese fuses can cause this problem I'm told), clean all the contacts with an emory board, Deoxit D5, and apply a thin layer of Stabilant to the contacts and your fuses and relays and let dry. I got all new relays because I wanted to purge all chances of electrical gremlins from the old CE panel. This can be expensive, so if your old relays are known good, you can save some $ here. This is not too expensive, and is an easy fix. Clean your grounds, Deoxit, stabilant WYIT, it really helps.

Here is my write up. My car is an 88, so I don't know older models and fuse 17. Maybe Alan can chime in.

Hope this helps.

https://rennlist.com/forums/928-foru...use-blues.html

Brian

Two fuses melted the contacts and the surrounding plastic into one giant ball.

I guess you can replace the block of 5 fuse holders....but that might be a pain with the grey spaghetti on the back of the panel. I didn't do this.

I went ahead and got a used CE panel from 928 Intl, all new GOOD fuses from one of the 3 known reliable 928 suppliers (cheap Chinese fuses can cause this problem I'm told), clean all the contacts with an emory board, Deoxit D5, and apply a thin layer of Stabilant to the contacts and your fuses and relays and let dry. I got all new relays because I wanted to purge all chances of electrical gremlins from the old CE panel. This can be expensive, so if your old relays are known good, you can save some $ here. This is not too expensive, and is an easy fix. Clean your grounds, Deoxit, stabilant WYIT, it really helps.

Here is my write up. My car is an 88, so I don't know older models and fuse 17. Maybe Alan can chime in.

Hope this helps.

https://rennlist.com/forums/928-foru...use-blues.html

Brian

#3

Find the cause before you go thru all the trouble of swapping CE panels just to have it melt again. It has happened.

Replacing the block is easy if you can label wires. Sounds like the motor might be on its way out, causing excessive draw

Replacing the block is easy if you can label wires. Sounds like the motor might be on its way out, causing excessive draw

#4

Electron Wrangler

Lifetime Rennlist

Member

Lifetime Rennlist

Member

This happens more commonly on high current circuits - but only because higher current => more heating when you have a connection problem. The current will actually have been lower than normal when this happened - due to the higher contact resistance at the fuse blade/end.

As the contact resistance builds up it drops voltage across it - more voltage is dropped with higher current. Then the combination of the current through the resistance and the voltage across it gets you the power: Voltage (V) x Current (A) = Power (watts)

On a 20A circuit if you get 0.1 ohm contact resistance at one fuse terminal it will drop 2V and 2 x 20 = 40W - dissipated in a tiny spot. Everything connected to it will see that heat - the fuse body and the fuseholder & the panel it plugs into..The high heat will cause the resistance to go up faster as the terminal contact degrades rapidly through oxidation & warping - if the contact resistance doubles to 0.2 ohms the current will likely go down (say to ~16A) but now the voltage dropped will be 3.2v and the power dissipated will be more like 3.2 x 16 = >51W.

Once this starts to happen everything degrades very fast and the extremely localized power means extreme temperatures. The fuse element will never burn out under these conditions because the current is actually going down - and is well below the fuse limit - and always was. Occasionally the fuse element will get ripped apart - purely by the mechanical stresses as the fuse body warps under the extreme heat.

Alan

#5

Rennlist Member

No - the cause is always a poor connection at the fuse - always - it is not related to anything else in the circuit.

This happens more commonly on high current circuits - but only because higher current => more heating when you have a connection problem. The current will actually have been lower than normal when this happened - due to the higher contact resistance at the fuse blade/end.

As the contact resistance builds up it drops voltage across it - more voltage is dropped with higher current. Then the combination of the current through the resistance and the voltage across it gets you the power: Voltage (V) x Current (A) = Power (watts)

On a 20A circuit if you get 0.1 ohm contact resistance at one fuse terminal it will drop 2V and 2 x 20 = 40W - dissipated in a tiny spot. Everything connected to it will see that heat - the fuse body and the fuseholder & the panel it plugs into..The high heat will cause the resistance to go up faster as the terminal contact degrades rapidly through oxidation & warping - if the contact resistance doubles to 0.2 ohms the current will likely go down (say to ~16A) but now the voltage dropped will be 3.2v and the power dissipated will be more like 3.2 x 16 = >51W.

Once this starts to happen everything degrades very fast and the extremely localized power means extreme temperatures. The fuse element will never burn out under these conditions because the current is actually going down - and is well below the fuse limit - and always was. Occasionally the fuse element will get ripped apart - purely by the mechanical stresses as the fuse body warps under the extreme heat.

Alan

This happens more commonly on high current circuits - but only because higher current => more heating when you have a connection problem. The current will actually have been lower than normal when this happened - due to the higher contact resistance at the fuse blade/end.

As the contact resistance builds up it drops voltage across it - more voltage is dropped with higher current. Then the combination of the current through the resistance and the voltage across it gets you the power: Voltage (V) x Current (A) = Power (watts)

On a 20A circuit if you get 0.1 ohm contact resistance at one fuse terminal it will drop 2V and 2 x 20 = 40W - dissipated in a tiny spot. Everything connected to it will see that heat - the fuse body and the fuseholder & the panel it plugs into..The high heat will cause the resistance to go up faster as the terminal contact degrades rapidly through oxidation & warping - if the contact resistance doubles to 0.2 ohms the current will likely go down (say to ~16A) but now the voltage dropped will be 3.2v and the power dissipated will be more like 3.2 x 16 = >51W.

Once this starts to happen everything degrades very fast and the extremely localized power means extreme temperatures. The fuse element will never burn out under these conditions because the current is actually going down - and is well below the fuse limit - and always was. Occasionally the fuse element will get ripped apart - purely by the mechanical stresses as the fuse body warps under the extreme heat.

Alan

#6

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

The blower motors get tired, and draw more current as they age. You can sometimes clean the old motor and maybe replace bearings to add life. I think there are new non-porsche replacements available from our suppliers. Otherwise, you still want to replace the fuse holder section, probably replace the heat-damaged terminals etc. And a new fuse of the correct size.

There are inexpensive plug in ammeters available from Harbor Freight and others. They plug into the fuse holder in place of the fuse. That let's you see if the motor is drawing a lot of current. If the draw is close to the fuse rating with fan on high, it's probably time for a new blower motor.

There are inexpensive plug in ammeters available from Harbor Freight and others. They plug into the fuse holder in place of the fuse. That let's you see if the motor is drawing a lot of current. If the draw is close to the fuse rating with fan on high, it's probably time for a new blower motor.

#7

thank you for the clarification Alan. :-)

No - the cause is always a poor connection at the fuse - always - it is not related to anything else in the circuit.

This happens more commonly on high current circuits - but only because higher current => more heating when you have a connection problem. The current will actually have been lower than normal when this happened - due to the higher contact resistance at the fuse blade/end.

As the contact resistance builds up it drops voltage across it - more voltage is dropped with higher current. Then the combination of the current through the resistance and the voltage across it gets you the power: Voltage (V) x Current (A) = Power (watts)

On a 20A circuit if you get 0.1 ohm contact resistance at one fuse terminal it will drop 2V and 2 x 20 = 40W - dissipated in a tiny spot. Everything connected to it will see that heat - the fuse body and the fuseholder & the panel it plugs into..The high heat will cause the resistance to go up faster as the terminal contact degrades rapidly through oxidation & warping - if the contact resistance doubles to 0.2 ohms the current will likely go down (say to ~16A) but now the voltage dropped will be 3.2v and the power dissipated will be more like 3.2 x 16 = >51W.

Once this starts to happen everything degrades very fast and the extremely localized power means extreme temperatures. The fuse element will never burn out under these conditions because the current is actually going down - and is well below the fuse limit - and always was. Occasionally the fuse element will get ripped apart - purely by the mechanical stresses as the fuse body warps under the extreme heat.

Alan

This happens more commonly on high current circuits - but only because higher current => more heating when you have a connection problem. The current will actually have been lower than normal when this happened - due to the higher contact resistance at the fuse blade/end.

As the contact resistance builds up it drops voltage across it - more voltage is dropped with higher current. Then the combination of the current through the resistance and the voltage across it gets you the power: Voltage (V) x Current (A) = Power (watts)

On a 20A circuit if you get 0.1 ohm contact resistance at one fuse terminal it will drop 2V and 2 x 20 = 40W - dissipated in a tiny spot. Everything connected to it will see that heat - the fuse body and the fuseholder & the panel it plugs into..The high heat will cause the resistance to go up faster as the terminal contact degrades rapidly through oxidation & warping - if the contact resistance doubles to 0.2 ohms the current will likely go down (say to ~16A) but now the voltage dropped will be 3.2v and the power dissipated will be more like 3.2 x 16 = >51W.

Once this starts to happen everything degrades very fast and the extremely localized power means extreme temperatures. The fuse element will never burn out under these conditions because the current is actually going down - and is well below the fuse limit - and always was. Occasionally the fuse element will get ripped apart - purely by the mechanical stresses as the fuse body warps under the extreme heat.

Alan

Trending Topics

The following users liked this post:

cgraner (10-17-2022)

#9

Pro

Join Date: Dec 2010

Location: Palgrave, Ontario, Canada

Posts: 700

Likes: 0

Received 2 Likes

on

2 Posts

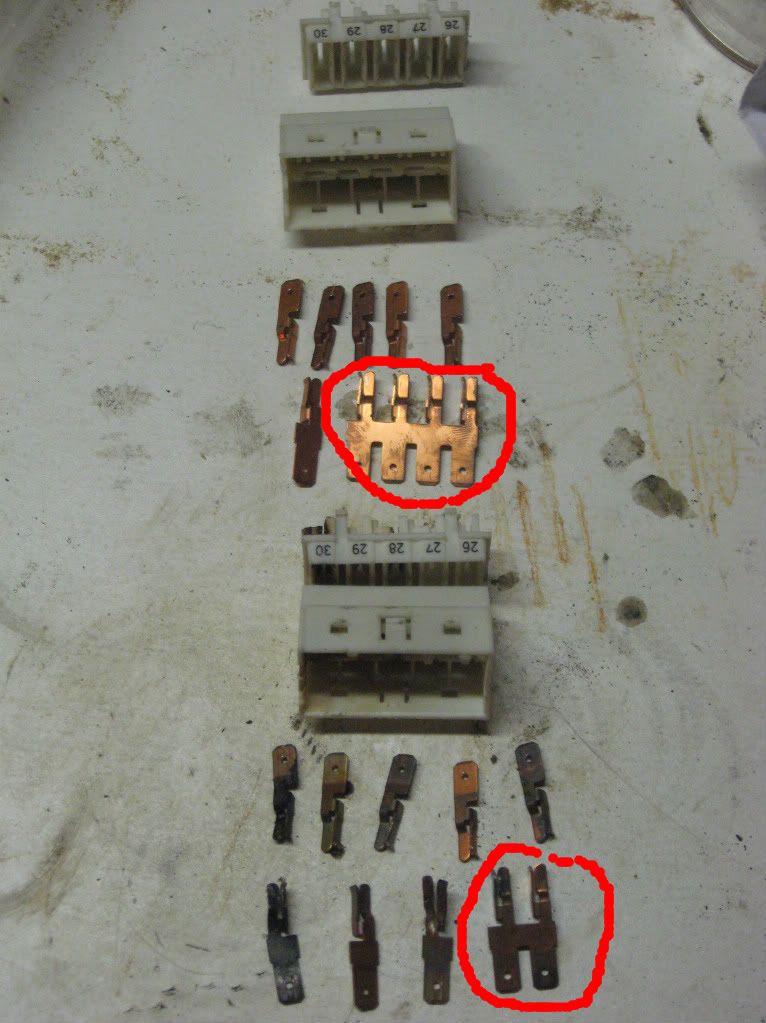

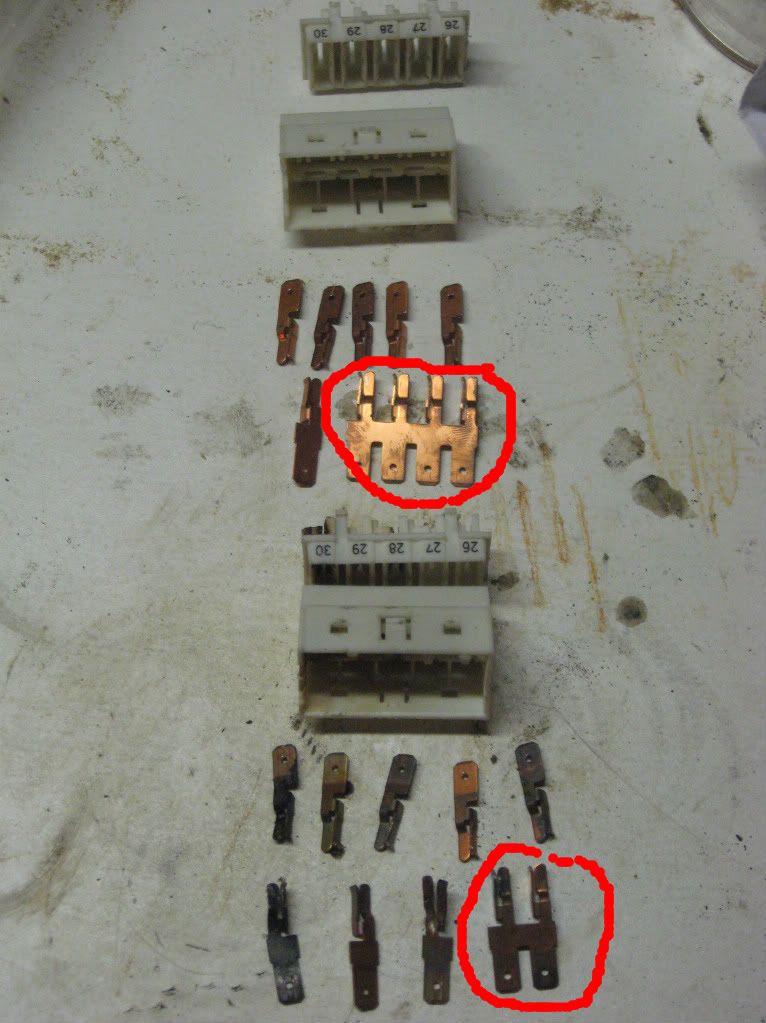

Replacing one of the blocks is not a big deal if you mark each of the grey/gray wires on the back first - I used black and blue marking pens to make simple lines:

The biggest issue is to realize that the blocks are different inside - some of the terminals are connected together. You have to match the pattern that was in the block you are replacing:

The biggest issue is to realize that the blocks are different inside - some of the terminals are connected together. You have to match the pattern that was in the block you are replacing:

#10

Electron Wrangler

Lifetime Rennlist

Member

Lifetime Rennlist

Member

From the Avatar it looks like this may be for an early car <'85 - in that case the story is different...

Best to always tell us the year - many things are year dependant...

Alan

Best to always tell us the year - many things are year dependant...

Alan

#11

Instructor

Thread Starter

Thanks for all the good information. The car is an 86.0 I was able to finally get the fuse out by clipping some of the fuse plastic and then getting the needle nose to pull it out piece by piece. After I was done it did look pretty funky as the 17 slot is pretty warped and expanded, but didn't quite make it to the 16 or 18 slot. I was able to relate the fuse and everything works now. I suspect I may want to look into an external fuse for this just to lower the chances of melting again and impacting other areas. Any other recommendations in the short term? In the long term I like the idea of just relaxing the piece of the panel and not the whole thing since I have never had this issue before. Thoughts?

#12

Rennlist Member

Rennlist Site Sponsor

If you just replace the fuse without improving the contact with the fuse block, you will just melt another fuse. Read Alan's post again...

#13

Electron Wrangler

Lifetime Rennlist

Member

Lifetime Rennlist

Member

I think your best bet is to replace the 5 fuse block. But pay attention to all the details here - you have to check the connections on both the old panel & the new one (you can do it with a DMM without opening it up).

Also you should evaluate if you have had a water leak onto the panel that caused the original issue... if so you may have other suspect connections - proactive chemical cleaning may be enough to save these...

Alan

Also you should evaluate if you have had a water leak onto the panel that caused the original issue... if so you may have other suspect connections - proactive chemical cleaning may be enough to save these...

Alan

#14

Instructor

Thread Starter

Thanks for the heads up everyone and yes the plan is to replace the 5-fuse block. Any idea on the best source for this? Or is it the standard Roger/929intl? In the mean time won't an inline fuse adapter take the risk from having another fuse melt the entire box? If I'm thinking about it the right way, the worst that could happen is that the fuse melts the adapter and doesn't risk the rest of the panel.

#15

Electron Wrangler

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Well - try Roger but probably 928Intl - I think only used are available at this point...?

Get the right numbered panel block, but get several others too... the internal connections INSIDE the fuse block varied by year, you must match these (spare blocks will help if needed). Use a DMM to test the connections.

An inline fuse-holder can be a temp solution - BUT get one with high current (12AWG min - better 10AWG) wire pigtail connections so those wires aren't the weakest link. This will also ensure a better fuse socket to match.

Alan

Get the right numbered panel block, but get several others too... the internal connections INSIDE the fuse block varied by year, you must match these (spare blocks will help if needed). Use a DMM to test the connections.

An inline fuse-holder can be a temp solution - BUT get one with high current (12AWG min - better 10AWG) wire pigtail connections so those wires aren't the weakest link. This will also ensure a better fuse socket to match.

Alan