86.5 Timing Belt / WP Mystery - Collective Wisdom Appreciated

#1

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Oct 2003

Location: Gone. On the Open Road

Posts: 16,329

Received 1,543 Likes

on

1,007 Posts

Folks, I've got a mystery and would appreciate some thoughts from The Collective - especially thoughts from 86.5 aficionados.

[EDIT: Turns out that the new pivot bolt got bent when I first put tension on it. A 1░ bend in the bolt is all that's necessary to throw-off the main tensioner roller by 2-3 mm.

Moral of the story: On the pre-87 (de-)tensioning systems with no brace for the pivot bolt, you can't EVER over-tighten the belt by even a hair or you risk bending the pivot bolt.]

Vital stats:

86.5 Auto

70k-ish miles

Last belt done 8+ years ago.

Belt and water pump job in-progress with new Laso pump, new pivot/shoulder bolt, new bushings, new rollers, Gates belt, tensioner rebuilt.

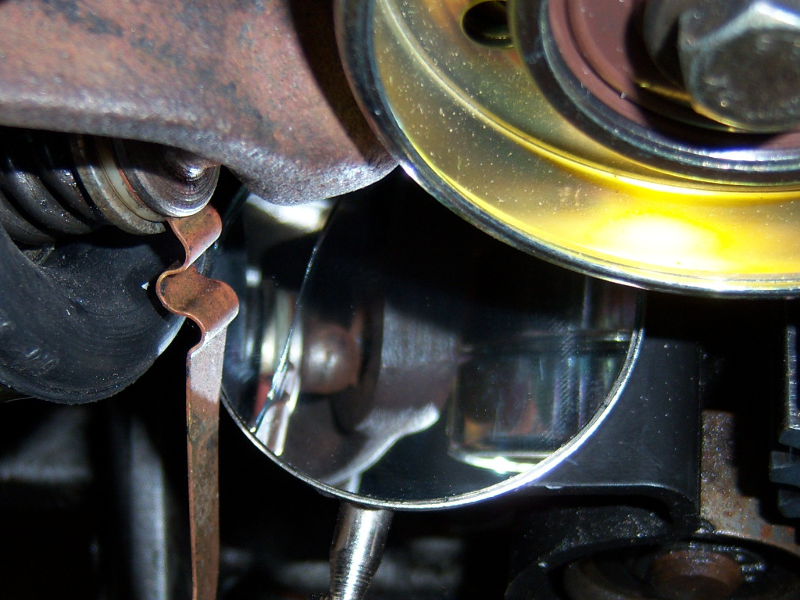

Here's the evidence of the problem (look in the mirror):

When everything is back together the roller carrier is about 4mm too far towards the block (roughly half the width of the tensioner pin.)

And yes, the circlip is on the main roller (double-checked and 100% certain it is seated properly; not that it would matter in this case) and the thick washer is between the pump stand-off and the shoulder bolt:

I have tripled checked that the new pivot bolt is straight. I've checked the casting number on the roller carrier: 928 105 489 0R

The predicable result of this misalignment of the tensioner, main roller, and carrier is:

... and that the belt is tracking to the forward edge of both cam sprockets.

I can't button-up this motor with the belt system in this condition. And, I'm at a loss as to how to proceed except for the obvious choice of Porkenizing it (however, this 928 is already well over-budget (due to something else.))

History:

This 86.5 was due for a belt change since the last belt was at least 8 years ago. As I started-in, inspection showed that the belt was tracking forward on the cam gears. There were 'witness marks' on the gears indicating that the belt had been tracking in the center, but had - at some point - migrated to the front of both gears.

My obvious thought was: bent pivot bolt and dead bushings. No big deal. But, now the problem is not so-obvious.

EDIT: One other thing: The old pivot bolt is straight and the old bushings were intact and in pretty good shape.

Additional observations:

The cam gears and oil pump gear are too 'un-worn looking' to be original; they are in very good shape. I would estimate that they have about 20-30k miles on them. The crank gear looks like it might be original but shows no uneven wear.

The pump that came off this 86.5 was a Laso pump.

I suspect that the gears where changed prior to the last TP/WP job and that the belt started migrating to the front after the last belt job. This would explain the witness marks on the gears.

The only thing I can think of is that the stand-off on the Laso pump castings is 'too short.' But, that doesn't make any sense, since someone prior to me would surely have noticed this? I measured the old Laso pump at 34.5mm (block sealing surface to face of stand-off) and the new Laso seems about the same; it's hard to get a good measurement with the pump attached.

Does anyone have a REALLY old Porsche OE pump from a pre-87? Can you measure the distance from the block sealing surface to the face of the stand-off?

Does anyone have an idea of WTF is going on here? Anyone BTDT?

I did scan through Roger's epic tome on this subject: Timing Belt Wear Question Completed 2-18-07 but it seems that the actual problem was never found. Roger just upgraded to an early-87-spec system. That's a less-desirable option - for the owner - than a) figuring out the issue and/or b) Porkenizing it.

TIA!

[EDIT: Turns out that the new pivot bolt got bent when I first put tension on it. A 1░ bend in the bolt is all that's necessary to throw-off the main tensioner roller by 2-3 mm.

Moral of the story: On the pre-87 (de-)tensioning systems with no brace for the pivot bolt, you can't EVER over-tighten the belt by even a hair or you risk bending the pivot bolt.]

Vital stats:

86.5 Auto

70k-ish miles

Last belt done 8+ years ago.

Belt and water pump job in-progress with new Laso pump, new pivot/shoulder bolt, new bushings, new rollers, Gates belt, tensioner rebuilt.

Here's the evidence of the problem (look in the mirror):

When everything is back together the roller carrier is about 4mm too far towards the block (roughly half the width of the tensioner pin.)

And yes, the circlip is on the main roller (double-checked and 100% certain it is seated properly; not that it would matter in this case) and the thick washer is between the pump stand-off and the shoulder bolt:

I have tripled checked that the new pivot bolt is straight. I've checked the casting number on the roller carrier: 928 105 489 0R

The predicable result of this misalignment of the tensioner, main roller, and carrier is:

... and that the belt is tracking to the forward edge of both cam sprockets.

I can't button-up this motor with the belt system in this condition. And, I'm at a loss as to how to proceed except for the obvious choice of Porkenizing it (however, this 928 is already well over-budget (due to something else.))

History:

This 86.5 was due for a belt change since the last belt was at least 8 years ago. As I started-in, inspection showed that the belt was tracking forward on the cam gears. There were 'witness marks' on the gears indicating that the belt had been tracking in the center, but had - at some point - migrated to the front of both gears.

My obvious thought was: bent pivot bolt and dead bushings. No big deal. But, now the problem is not so-obvious.

EDIT: One other thing: The old pivot bolt is straight and the old bushings were intact and in pretty good shape.

Additional observations:

The cam gears and oil pump gear are too 'un-worn looking' to be original; they are in very good shape. I would estimate that they have about 20-30k miles on them. The crank gear looks like it might be original but shows no uneven wear.

The pump that came off this 86.5 was a Laso pump.

I suspect that the gears where changed prior to the last TP/WP job and that the belt started migrating to the front after the last belt job. This would explain the witness marks on the gears.

The only thing I can think of is that the stand-off on the Laso pump castings is 'too short.' But, that doesn't make any sense, since someone prior to me would surely have noticed this? I measured the old Laso pump at 34.5mm (block sealing surface to face of stand-off) and the new Laso seems about the same; it's hard to get a good measurement with the pump attached.

Does anyone have a REALLY old Porsche OE pump from a pre-87? Can you measure the distance from the block sealing surface to the face of the stand-off?

Does anyone have an idea of WTF is going on here? Anyone BTDT?

I did scan through Roger's epic tome on this subject: Timing Belt Wear Question Completed 2-18-07 but it seems that the actual problem was never found. Roger just upgraded to an early-87-spec system. That's a less-desirable option - for the owner - than a) figuring out the issue and/or b) Porkenizing it.

TIA!

Last edited by worf928; 09-08-2013 at 01:34 PM. Reason: Add solution

#2

Rennlist Member

Is the idle roller on the pivot the correct part? There are three different versions from '83-'86. That's the only thing I can think that might be causing the incorrect position.

Mike

Mike

#3

Team Owner

I think before you measure the belt/tensioner bearing,

you need to install the upper IDLER bearing behind the pivot bolt,

this will move the tensioner arm out about 1.5 MM ,

then things should look good.

On an old pump I get

21MM pump gasket surface to the seat of the idler bearing seat ,

and the gasket surface to the tip of the idler shaft 34.5mm

you need to install the upper IDLER bearing behind the pivot bolt,

this will move the tensioner arm out about 1.5 MM ,

then things should look good.

On an old pump I get

21MM pump gasket surface to the seat of the idler bearing seat ,

and the gasket surface to the tip of the idler shaft 34.5mm

#4

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Oct 2003

Location: Gone. On the Open Road

Posts: 16,329

Received 1,543 Likes

on

1,007 Posts

That last picture in the OP was of the belt system completely installed with proper belt tension on the belt. (I didn't come to the conclusion that something was messed-up after only installing half the belt parts. I had sent final tension and noticed that the belt had tracked to the front of the gears after I'd put it dead center before beginning to rotate and set tension.)

The idler roller I have cannot effect the position of the carrier arm. And thus ...

... Mike's response may be on track towards some sort of answer.

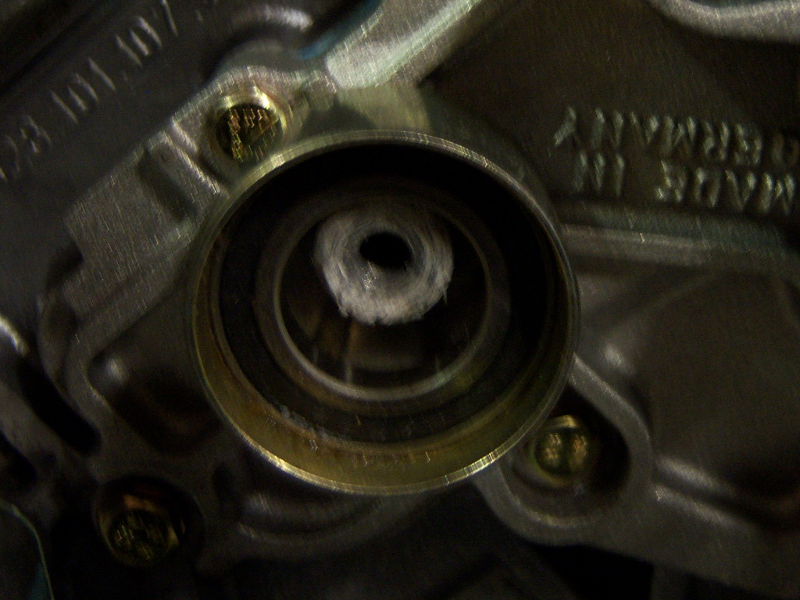

I ordered a 928 105 571 04 as shown in PET. When it arrived it was not round (damaged) and looked exactly like a S4 idler. That's because the 571 04 IS the S4 idler and it can't fit over the pump stand-off. (Actually, it fits a bit 'too well' over the stand-off.) This is a picture of what the 571 04 looks like on an old pump (sorry for the fuzzy picture):

Call me crazy, but that doesn't look like it's going to work too well.

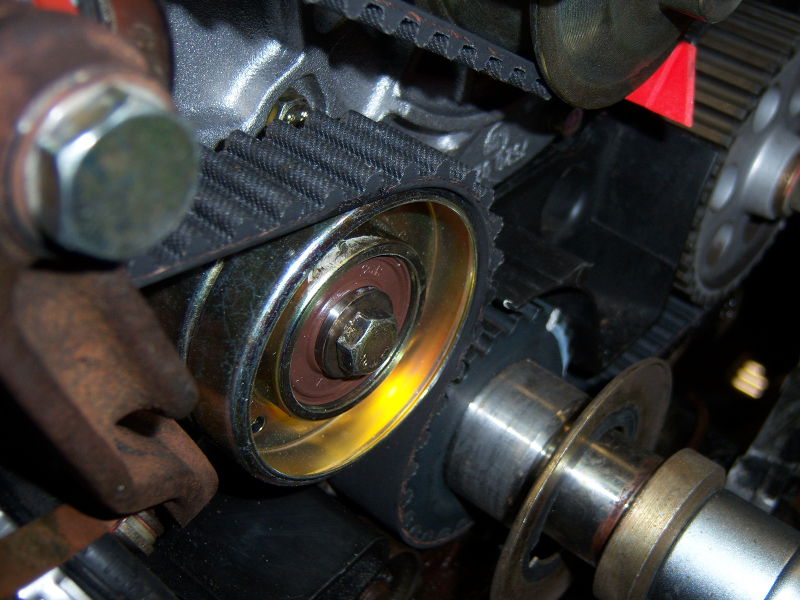

So, since the 04 was bent - and wasn't going to work even if it was round - I returned it and got a 571 02 (same M28/43-44 engine right?). This is what the 02 looks like installed:

As far as I can see this 02 roller cannot effect the position of the roller carrier arm. It's flush to the face of the pump's stand-off.

If Stan's right, then there is an idler out there that fits on an old pre-S4 pump and does effect the position of the carrier on an 86 (or 86.5.) However, it's not an 04 or 02.

Anyone got a picture of this idler? Or a part number?

I'm beginning to wonder if the idler for the '86 (or 86.5) was unique, was mis-keyed into the parts database at Porsche, and has now joined the Dodo bird. That would explain why Roger (see thread link above) gave up and converted to the S4 system.

What now?

this will move the tensioner arm out about 1.5 MM ,

I ordered a 928 105 571 04 as shown in PET. When it arrived it was not round (damaged) and looked exactly like a S4 idler. That's because the 571 04 IS the S4 idler and it can't fit over the pump stand-off. (Actually, it fits a bit 'too well' over the stand-off.) This is a picture of what the 571 04 looks like on an old pump (sorry for the fuzzy picture):

Call me crazy, but that doesn't look like it's going to work too well.

So, since the 04 was bent - and wasn't going to work even if it was round - I returned it and got a 571 02 (same M28/43-44 engine right?). This is what the 02 looks like installed:

As far as I can see this 02 roller cannot effect the position of the roller carrier arm. It's flush to the face of the pump's stand-off.

If Stan's right, then there is an idler out there that fits on an old pre-S4 pump and does effect the position of the carrier on an 86 (or 86.5.) However, it's not an 04 or 02.

Anyone got a picture of this idler? Or a part number?

I'm beginning to wonder if the idler for the '86 (or 86.5) was unique, was mis-keyed into the parts database at Porsche, and has now joined the Dodo bird. That would explain why Roger (see thread link above) gave up and converted to the S4 system.

What now?

#6

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Oct 2003

Location: Gone. On the Open Road

Posts: 16,329

Received 1,543 Likes

on

1,007 Posts

I've considered that. But, that shoulder bolt is a known weakness of the older style tensioning system. If I shim the bolt to move the carrier out, it will make the bolt weakness even weaker because there will be ~20% fewer threads in the water pump. I'm not willing to bet someone's 928 engine on that.

Now, if I could source a shoulder bolt with a few extra mm of thread then I would consider that and a shim. But, the interwebs were not helpful in finding metric hex-head shoulder bolts.

Furthermore, I really want to pursue the right solution as opposed to a make-do solution.

Now, if I could source a shoulder bolt with a few extra mm of thread then I would consider that and a shim. But, the interwebs were not helpful in finding metric hex-head shoulder bolts.

Furthermore, I really want to pursue the right solution as opposed to a make-do solution.

Trending Topics

#8

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Oct 2003

Location: Gone. On the Open Road

Posts: 16,329

Received 1,543 Likes

on

1,007 Posts

#9

Team Owner

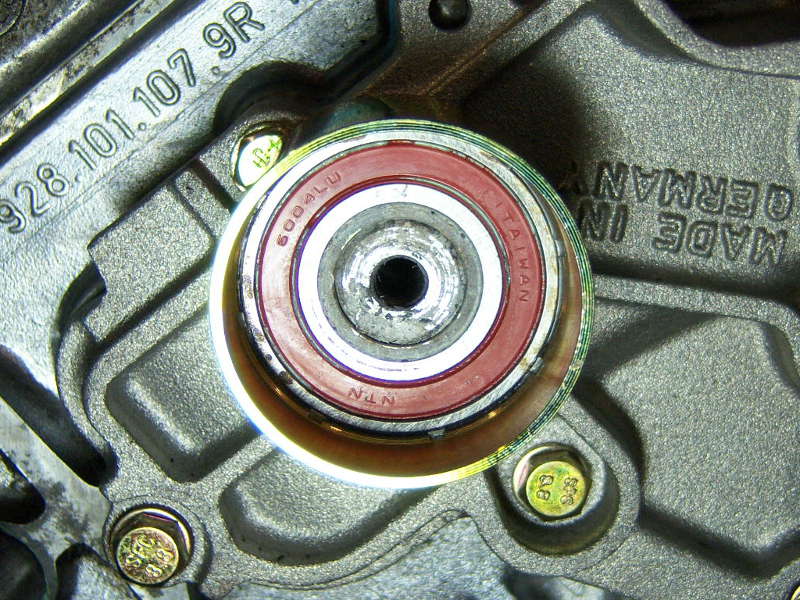

here is what I am working with this bearing looks a bit different,

and after fitting it it sits proud of the standoff by .045 MM

not the original 1.5mm I reported earlier

and after fitting it it sits proud of the standoff by .045 MM

not the original 1.5mm I reported earlier

#10

Rennlist Member

Could the sleeves in the pivot arm be incorrect? There are two part numbers in the "83-'86 PET for this part. The early part is called a bush and the '85&up part is called a bearing sleeve. Should the tensioner arm have some front to rear float on the pivot bolt? Perhaps the arm is allowed to float slightly fore and aft such that it naturally self-centers with the tension roller? If the wrong bush/bearing is installed in the pivot could it eliminate this desired float and fix the position of the arm too far aft? I'm not very familiar with the factory tensioning system as I put Ken's system on at my first belt change.

Mike

Mike

#11

Rennlist Member

Dave, the Porsche pump we removed from my 84 euro measures 34.0 mating surface to standoff. Not sure if same pump for 86.5.

#12

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Oct 2003

Location: Gone. On the Open Road

Posts: 16,329

Received 1,543 Likes

on

1,007 Posts

A bit different is an understatement. What's that idlers lineage? Is it Porsche? 86.5 OE? Etc.

That ain't hardly enough to solve my problem.

What's the deal with that pump and idler? Is it from an 86.5?

Anything is possible. The bushings I have are those shown in pet for the M28.43/44 motor and are IIRC the same as those for S4s.

Nope. It needs to keep the belt centered on the tension roller. The roller is wide enough to keep the belt on it regardless of where the belt tracks due to causes OTHER than a mis-aligned-from-the-start roller.

and after fitting it it sits proud of the standoff by .045 MM

not the original 1.5mm I reported earlier

not the original 1.5mm I reported earlier

What's the deal with that pump and idler? Is it from an 86.5?

Should the tensioner arm have some front to rear float on the pivot bolt?

#13

Inventor

Rennlist Member

Rennlist Member

Plan B.

Pull the pin. Done. "See you in five years."

Pull the pin. Done. "See you in five years."

#14

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Oct 2003

Location: Gone. On the Open Road

Posts: 16,329

Received 1,543 Likes

on

1,007 Posts

Unless there are any brainstorms on this issue, I think my next step is to assume that nothing about the belt system is correct and start checking part and casting numbers on everything against PET.

The pump measurements Stan and BB have provided show that there's nothing obviously "off" about the pump. Since the essential problem is that the main tension roller is ~4mm too far from the block means that it has to be a carrier arm, idler, or main roller issue of some sort.

PET shows that the main tensioner roller is the same for all 928s. The new one I have looks just like the old one and seems just like every other one I've ever pulled off. I've got several old ones to compare with.

If the carrier arm is 'wrong' how did it ever work? Or how/why was the 'right' one swapped for the 'wrong' one?

The pump measurements Stan and BB have provided show that there's nothing obviously "off" about the pump. Since the essential problem is that the main tension roller is ~4mm too far from the block means that it has to be a carrier arm, idler, or main roller issue of some sort.

PET shows that the main tensioner roller is the same for all 928s. The new one I have looks just like the old one and seems just like every other one I've ever pulled off. I've got several old ones to compare with.

If the carrier arm is 'wrong' how did it ever work? Or how/why was the 'right' one swapped for the 'wrong' one?

#15

Team Owner

maybe the tensioner is also the wrong part or are new parts that were not correct.

To answer a few of the questions you had about the parts I was showing they should be from a 1983 Euro the pumps are the same,

and the bearing is a bit different but not enough to matter.

I can go dig out a few different tensioner arms to see if any have differences.

Does the car your working on have a belt tension light as it has the brass ground strap for the alarm

To answer a few of the questions you had about the parts I was showing they should be from a 1983 Euro the pumps are the same,

and the bearing is a bit different but not enough to matter.

I can go dig out a few different tensioner arms to see if any have differences.

Does the car your working on have a belt tension light as it has the brass ground strap for the alarm