86.5 Timing Belt / WP Mystery - Collective Wisdom Appreciated

#16

Team Owner

what does the old tensioner roller look like IE how was it wearing is there an unused portion on the inner edge?

#17

Rennlist Member

Is the distance from the top and bottom edges of the tensioner pulley to co-planar reference point (pump flange, block, etc.) the same? Just trying to determine if the issue is that the entire tensioner arm is out of position or just the pulley.

Is the amount of mis-tracking consistent around all the sprockets/pulleys or just the tensioner pulley?

Mike

Is the amount of mis-tracking consistent around all the sprockets/pulleys or just the tensioner pulley?

Mike

#18

Rennlist Member

The plastic bushings changed in 85.

The tensioner arm itself changed sometime in 86. (from the 1986 Service Info Tech book).

Possibly too the console.

Taking part number inventory makes sense.

The tensioner arm itself changed sometime in 86. (from the 1986 Service Info Tech book).

Possibly too the console.

Taking part number inventory makes sense.

Last edited by Landseer; 09-04-2013 at 01:28 AM.

#20

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Oct 2003

Location: Gone. On the Open Road

Posts: 16,329

Received 1,543 Likes

on

1,007 Posts

An incorrect tensioner arm aka roller carrier I can go with. And, I could also believe that the tensioner is the wrong part too. BUT, I do not see how an incorrect tensioner could cause the problem I'm most concerned about and shown in the third picture of the OP.

Help me out here, either I'm not communicating or I'm missing something.

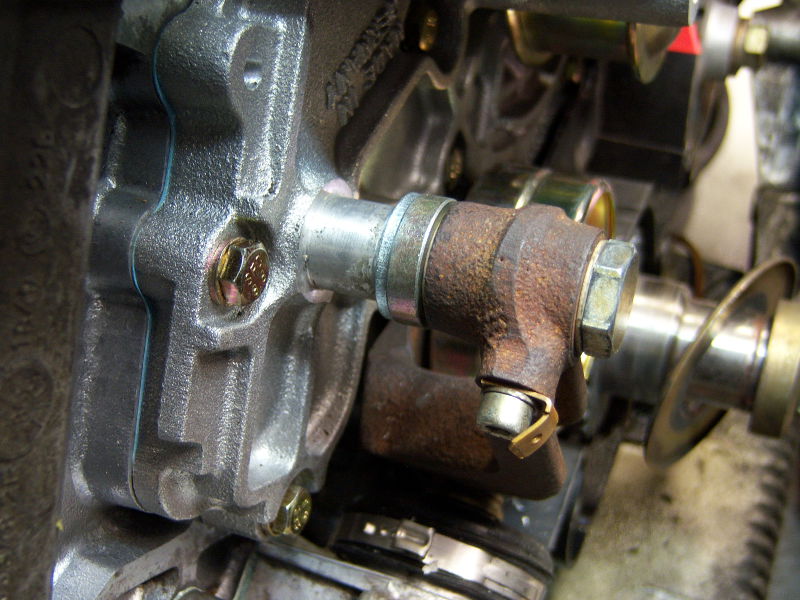

That third picture shows that the main roller is not (center-line to center-line) on the same plane with the crank gear. The leading face of the main roller is actually slightly to the rear of the crank gear face and that's why you see the leading edge of the belt hanging-off the main roller. If I take the tensioner completely off the block or if I put the carrier with the main roller on the block without the belt the position of the main roller is the same: it's 'behind' the crank gear. I've already done the latter and that's in the second picture of the OP. So, no tensioner involved; it's not touching the carrier in that picture.

I can't for the life of me see how any tensioner could "move" the roller forward and center it with the crank gear. Certainly, a wrong tensioner could 'cause' the first picture if the main roller center was aligned with the center of the crank gear and the tensioner pin wasn't lined-up with the cup in the carrier. Then the tensioner would be the suspect.

Does that make logical sense?

Thanks Stan, but let's hold off until I can do some more due diligence. There's plenty of posts with pictures of the different carrier arms.

Yeah. The brass is shown in the pictures. I just have it unbolted from the carrier arm - makes it easier.

The old roller was worn all the way to the leading edge.

I'll have to go check. I'm virtually certain that the roller is correct assuming that PET is correct and that the main roller is the same for all model years. If the '86.5 had some wacky main roller then all bets are off. (heh... I could just machine a new groove into the roller for the circlip to 'push' the roller towards the front and be done with it.)

The belt is tracking at the leading edge of both cam gears. It's touching (or almost damn-near touching) the leading lip of the water pump pulley. I have to wonder if the water pump pulley is the only thing keeping the belt from walking-off the cam gears. It's aligned with the crank and oil pump gear.

The tracking of the belt on the forward edge of the cam gears I can live with. I would not be worried about it since it is consistent IF the belt didn't hang-off the main roller as shown in the third picture of the OP. That's what bothers me.

Tensioner arm == carrier arm == tensioning roller console == roller carrier (as far as I have been using those terms.)

So the carrier arm and tensioner changed in '86. Makes sense. You can't change where the 'cup' in the arm is located without also changing something about the tensioner (Tensioning Roller Housing.)

I will take a closer look at the carrier arm the next time I get a chance to spend some time in the garage on this.

Thanks guys.

Yeah. I've made you a few bucks richer. One of your contraptions will be here in a few days and is the backup plan if a solution for using the OE system does not present itself. (And if a solution does present, the PKT will go on one of mine at some point.)

I waiting for a bunch of 86.5 guys to jump in here and post that their belt has been hanging off the main roller for years and years and years.

Help me out here, either I'm not communicating or I'm missing something.

That third picture shows that the main roller is not (center-line to center-line) on the same plane with the crank gear. The leading face of the main roller is actually slightly to the rear of the crank gear face and that's why you see the leading edge of the belt hanging-off the main roller. If I take the tensioner completely off the block or if I put the carrier with the main roller on the block without the belt the position of the main roller is the same: it's 'behind' the crank gear. I've already done the latter and that's in the second picture of the OP. So, no tensioner involved; it's not touching the carrier in that picture.

I can't for the life of me see how any tensioner could "move" the roller forward and center it with the crank gear. Certainly, a wrong tensioner could 'cause' the first picture if the main roller center was aligned with the center of the crank gear and the tensioner pin wasn't lined-up with the cup in the carrier. Then the tensioner would be the suspect.

Does that make logical sense?

Does the car your working on have a belt tension light as it has the brass ground strap for the alarm

Is the amount of mis-tracking consistent around all the sprockets/pulleys or just the tensioner pulley?

The tracking of the belt on the forward edge of the cam gears I can live with. I would not be worried about it since it is consistent IF the belt didn't hang-off the main roller as shown in the third picture of the OP. That's what bothers me.

So the carrier arm and tensioner changed in '86. Makes sense. You can't change where the 'cup' in the arm is located without also changing something about the tensioner (Tensioning Roller Housing.)

I will take a closer look at the carrier arm the next time I get a chance to spend some time in the garage on this.

Thanks guys.

Yeah. I've made you a few bucks richer. One of your contraptions will be here in a few days and is the backup plan if a solution for using the OE system does not present itself. (And if a solution does present, the PKT will go on one of mine at some point.)

I waiting for a bunch of 86.5 guys to jump in here and post that their belt has been hanging off the main roller for years and years and years.

#21

Team Owner

I looked at the some of the old tension rollers I have and a few of them have an unworn rear edge if you like I can take some pictures,

optimum of course is that the belt is fully running on the roller surface, but most of the rollers i have removed are with the rear edge unworn . the only glitch with what i just said is that i found opne roller that was completely worn on its whole surface..

Yes your correct the tensioner wouldnt have anything to do with moving the arm, though maybe the arm has been swapped.

optimum of course is that the belt is fully running on the roller surface, but most of the rollers i have removed are with the rear edge unworn . the only glitch with what i just said is that i found opne roller that was completely worn on its whole surface..

Yes your correct the tensioner wouldnt have anything to do with moving the arm, though maybe the arm has been swapped.

#22

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Oct 2003

Location: Gone. On the Open Road

Posts: 16,329

Received 1,543 Likes

on

1,007 Posts

Here's the way I'm probably going to leave it.

I put a 2.3mm thick washer along with the stock washer on the pivot bolt. This reduces the amount of pivot bolt thread from 17.4 mm to just over 15mm. I'm comfortable with that slight reduction in how much of the bolt is in the pump.

This extra washer is all that's needed to get everything to line up nicely with the belt in the middle of the roller.

That's with the belt at proper tension. The belt tracks a wee bit further towards the center of the cam gears that it did previously. It's still more-forward than centered, but it's even side-to-side.

I put a 2.3mm thick washer along with the stock washer on the pivot bolt. This reduces the amount of pivot bolt thread from 17.4 mm to just over 15mm. I'm comfortable with that slight reduction in how much of the bolt is in the pump.

This extra washer is all that's needed to get everything to line up nicely with the belt in the middle of the roller.

That's with the belt at proper tension. The belt tracks a wee bit further towards the center of the cam gears that it did previously. It's still more-forward than centered, but it's even side-to-side.

#23

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Oct 2003

Location: Gone. On the Open Road

Posts: 16,329

Received 1,543 Likes

on

1,007 Posts

Stan, the last two rollers you pictured above look to be different heights?

#24

Team Owner

I would guess that they are made by two different vendors.

the only thing to consider with the mod you have is how close the front edge of the tensioner roller is going to be to the back of the damper worth a check

the only thing to consider with the mod you have is how close the front edge of the tensioner roller is going to be to the back of the damper worth a check

#26

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Oct 2003

Location: Gone. On the Open Road

Posts: 16,329

Received 1,543 Likes

on

1,007 Posts

It looks like the 'taller' roller is the one I needed...

I do plan to fit the center cover and balancer before declaring victory. However, I will be shocked if they don't fit. The tensioner roller is right where it usually is - for every other 928 I've ever done.

I am, though, not happy about not finding anything like a root cause.

the only thing to consider with the mod you have is how close the front edge of the tensioner roller is going to be to the back of the damper worth a check

I am, though, not happy about not finding anything like a root cause.

#27

Team Owner

what did your old tensioner roller look like was one edge unworn like the ones I posted?

#28

Rennlist Member

With the later tensioner arm as shown in the clip from the MY86 Tech info book, that mod also changed the bottom cover to have a bulge where the arm comes close to the cover. ALso, I believe it was at this time that the dipstick assembly was made longer and bent to clear the new cover.

Which combo of cover and dipstick does this car have ?

Which combo of cover and dipstick does this car have ?

#29

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Oct 2003

Location: Gone. On the Open Road

Posts: 16,329

Received 1,543 Likes

on

1,007 Posts

I've done some simple math this morning...

Assuming the carrier arm is not bent what deflection angle below horizontal would result in a 2.3mm offset (thickness of the extra washer) of the main roller?

The answer is 1.01░ (*)

I don't know about the general population of Rennlist Wrenches, but I'm pretty sure I'm not going to be able to detect a 1░ bend in the pivot bolt without the aid of measurement equipment or by screwing an extension on it.

(*) I did the harder problem of assuming that the "rotation point" was offset from the "length axis" of the carrier arm. But, a simple (approximate) calculation assuming that the point of rotation is on the axis is TAN(angleR) * Carrier Arm Length, where angleR is the deflection angle in radians. Both calculations result in the same answer to the first two decimal places since the "rotation point" is offset from the length axis by 5 - 7 mm. I measured the carrier length at ~130mm. (The simple calculation only works if the angle is very small and the carrier long.)

So.... I'm thinking that

- a) I bent the pivot bolt the first time I put tension on the bolt or that it wasn't straight to start with or the boss on the new pump could be off by a wee bit. Probably the former and with the small angle required, I'm not going to see the bend easily.

- b) it is not surprising to see the main tensioner roller not lined up with the belt on the pre-87 belt systems. Actually, since the deflection angle required to move a 130mm lever arm by a few mm is so small, it's a wonder I see any belts lined up on main rollers.

- c) I really do not like the pre-87.5 system (without the pivot bolt support.)

Yes. But, at this point I may have lost track of which main roller came off of this one.

I'm going to take two steps back on this, remove the carrier again, and see if I can verify an ever-so-slightly bent pivot bolt. If I haven't lost track of the old pivot bolt, I'll check it too.

Assuming the carrier arm is not bent what deflection angle below horizontal would result in a 2.3mm offset (thickness of the extra washer) of the main roller?

The answer is 1.01░ (*)

I don't know about the general population of Rennlist Wrenches, but I'm pretty sure I'm not going to be able to detect a 1░ bend in the pivot bolt without the aid of measurement equipment or by screwing an extension on it.

(*) I did the harder problem of assuming that the "rotation point" was offset from the "length axis" of the carrier arm. But, a simple (approximate) calculation assuming that the point of rotation is on the axis is TAN(angleR) * Carrier Arm Length, where angleR is the deflection angle in radians. Both calculations result in the same answer to the first two decimal places since the "rotation point" is offset from the length axis by 5 - 7 mm. I measured the carrier length at ~130mm. (The simple calculation only works if the angle is very small and the carrier long.)

So.... I'm thinking that

- a) I bent the pivot bolt the first time I put tension on the bolt or that it wasn't straight to start with or the boss on the new pump could be off by a wee bit. Probably the former and with the small angle required, I'm not going to see the bend easily.

- b) it is not surprising to see the main tensioner roller not lined up with the belt on the pre-87 belt systems. Actually, since the deflection angle required to move a 130mm lever arm by a few mm is so small, it's a wonder I see any belts lined up on main rollers.

- c) I really do not like the pre-87.5 system (without the pivot bolt support.)

I'm going to take two steps back on this, remove the carrier again, and see if I can verify an ever-so-slightly bent pivot bolt. If I haven't lost track of the old pivot bolt, I'll check it too.

#30

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: Oct 2003

Location: Gone. On the Open Road

Posts: 16,329

Received 1,543 Likes

on

1,007 Posts

Verdict is in: new pivot bolt is in fact slightly bent. So is the old pivot bolt, but not as much as the new one.

I put the carrier arm with pivot bolt in a vice. I screwed a die on to the end of the bolt to exaggerate any eccentric movement and then turned the bolt with an air ratchet (new bushings make it tough to turn.)

I put the carrier arm with pivot bolt in a vice. I screwed a die on to the end of the bolt to exaggerate any eccentric movement and then turned the bolt with an air ratchet (new bushings make it tough to turn.)