Clutch adjustment on 2 plate'ers

#1

Rennlist Member

Thread Starter

Has anyone had a dragging clutch (very hard to get into 1st and reverse and all shiifting is bad unless the clutch pedal is to the floor?

It happened after the pressure plate change, but i guess anything is possible.

I think i understand, basically, how to do it, but what keeps the adjustment in place. You just take a flathead screwdriver and just move the pressure plate from the "stop" ? sounds easy, but what keeps the adjustment in place? is it a friction adjustment? How does it move around? Or, if it is adjusted, does it just stay in place?

Thanks,

Mk

It happened after the pressure plate change, but i guess anything is possible.

I think i understand, basically, how to do it, but what keeps the adjustment in place. You just take a flathead screwdriver and just move the pressure plate from the "stop" ? sounds easy, but what keeps the adjustment in place? is it a friction adjustment? How does it move around? Or, if it is adjusted, does it just stay in place?

Thanks,

Mk

#2

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Some go by the "move it all they back (or forward, cannot remember)" and let the plate adjust itself. This has never worked on the four cars I've tried it on.

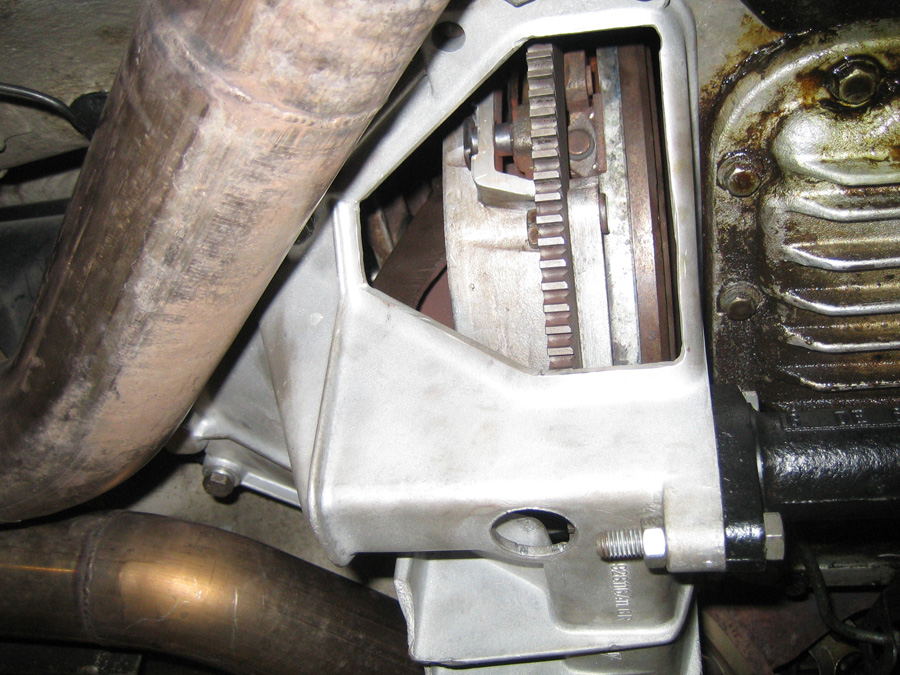

I have a lower bellhousing with a hole cut in it to adjust mine. With someone pushing the clutch pedal to the floor, I move the three T-adjusters to center the intermediate plate between the clutch discs. This method had worked many times on a few different cars (from 79-86).

Unless you intermediate disc is worn out and it's floating around. Then all bets are off

EDIT - MARK, I PUT THE SECTION IN BOLD YOU MISSED THE FIRST TIME AROUND

I have a lower bellhousing with a hole cut in it to adjust mine. With someone pushing the clutch pedal to the floor, I move the three T-adjusters to center the intermediate plate between the clutch discs. This method had worked many times on a few different cars (from 79-86).

Unless you intermediate disc is worn out and it's floating around. Then all bets are off

EDIT - MARK, I PUT THE SECTION IN BOLD YOU MISSED THE FIRST TIME AROUND

Last edited by hacker-pschorr; 09-25-2008 at 01:44 PM.

#3

Rennlist Member

Thread Starter

worn out and floating around, what does that look like? what wears out? the disc surface looks great, but i guess i never looked much at the intermediate plate to see how it works. I just thought it was in the middle and when the clutch was engaged, it just floated with nothign pressing on it front or back.

do you have a picture of the adjustment? I see the drawing, but cant picture what is being done.

How do I know if mine is " worn out"? a picture of the adjustment window would be GREAT! Ill just cut the hole to begin with, and scot can use this two as he is having the same issue, except worse. I could probably still race it like this, but im probably putting unnatural stress on those BEAUTIFUL Borg Warner synchros and i dont want my gear box to end up feeling like my old 84!

do you have a picture of the adjustment? I see the drawing, but cant picture what is being done.

How do I know if mine is " worn out"? a picture of the adjustment window would be GREAT! Ill just cut the hole to begin with, and scot can use this two as he is having the same issue, except worse. I could probably still race it like this, but im probably putting unnatural stress on those BEAUTIFUL Borg Warner synchros and i dont want my gear box to end up feeling like my old 84!

#4

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

The three T-adjusters wear out allowing the center disc to float back and forth causing the clutch to hang up.

Some have drilled out the friction adjusters in favor of a nut / bolt. Needs to be very shallow or it will rub. Only problem with this method is you lose the "self adjusting" as the discs wear out. Might be a non issue but worth noting.

Some have drilled out the friction adjusters in favor of a nut / bolt. Needs to be very shallow or it will rub. Only problem with this method is you lose the "self adjusting" as the discs wear out. Might be a non issue but worth noting.

#5

Rennlist Member

Thread Starter

I think i get what you are saying! It would be nice to see some pics of this other than what is in the WSMs. especially your inspection hole that you made!

thanks

MK

thanks

MK

The three T-adjusters wear out allowing the center disc to float back and forth causing the clutch to hang up.

Some have drilled out the friction adjusters in favor of a nut / bolt. Needs to be very shallow or it will rub. Only problem with this method is you lose the "self adjusting" as the discs wear out. Might be a non issue but worth noting.

Some have drilled out the friction adjusters in favor of a nut / bolt. Needs to be very shallow or it will rub. Only problem with this method is you lose the "self adjusting" as the discs wear out. Might be a non issue but worth noting.

#6

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

#7

Yep..the extra strength pressure plate has the unique ability to expose a weak intermediate plate....No matter how much you adjust the intermediate plate, it will just get pushed out of whack...

You may need to get a new one (pricey)..or I believe someone on here actually was able to strengthen the intermediate plate holding tabs??...do a search..I think it was a year ago or so that I ran across it..

Good Luck,

You may need to get a new one (pricey)..or I believe someone on here actually was able to strengthen the intermediate plate holding tabs??...do a search..I think it was a year ago or so that I ran across it..

Good Luck,

Trending Topics

#8

Nordschleife Master

Mark, I will echo Eric's comments that you have to manually place the tabs for the intermediate plate.

However I would also verify that your clutch is fully bled, and that there is no issues with the hydraulics.

How I check the clutch is to use a large screwdriver and actuate the clutch arm manually while being able to look at the intermediate plate and verify that it is letting both discs spin freely. if it is. then the hydrualics are your issue.

However I would also verify that your clutch is fully bled, and that there is no issues with the hydraulics.

How I check the clutch is to use a large screwdriver and actuate the clutch arm manually while being able to look at the intermediate plate and verify that it is letting both discs spin freely. if it is. then the hydrualics are your issue.

#9

Rennlist Member

Thread Starter

Great picture. Now, THATS A HOLE! does it really need to be so large?

I have a 79 pressure plate and i was playing around with the friction adjusters. its pretty simple.

my worry now is that its not out of adustement, but being man-handled by the new pressure plate as Tom says, but i dont really know how that would change things.

I dont really see the gap you need to keep at 1.5mm. I can see that you can put a screwdriver in the gap between the adjuster and the intermediate plate . (two parallel surfaces one being rusty and the other being shiney on the intermediate plate ). however , if you push the adjuster out too far, can you wedge it back with the screwdriver against the pressure plate surface?

mk

I have a 79 pressure plate and i was playing around with the friction adjusters. its pretty simple.

my worry now is that its not out of adustement, but being man-handled by the new pressure plate as Tom says, but i dont really know how that would change things.

I dont really see the gap you need to keep at 1.5mm. I can see that you can put a screwdriver in the gap between the adjuster and the intermediate plate . (two parallel surfaces one being rusty and the other being shiney on the intermediate plate ). however , if you push the adjuster out too far, can you wedge it back with the screwdriver against the pressure plate surface?

mk

#10

#11

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

My clutch problem was so bad when this was made, I had my clutch pack in / out about 15 times in one afternoon. So swapping covers is a walk in the park now.

#12

Team Owner

you might be headed for the.... remove the rivet and use a fastener, a few times I have adjusted these fingers and they work great on the lift then after a few miles the clutch starts to drag due to the fingers moving, the rivet and finger assembly isnt the best as with old age and corrosion the parts wont hold their position like they were designed to do. Even adding a new inter plate isnt any guarantee of it working correctly, as a new plate I installed was also having the same problems

#13

Rennlist Member

Thread Starter

the intermediate plate is in pretty new looking shape. It has never been adjusted as i didnt even know what that procedure was all about. Now, after learning about it and practicing on a used intermediate plate, it looks pretty simple. a much smaller hole could be made to do this job and the screwed back on or RTV'ed. anyway, do you just wedge a screwdriver on to that "fork" and twist or lever until it moves back toward the pressure plate? If so, there will then be a small space to measure 1-2mm or so. at that point, the manual guarantees its adjusted properly. does it self adjust back as it needs to, otherwise, why not just weld the darn adjusters in that position?

mk

mk

#14

Team Owner

Mark there is a detailed proceedure in the WSM for inter plate adjusting

#15

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member