928 crank issue with scot's rebuild / QUESTION to the gurus

#1

Rennlist Member

Thread Starter

WE are all set for the rebuld process to begin. started with replacing the burned rods and an entire new set of bearings as well as a new crank.

As ive mentioned, we are using a 4.7 euro block M28/11 however, the replacement crank has much larger oiling holes on the rod journals than the crank on the car that was damaged, and when we rotate it in the block before we put on the bock girtle, the crank rotates only 180 degrees and jams. pretty hard too. we have to lift the crank out of the bearings to turn, and then it does it again. just to make sure it wasnt a bearing problem, put in the old thrust bearing center bearing, and same thing happens. next, remove the center main bearing and just have the other 4 bearings and no problem, it spins fine.

So, my question, is there much of a difference between the older cranks?? the replacement crank also has the same size oiling holes on the rod journals as the main bearing journals, whereas the original crank has smaller holes on the rod journals vs the mains.

anyone heard of cranks that will not work in another engine?

do all the cranks for the pre 5 liter, work on all engines. ive read in the manuals that they all have the same weight pistons and rods. spec is 720g +/- 3 grams, and we are seeing 730-732g on the two pistons we pulled . it is a one size oversized, but i thought even the oversized pistons were suppose to weigh the same. the rods were within a gram of each other at 458g each. Im thinking that the next crank we get may not be balanced for this piston rod combo and it may be worth the $150 or so to get it all balanced. comments.

we may have to try another crank next week.

Looks like scot will be missing the next race this month . oh well, we will have it running by June for him!

MK

As ive mentioned, we are using a 4.7 euro block M28/11 however, the replacement crank has much larger oiling holes on the rod journals than the crank on the car that was damaged, and when we rotate it in the block before we put on the bock girtle, the crank rotates only 180 degrees and jams. pretty hard too. we have to lift the crank out of the bearings to turn, and then it does it again. just to make sure it wasnt a bearing problem, put in the old thrust bearing center bearing, and same thing happens. next, remove the center main bearing and just have the other 4 bearings and no problem, it spins fine.

So, my question, is there much of a difference between the older cranks?? the replacement crank also has the same size oiling holes on the rod journals as the main bearing journals, whereas the original crank has smaller holes on the rod journals vs the mains.

anyone heard of cranks that will not work in another engine?

do all the cranks for the pre 5 liter, work on all engines. ive read in the manuals that they all have the same weight pistons and rods. spec is 720g +/- 3 grams, and we are seeing 730-732g on the two pistons we pulled . it is a one size oversized, but i thought even the oversized pistons were suppose to weigh the same. the rods were within a gram of each other at 458g each. Im thinking that the next crank we get may not be balanced for this piston rod combo and it may be worth the $150 or so to get it all balanced. comments.

we may have to try another crank next week.

Looks like scot will be missing the next race this month . oh well, we will have it running by June for him!

MK

#2

Addict

Rennlist Member

Rennlist Member

What causes jaming? Have seen one 951 engine where crank was ever so slightly bent that it rotated easily some 2/3 of 360 and then stuck really hard. This was also when lower graddle was removed. Crank had clearly visible damage made by lower half of connecting rod when rod snapped in two because of over boost caused by stuck (what exactly it's called ?) dump valve.

You might try to take one main bearing out at a time and then rotate crank. Four others should be enough to support it and if crank is bend you might find out from where exacly. It doesn't take much to cause it to stick. What you really need to do is establish that crack is straight. This can be done by building wooden fixture, rotating crank in it and measuring main bearing surface roundness with normal dial indicator.

I can't remembers exactly when it happend but I think oil channels were enlarged some time during S model production. Perhaps unsuccessful attempt from Porsche to fix oiling problems? Anyway, larger journals shouldn't affect it's rotation as all critical measurements should still be same. Extra 10g on pistons could be rings or lock rings if you had them on scale and factory number do not include them.

According to owner 951 engine was still running and shut off from key.

You might try to take one main bearing out at a time and then rotate crank. Four others should be enough to support it and if crank is bend you might find out from where exacly. It doesn't take much to cause it to stick. What you really need to do is establish that crack is straight. This can be done by building wooden fixture, rotating crank in it and measuring main bearing surface roundness with normal dial indicator.

I can't remembers exactly when it happend but I think oil channels were enlarged some time during S model production. Perhaps unsuccessful attempt from Porsche to fix oiling problems? Anyway, larger journals shouldn't affect it's rotation as all critical measurements should still be same. Extra 10g on pistons could be rings or lock rings if you had them on scale and factory number do not include them.

According to owner 951 engine was still running and shut off from key.

#3

Three Wheelin'

I second that thought. Sounds like a bent crank or possibly a block that needs align boring. But I don't think they make oversize bearings for 928's with that problem.

#5

Rennlist Member

I have a 4.7 Euro engine sans the heads and intake left over from my 5.0 Euro hybrid project. It is almost perfect. There is a broken piece off the block where the alternator bracket bolts on. I have the broken piece. I've been told it is repairable. It's just gathering dust at my shop.

#6

Rennlist Member

Thread Starter

HI Vihuer,

Thanks for the information. that was some 951 failure!

I was somewhat in denial thinking, " how can a strong crank like a 928 crank, have a problem, as it looks fine". there is a area near the center thrust main bearing that looks like it could have been hot.

I did some of the tests, spun the crank fine without the center main bearing. both new and old cranks spin fine. once the center main is installed, the crank in question sticks and sticks pretty firm. i mean, its jammed until you life the crank out 1/2 ". then rotates again, but only 180 degrees and then it sticks again. it almost looks as though the counterweights that run so close to the sides of the center main bearing, that its its got a wobble and sticks to the side of the bearing. like i said, the old crank spins no problem.

the digital caliper tells us the journal sizes on both cranks are the same, so i suspect the block wasnt touched in that area, however, the engine is using oversized pistons (ie 4.7 97.465mm )

i think just trying another crank may prove the issue.

Nice catch about the pistons WITH the rings being 10grams heavier. that makes sense.

now, we have to scrap off that Yamabond we so perfectly laid down to put the block together.

too bad, we were trying to stay on schedule to get scot back on the track by the 2nd. so far, we spent 12 hours getting the engine out and on a stand. and i forcast 12 more hours to get the engine back together and back in the car! saturday's schedule was for putting the pistons on and a couple rounds of tightening on the heads!!!

mk

[QUOTE=Vilhuer]What causes jaming? Have seen one 951 engine where crank was ever so slightly bent that it rotated easily some 2/3 of 360 and then stuck really hard. This was also when lower graddle was removed. Crank had clearly visible damage made by lower half of connecting rod when rod snapped in two because of over boost caused by stuck (what exactly it's called ?) dump valve.

You might try to take one main bearing out at a time and then rotate crank. Four others should be enough to support it and if crank is bend you might find out from where exacly. It doesn't take much to cause it to stick. What you really need to do is establish that crack is straight. This can be done by building wooden fixture, rotating crank in it and measuring main bearing surface roundness with normal dial indicator.

I can't remembers exactly when it happend but I think oil channels were enlarged some time during S model production. Perhaps unsuccessful attempt from Porsche to fix oiling problems? Anyway, larger journals shouldn't affect it's rotation as all critical measurements should still be same. Extra 10g on pistons could be rings or lock rings if you had them on scale and factory number do not include them.

According to owner 951 engine was still running and shut off from key.

[IMG]QUOTE]

Thanks for the information. that was some 951 failure!

I was somewhat in denial thinking, " how can a strong crank like a 928 crank, have a problem, as it looks fine". there is a area near the center thrust main bearing that looks like it could have been hot.

I did some of the tests, spun the crank fine without the center main bearing. both new and old cranks spin fine. once the center main is installed, the crank in question sticks and sticks pretty firm. i mean, its jammed until you life the crank out 1/2 ". then rotates again, but only 180 degrees and then it sticks again. it almost looks as though the counterweights that run so close to the sides of the center main bearing, that its its got a wobble and sticks to the side of the bearing. like i said, the old crank spins no problem.

the digital caliper tells us the journal sizes on both cranks are the same, so i suspect the block wasnt touched in that area, however, the engine is using oversized pistons (ie 4.7 97.465mm )

i think just trying another crank may prove the issue.

Nice catch about the pistons WITH the rings being 10grams heavier. that makes sense.

now, we have to scrap off that Yamabond we so perfectly laid down to put the block together.

too bad, we were trying to stay on schedule to get scot back on the track by the 2nd. so far, we spent 12 hours getting the engine out and on a stand. and i forcast 12 more hours to get the engine back together and back in the car! saturday's schedule was for putting the pistons on and a couple rounds of tightening on the heads!!!

mk

[QUOTE=Vilhuer]What causes jaming? Have seen one 951 engine where crank was ever so slightly bent that it rotated easily some 2/3 of 360 and then stuck really hard. This was also when lower graddle was removed. Crank had clearly visible damage made by lower half of connecting rod when rod snapped in two because of over boost caused by stuck (what exactly it's called ?) dump valve.

You might try to take one main bearing out at a time and then rotate crank. Four others should be enough to support it and if crank is bend you might find out from where exacly. It doesn't take much to cause it to stick. What you really need to do is establish that crack is straight. This can be done by building wooden fixture, rotating crank in it and measuring main bearing surface roundness with normal dial indicator.

I can't remembers exactly when it happend but I think oil channels were enlarged some time during S model production. Perhaps unsuccessful attempt from Porsche to fix oiling problems? Anyway, larger journals shouldn't affect it's rotation as all critical measurements should still be same. Extra 10g on pistons could be rings or lock rings if you had them on scale and factory number do not include them.

According to owner 951 engine was still running and shut off from key.

[IMG]QUOTE]

#7

Hi Mark, I was wondering if you could verify something for me? The conrod weight has me fasinated. I have rods out of a 1987 model which are marked 944. These things weigh 850 grams each and that is without the piston pin or bearing. You have in your post that the rods weighed 458 grams, that is almost half of what mine weigh! Please before I go and spend a lot of money on these rods, I have bought new ARP 2000 series bolts for them already, can you please verify the weight?

I plan on having the rods cleaned up and balanced, this will be expensive, also Carl posted on balancing these rods and his were different again at 590 grams.

If anybody else out these knows what these rods weigh please sing out.

I know the GTS rods weighed 615 grams but these rods were quite different to any other rod used in the 928 engine.

Cheers

I plan on having the rods cleaned up and balanced, this will be expensive, also Carl posted on balancing these rods and his were different again at 590 grams.

If anybody else out these knows what these rods weigh please sing out.

I know the GTS rods weighed 615 grams but these rods were quite different to any other rod used in the 928 engine.

Cheers

Trending Topics

#8

Rennlist Member

Thread Starter

we looked a little more carefully at the crank where it was hitting and jamming. turns out , it looks as thought this crank (the new one) was balanced by someone that welded some weight near the center thrust main bearing.

its just large enough now to hit the area on the block, just below the side of the thrust main bearing. you can see from the picture , that it scribed an arc just below the center main bearing. on the crank, ive dremmeled off the material on the crank just slightly, to make the crank spin freely. you can see it on the side of the crank counter weight as its the shiny area.

we probably now will have the entire rotating assembly balanced, not that we have more time and my engine builder shop can balance it for about $150. (not that the material removed would do anything, but im worried as this crank was balanced for some other set of pistons and rods)

The next pic is one of the old original crank and the newer one. look at the oiling holes at the rod journals. they are much bigger on the new crank, and ive been told that that means this new crank could be for a later year. notice the new oiling holes on the rod journals are the same size now as they are at the mains. notice the rod bearing journal on the old crank . thats where the rod bearings were welded to the crank!! the new crank is jounals are shiny new looking, the smearing is just remainding oil and assembly lube we used to put it together, unitl we went to turn the crank and it STOPPED!!! !

Does anyone know why this crank cant work in a early M28/11 block?

If its ok, i thing we will run with it and have the rotating assembly balanced.

here are the pics. let me know what you guys think

MK

its just large enough now to hit the area on the block, just below the side of the thrust main bearing. you can see from the picture , that it scribed an arc just below the center main bearing. on the crank, ive dremmeled off the material on the crank just slightly, to make the crank spin freely. you can see it on the side of the crank counter weight as its the shiny area.

we probably now will have the entire rotating assembly balanced, not that we have more time and my engine builder shop can balance it for about $150. (not that the material removed would do anything, but im worried as this crank was balanced for some other set of pistons and rods)

The next pic is one of the old original crank and the newer one. look at the oiling holes at the rod journals. they are much bigger on the new crank, and ive been told that that means this new crank could be for a later year. notice the new oiling holes on the rod journals are the same size now as they are at the mains. notice the rod bearing journal on the old crank . thats where the rod bearings were welded to the crank!! the new crank is jounals are shiny new looking, the smearing is just remainding oil and assembly lube we used to put it together, unitl we went to turn the crank and it STOPPED!!! !

Does anyone know why this crank cant work in a early M28/11 block?

If its ok, i thing we will run with it and have the rotating assembly balanced.

here are the pics. let me know what you guys think

MK

#9

Rennlist Member

Thread Starter

just checked the rods alone on a calabrated digital scale. 856 grams. i got two replacement rods from 928intl for the two that welded to the crank, and they were 856 and 842. we are probably going to look for one more closer in weight. the rods included the rod nuts caps and bearing up top, but not the rod bearings.

pistons were 730g and 732g with rings and pins . spec is 720g, but i dont think that includes the wrist pins, as they are pretty heavy. they are also Mahle porsche pistons, once oversized at 97.465mm

Mk

pistons were 730g and 732g with rings and pins . spec is 720g, but i dont think that includes the wrist pins, as they are pretty heavy. they are also Mahle porsche pistons, once oversized at 97.465mm

Mk

#10

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Mark,

The main journal doen't look to good in the picture ofthe "new" crank. Is it just a bunch of oil or is there marks on it?

The old crank does look to have very small rod oil holes.

The main journal doen't look to good in the picture ofthe "new" crank. Is it just a bunch of oil or is there marks on it?

The old crank does look to have very small rod oil holes.

#11

Rennlist Member

Thread Starter

the first picture is the main center journal, and thats a new bearing with the assembly lube and some oil mix . the other picture of the crank, shows the main center bearing area on the crank with some oil on there also. we were spinning the crank in the bearing half, to find the jam. the "new" cranks bearing areas are mirror shiny, but, im a little concerned with the black area in the corners, as that looks like it could be heat related, but probably is ok. what do i know, im just a shade tree mechanic. (actually, scot doesnt even give me shade, im outside in his backyard, one time even in the RAIN! finally, convinced him that this engine building stuff should be in the garage with towels over the engine when we are done!!! sheezzz!)

im also wondering about that front main bearing as it is 2 halves, yet the engine is a euro 4.7l m28/11 . is it possible for someone to mistakenly put in a two section front main bearing when it should be a single round piece?

Im hoping the new oiling passages are better too as they are much larger as you saw.

attached is another picture of where we dremmeled the crank so that it doesnt hit the block below the thrust bearing, and a picture of the old main thrust bearing. two little wear lines as you would see on an old engine, but its getting replace with a new set obviously.

thanks,

MK

im also wondering about that front main bearing as it is 2 halves, yet the engine is a euro 4.7l m28/11 . is it possible for someone to mistakenly put in a two section front main bearing when it should be a single round piece?

Im hoping the new oiling passages are better too as they are much larger as you saw.

attached is another picture of where we dremmeled the crank so that it doesnt hit the block below the thrust bearing, and a picture of the old main thrust bearing. two little wear lines as you would see on an old engine, but its getting replace with a new set obviously.

thanks,

MK

Originally Posted by John Veninger

Mark,

The main journal doen't look to good in the picture ofthe "new" crank. Is it just a bunch of oil or is there marks on it?

The old crank does look to have very small rod oil holes.

The main journal doen't look to good in the picture ofthe "new" crank. Is it just a bunch of oil or is there marks on it?

The old crank does look to have very small rod oil holes.

#12

Addict

Rennlist Member

Rennlist Member

AFAIK one piece #1 main bearing was introduced for '82 model year. M28/11 were done '80-83. You'd need to check engine number to know which design it should have. One other hint is small stopper in upper half to stop bearing from rotating. This is one in GTS block, black dot in the middle of mains support #1.

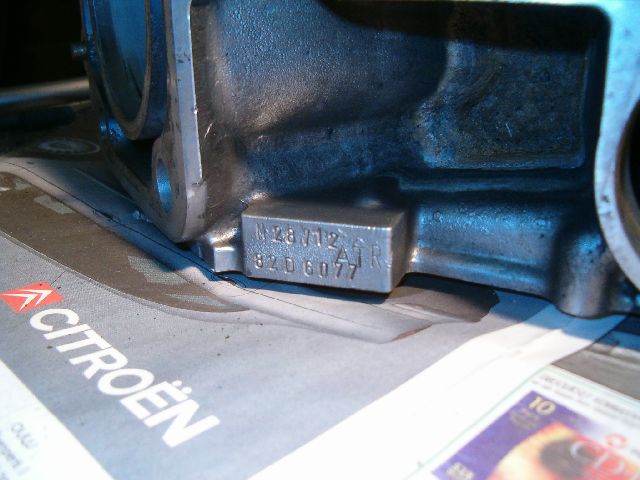

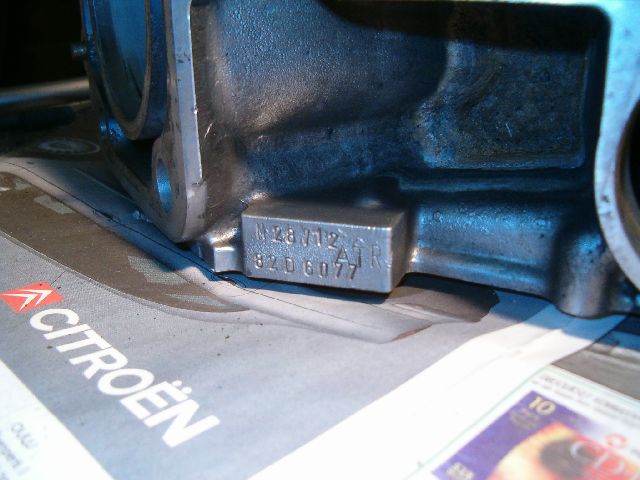

Check what letter block has in place of D ('83) in this picture.

If A or B ('80-81) it should have 2 part bearing and notches in both block halves to keep them stationary. If C or D ('82-83) 360 degrees round bearing.

Check what letter block has in place of D ('83) in this picture.

If A or B ('80-81) it should have 2 part bearing and notches in both block halves to keep them stationary. If C or D ('82-83) 360 degrees round bearing.

#13

Rennlist Member

Thread Starter

so, i checked the serial number, and its clearly printed M28/11 and underneath 8200778. what does that mean? plus, there is no stationary notches on the bearing area on the block bearing area in front.

what do you think?

MK

what do you think?

MK

#14

Addict

Rennlist Member

Rennlist Member

Can first 0 be D in 8200778 as 82D0778? If not, you have some strange number without year in it at all.

Is there that small thing at upper block half to keep bearing from moving? If not and there are no notches either what keeps #1 bearing from rotating?

More questions than answers but lets get to the bottom of this.

Is there that small thing at upper block half to keep bearing from moving? If not and there are no notches either what keeps #1 bearing from rotating?

More questions than answers but lets get to the bottom of this.

#15

Rennlist Member

Thread Starter

I checked for that. its a "0" not a d or a "O". so what the heck?

there is no notches, like there is no notches on the main bearings other than the edge notches like the other mains have on one side.

what cha think?

mk

there is no notches, like there is no notches on the main bearings other than the edge notches like the other mains have on one side.

what cha think?

mk

Originally Posted by Vilhuer

Can first 0 be D in 8200778 as 82D0778? If not, you have some strange number without year in it at all.

Is there that small thing at upper block half to keep bearing from moving? If not and there are no notches either what keeps #1 bearing from rotating?

More questions than answers but lets get to the bottom of this.

Is there that small thing at upper block half to keep bearing from moving? If not and there are no notches either what keeps #1 bearing from rotating?

More questions than answers but lets get to the bottom of this.