Who has had multiple rod bearing failures and what you did to fix it?

#1

Racer

Thread Starter

Join Date: Apr 2005

Location: Tallinn, Estonia

Posts: 498

Likes: 0

Received 0 Likes

on

0 Posts

My car is 1988 944S and rod bearing went again after less than 8000 km.

I use my car for open track days and sunday driving.

Engine is stock.

I use street slicks Toyo R888 225/50 R15

I used search and found topics that suggested

1. Perp drill #2 and #3 rod bearing.

2. Install Lindsay Racing baffle

3. Install cranck scraper or windage tray

4. Install external oil cooler

5. Use good high performance oil (20W60 weight)

Who has had multiple rod bearing failures and what you did to fix it?

I use my car for open track days and sunday driving.

Engine is stock.

I use street slicks Toyo R888 225/50 R15

I used search and found topics that suggested

1. Perp drill #2 and #3 rod bearing.

2. Install Lindsay Racing baffle

3. Install cranck scraper or windage tray

4. Install external oil cooler

5. Use good high performance oil (20W60 weight)

Who has had multiple rod bearing failures and what you did to fix it?

#2

Nordschleife Master

I honestly doubt there are many people that have had MULTIPLE rod bearing problems. I'd think most ppl fixed it after the first one, or at least the second.

I haven't had a failure yet at 140,000miles with no bearing replacements, but I'm in the process of converting my 951 to track car, and I'll be putting an oil baffle, oil-to-water cooler (instead of air-to-oil cooler) and racing oil. And of course, while I'm in there, I'll be putting in fresh bearings.

I haven't had a failure yet at 140,000miles with no bearing replacements, but I'm in the process of converting my 951 to track car, and I'll be putting an oil baffle, oil-to-water cooler (instead of air-to-oil cooler) and racing oil. And of course, while I'm in there, I'll be putting in fresh bearings.

#3

Race Car

Who replaced your bearing and did they measure the tolerance? Also was the crank or the rods damaged? Normally multiple occurances of bearing failure is due to improper installation of bearings or crank bolt not torqued enough for the oil pump to work properly. A broken pick up tube sucking air instead of oil can cause problems too.

#4

Racer

Thread Starter

Join Date: Apr 2005

Location: Tallinn, Estonia

Posts: 498

Likes: 0

Received 0 Likes

on

0 Posts

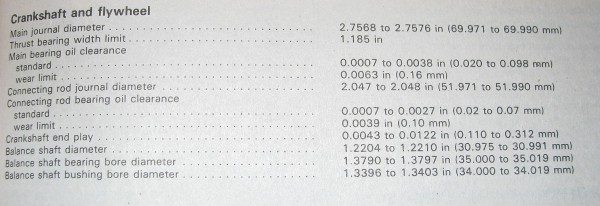

Rod bearing #2 damaged the crankshaft. It was machined to next undersize (0,25) and they installed new main and rod bearings (oversize 0,25).

I do not know if they measured oil clearance.

Can you suggest some values from you personal experience or the factory ones should do?

#5

Race Director

I have had 2 failures, but not on the same engine. First one was broke pick up tube and the second was too muc goop used to seal the girddle to the block.

As for fixes....

I documented alot of the things track drivers need to do here... ( See page 2)

http://944spec.org/944SPEC/component...1281/catid,10/

As for fixes....

I documented alot of the things track drivers need to do here... ( See page 2)

http://944spec.org/944SPEC/component...1281/catid,10/

#7

Three Wheelin'

I honestly doubt there are many people that have had MULTIPLE rod bearing problems. I'd think most ppl fixed it after the first one, or at least the second.

I haven't had a failure yet at 140,000miles with no bearing replacements, but I'm in the process of converting my 951 to track car, and I'll be putting an oil baffle, oil-to-water cooler (instead of air-to-oil cooler) and racing oil. And of course, while I'm in there, I'll be putting in fresh bearings.

I haven't had a failure yet at 140,000miles with no bearing replacements, but I'm in the process of converting my 951 to track car, and I'll be putting an oil baffle, oil-to-water cooler (instead of air-to-oil cooler) and racing oil. And of course, while I'm in there, I'll be putting in fresh bearings.

Trending Topics

#9

Race Director

#13

Three Wheelin'

#14

Racer

Thread Starter

Join Date: Apr 2005

Location: Tallinn, Estonia

Posts: 498

Likes: 0

Received 0 Likes

on

0 Posts

My car is 1988 944S and rod bearing went again after less than 8000 km.

I use my car for open track days and sunday driving.

Engine is stock.

I use street slicks Toyo R888 225/50 R15

I used search and found topics that suggested

1. Perp drill #2 and #3 rod bearing.

2. Install Lindsay Racing baffle

3. Install cranck scraper or windage tray

4. Install external oil cooler

5. Use good high performance oil (20W60 weight)

Who has had multiple rod bearing failures and what you did to fix it?

I use my car for open track days and sunday driving.

Engine is stock.

I use street slicks Toyo R888 225/50 R15

I used search and found topics that suggested

1. Perp drill #2 and #3 rod bearing.

2. Install Lindsay Racing baffle

3. Install cranck scraper or windage tray

4. Install external oil cooler

5. Use good high performance oil (20W60 weight)

Who has had multiple rod bearing failures and what you did to fix it?

I installed the oil temperature sender in the plug that is where the turbo oil return is connected. I have 88' 944S so no turbo.

I run 20W60 Motul engine oil. Right now I do not have oil cooler and during the track events oil temp goes past 110 C (230 F) after two fast laps.

During highway driving I get temps between 80C (176 F) and 90C (194 F). Temps go higher if the revs are higher.

Coolant temperature gauge stays at first mark on highway and track. It should be around 80 C.

When I am at the track I start 4,5 bar pressure at high revs oil temp 80 C. Oil temp starts rising and after two laps it goes past 110 C. At 110 C the oil pressure is dropped to 4 bar or little lower. I rev the engine to 6000 rpm right now to be safe, used to run near redline at 6840.

If we use 0,7 bar (10 psi) per 1000 rpm rule I should not rev past 5700 rpm when I get 4 bar oil pressure. With 4,5 bar my rev limit should be 6400 rpm.

What I see is that oil temp goes up really fast but coolant temp stays normal.

During startup I get 4,5 bar at idle. If I rev it a little it goes over 5 bar. Is it normal or should I get 5 bar when cold at idle?

I obviously need external oil cooler. If the temp goes up I get off the track for now.

Some of you race you 944-s. At what rpm you change gears and what oil pressure are you getting at high revs.

Sould I try to play with OPRV? How to find out when the OPRV opens?